Professional Documents

Culture Documents

UPC Hollowcore Slabs

Uploaded by

rabeeabuahmad0 ratings0% found this document useful (0 votes)

27 views16 pagesOriginal Title

UPC hollowcore slabs

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views16 pagesUPC Hollowcore Slabs

Uploaded by

rabeeabuahmadCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 16

ME Page 6

Design load qui, (kN/m*) in excess of

slab self weight

_| 22000

21000

m@ COMBINED LOAD CURVE

_} 20000

18000

|] 17000

16000

15000

| 14000

+3000

12000

11000

10000

9000

2000

7000

Load curves for UPC Hollowcore slabs

‘6000

G

Span (mm)

HOLLOWCORE LOAD SPAN TABLES

sm Deep Sab wan 10.6.3 Darel Grands

150 [Gearspanin» | 20] 25] a0] 35] 40] a5] so] sa] ool sal Tal 7a aa

Maximum Load Capacity (kNim*)

Without Structural Screed 71.0] 475] 930] 23.8] 17.9] 13.8] 108] 66] 69] 56] 45

with 75mm Structural Screed ]125.0] 91.6] 62.5] 44.0] 30.0] 240] 187] 13.6] 10:3] 7.6] 55]

‘ols Sarweght of unt= RR aed SoSaed Tor

Srucural ced = 1 aaa edits ta be

200nm Boop Sab win 6, o.Sn and 2 No 12.Smm Danae Sana

200 [Gesrsoanim | 80] a8] a0] aa] sol ssl ool oa[ zal Tal eal aaa

Maximum Load Capacity (kN/m?)

Without Sructual Screed 354] 285] 204] ves] v32] woe] eal 7a] eo] so] aa] aa

With 75mm Structural Screed so.of 37.5] 29.0] 22.9] 18.4] 149] 121] 97] 74] 57] 42] 30]

‘oe Salwaghtofunt= aN aleay dooosed For fab)

Sructral sce » 1 KNim®(aeady dace om abe)

25h Oesp Sa wind Na 12S Dat Stans

250 [Gearspanim | sol 55] 6016s] 70 7a] ao] as] sol os] 10a

[Maximum Load Capacity (kN/m*)

|Without Structural Screed 26.6] 25.0] 20.8] 16.6] 14.1] 11.6[ 100] 8.3] 7.5] 6.3] 5.4]

[With 75mm Structural Screed | 26.8[ 23.3] 20.8] 19.1] 17.0] 154/713.) 11.1] 9.1] 7.5] 60]

‘ole: Serweight of unt = 6K aeady Goductod Wom TaD) 7

‘Strvctua screed» 1.8kWin? (aad deducted rom tabi)

oor Deep Sab wa No.2 Sn Dani Sane

300 [ovarspanim [sol est 70] 75] 80] aa] aoa] 00] sol

Maximum Load Capacity (kN/m?)

WinowtSiuctwal Screed | 66] 225] 190] 153] 108] 118] 100] aa] 75] oa] oa

With 75mm Structural Soreed vas} 129] 104) 85] 75] 53

‘ole Salwaght lun = TaN aad daduied Tom obey

Stvetal sored « 1.akN* (ready deta tom abe)

comm Geep Sab wth 12 No. 1-Snm Date Grands on ton, No Gm Dane

400 [Gearspan im | 10.0] 10s] 110] 181 120] 124] 130] 135] 140] 145

Maximum Load Capacity (kN/m?)

[Without Structural Screed i6.0] 14.4] 128] 114] 102] 90] so] 72] 65] 57] 52]

[With 76mm Structural Screed | 16.0] 150] 13.5] 12.3] 11.3] 102] 9.2] 8.1] 7.0] 62|

Note Sat-waphtat ost = <6QxN areal deduced Tm aio

‘Stuer sereed = 1 akin (aoa dedted rom tbl)

OQ [sata Sabine 12mm Oar Stands on Boon «No, nm Dametr Stands on Top

[Clear Span (m) | 8.0] 85] 90] 95 [rool tos[ n.0[ 15] 20/125] 13 [135

Maximum Load Gapacity (kNim*

Without Structural Screed 30.0] 27.0] 245] 220] 200] 185] 17.0] 155] 140] 130] 120] 11.0] 100]

Jwith 75mm Structural Screed | 32.5] 30.0[ 26.0 26.0] 25.0 215/195] 180] 165

500mm Siab wih 14 No, 125mm Diameter Svands on Botlom, 4 No, 83mm Diameter Sands on Top

500 [Gearspan [145] 150] 158] 160] 1651 170] 175] 160

Maximum Load Capacity (kNim*)

Without Structural Screed s0TsoTrvoTes[ss[ so] 45] 40

with 75mm Structural Screed __[11.0[ 95 | a5 [70] 60] 55] 40] 25

‘ots Se weg oon = SBN ate) eodaaed Fo ae)

cased = 1 (area eed tom ae)

{ssa on Sonn Beaeg

LOAD AND DEFORMATION TABLE

UPC HCS 8/150

m UPC 8/150

[Slab weight [2.25 kNim? Maximum ultimate design load (q,) and maximum load at serviceability limit state

joint grout [0.11kN/m? | (@,) in excess of slab weight in kN/m? and calculated deformation in mm

STRANDS SPAN [3.0135] 40/45] 5.0] 55[60[65|7.0[75|80| 8519.0

ui 25.1|17.6|12.7) 9.3 | 6.9 | 5.2/3.8 |

4n0s 9.3mm 4y: [16.7|11.7| 8.4) 6.2/4.6) 3.4/2.5 -

fv 1770Nimm? | Coy ft [-t [-t [1 [-1 [1 Jo | | ||

Co 2 |-2 [2 |-2 |-2}afo | | | I

Mazounmi [ay [0 [o [o [1 [1 [2 [2

vg =s7kwu fay, 10 [1 [1/1 [2 [3 [4

dus __|29.6]22.4]16.4]12.3| 9.3 | 7.1/5.4 [41 | 3.1|

Srosaamm | da 19.7/15.0]10.9] 6.2 | 6.2/ 4.7/3.6 [2.8 | 2.1

f= 1770Nimm? | cy, [a [2 [272 ;272 [a fo fi |

Co 2 (3/3 4 [4[3]2/4h [

Mae 47 kms | gy o_o fo [1 |i [2 [2 [3 [a td

Vg_=59 KN isu aigy oO ji ji 1 2 3 4 6 8

us 31.0] 26.1] 20.0 15.1 11.6) 9.0| 7.1/5.5 | 43 [33

6.008 9.3mm “Gis [20.6|17.4 13.4110.1| 7.7 6.0/4.7] 3.7 2912.2

fou =1770Nimm® [Cp [2 [2 [2 [3 [313 [2 [2 [4 fo

w (3 |4[s 15/5 i515]

Mu=soknmiu [ ay, [0 [0 [0 |1 |t [2 [2

vy semi [ao; |0 [1 [1 [1 [2 [3 [4

Guis 27.2] 23.4/17.9|13.9/10.9| 8.6

7 nos 9.3mm uss 16.1[15.2| 11.6 9.1 | 7.1/5.7 |

fye=t770NImM? | Cay 2/3 [3 [4 [4 [4

Go. Lis|*(ye Pye? |

Ma =65kNmvsu | ayn ojo ii | 2 (2

vs sotinu [ao | | [1 [1 [23 [4 |

us 24.3/20.3] 15.8|12.5] 10.0]

8.905 9.3m Gus | [ie2/127/9.9 [78/63

1770Nimm? | Cy 3 [4 [4/5 [5 o |

Cio 7/819 )-9/-10 0 |

My=73kNmie | ayy oli (1 [2 [2 [3 |4 [5 |7 [9 |

vg =06kN iu | aig - 1 {i [2/3 [4 fe [es [un [liz]

Gus (21.4/16.713.3/10.7/8.6 [7.0 5.7/4.7 | 3.8

9108 9.3mm is ~ 113.4) 10.5) 8.3167 [54 | 44/36/29 | 24

770 Nim? | Cay 7 ys [5 ~6 [-6 |-6 [-5 [-4 |-2

[6 LLP] “12 [-12|-10[-8 | -5

Miya st tam | Bay | it {17212 13 1415 17 19 |]

ve _=68knu | aig - 1/2 (3 [4 fe [es [un fia [a7]

For guidance only

Page 7

@ UPC 6/200

Mi Page 8

LOAD AND DEFORMATION TABLE

UPC HCS 6/200

Slab weight |2.90 KN/m?] Maximum ultimate design load @,. and maximum load at serviceability mit sate

Joint grout 0.16 kNém2| (q,) in excess of slab weight in kN/m? and calculated deformation in mm

STRANDS SPAN |4.04.5[5.0]5.5| 6.016.5 |7.0|7.5[8.0/8.5| 9.0] 9.5 [10.0/10.511.0}

us (19.3/14.410.9 8.3) 6.4/4.8 3.6) | |

S108 9m du. 112.9) 9.6|7.3|5.6| 4.2/3.2 |2.4

fou =1770Nimm? | Gay a {a fa fa fafa fo |

|e -2 |-2 [3 [2 [2/4 |o |

sownmu | ae 0 [0 [O ft 1 it [2 | L

Vg_=73 KNiu es o fi [i fi [2 [3 [4 Tt [

du 12.810.2/8.1 [6.4 |5.1/4.0 |

2089.30 + di 8.6 6.8/5.4 (4.3 3.4|2.7 : |

2 os 12.5mm a 2 [2 [2 [2 [4 Jo _

f= 1770Ninm? |p 4 [5 [5 [4 |-4 [2 [a |

an of; ft ftp i2 fs

Em oO 3 |4 [5 [6 on

“Gus : 1.2/9.1 /7.4/6.0/4.9/3.9 |

44908 12.5 mm de | haals)9.2|7.5[61/49/40/33/26) |

fue t770Nimm | Cy [_ [3 [4 | [4 [4 [3 [3 [2 fo I

Go [6 [7 [-8 [8 [7 17 [6 [4 [a [

Myc = 96 kNevsu ans vit ii i2 2 13 |4 [5s I

Vg_=79 KNAW aig 1/2 /3 |4 [5 |e [8 lio |

Gus .914.712.110.0, 8.3 6.9 | 5.7 | 4.8 3.9 I

5 nos 125mm du fi 49.4/7.8 6.5

fu 1770 Nim? | Cy 5/5 [6-6 1-6 |

[ee | -10| -11|-12/-12|-12 |

movettoiem [ax [| | fy [a |r [2 [2 [a [a Ts To

Vg = a3 kN ay | jy fais Ta [se [8 [10 [12 fis

du LT | 20.7h7.ah4.512.2h10.3[8.7|7.4/6.25.3 [4.4

2 nos 9.3mm + as L 13.210.9)9.1|7.6|6.4|5.4/4.6/3.93.3 28 |

Sos 125mm | Gy i A Ee 9-8 |-8 lo 4

fw =1770Nimm? | Cy -15|-16|-17| -18]-18|-18|-17)-15/13 19

a lafif2 3 [4s lela lo

Vy = 89 kN aa 2[3]4 10

Gu 20.918.7/15. 8.0/6.8 [5.8/4.9] 4.2

7 908 12.51 a 13.9[11.7|9.7 [8.2/6.9 /5.9|5.0/4.3|3.6| 3.1) 2.6]

770 Nim? | Ca -8 |-9 [10 -1|-10| -9 | -8 | 5

Co | -17| -18|-20 -22|-20| -18|-15| -11

am | 1[2 slelelay i

ay 1 | [ [ets la fo [12 [15 [is [22

For guidance only

LOAD AND DEFORMATION TABLE

UPC HCS 5/265

Slab weight ]3.75 KN/m®] maximum ultimate design load (9, and maximum load at serviceability imi sate

joint grout 0.19 N/m? (g,.) in exces of slab weight in Nin? and calculated deformation in mm

STRANDS SPAN |4.0 [5.0 [60 [7.0 [8.0 [9.0 | 10.0) 11.0) 12.0] 13.0] 14,

Gus __| 27.7| 15.9] 9.4 | 5.6 | 3.1 | | I

snosaamm — | qys [18.4] 10.6 6.3 | 3.7 [20 | TI

70Nimm? | Cy A fa fa fo fy | |

Clo ctf -2 | 2 1 1 | | |

Maya 79k | gy o fo jo ji ia | LI | |

Vg_=85 ku aps lo jo |i [2 [3 I

dus 23.7) 14.9) 9.6 (6.1), 3.8 L

2 n0s9.3 mm+ as 15.8, 9.9 | 6.4 | 4.1 | 2.5 _ 7

2nos2smm | cy af2[2iah | | |_|}

fe=1770Nmm? | Cg 3 [3 [3 [21 | I

Mag= 108 kNmsy | ayy jo jo fi ft 2 _

va sk | aig fo fy [2 [3 [4

a [253] 202, 135) 9.1461 [40 T ~

srosr2snm [ae Treat 135,90 [61 141127

fen izroninm? [egy [2 [3 [3 [24 Jo ty]

| cio 405 (5 5 3 11 |

Mace 137 km | ayy) fo fo fy fi [2 [3 [Ty

va =e | aig jo) [2 [3 [4 fe Ty

[us 22.4 18.5 15.5] 114/82 15.9 41 |

Gnas 125mm — | ig - 14.9) 12.3 9.8 [7.2 [5.2 [3.8

“Ch 4 [5 [6 [5 [4 [2

ee | [s [ao[-1 [ar fs _[s

Muv=20rksmss | aga | _fo ft ft 2 2 is

Ve_=990neu | aig _i2 3 [4 fe [9

Gus 24.1] 19.9)

snost2smm — | ge : 3

fu 1770Nimm? [cay

Cus

My. 261 kNevsu [ag y

Ve =1054Nsu | aig | 6/9

dus | 25.6) 21.2) 17.9 15.4) 12.0]9.1 [6.9 S27 3.8

wonostz5mm | qs || [17.1/142/12.0)99 [75 [57 [43 (32 24

fen 1770Nimm? | Cy [12 [13 [13 [-1 [8 [3

Clo 22 |-24 |-26 |-25 |-22 [6 | -6

2 [3 [5 [7 [9 |12 |

mikwsu | aig [3 [4 [e_ [9 [33 [ie [24

B1BkNmsy | ayy

For guidance only

@ UPC 5/265

Ml Page 9

ME Page 10

LOAD AND DEFORMATION TABLE

UPC HCS 4/320

o

a

o

>

vt

iS)

a

2

a

Slab weight 4.05 kN/m2] Maximum ultimate design oad (q,) and maximum load at serviceability limit sate

Jjoint grout 0.22 kN/m2| fq.) in excess of slab weight in kNim2 and calculated deformation in mm

‘STRANDS, ‘SPAN 6.0 | 7.0 [8.0 | 9.0_]10.0]11.0 [12.0 13.0 [14.0]15.0/16.0]

us | 27.7| 23.0, 16.6 12.0 8.7 |6.2 [4.3 | LI

5 nos 12.5 mm

18.5| 15.3, 11.1) 8.0/5.8 |4.1 [2.9 [ |

Spy = 1770 Nien? 3 4 |4 [3 [2 [1 L |

6 7\[7/*6 [ah | [T

May = 212 kN [o 1 |i i213 [4 [Ty

Vg = 119 Now fi 2 (3 [4 le [e |

| 21.6 18.5) 13.9] 106/80 6044) |_|

7 mos 12.5 mm | 14.4 11.8 5.2 4.0 | 3.0 |

fy. 1770. Nim? | 6 [7 35 [3 [1 | _|

I 213 | 14 je ji |]

My = 291 Kev | 1 4 [6 (7

Vq_=130kNAU | 2 B - ain [is |

[ 122.6 19.5] 9.5 17.3 15.6 [4.3

‘nos 12.5 mm

|

I 15.1) 13.0, 9.9 [7.7 |5.9 [4.6 [3.5 [27

fu 1770Ninm? 3 io |9 [9 4a

-16 | -18 | -19 |-19 7 [2]

30 kN | Tit i 7 (10

2-13 [4 fe |e [a [15 [20

[ 23.2| 20.0] 16.8] 13.0] 10.1[7.9 | 6.1 [4.7

15.5 63 [4.9 138 (29

Vg_= 135 kN‘

9.n0s 12.5 mm

fu 1770 Nine? 9 “10 |-9 |-6 [2

| “17 2 [18 [-13 [4 |

167 kN mh 4 [6 (7 {10

Vg_= 138 kN | 2 a [iis [20

| 23.8 10.7/8.4 (6.5 | 5.1 | 3.8

10.05 12.5 mm iz

[15.9[13.7| 1.0/8.6 [67 [5.2 41 [3.2 [24

=1770Nimm? | -to [-11 [12 [13 [2-1 [-9 fs [a

|__| -19 [22 |-24 [-25 [-25 [-22 [18 [10 |

| 1 oii [2 [3 [4 le [7 [10 [13

[ 2° [3 [4 Je fe fn 1s [20 [25

(244) 21.1] 18.4 7.0 [55 | 42

nos 12.5 mm I 16.2) 14.0] 11.6 44 [3.4 | 26 |

y= 170Nimm? | Cy | 10 f-12 [3 2/8 [3

[a6 T_i -21 | -24 | -27 23 |-16 | -6

My=438kNmisu | gh | 1 it 22 7 [10 [32 |

Vy =143kNsu | aig | 2 53 |4 15/20 | 25

LOAD AND DEFORMATION TABLE

UPC HCS 4/400

Stab weight |4.69 kN/im?] Maximum ultimate design load (q,) and maximum load a seviceabiny Wana]

joint grout (0.26 kN/im?|(q,) in excess of slab weight in kN/m? and calculated deformation in mm

STRANDS SPAN [8.0 [9.0110.0/17.0]12.0[13.0/14.0]15.0] 16.0,17.0| 18.0 19.0

ut 22.3/16.3] 12.0] 6.8) 64] 4.5] 3.0) ‘|

5 nos 125m cn 14.9) 10.9] 8.0/ 5.9/4.3) 3.0/ 20] | [Ty

iu 1770Nimm? |G, 3(3/3]3[4a/7]3 | [

So 6 (7 |6[5[3\i [7 tT]

Mue= 275 km | ayy o |i [a [2 [2 [3 [a |

va =174kwiu [aig 1 |i [2 [3 fale le

| Guts 24.9| 18.9 14.5] 11.2] 86) 66/49 3.5) 7

7ros 125mm | Ge | [t6-4[12.6 9.7] 7.5] 5.7) 44] 3.3] 24]

f= 170Nimm? | cyy 6 [-6 |-7 [6 [s5]3/o r |

[ee - -13) 12) 10/6 [a [7 _|

My, =379 Nou | ag, y 2]2 [3/4 [sl/7] 1

Vg 2189 KN | alg 3 [4 Te fe [nti

[aus 19.1) 15.2112.1] 9.6 7.6) 6.0/4.6) 3.5 |

a 12.0] 9.5 | 7.5 2.9] 2.2|

fu=t770Ninm? | ey apy [ays

Co __|-20/ -21/ 22) -21 1/10

My=480kNmiu | ag, |) 1 [2 [2 [3 [fo [1]

Vg_=2024N/u | apy [2 [3 Ta Te 18 | 23 |

ats [|] fa26aa.ijias 6.1| 4.8]

vino 125mm [aus | [fraapn) 9.1 8] 3.8] 3.0

fou 1770Nimm® [Cy | || -s| -t6) 16) 16/15] 13 -10/ -6

Co -29] -31| -32) -32/ -30/ -26] -20/ -11

Mo=s7eiomie [ayy | 2/2 [3 /4|[s/7 to fa]

Vg =216KNsu [| alos LT] 3 [4 [6 | ain |i) is) 23

dus | | [23.4)16.8)15.1112.2/ 99[ 80 6.4/5.1) 40)

V3 n0s 125mm | Gag I 14.6] 11.7/ 9.5) 7.7

f= 1770Nimm? | cy, | 5 -15| -17] -17] -18]

Clo | [__[-3i] 33] -35) -35| -34] 30) -25] 16) <5

Mu =6554Nmis [ag 22 (3/4 [3 [719 [nu imc

Ve =22kN iu | aig I 314 (6 (8 |i] 14/18 | 23 | 28

us _ I 119.1115.4] 12.5 10.7 8.2) 6.6) 5.3] 4.1

14 nos 12.5mm, Gas | | 11.9] 9.6] 7.8/6.3] 5.1] 4.1) 33] 2.6]

f= 1770Nimm? | Cay tt -17/ -18| -18| -18| -16| -14| 10-4

leo 1 -37| -36| -33/ -27/ -19| -8 |

On I 4 [5s [7/9 [nl

En A 8 [| 14/18 [23 | 28

For guidance only

m UPC 4/400

ME Page 11

@ UPC 4/500

HE Page 12

LOAD AND DEFORMATION TABLE

UPC HCS 4/500

Slab weight [6.25 KNim?] Maximum ultimate design load (q,) and maximum load at serviceability limit sate

joint grout (0.43 KN/m?|(q,) in excess of slab weight in kNim2 and calculated deformation in mm

STRANDS ‘SPAN | 11.0[12.0/13.0/14.0 [15.0] 16.0] 17.0/18.0)19.0)20.0[21.0

Gis [18.8] 14.0|10.3| 7.4] 5.1] 33 {|

6 nos 12.5mm Gis 12.6|9.3 | 6.8) 4.9| 3.4 I -

ronimm? [cy [3 | 3 1

Go 6 [5 |

Mu 42rkNmisa | ag 1 iq L

Lama 1 7 |

Va =267kNw | ajo) 1 (2 {2/3 LI

Gus 21.3/16.5] 12.7, 9.7 LT]

Bros t2smm | Gus | 14.2/11.0] 8.4) 6.4 |

fou 1770Nimm? | Cay [5 [5 [5 | a [2 I

Lio [s0/-10[-9 [7 [4 | |

Myo 555 KN | gy Thais |

vy 22264 su | aig 2 [2 [3 [4 [s {71/9 | -

Sots i Bal _

1008125 Cr 23, |

| is |

[ 10

Mas= 685 kimi | ashy | 7 |

Ve_=3084N 50 | aig 13 |

dus | [21.2/17.0/13.7[ 11.0] 8.8 | 6.9| 5.4) 4.0

13008 125mm | Oye LL 25

f= 1770Nimm? | Cy LI 4

[eto 8

Muy = B62 kms | ayy fy j2 [3 [3 [4 js [7 [ae

Vg =320kN Au | aig

ute

| 3 4 5 7\9 W113) 16 |

iseort2sam [ae |

T

770NImm? | Cy

g7aknmisu | ayn I

Va =333kN iv | alg

ais

17 0s 125mm — | ys

770 Nim? | Co

Go | [32-33] -32| -30/ -26 | 21 13

Myy=1079 kms [ag 213 13 [4 (5 [7/8 /10|

Ve_=303kNu | aio 4 [5 [7 jo (1/13/16 | 20

For guidance only

Example using load tables

Roof structure, span 17 m

Loads:

Chippings 8 = 1.00 kNim?

Insulation & Roofing g = 0.25 kN/m?

Screed B= 1.50 kN/m'

Live Load = 0.75 Nim

Total characteristic load P,

Py = 1.00+0.2541,5040.75 = 3.50 kN/m?

Total ultimate design load Py

Py = 1.4(1.0040.25+1.50) +

1.6x0.75 = 5.05 kN/m*

Total characteristic dead load G,

Gy = 1.0040.25+1.50 = 2.75 kN/m?

1. Load Capacity

HOLLOWCORE SLAB UPC 4/400 with 13 Nos.

strands of 12.5 mm has

the capacity Guts = 6.40 kN/m! > Py

2. Deformations:

~ Short term camber cy, = -12 mm

~ Short term deflection

for live load Qy: ayy = 90.75 =7 mm

_ Short term deflection

for dead load Gy: ayy= 9X2.75=25mm

Distribution of loa from partion wall on Hollowcore Slab

- Resulting short term

deformation for Gz a, = -12+25=13mm

~ Long term camber cy = -25 mm

~ Long term deflection

for dead load Gy: aj = 18x2.75=50mm

- Resulting long term

deformation for Gy: ay = -25 +50= 25mm

~ Long term settlement

for Gx a3 = 25-13212mm

Conclusion

Elastic settlement for full live load is at any

time 7mm < span / 350.

Final combined long term deflection and

camber is 25mm < span/250, and the

deflection taking place after application of

long term load is 12mm < span/350.

Concentrated loads

Hollowcore slabs are capable of resisting

concentrated loads like point and line loads

Extra care shall be taken to check the overall

moment and shear capacity of the

hollowcore slabs.

Point loads shall be distributed over an area

of minimum 150 x 150 mm and may not

exceed 30 KN.

AS per BS 8110, part 1, clause 5.2.2.2 line

loads can be distributed over the lesser of the

width of three hollowcore slabs plus the

width of the loaded area or the quarter of the

span on either side of the loaded area.

m@ DESIGN EXAMPLES

HE Page 13

Page 15

Page 14

@ DIAPHRAGM ACTION

Hollowcore slabs can act as diaphragms for

transfer of horizontal forces to the bracing

elements. Horizontal forces are generally

wind loads, seismic load and load due to

eccentric vertical load,

The diaphragm action is obtained by

connecting the hollowcore slabs and

providing the completed floor with a tying

system capable of transferring the horizontal

forces by arching or bending. The tying

system shall be able to obtain all forces due

to in-plane action like bending, shear and

tension and shall be continuous both in

longitudinal and transverse direction

Typical connections between hollowcore

slabs and bracing elements are shown on the

sectional details

Schematic system of diaphragm action

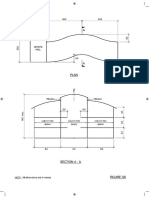

Diaphragm action without topping

Diaphragm action can be achieved without

topping, by placing the tie reinforcement in

the joints between the slabs, as shown below:

,

D_U-BAR IN EACH SLAB

\, HOLLOWCORE SLAB

TaMPING

(NOT NECESSARY ON

PRECAST BEAM/WALL)

DOWEL BAR

$——BEAM/WALL

Section 1

[HACKING ar INTERVALS

Tie aaove {

Re wax. 1200 MM

anentb ~ STIRRUP PLACED IN

EACH HACKING MIN, Y10

1 LOCKER BAR Y10

i ytd 4

t

\\ HOLLOWCORE SLAB

$9 \ rawewnc

(NOT NECESSARY ON

PRECAST BEAM/WALL)

DOWEL BAR

{Beau wa

Section 2

/

TE ABOVE, BEAM /WALL

Jun.-1 Nos. v0

| Te wy EACH SLAB JowT

J wt No. ¥10

\\ HOLLOWCORE SLAB:

Pat \ pein:

\ ‘(NOT NECESSARY ON

\__PRECAST BEAM/WALL)

> DOWEL BAR

{enw wa

© Section 3

Diaphragm action with topping

If topping is provided, the diaphragm can be

established in the topping as shown below:

BEML — MESH

Sul

im e6 | Semeeo

—

T

HOLLOWCORE SLAB

\ rveine

(NOT NECESSARY ON

PRECAST BEAM/WALL)

LBA

| —BEAM/WALL

Section 1

1 ss0VE

SEAW/WALLp— MESH

MN 2 Y10 | -soREED

T

HOLLOWCORE SLAB

\ JAMPING

S| WOT Necessary oN

PRECAST BEAM/WALL)

~ oa

| — BEAM WAL

$0 « Side Overlab Section 2

Structural Topping,

Provided that the topping is connected

properly to the hollowcore slabs, the

moment capacity of the hollowcore slabs

can be enhanced as the hollowcore slab

and the topping will act as a composite

slab. UPC will advise about the enhanced

capacity and requirements for connecting

the topping to the hollowcore slabs.

Typical connections between topping and

Hollowcore Slabs are shown on the

sectional details below.

If a structural topping is chosen, its most

economical also to create the diaphragm in

the topping,

Reinf. bors in screed: A142

35min.

TIE ABOVE BEAW/WALL

| MN. 1-Nos. Y10

ai.—=—=4

8

He \ ravenna:

HOLLOWCORE SLAB

NOT NECESSARY ON

PRECAST BEAM/WALL)

‘Ay 18. Uctinks every 400 mem

ups

in. 30 mm in all joints.

L

BENT IN TO SCREED

. DOWEL BAR

Bees

Section 3

ke Ad

Section AVA Section 8-8

@ DIAPHRAGM ACTION

BE Page 15

BE Page 16

@ STANDARD DETAILS

Slab Joint

The joints between the slabs can be filled

without the need of shuttering,

Joint grout

normal

HOLLOWCORE SLABS will

minimum bearing not less than 60 mm

conditions the

need a

Bearing will, under normal conditions,

always be designed as 80mm in order to

allow for tolerances in the main load

bearing structure,

For spans more than 12m, the designed

bearing should be 100mm due to the

increased tolerances.

For support on blockwork walls, it is

important to check that the compression

stresses in the blockwork wall are

acceptable in the support zone of the

hollowcore slabs. If not a reinforced

concrete coping beam should be provided

on the top.

For erection on cast in-situ concrete beams

or block walls, a 20mm horizontal joint is

required to take the variances of the level of

the support and secure a uniform load

transfer. Concrete beams can be casted full,

half or not at all before erection of the

hollowcore slabs as shown on the details

below:

Typical details for Hollowcore Slabs

supported on load bearing blockwork

walls (D1 - D3).

oP

110 © 400 GROUTED INTO

BLOCK WALL UPTO. 400mm

ABOVE SSL (TYP.)

be

wowowcoRe stab! /

wpe ~/

mo

-2100K

LOAD BEARING

BLOCK WALL

Wouowcore sta! /

4

Loan sears |

3 BLOCK WALL

10 @ 400 GROUTED INTO

BLOCK WALL UPTO. 400mm

TE BAR IN SLAB JOT

BOVE SSL (YP.)

HOLLOWCORE SuAB~

ANPING

m0

=

&

Te BAR IN SLAB JOINT

7204 120

Taping ~/

mmo

-avack

Typical details of Hollowcore Slabs

supported on concrete beams (D4 - D8).

|

|

|

|

TE. RENFORCEMENT

fp v-eaR,

IN SUB JONT

Vk 4

yeast

at

: faa ove

“Lach \ wt

Porat

| cts Gen

+— BLOCK WALL ww

TE. REINFORCEMENT

HLA sowoweore sue |

\-TaWeING, |

| U-BAR |

}-—CAST-IN-SITU BEAM |

— BLOCK WALL |

50 = Side Over |

et

//-— We renworcount

— cAST-IN-SmTU AM

100K WAL

=I

|

4

(0 CASTED EIER BEFORE — gout

DSTER ERECTION OF SUB /—

HOLLONCORE. SLAB

m0, | 0, |

CSt-W-STU BEAL

2 NOS. HACKING IN EACH SLABS

To BE CASTED WITH SCREED

STRUCTURAL TOPPING

WT MESH

ae

+ | “TE, BAR IN BETWEEN

TY rien v

free stew | 9 Err Hs | | SUB ONT

(Ce Wt) | EOS

‘asT-N-STU BEAM | |-—tew. support

| | FoR eRECTON OF Hes

For erection on steel. structures, precast

beams and walls, the slabs can be placed

directly on the support structure or on a

bearing strip. Typical details for support on

steel beams are shown below and for details

D-15 & D-16 the capacity of the steel

beams can be increased as the beam and

slab work as composite action.

Diaphragm action in the slabs can be

achieved as on all other supports if

required. See page 14 for further details.

Typical details of Hollowcore Slabs

supported on steel structures (D9 - D16).

(NE REINFORCEMENT

| dower. ear

-8AR

[Ww 'StA8 Jowr

| cs

HOLLOWCORE SLAB

pew ee STEEL Bea

|

@ STANDARD DETAILS

ME Page 17

@ STANDARD DETAILS

rout

TIE REINFORCEMENT

| -—DoweL BAR

aR

/ [SiaB Jowr |

|

| Howowcore siz olga, HoLLowcone sina |

STEEL aan

For details D12 - D14 the steel beams also

have to work as tie beams, as no tie

reinforcement are provided. Steel beams

have to be checked for torsion, specially

p12.

] 2% solioecore sue

[ek crcoa soa

39. _Woworcore sus

— suweuoR BEAM

bea so.

£9. ouowcore sta}

~ SUMFLOR BEAM. |

| sek suo # am oe

| he Se

| STRUCTURAL TOPPING

‘SOREED

HOLLOWCORE SLAB

STEEL EAM

ACTION WITH THE STEEL BEAM

SHEAR STUD @ 300 C/C

coke crout-, [Ma Bab

| -—ScREED

|-_ TRANSVERSE STEEL TO CREATE COMPOSITE | CD

|

HOLLOWCORE SLAB

STEEL BEAM

Tie Reinforcement

Tie reinforcement according to BS 8110 can

either be placed in a structural screed or in

the joints between and at the end of the

HOLLOWORE SLABS. See also under

Diaphragm action for further explanations.

Double Tee Load Span Table

2.4 m wide Auckland Tees with 65 mm to topping

nisin Aang Forse | Clear spans in metres, Maximum superimposed (unfactore) loads in KPa_Based on 65 topping

eee

om gee test [sm [em | rm | am | om | tom] tim | 12m | ram | sam | 15m | t6m | 17m | 12m

zo 6238 [iso] o2 | 60] 30

2507837 130 | 60 | 65 | «0

m0 833 120 | 86 | 62 | #4

36010844 20 [07 [eo |sa[ ar

404 4a 18 | 6s [68 | 52 | 39 | 20

4013948 28 | 100 | 79 | 62 | 49 | 38

50015548 ws [ot | 72 | 7 [4s | 35

56017060 v0 [90 | eo | ea | 2] a2] as

Note:

This load span table applies to 2.4 m wide units supplied ex Auckland. Auckland units have 2400 wide by 50

thick flanges and 200 wide webs. Widths, profiles and other details vary in other centres.

Shallow units and units near their load limit will have high camber.

Units near their load limit may be excessively lively,

The shallowest tee may not be the most economical

Increasing the depth of the tee reduces the cost of prestressing and stiups and also reduces camber and

deflections, generally improving performance and buildabilty

For any particular load span combination, there is litle additional cost to increase the depth of the tee.

Data Sheet Double Tee 10.05

2400 mm Double Tees (ex Auckland)

Note: Refer to the licensee manufacturers for profiles in other areas.

Self Weights for Handling:

Tee Size: 200mm | 250mm | 300mm | 350mm | 400mm | 450mm | 500mm | 550mm

Sel Weight "| 465 515 565 620 670 720 770 825

| teatinm | |

Data Sheet Double Tee 10.05

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Eurocode Load Combinations For Steel Structures 2010Document29 pagesEurocode Load Combinations For Steel Structures 2010Aram Chtchyan73% (11)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Calculus Cheat Sheet Limits Definitions Limit at InfinityDocument11 pagesCalculus Cheat Sheet Limits Definitions Limit at Infinityapi-1192241886% (7)

- CM Prep Course - Lecture 4 ConcreteDocument23 pagesCM Prep Course - Lecture 4 Concreterabeeabuahmad100% (3)

- CM SI Units 2013Document2 pagesCM SI Units 2013rabeeabuahmadNo ratings yet

- UPC Hollowcore SlabsDocument16 pagesUPC Hollowcore SlabsrabeeabuahmadNo ratings yet

- TUTORING David Lowe PDFDocument1 pageTUTORING David Lowe PDFrabeeabuahmadNo ratings yet

- Wind Load ExampleDocument4 pagesWind Load Examplemerlin1112255100% (1)

- AS3600 CombosDocument1 pageAS3600 CombosrabeeabuahmadNo ratings yet

- DK1654 AppaDocument6 pagesDK1654 AppagargmonicacivilNo ratings yet

- Angle of Internal FrictionDocument2 pagesAngle of Internal FrictionrabeeabuahmadNo ratings yet

- Columns To AS 3600-01-ExampleDocument8 pagesColumns To AS 3600-01-ExamplerabeeabuahmadNo ratings yet

- Hoenderkamp & Bakker PDFDocument16 pagesHoenderkamp & Bakker PDFrabeeabuahmadNo ratings yet

- Columns To AS 3600-01Document7 pagesColumns To AS 3600-01rabeeabuahmadNo ratings yet

- Lipped C Sections PDFDocument3 pagesLipped C Sections PDFrabeeabuahmadNo ratings yet

- Seismic Loads Summary by RKDocument5 pagesSeismic Loads Summary by RKrabeeabuahmadNo ratings yet

- Exam Paper CM 2009Document24 pagesExam Paper CM 2009rabeeabuahmadNo ratings yet

- RSJ Exam Prep Slides - Feb 2011Document19 pagesRSJ Exam Prep Slides - Feb 2011rabeeabuahmadNo ratings yet

- Ret WallsDocument2 pagesRet WallsrabeeabuahmadNo ratings yet

- Methods of Preparing Horizontal Construction Joints in Mass ConcreteDocument82 pagesMethods of Preparing Horizontal Construction Joints in Mass ConcreterabeeabuahmadNo ratings yet

- Writing A Dissertation PDFDocument14 pagesWriting A Dissertation PDFrabeeabuahmadNo ratings yet

- ESDEP ConnectionsDocument268 pagesESDEP ConnectionsrabeeabuahmadNo ratings yet

- Lipped C SectionsDocument3 pagesLipped C SectionsrabeeabuahmadNo ratings yet

- Seismic Design of Steel-Framed Structures To Eurocode 8Document8 pagesSeismic Design of Steel-Framed Structures To Eurocode 8dimitris22No ratings yet

- Writing Dissertations and ThesisDocument16 pagesWriting Dissertations and ThesisrabeeabuahmadNo ratings yet

- Cold Formed Cees and ZeesDocument1 pageCold Formed Cees and ZeesrabeeabuahmadNo ratings yet

- Pucher Chart ExtractsDocument19 pagesPucher Chart ExtractsClaudio MiglioriniNo ratings yet

- BDA Free Standing WallsDocument7 pagesBDA Free Standing WallsEnginerdouglasNo ratings yet

- Timeline of ConcreteDocument7 pagesTimeline of ConcreterabeeabuahmadNo ratings yet

- 3 Hinged FrameDocument2 pages3 Hinged FramerabeeabuahmadNo ratings yet