Professional Documents

Culture Documents

Assignment 1 Productivity3792014023839124809

Assignment 1 Productivity3792014023839124809

Uploaded by

rajitaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment 1 Productivity3792014023839124809

Assignment 1 Productivity3792014023839124809

Uploaded by

rajitaCopyright:

Available Formats

Chapter 1, Operations and Productivity

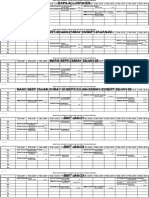

Problem 1:

Mance Fraily, the Production Manager at Ralts Mills, can currently expect his operation to produce 1000

square yards of fabric for each ton of raw cotton. Each ton of raw cotton requires 5 labor hours to

process. He believes that he can buy better quality raw cotton, which will enable him to produce 1200

square yards per ton of raw cotton with the same labor hours.

What will be the impact on productivity (measured in square yards per labor-hour) if he purchases the

higher quality raw cotton?

Problem 2:

C. A. Ratchet, the local auto mechanic, finds that it usually takes him 2 hours to diagnose and fix a typical

problem. What is his daily productivity (assume an 8 hour day)?

Mr. Ratchet believes he can purchase a small computer trouble-shooting device, which will allow him to

find and fix a problem in the incredible (at least to his customers!) time of 1 hour. He will, however, have

to spend an extra hour each morning adjusting the computerized diagnostic device. What will be the

impact on his productivity if he purchases the device?

Problem 3:

Joanna French is currently working a total of 12 hours per day to produce 240 dolls. She thinks that by

changing the paint used for the facial features and fingernails that she can increase her rate to 360 dolls

per day. Total material cost for each doll is approximately $3.50; she has to invest $20 in the necessary

supplies (expendables) per day; energy costs are assumed to be only $4.00 per day; and she thinks she

should be making $10 per hour for her time. Viewing this from a total (multifactor) productivity

perspective, what is her productivity at present and with the new paint?

Problem 4:

How would total (multifactor) productivity change if using the new paint raised Ms. French’s material

costs by $0.50 per doll?

Problem 5:

If she uses the new paint, by what amount could Ms. French’s material costs increase without reducing

total (multifactor) productivity?

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Income Taxation - Tabag & Garcia Income Taxation - Tabag & GarciaDocument34 pagesIncome Taxation - Tabag & Garcia Income Taxation - Tabag & GarciaShaira Villaflor100% (20)

- Fuel Supply System of Petrol EngineDocument4 pagesFuel Supply System of Petrol EngineBanwari Lal Prajapat100% (1)

- LCM and HCF (001-050)Document5 pagesLCM and HCF (001-050)Banwari Lal PrajapatNo ratings yet

- Introduction To Offshore StructuresDocument18 pagesIntroduction To Offshore StructuresBolarinwa89% (9)

- LCM and HCF (101-138)Document4 pagesLCM and HCF (101-138)Banwari Lal PrajapatNo ratings yet

- Ss Circular No. 2011-002Document4 pagesSs Circular No. 2011-002Jayzell Mae Flores100% (2)

- Praise and Worship Line Up May 23, 2021Document5 pagesPraise and Worship Line Up May 23, 2021Gladys L. LaguraNo ratings yet

- Kracauer, Siegfried - The Mass Ornament (Pg237 - 269)Document415 pagesKracauer, Siegfried - The Mass Ornament (Pg237 - 269)Thiago Brandão Peres100% (6)

- Part 1 - Contract Administration ManualDocument32 pagesPart 1 - Contract Administration ManualGopi C Shrestha0% (2)

- Property - Movable/personal Property: Philippine Refining Co V. JarqueDocument1 pageProperty - Movable/personal Property: Philippine Refining Co V. JarqueChachi SorianoNo ratings yet

- Hindi Comp I SrajanDocument105 pagesHindi Comp I SrajanBanwari Lal PrajapatNo ratings yet

- Rajasthan Technical University, Kota: Office of PG/PHD AdmissionsDocument2 pagesRajasthan Technical University, Kota: Office of PG/PHD AdmissionsBanwari Lal PrajapatNo ratings yet

- BSER Raj Adhyan-4 PDFDocument158 pagesBSER Raj Adhyan-4 PDFBanwari Lal PrajapatNo ratings yet

- Aptitude Mock Test 5Document13 pagesAptitude Mock Test 5Banwari Lal PrajapatNo ratings yet

- BSER Raj Adhyan-3 PDFDocument110 pagesBSER Raj Adhyan-3 PDFBanwari Lal PrajapatNo ratings yet

- Sankhayatmak AbhiyogitaDocument112 pagesSankhayatmak AbhiyogitaBanwari Lal Prajapat100% (2)

- Jit 1Document5 pagesJit 1Banwari Lal PrajapatNo ratings yet

- घटना चक्र.. दृष्टि वार्षिक one linerDocument15 pagesघटना चक्र.. दृष्टि वार्षिक one linerBanwari Lal PrajapatNo ratings yet

- Jja Paper 2016Document8 pagesJja Paper 2016Banwari Lal PrajapatNo ratings yet

- TEST PAPER 06 Samas PrakarnamDocument12 pagesTEST PAPER 06 Samas PrakarnamBanwari Lal Prajapat100% (3)

- TEST PAPER 3 Sandhi PrakarnamDocument9 pagesTEST PAPER 3 Sandhi PrakarnamBanwari Lal PrajapatNo ratings yet

- TEST PAPER 4 Sangya PrakranDocument13 pagesTEST PAPER 4 Sangya PrakranBanwari Lal PrajapatNo ratings yet

- Radix: "Previous Year Questions"Document3 pagesRadix: "Previous Year Questions"Banwari Lal PrajapatNo ratings yet

- Radix: "Previous Year Questions"Document3 pagesRadix: "Previous Year Questions"Banwari Lal PrajapatNo ratings yet

- Radix: "Previous Year Questions"Document3 pagesRadix: "Previous Year Questions"Banwari Lal PrajapatNo ratings yet

- Radix: "Previous Year Questions"Document3 pagesRadix: "Previous Year Questions"Banwari Lal PrajapatNo ratings yet

- To Study The Construction and Working of 4 - Stroke Petrol / Diesel EngineDocument7 pagesTo Study The Construction and Working of 4 - Stroke Petrol / Diesel EngineBanwari Lal PrajapatNo ratings yet

- Thermal Engineering Lab ManualDocument31 pagesThermal Engineering Lab ManualBanwari Lal PrajapatNo ratings yet

- To Study The Construction and Working of 4 - Stroke Petrol / Diesel EngineDocument3 pagesTo Study The Construction and Working of 4 - Stroke Petrol / Diesel EngineBanwari Lal Prajapat100% (1)

- PPTC 154Document8 pagesPPTC 154treeangel35No ratings yet

- ASTM C 139 Standard Specification For Concrete Masonry Units For Construction of Catch Basins andDocument2 pagesASTM C 139 Standard Specification For Concrete Masonry Units For Construction of Catch Basins andRyan LasacaNo ratings yet

- WHO RHR 11.35 EngDocument4 pagesWHO RHR 11.35 EngNove Claire Labawan EnteNo ratings yet

- Proforma 2011 MBADocument7 pagesProforma 2011 MBApashariyanNo ratings yet

- ĐỀ ANH CHUYÊN 2021-CHÍNH THỨC-FinalDocument7 pagesĐỀ ANH CHUYÊN 2021-CHÍNH THỨC-FinalHa NguyenNo ratings yet

- Class V Social Studies Worksheet Gandhi Leads The NationDocument3 pagesClass V Social Studies Worksheet Gandhi Leads The Nationrahul.mishra60% (5)

- Abhinav Jain SynopsisDocument14 pagesAbhinav Jain SynopsisSonal JainNo ratings yet

- Game RequestsDocument27 pagesGame RequestsFishing ManiaNo ratings yet

- Classic Bike UK - April 2020 PDFDocument134 pagesClassic Bike UK - April 2020 PDFsergio100% (1)

- NCR in Isms 27001 Ver 2013Document1 pageNCR in Isms 27001 Ver 2013GVS RaoNo ratings yet

- BI Biorenewable InsightsDocument2 pagesBI Biorenewable InsightsLeo DennisNo ratings yet

- Bachelors & Postgraduate Updated Teaching Timetables - Jan-Apr 2023Document69 pagesBachelors & Postgraduate Updated Teaching Timetables - Jan-Apr 2023manam unguNo ratings yet

- International Business: by Charles W.L. HillDocument25 pagesInternational Business: by Charles W.L. Hilljero62No ratings yet

- Activity 3 Wilmarie Hope Aliling 12-STEM 2Document2 pagesActivity 3 Wilmarie Hope Aliling 12-STEM 2Wilmarie Hope Aliling100% (4)

- Imf Annual Report 2019Document108 pagesImf Annual Report 2019MALAY KUMARNo ratings yet

- Being An Application For Review of The Judgement and Decree of The Business & Rent Tribunal of Hon. Gakuhi Chege Delivered On 2 November, 2022Document10 pagesBeing An Application For Review of The Judgement and Decree of The Business & Rent Tribunal of Hon. Gakuhi Chege Delivered On 2 November, 2022Samuel NgatheNo ratings yet

- NSS Labs Enterprise Endpoint Comparative Report ExploitsDocument5 pagesNSS Labs Enterprise Endpoint Comparative Report ExploitsxkerberosxNo ratings yet

- PGDPMDocument22 pagesPGDPMMaya AsherNo ratings yet

- Sakthi Mineral CoDocument33 pagesSakthi Mineral Cojai kumarNo ratings yet

- Wasting Food Is Like Stealing From The PoorDocument1 pageWasting Food Is Like Stealing From The PoorKavilashini Subramaniam100% (1)

- Immigration BrochureDocument2 pagesImmigration Brochurelp456No ratings yet

- Youngblood Flocos PracticalLawyerDocument17 pagesYoungblood Flocos PracticalLawyerKnowledge Guru100% (1)

- Construction Safety and Health ProgramDocument3 pagesConstruction Safety and Health ProgramLucio Loyloy SanchezNo ratings yet