Professional Documents

Culture Documents

Aoac960 09 PDF

Uploaded by

Allen Wei ChnugOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aoac960 09 PDF

Uploaded by

Allen Wei ChnugCopyright:

Available Formats

6.3.03 (f) Phosphate buffer dilution water.—Add 1.25 mL 0.

25M phos-

AOAC Official Method 960.09 phate buffer stock solution, (e), to 1 L H2O and dispense in 99 mL

Germicidal and Detergent portions. Autoclave 20 min at 121°C.

Sanitizing Action of Disinfectants (g) Test organisms.—Use Escherichia coli ATCC No. 11229 or

First Action 1960 Staphylococcus aureus ATCC 6538. Incubate 24 and 48 h, respec-

Final Action tively. Maintain stock cultures on nutrient agar (AOAC), (a)(3), at

refrigerator temperature.

(Suitable for determining minimum concentration of chemical that

B. Resistance to Phenol of Test Cultures

can be permitted for use in sanitizing precleaned, nonporous food

contact surfaces. Minimum recommended starting concentration is Determine resistance to phenol at least every 3 months by 955.11

2–4× this concentration. Test also determines maximum water hard- (see 6.1.01). Resistance of E. coli should be equivalent to that speci-

ness for claimed concentrations. As control, check accuracy of fied for S. typhi in 955.11D (see 6.1.01) and that for S. aureus equiv-

hard-water tolerance results with pure C14 alkyl dimethyl benzyl am- alent to that specified for this organism in 955.12 (see 6.1.02); also,

monium chloride at 700 and 900 ppm (µg/mL) hardness, and pure use procedures under 991.48A(b) (see 6.2.03) for S. aureus.

C16 alkyl dimethyl benzyl ammonium chloride [Cetalkonium Chlo-

C. Apparatus

ride], at 400 and 550 (µg/mL) ppm hardness, expressed as CaCO3.)

(a) Glassware.—250 mL wide-mouth Erlenmeyers; 100 mL

graduate; Mohr, serological, and/or bacteriological (APHA specifi-

A. Reagents

cation) pipets; 20 × 150 mm test tubes. Sterilize at 180°C in hot air

(a) Culture media.—(1) Nutrient agar A.—Boil 3 g beef extract, oven ≥2 h.

5 g peptone (from Difco No. 0118 or equivalent; special grades must (b) Petri dishes.—Sterile.

not be used), and 15 g salt-free agar in 1 L H2O. Do not use premixed, (c) French square bottles.—175 mL, flint glass.

dehydrated media. Tube, and autoclave 20 min at 121°C. Use for (d) Water bath.—Controlled at 25°C.

daily transfer of test culture. (2) Nutrient agar B.—Prepare as above

but use 30 g agar. Use for growing test cultures in French square bot- D. Preparation of Culture Suspension

tles. (3) Nutrient agar (AOAC).—See 955.11A(c) (see 6.1.01). Use From stock culture inoculate tube of nutrient agar A, A(a)(1), and

for preparing stock culture slants. make ≥3 consecutive daily transfers (≤30), incubating transfers

(b) Subculture media.—(1) Use tryptone glucose extract agar 20–24 h at 35–37°C. Do not use transfers >30 days. If only 1 daily

(Difco No. 0002), adding 25 mL stock neutralizer, (c),/L. transfer has been missed, no special procedures are required; if

(2) Tryptone glucose extract agar (Difco). 2 daily transfers are missed, repeat with 3 daily transfers.

(c) Neutralizer stock solution.—Mix 40 g Lecithin (Alcolec Prepare 175 mL French square culture bottles containing 20 mL

Granules, American Lecithin, PO Box 1908, Danbury, CT 06813, nutrient agar B, A(a)(2), autoclave 20 min at 121°C, and let solidify

USA [25–50 kg containers only] or Advanced Lecithin Products, with bottle in horizontal position. Inoculate culture bottles by wash-

PO Box 677, Danbury, CT 06804, USA), 280 mL polysorbate 80, ing growth from slant with 5 mL phosphate buffer dilution H2O,

and 1.25 mL phosphate buffer, (e); dilute with H2O to 1 L and adjust A(f), into 99 mL phosphate buffer dilution H2O, and adding 2 mL of

to pH 7.2. Dispense in 100 mL portions and autoclave 20 min at this suspension to each culture bottle, tilting back and forth to dis-

121°C. tribute suspension; then drain excess liquid. Incubate 18–24 h at

(d) Neutralizer blanks.—For use with ≤200 ppm quaternary am- 35–37°C, agar side down. Remove culture from agar surface of 4 or

monium compound. Mix 100 mL neutralizer stock solution, (c), more bottles, using 3 mL phosphate buffer dilution H2O and glass

25 mL 0.25M phosphate buffer stock solution, (e), and 1675 mL H2O. beads in each bottle to suspend growth. Filter suspension through

Dispense 9 mL portions into 20 × 150 mm tubes. Autoclave 20 min Whatman No. 2 paper prewet with 1 mL sterile phosphate buffer,

at 121°C. and collect in sterile tube. (To hasten filtration, rub paper gently with

(e) Phosphate buffer stock solution.—0.25M. Dissolve 34.0 g sterile policeman.) Standardize suspension to give average of 10 ×

KH2PO4 in 500 mL H2O, adjust to pH 7.2 with 1M NaOH, and dilute 109 organisms/mL by dilution with sterile phosphate buffer dilution

to 1 L. H2O, A(f).

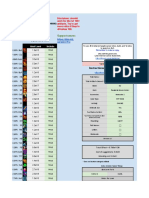

Table 960.09A Percent light transmission at various wavelengths corresponding to bacterial concentrations

% Light transmission with filters, nm

Average bacterial

370 420 490 530 550 580 650 count/mL

7.0 4.0 6.0 6.0 6.0 7.0 8.0 13.0 × 109

8.0 5.0 7.0 7.0 7.0 8.0 9.0 11.5

9.0 6.0 8.0 8.0 8.0 9.0 10.0 10.2

10.0 7.0 9.0 9.0 9.0 11.0 11.0 8.6

11.0 8.0 10.0 10.0 10.0 12.0 13.0 7.7

13.0 9.0 12.0 12.0 12.0 13.0 15.0 6.7

2000 AOAC INTERNATIONAL

Table 960.09B Preparation of BaSO4 suspensions (c) Determination.—Dilute 5–25 mL test sample (depending on

corresponding to bacterial concentrations hardness) to 50 mL with H2O in Erlenmeyer or casserole. Add 1 mL

buffer solution (67.5 g NH4Cl and 570 mL NH4OH diluted to 1 L with

2% BaCl2 1% H2SO4 Average bacterial

Standard No. solution, mL (v/v) solution, mL count/mL H2O), 1 mL inhibitor (5.0 g Na2S⋅9H2O or 3.7 g Na2S⋅5H2O dissolved

in 100 mL H2O), and one or 2 drops indicator solution (0.5 g Chrome

1 4.0 96.0 5.0 × 109 Black T in 100 mL 60–80% alcohol). Titrate with EDTA standard so-

2 5.0 95.0 7.5 lution slowly, stirring continuously, until last reddish tinge disappears

3 6.0 94.0 8.5

from solution, adding last few drops at 3–5 s intervals.

4 7.0 93.0 10.0

Hardness as mg CaCO3/L =

5 8.0 92.0 12.0 (mL standard solution × 1000)/mL test sample

6 10.0 90.0 13.5

G. Preparation of Test Samples

7 12.0 88.0 15.0 Use composition declared or determined as guide to test sample

weight required for volume sterile H2O used to prepare 20 000 ppm

(µg/mL) solution. From this stock dilution, transfer 1 mL into 99 mL

If Lumetron colorimeter is used, dilute suspension in sterile of the water to be used in test to give concentration of 200 ppm

Lumetron tube to give % T according to Table 960.09A. (µg/mL) . In making transfer, fill 1 mL pipet and drain back into

If McFarland nephelometer and BaSO4 standards are used, select stock solution; then refill, to correct for adsorption on glass. After

7 tubes of same id as that containing test culture suspension. Place mixing, discard 1 mL to provide 99 mL of the test water in H.

10 mL of each suspension of BaSO4, prepared as indicated in Ta-

H. Operating Technique

ble 960.09B, in each tube and seal tube. Standardize suspension to

correspond to No. 4 standard. Measure 99 mL water to be used in test, containing bactericide at

concentration to be tested, into chemically clean, sterile, 250 mL

E. Synthetic Hard Water wide-mouth Erlenmeyer and place in constant temperature bath un-

Prepare Solution 1 by dissolving 31.74 g MgCl2 (or equivalent of til it reaches 25°C, or ≥20 min. Prepare duplicate flasks for each ger-

hydrates) and 73.99 g CaCl2 in boiled distilled H2O and diluting to micide to be tested. Also prepare similar flask containing 99 mL

1 L. Prepare Solution 2 by dissolving 56.03 g NaHCO3 in boiled dis- sterile phosphate buffer dilution H2O, A(f), as “initial numbers”

tilled H2O and diluting to 1 L. Solution 1 may be heat sterilized; So- control.

lution 2 must be sterilized by filtration. Place required amount Add 1 mL culture suspension to each test flask as follows: Whirl

flask, stopping just before suspension is added, creating enough re-

Solution 1 in sterile 1 L flask and add ≥600 mL sterile distilled H2O;

sidual motion of liquid to prevent pooling of suspension at point of

then add 4 mL Solution 2 and dilute to 1 L with sterile distilled H2O.

contact with test water. Add suspension midway between center and

Each mL Solution 1 will give a water equivalent to ca 100 ppm of

edge of surface with tip of pipet slightly immersed in test solution.

hardness calculated as CaCO3 by formula:

Avoid touching pipet to neck or side of flask during addition. Trans-

fer 1 mL portions of this exposed culture to neutralizer blanks ex-

Total hardness as ppm (µg/mL) CaCO3 = 2.495 × ppm (µg/mL) Ca actly 30 and 60 s after addition of suspension. Mix well immediately

after transfer.

+ 4.115 × ppm (µg/mL) Mg

For “numbers control” transfer, add 1 mL culture suspension to

99 mL sterile phosphate dilution H2O in same manner. In case of

pH of all test waters ≤2000 ppm (µg/mL) hardness should be numbers control, plants need be made only immediately after adding

7.6–8.0. Check prepared synthetic waters chemically for hardness at and mixing thoroughly ≤30 s. (It is advantageous to use milk pipets

time of tests, using following method or other methods described in to add culture and withdraw test samples.)

APHA, Standard Methods for the Examination of Water and Plate from neutralizer tube to agar, using subculture medium

Wastewater 20th Ed., 1998. A(b)(1) for quaternary ammonium compounds and A(b)(2) with

numbers control. Where 0.1 mL portions are planted, use 1 mL pipet

F. Hardness Method

graduated in 0.1 mL intervals. For dilutions to give countable plates,

(a) EDTA standard solution.—Dissolve 4.0 g use phosphate buffer dilution H2O, A(f). For numbers control, use

Na2H2EDTA⋅2H2O and 0.10 g MgCl2⋅6H2O in 800 mL H2O and ad- following dilution procedure: Transfer 1 mL exposed culture (1 mL

just by subsequent dilution so that 1 mL of solution is equivalent to culture suspension transferred to 99 mL phosphate buffer dilution

1 mg CaCO3 when titrated as in (c). Check EDTA solution after H2O in H2O bath) to 99 mL phosphate buffer dilution H2O, A(f), (di-

preparation or, if commecially purchased, against CaCO3 standard lution 1). Shake thoroughly and transfer 1 mL dilution 1 to 99 mL

at least every 2 months. phosphate buffer dilution H2O, A(f), (dilution 2). Shake thoroughly

(b) Calcium standard solution.—1 mL = 1 mg CaCO3. Weigh and transfer 1 mL dilution 2 to 99 mL phosphate buffer dilution H2O

1.00 g CaCO3, dried overnight or longer at 105°C, into 500 mL (dilution 3). Shake thoroughly and transfer four 1 mL and four

Erlenmeyer and add dilute HCl through funnel until CaCO3 is dis- 0.1 mL aliquots from dilution 3 to individual sterile Petri dishes.

solved. Add 200 mL H2O, boil to expel CO2, and cool. Add few For test samples, use following dilution procedure: Transfer 1 mL

drops methyl red indicator and adjust color to intermediate orange exposed culture into 9 mL neutralizer, A(d). Shake and transfer four

with dilute NH4OH or HCl as required. Transfer quantitatively to 1 L 1 mL and four 0.1 mL aliquots to individual sterile Petri dishes. For

volumetric flask and dilute to volume. numbers control, use subculture medium A(b)(2); for tests with qua-

2000 AOAC INTERNATIONAL

ternary ammonium compounds, use medium A(b)(1). Cool agar to J. Sterility Controls

solidify, and then invert and incubate 48 h at 35°C before counting. (a) Neutralizer.—Plate 1 mL from previously unopened tube.

(b) Water.—Plate 1 mL from each type of water used.

I. Results

(c) Sterile distilled water.—Plate 1 mL. After counting plates,

To be considered valid, results must meet standard effectiveness:

confirm that surviving organisms are E. coli by transfer to brilliant

99.999% reduction in count of number of organisms within 30 s. Re-

green bile broth fermentation tubes or lactose broth and EMB agar;

port results according to actual count and percent reduction over

confirm S. aureus by microscopic examination.

numbers control. Counts on numbers control for germicide test mix-

ture should fall between 75 and 125 × 106/mL for percent reductions References: Am. J. Public Health 38, 1405(1948).

to be considered valid. J. Milk Food Technol. 19, 183(1956).

Fed. Regist. 21, 7020(1956).

JAOAC 41, 541(1958); 56, 308(1973).

2000 AOAC INTERNATIONAL

You might also like

- 6.2.04 AOAC of Fi Cial Method 955.15 Testing Dis in Fec Tants Against Staph y Lo Coc Cus AureusDocument4 pages6.2.04 AOAC of Fi Cial Method 955.15 Testing Dis in Fec Tants Against Staph y Lo Coc Cus AureusPiruzi MaghlakelidzeNo ratings yet

- 955.17 Actividad Fungicida de Desinfectantes Trichophyton MentagrophytesDocument1 page955.17 Actividad Fungicida de Desinfectantes Trichophyton MentagrophytesMlian Mindiola PabloNo ratings yet

- Astm 1292 - Verificación de La IncubadoraDocument2 pagesAstm 1292 - Verificación de La IncubadoraAmayrani Figueroa DIazNo ratings yet

- Manual Microbiological Air Sampler SAS SUPER DUO & ISOLATORDocument125 pagesManual Microbiological Air Sampler SAS SUPER DUO & ISOLATORwanabacoa0% (1)

- WHO Expert Committee On Specifications For Pharmaceutical PreparationsDocument324 pagesWHO Expert Committee On Specifications For Pharmaceutical PreparationsKulfi BarfiNo ratings yet

- 1116 Control Microbiologico y Monitoreo Ambiental de Procesos AsepticosDocument12 pages1116 Control Microbiologico y Monitoreo Ambiental de Procesos Asepticosana maria tobonNo ratings yet

- Quality Control of Microbiological Culture MediaDocument7 pagesQuality Control of Microbiological Culture Mediamustea_ana9616No ratings yet

- Agua BPDocument3 pagesAgua BPEdgar Condori MendozaNo ratings yet

- Handbook PMBDocument188 pagesHandbook PMBgsakthivel2008No ratings yet

- Accela CotaDocument5 pagesAccela CotaHassan HaniNo ratings yet

- Iso 21148 2017 en PDFDocument11 pagesIso 21148 2017 en PDFRui SantosNo ratings yet

- Food AOAC-991.14Document2 pagesFood AOAC-991.14Jocilene DantasNo ratings yet

- Usp 43 NF 38 IndexDocument72 pagesUsp 43 NF 38 IndexNumixx SasNo ratings yet

- Acculan 3ti Ga677Document146 pagesAcculan 3ti Ga677LowayNo ratings yet

- Determining Acid Composition by Alkalimetric TitrationDocument3 pagesDetermining Acid Composition by Alkalimetric Titrationkarachi85No ratings yet

- ATI-PAO-Safety Data Sheet in Compliance With RegulationDocument7 pagesATI-PAO-Safety Data Sheet in Compliance With RegulationGochepz Shanz0% (1)

- Official Status and DocId for USP Chapter 1010Document29 pagesOfficial Status and DocId for USP Chapter 1010alexanderaristizabal100% (1)

- Stage 1 Diffusion Master Worksheet: Disclaimer and InstructionsDocument6 pagesStage 1 Diffusion Master Worksheet: Disclaimer and InstructionsSpectre Spectre0% (1)

- TsaDocument2 pagesTsanhlhNo ratings yet

- Ph4 ManualDocument14 pagesPh4 ManualAnonymous hISvHbfiB10% (1)

- Prominence SIL-20aDocument4 pagesProminence SIL-20amr_stali2987No ratings yet

- BAM: Enumeration of Escherichia Coli and The Coliform BacteriaDocument8 pagesBAM: Enumeration of Escherichia Coli and The Coliform BacteriatintfenNo ratings yet

- Hard Gelatin Capsule Shell SpecificationsDocument4 pagesHard Gelatin Capsule Shell Specificationspeter mackey mamani mamanchura100% (1)

- Muffle Furnace 6000 PDFDocument56 pagesMuffle Furnace 6000 PDFAshraf MohamedNo ratings yet

- Uv Winlab Software Manual EspañolDocument2 pagesUv Winlab Software Manual EspañolRoberto BonillaNo ratings yet

- 71 Sterility Test Usp41Document8 pages71 Sterility Test Usp41hh_543No ratings yet

- 17.3.04 AOAC Official Method 991.14 Coliform and Escherichia Coli Counts in FoodsDocument2 pages17.3.04 AOAC Official Method 991.14 Coliform and Escherichia Coli Counts in FoodsCalidad NKAPSRLNo ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- AAS-8510154700 SeriesAA UserManualDocument72 pagesAAS-8510154700 SeriesAA UserManualHuỳnh Bảo ChâuNo ratings yet

- Aerosol Diluter - 1 - 100, 28.3 L - Min - DIL 554 - Topas GMBHDocument5 pagesAerosol Diluter - 1 - 100, 28.3 L - Min - DIL 554 - Topas GMBHDragan IlicNo ratings yet

- DQdocument For VP - EngDocument23 pagesDQdocument For VP - EngAbdul KalimNo ratings yet

- Alcohol Determination Apparatus KitDocument2 pagesAlcohol Determination Apparatus KitMulayam Singh YadavNo ratings yet

- Perkin Elmer Spectrum 2000 FTIR Manual PDFDocument1 pagePerkin Elmer Spectrum 2000 FTIR Manual PDFrbn.santiagoNo ratings yet

- EuSalt AS008-2005 Potassium - Flame Atomic Absorption Spectrometric MethodDocument4 pagesEuSalt AS008-2005 Potassium - Flame Atomic Absorption Spectrometric MethodRuth Patinggi LPNo ratings yet

- Aerobic Plate Count TVC Petrifilm AOAC 998.12Document2 pagesAerobic Plate Count TVC Petrifilm AOAC 998.12GEOW CHIN HONGNo ratings yet

- Enumeration of Coagulase-Positive StaphylococciDocument23 pagesEnumeration of Coagulase-Positive Staphylococcianil_hod8353No ratings yet

- Connectionsaqt For Empower 3: Requirements Before Qualification BeginsDocument45 pagesConnectionsaqt For Empower 3: Requirements Before Qualification BeginsJorge MorenoNo ratings yet

- DiacereinDocument3 pagesDiacereinMulayam Singh Yadav0% (2)

- Cleaning Validation 2Document16 pagesCleaning Validation 2Yulis AdrianaNo ratings yet

- SQ Prove 300 - Analytical Procedures and Appendices 2017-07Document264 pagesSQ Prove 300 - Analytical Procedures and Appendices 2017-07Rizali MaulanaNo ratings yet

- Membrane Filtration UpdatedDocument12 pagesMembrane Filtration UpdatedFazlie IslamNo ratings yet

- AOAC 936 16 Hidroxido de Sodio PDFDocument1 pageAOAC 936 16 Hidroxido de Sodio PDFAdufe RufaiNo ratings yet

- Sds Rewocid WK 30 PDFDocument14 pagesSds Rewocid WK 30 PDFSaptina Walida0% (1)

- Final Microbiology Method Guidance 110409.Pdf11Document107 pagesFinal Microbiology Method Guidance 110409.Pdf11rominutza23No ratings yet

- Preliminary Free Radical Scavenging BrinDocument5 pagesPreliminary Free Radical Scavenging BrinsanjoyNo ratings yet

- Meclizine HCLDocument10 pagesMeclizine HCLChEng_No ratings yet

- AGAR CHROMOCULT Merck Rebrand - 110426 - 1906Document6 pagesAGAR CHROMOCULT Merck Rebrand - 110426 - 1906Luz Katherine MartinezNo ratings yet

- Microflow Air Sampler User ManualDocument31 pagesMicroflow Air Sampler User Manualira rahmaNo ratings yet

- Guía Revisión Periódica (Anual) de ProductoDocument18 pagesGuía Revisión Periódica (Anual) de ProductoNerito MONo ratings yet

- 2.5.11. Complexometric TitrationsDocument1 page2.5.11. Complexometric TitrationsMulayam Singh YadavNo ratings yet

- MilliQ WaterDocument16 pagesMilliQ Wateralen19819072No ratings yet

- Compilado de Ion para Cuartos LimpiosDocument49 pagesCompilado de Ion para Cuartos LimpiosEnrique Romero SanchezNo ratings yet

- MentholDocument4 pagesMentholLipsi Merchán100% (1)

- Q3A Impurities in New Drug SubstancesDocument23 pagesQ3A Impurities in New Drug SubstancesDoobyduckktrucksNo ratings yet

- PH Eur 2.4.27. Heavy Metals in Herbal Drugs and Fatty OilsDocument2 pagesPH Eur 2.4.27. Heavy Metals in Herbal Drugs and Fatty OilsLuis SanabriaNo ratings yet

- Bioprocessing Technology for Production of Biopharmaceuticals and BioproductsFrom EverandBioprocessing Technology for Production of Biopharmaceuticals and BioproductsClaire KomivesNo ratings yet

- Aoac 983.16 CGDocument1 pageAoac 983.16 CGJuanNo ratings yet

- BMC Infectious Diseases: The Efficacy of Chemical Agents in Cleaning and Disinfection ProgramsDocument8 pagesBMC Infectious Diseases: The Efficacy of Chemical Agents in Cleaning and Disinfection ProgramsAllen Wei ChnugNo ratings yet

- Product Performance Test GuidelinesDocument20 pagesProduct Performance Test GuidelinesRashid SaleemNo ratings yet

- Asia Pacific Society of Infection Control (APSIC) Guidelines For Environ PDFDocument9 pagesAsia Pacific Society of Infection Control (APSIC) Guidelines For Environ PDFHoward TuanquiNo ratings yet

- Tga Instructions Disinfectant Testing PDFDocument24 pagesTga Instructions Disinfectant Testing PDFAllen Wei ChnugNo ratings yet

- Tga Instructions Disinfectant Testing PDFDocument24 pagesTga Instructions Disinfectant Testing PDFAllen Wei ChnugNo ratings yet

- Journal of Clinical Microbiology-1993-Lee-2764.fullDocument5 pagesJournal of Clinical Microbiology-1993-Lee-2764.fullAllen Wei ChnugNo ratings yet

- The European approach to disinfectant qualificationDocument5 pagesThe European approach to disinfectant qualificationAllen Wei ChnugNo ratings yet

- The European approach to disinfectant qualificationDocument5 pagesThe European approach to disinfectant qualificationAllen Wei ChnugNo ratings yet

- Pathogens 04 00269 PDFDocument14 pagesPathogens 04 00269 PDFAllen Wei ChnugNo ratings yet

- Duo Max bactericidal efficacy assessmentDocument7 pagesDuo Max bactericidal efficacy assessmentAllen Wei ChnugNo ratings yet

- Manufacture of Sterile Products Annex GuidanceDocument52 pagesManufacture of Sterile Products Annex GuidanceLuis Gerardo Rendón BeltránNo ratings yet

- Demonstration POSTNATAL EXAMINATION Easy WayDocument9 pagesDemonstration POSTNATAL EXAMINATION Easy Wayjyoti singhNo ratings yet

- Design Calculations of Thrust Blocks at Lower Indira: L&T Construction Water & Effluent Treatment ICDocument3 pagesDesign Calculations of Thrust Blocks at Lower Indira: L&T Construction Water & Effluent Treatment IClagnajit dasNo ratings yet

- Shivag Itim Al ADocument27 pagesShivag Itim Al AKellie RamosNo ratings yet

- Pip Venix LRDocument2 pagesPip Venix LRThanh VoNo ratings yet

- Random Variate Generation-1Document21 pagesRandom Variate Generation-1Christian Delas AlasNo ratings yet

- Encapsulation and Inheritance in Object-Orlented Programming LanguagesDocument8 pagesEncapsulation and Inheritance in Object-Orlented Programming Languageszsolt kormanyNo ratings yet

- Treatment of Headaches in The ED With Lower Cervical Intramuscular Bupivacaine Injections: A 1-Year Retrospective Review of 417 PatientsDocument9 pagesTreatment of Headaches in The ED With Lower Cervical Intramuscular Bupivacaine Injections: A 1-Year Retrospective Review of 417 PatientsLarry B. Mellick, MDNo ratings yet

- Engineering StudiesDocument4 pagesEngineering StudiesSamuel PhegelloNo ratings yet

- AABB Accredited DNA Testing FacilitiesDocument2 pagesAABB Accredited DNA Testing Facilitiesjosueduran75No ratings yet

- A Review: HPLC Method Development and Validation: November 2015Document7 pagesA Review: HPLC Method Development and Validation: November 2015R Abdillah AkbarNo ratings yet

- 3.1 Artifact OptimiserDocument120 pages3.1 Artifact Optimiseralex joNo ratings yet

- Learn More: National Weather ServiceDocument2 pagesLearn More: National Weather Servicedamien boyerNo ratings yet

- Computer Engineering SyllabusDocument47 pagesComputer Engineering SyllabusLily ChanNo ratings yet

- Sample Article Used by MeDocument14 pagesSample Article Used by MeMagnum OpusNo ratings yet

- vCloudPoint Sharing Computing Solution Data Sheet PDFDocument8 pagesvCloudPoint Sharing Computing Solution Data Sheet PDFkus satria dNo ratings yet

- Experimental Monitoring of The Humber Bridge UsingDocument7 pagesExperimental Monitoring of The Humber Bridge Using정주호No ratings yet

- Permeability Test Constant Head MethodDocument10 pagesPermeability Test Constant Head MethodLouise LuyNo ratings yet

- F825 - Hotcakes Baby Cardigan FinalDocument2 pagesF825 - Hotcakes Baby Cardigan Finaladina100% (1)

- A Robust Firearm Identification Algorithm ProposalDocument7 pagesA Robust Firearm Identification Algorithm ProposalEuneel EscalaNo ratings yet

- Manual Hoist ProductsDocument40 pagesManual Hoist Productskavin bhagavathyNo ratings yet

- Validation of Correlations Between A NSPT PDFDocument12 pagesValidation of Correlations Between A NSPT PDFAgus WahyudiNo ratings yet

- IP Modulator User's Guide - Oct - 09Document68 pagesIP Modulator User's Guide - Oct - 09reivajjwNo ratings yet

- Model Question Paper and Solution 2022Document14 pagesModel Question Paper and Solution 2022R Y AnushNo ratings yet

- Legend of Nueva VizcayaDocument10 pagesLegend of Nueva VizcayaAndreanna Maria100% (1)

- Tooth Development, Eruption & Applied Aspects: Saurabh Roy 09.03.2016Document95 pagesTooth Development, Eruption & Applied Aspects: Saurabh Roy 09.03.2016reema aslamNo ratings yet

- Girbau STI-54 STI-77 Parts ManualDocument74 pagesGirbau STI-54 STI-77 Parts Manualrpm14sheratonbsasNo ratings yet

- Thalassemia: Submitted By: Jovan Pierre C. Ouano Submitted To: Mark Gil T. DacutanDocument8 pagesThalassemia: Submitted By: Jovan Pierre C. Ouano Submitted To: Mark Gil T. DacutanJvnpierre AberricanNo ratings yet

- Gen Ed Answer Key (A)Document7 pagesGen Ed Answer Key (A)Antonette Escarpe TorcinoNo ratings yet

- Catalogus 2010 ENGELSDocument52 pagesCatalogus 2010 ENGELShacikadiNo ratings yet