Professional Documents

Culture Documents

Labsystem Building Ventilation Systems and Building Services Management

Uploaded by

Julio AlceramOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Labsystem Building Ventilation Systems and Building Services Management

Uploaded by

Julio AlceramCopyright:

Available Formats

Building ventilation systems and building services management

6.0

Chapter 6.0

LabSystem

Building ventilation systems and

building services management

Table of contents

Section Title Page

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Building services management (BSM) . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 PAD-3000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Graphic interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Duct pressure optimiser with FI fan actuation . . . . . . . . . . . . . 4

2.3 Duct pressure controller with fan FI actuation . . . . . . . . . . . . . 4

2.4 Constant duct pressure controller . . . . . . . . . . . . . . . . . . . . 4

3.1 Energy savings taking into account the diversity factor . . . . . . . . . . . . 5

3.1.1 Diversity factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Remote maintenance and safety . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Fire and smoke detection . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.1 System networking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.1.1 LON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.1.2 BACnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.1.3 ETHERNET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.1.4 INDUSTRIAL ETHERNET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.1 Ventilation system with central supply and exhaust air . . . . . . . . . . . 7

6.1.1 Pressure control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.1.2 Duct dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.1.3 Negative pressure in the laboratory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.1.4 Temperature control, heating and cooling . . . . . . . . . . . . . . . . . . . . 8

6.1.5 Volume flow control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.2 Ventilation system with central supply and exhaust air via individual fans . 8

7.0 Building ventilation systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7.1 Constant volume flow control . . . . . . . . . . . . . . . . . . . . . . . 9

7.1.1 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LabSystem Planning Manual ● Air technology for laboratories 1

Building ventilation systems and building services management

Chapter 6.0

Table of contents

Section Title Page

8.1 Variable volume flow control . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.1.1 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9.1 Ventilation system with speed controlled supply and exhaust air . . . . . . 13

9.2 Ventilation system with speed controlled supply and exhaust air

with bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9.2.2 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10.1 Variable volume flow control of 4 laboratories in the LON network . . . . 15

10.2 Connection to the building services management . . . . . . . . . . . 16

10.2.1 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

11.1 Additional savings potential with a DPO duct pressure optimiser in the

LON network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

11.1.1 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12.1 Product overview Duct pressure controllers, Duct pressure optimisers . . 18

2 LabSystem Planning Manual ● Air technology for laboratories

Building ventilation systems and building services management

Chapter 6.0

1.1 Introduction

A perfectly functioning full system requires well planned

building ventilation control of the central supply air and the

exhaust air and the selection of products that are well mat-

ched. The advantage for the user is that the entire system

functions without compatibility problems.

The following SCHNEIDER LabSystem products are used

for building ventilation and fan control:

Building services management

software PAD3000

Duct pressure optimiser, LON

networked, with fan FI actuation DPO-L

Central duct pressure controller

with fan FI actuation DPC

Decentral constant duct pressure

controller CDP Figure 6.1: Large-scale project ETH-Zurich with 2150

SCHNEIDER fume hood controllers

The individual area of application determines which pro-

duct is used, taking into account what gives the best value

for money. 2.1.2 Graphic interface

In addition to the correct dimensioning of the air ducts, this The software runs on WINDOWS® and every SCHNEI-

also includes the correct selection of the supply air and DER product is displayed graphically on the monitor. The

exhaust air fans. actual values, such as the sash position, exhaust air volu-

me flow, face velocity, operating status, etc., are display-

ed.

2.1 Building services management (BSM)

Remote maintenance via the BSM enables cost-efficient,

Building services management forms a considerable part regular maintenance and test functions, which conside-

of building and facility management. Companies such as rably increases the safety of the entire system.

ABB, Siemens/Landis Staefa, Honeywell, Johnson Con-

trols, Sauter, etc. have a leading market position in this In addition, recording of consumption and energy as well

area. as simple accounting (e.g. in relation to the individual labo-

ratories) is possible via the BSM.

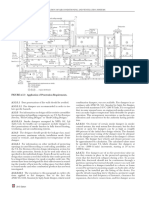

With the PAD-3000 management software, SCHNEIDER

offers a product that has been specially developed for con-

trol, regulation and remote maintenance of fume hoods

and fume hood controllers.

2.1.1 PAD-3000

PAD-3000 is written in the C++ programming language

and can easily be integrated as an independent task in the

existing building management system.

This software enables the building services management

to access all SCHNEIDER products via the network that is

installed in the building. Every variable of the fume hood

controller, such as the sash position, exhaust air volume

flow, face velocity, operating status, etc., is available and

can be controlled remotely via the BSM (see Technical da-

tasheet FC500, variables list).

Figure 6.2: PAD-3000 interface

The data and parameters of the LCO500 laboratory cont-

roller, the GC10 group controller and the LON connected

VAV-L volume flow controller (see Technical data sheet

VAV-L, variables list) are also available via the BSM.

LabSystem Planning Manual ● Air technology for laboratories 3

Building ventilation systems and building services management

Chapter 6.0

2.2 Duct pressure optimiser with fan load that is least well ventilated.

FI actuation

With weakest point measurement, the duct pressure at

The DPO-L duct pressure optimiser is used primarily in lar- the measuring point is constantly regulated to approx. 130

ge LON networked projects and takes over the optimised Pa (all values stated are only sample values), while at the

actuation of the fan frequency inverter. Via the LON net- measuring point close to the fan the duct pressure is regu-

work the damper positions of all controllers (fume hood, lated to approx. 450 Pa.

room exhaust air, etc.) are automatically checked at regu-

lar intervals and the frequency inverter (FI) for the exhaust In buildings that mainly have laboratories and rooms in a

air fan is regulated downwards until the "weakest" damper state of negative pressure, the exhaust air pressure value

is still at 80° (90° = damper fully open, 0° = damper fully that is to be regulated is always approx. 10 % higher than

shut) and thus is still in the control range. the supply air pressure value that is to be regulated.

This measure ensures that the entire system is optimised

in such a way that as little energy as possible is wasted

and controllers are still within the control range.

The same approach is also valid for the supply air and for

actuation of the supply air fan frequency inverter.

The fans are always operated at the ideal (minimum) ope-

rating point, which achieves considerable savings with re-

gard to electrical energy.

In addition to the energy savings, sound levels are also re-

duced, because the control dampers are always open as

far as possible and thus do not "waste" much pressure.

Figure 6.4: DPC duct pressure controller with display

of the duct pressure (optional)

The optimal duct pressure that is to be regulated for all

operating states is calculated by measurements taken du-

ring set-up and is then programmed as a fixed value. If

the operating states change and the air requirement of the

connected consumer loads (e.g. fume hood controllers)

changes, the fan is regulated upwards or downwards via

the frequency inverter (FI) until the constant duct pressure

is reached.

With this solution as well, the electrical energy of the re-

quired air (exhaust air and supply air) is adjusted and thus

Figure 6.3: DPO duct pressure optimiser with display savings are made, even if the savings potential of the DPO

of the duct pressure (optional) duct pressure optimiser is considerably higher.

2.3 Duct pressure controller with 2.4 Constant duct pressure controller

fan FI actuation

The CDP constant duct pressure controller regulates a

The DPC duct pressure controller automatically regulates branch duct to a constant, programmable duct pressure

the duct pressure to a constant value in relation to a pre- (e.g. 130 Pa). This means that all consumer loads con-

defined measuring point (e.g. at the weakest point or close nected to this branch duct have the same pressure con-

to the fan). ditions.

The disadvantage of weakest point measurement is the In large buildings or in inappropriately constructed ventila-

higher installation effort required, because in this case a tion networks, it is very important to install constant duct

measurement cable must be laid from the consumer load pressure controllers in appropriate places. For example,

that is least well ventilated to the DPC, which is usually the exhaust air and supply air for each floor should be se-

mounted directly on the ventilator FI. parated from the main ventilation network with constant

duct pressure controllers.

The advantage of weakest point measurement is that

measurement can take place directly on the consumer

4 LabSystem Planning Manual ● Air technology for laboratories

Building ventilation systems and building services management

Chapter 6.0

This results in considerable advantages with regard to lo- 3.2 Remote maintenance and safety

wer sound levels.

A special feature is the remote maintenance of fume hoods

in networked systems. With the PAD-3000 management

software, the safety functions of every fume hood can be

checked at regular intervals and remote maintenance with

the appropriate documentation (maintenance plan) can be

efficiently and cost-effectively carried out.

Thus, for example, the damper of the fume hood control-

ler can be forced shut via the building services manage-

ment. This cuts off the exhaust air volume flow locally.

The FC500 controller now tries to maintain the required

exhaust air volume flow, which, however, is unsuccessful

and after an alarm delay time an alarm is activated accor-

dingly. This alarm again appears as feedback on the BSM,

together with the measured exhaust air volume flow actual

value (0 m³/h).

The damper running time (over a 90° delay angle) of the

Figure 6.5: Constant duct pressure controller FC500 fume hood controller can also be read by the BSM,

whereby the damper motor and the function of the damper

is checked. At the same time, the damper position can be

read.

3.1 Energy savings taking into account

the diversity factor In addition, the ventilation system can be checked by fully

forcing open the damper(s) of one or more FC500 fume

Taking into account the diversity factor, the entire system hood controller(s) via the building services management.

can be planned at minimum cost. The fume hood controllers return the measured exhaust

air volume flows (the maximum possible value when the

damper is fully open) to the BSM.

3.1.1 Diversity factor

In addition to switching from daytime operation to night-

A diversity factor of 50 % can be calculated when an time operation (or work-free time) numerous other func-

FC500 sash-dependent variable fume hood controller and tions are conceivable. The variables required to carry out

an SC500 automatic sash controller are used. The buil- further functions are already implemented and are availab-

ding ventilation system thus only has to be dimensioned to le to the user via the BSM as standard variables (SNVT).

50 % of the value that would be necessary if the connec-

ted fume hoods were regulated constantly and the full flow

rate (100 %) would always be required. This approach ge- 4.1 Fire and smoke detection

nerates a considerable reduction in building system costs

without compromising the safety of the user. The danger of a fire breaking out or smoke forming is par-

ticularly high in laboratories and in fume hoods.

The SC500 automatic sash controller automatically closes

the sash when the fume hood is not in use, whereby the SCHNEIDER has recognised this potential danger and

controller reduces the sash-dependent exhaust air volume therefore provides two additional inputs on the FC500

flow by approx. 70 % in relation to the maximum value fume hood controller. An analogue input, suitable for con-

(VMAX = sash shut). This means that when the two pro- nection of a PT 1000 thermal element and a digital input

ducts mentioned above are used at the same time, there for connection of a smoke detector. These signals are also

is enough leeway in the dimensioning of the building if a provided as variables on the LON network. Thus local and

diversity factor of 50% is assumed. at the same time global use of the data is possible.

In this chapter various examples for building ventilation This means that when the temperature in the fume hood

controllers (supply air and exhaust air) are presented. is increased (within specific limits), the exhaust air volume

flow can also be increased in order to disperse the thermal

loads.

LabSystem Planning Manual ● Air technology for laboratories 5

Building ventilation systems and building services management

Chapter 6.0

Recognition of the temperature increase via the air flow SCHNEIDER supports the BACnet ® technology and has

sensor is not recommended, as this requires very precise extensive know-how in this area. BACnet® technology is

temperature balancing. becoming increasingly established in building automation

as a manufacturer-independent and licence-free technolo-

Without this necessary temperature compensation the gy. However, the costs for connecting BACnet® at field

airflow sensor would not be suitable for measuring repro- bus level are currently still relatively high.

ducible face velocity values at different laboratory tempe-

ratures (e.g. 19° C to 25° C). In order to technically ensu-

re safe and reproducible fire recognition, we recommend Management level

using a PT 1000 thermoelement.

If a specific temperature value is exceeded, the damper

can be closed both locally or globally via the BSM in order

Automation level

to prevent a possible outbreak of fire. LON ► BACnet

A similar scenario can also be implemented with the con- Field level

nectable smoke detector.

5.1 System networking Figure 6.7: BACnet network

The features described are only possible with an integra-

ted system network or a building services management

system. Which building services management system is Chapter 10.0 describes the BACnet technology in detail.

used is irrelevant.

Different networks can be interconnected with routers and 5.1.3 ETHERNET®

gateways, which facilitates communication, be it at the

field bus or building services management level. ETHERNET is used primarily in computer networking and

ensures very fast data transfer via coaxial cables.

5.1.1 LON®

5.1.4 INDUSTRIAL ETHERNET®

SCHNEIDER supports the LON® technology and has

extensive know-how in this area. The LON technology is INDUSTRIAL ETHERNET builds on ETHERNET and is

increasingly becoming well established in building auto- increasingly becoming established at field bus level. Ho-

mation. wever, the costs for the field bus subscribers (nodes) are

currently still very high.

LON is a decentral network and thus has a very high level

of safety. Every network or protocol has been developed for a spe-

cific area of application and thus has its own specific ad-

vantages for that area of application. Unfortunately, even

in the near future there will not be only one standardised

network for all areas of application and thus all networks

will continue to have one thing in common: they must un-

derstand one another.

Figure 6.6: LON network in free topology, FTT-10A

Chapter 10.0 describes the LON technology in detail.

5.1.2 BACnet®

BACnet is a standardised protocoll of ASHRAE (American

association of HRA manufacturers) and uses any type of

network topology as a transport medium. Thus LON is also

suitable as a transport medium for BACnet.

6 LabSystem Planning Manual ● Air technology for laboratories

Building ventilation systems and building services management

Chapter 6.0

6.1 Ventilation system with central

supply and exhaust air 6.1.2 Duct dimensions

Figure 6.8 shows a ventilation system with central supp- In order to keep flow noise and sound emission to a mi-

ly and exhaust air. This version includes components for nimum, the dimensions of the ventilation ducts must be

heat recovery (integrated circulation system), filters, air selected so that a face velocity of 7 m/sec is not exceeded.

heaters, air coolers and fans that are speed-controlled by Otherwise the required sound levels of max. 52dB(A) in

a frequency inverter. laboratories can only be achieved with very considerable

effort (e.g. sound absorbers).

6.1.1 Pressure control

6.1.3 Negative pressure in the laboratory

The air flows of the supply and exhaust air fans are ad-

justed so that the control variable pressure is centrally In the usual operating mode, the supply air volume flow is

maintained at a constant level. In the case of this system, reduced by approx. 10% in relation to the exhaust air volu-

constant pressure is maintained both on the pressure side me flow. This ensures that negative pressure is maintained

and on the suction side. The pressure control takes into in the laboratory while at the same time preventing conta-

account the pressure drop in the system components and minated air from flowing into adjacent rooms.

in the pipes of the branch ducts. A practical value here is

between 400 and 500 Pascal negative or positive pressu-

re (supply air and exhaust air fan).

Depending on the unit model and operation types, the unit

components can be dimensioned to 70% (controlled fume

hoods) or 100% (uncontrolled fume hoods) of the maxi-

mum volume flow. Figure 6.8: Ventilation system with central supply and

exhaust air

Heat Filter

exchanger Exhaust fan

FI

Exhaust air

FI

Lab 1

CAV CAV

Supply air

Air volume Air volume

Silencer

control control

Filter Heat

Air heating Air cooling Supply fan Silencer

exchanger

Lab 2

CAV CAV

Air volume Air volume

Silencer

control control

Lab 3

CAV CAV

Air volume Air volume

Silencer

control control

Lab 4

CAV CAV

Air volume Air volume

Silencer

control control

LabSystem Planning Manual ● Air technology for laboratories 7

Building ventilation systems and building services management

Chapter 6.0

6.1.4 Temperature control, heating Fume hoods that are regulated variably and in accordance

and cooling with the demand require variable volume flow control of

the laboratory supply air and, if necessary, variably regu-

The supply air temperature is regulated to a constant va- lated additional laboratory exhaust air in order to maintain

lue of 19° C and thus is 3K below the setpoint temperature the required room air exchange levels.

of the laboratories (tRA = 22° C). The heating surfaces then

regulate the room temperature to the setpoint. Internal and For unregulated or constantly regulated fume hoods, con-

external thermal loads can thus be taken into account. stant volume flow control of the laboratory supply air and

the laboratory exhaust air is sufficient.

As the outdoor temperature increases (transitional periods

and summer time), first heating of the air by the heater and

then heat recovery is reduced and switched off. The coo- 6.2 Ventilation system with central supply air

ling circuit is then activated so that the room temperature and exhaust air via individual fans

can be regulated to the setpoint for as long as possible.

Figure 6.9 shows a ventilation system with central supply

and exhaust air via individual fans. This version includes

6.1.5 Volume flow control filters, air heaters and coolers and the corresponding fans.

With this version, heat recovery cannot be implemented or

Supply air volume flow is fed into the laboratories, de- can only be implemented with a good deal of effort. The

pending on the laboratory exhaust air either variably or fans work at a one-level or two-level constant speed.

constantly with a volume flow controller. It is advisable to

activate a sound absorber after the supply air volume flow

controllers in order to adhere to the sound emission levels Figure 6.9: Ventilation system with central supply and

required in laboratories of max. 52 dB(A). exhaust air via individual fans

Exhaust air

Exhaust fans

Lab 1

CAV

Supply air

Air volume

Silencer

control

Filter Air heating Air cooling Supply fan Silencer

Lab 2

CAV

Air volume

Silencer

control

Lab 3

CAV

Air volume

Silencer

control

Lab 4

CAV

Air volume

Silencer

control

8 LabSystem Planning Manual ● Air technology for laboratories

Building ventilation systems and building services management

Chapter 6.0

7.0 Building ventilation systems 7.1 Constant volume flow control

In the following examples various building ventilation con- Figure 6.10 shows constant volume flow control of the la-

cepts are presented. The individual requirements of the boratory supply air and the laboratory exhaust air. Energy

laboratory are taken into account. The supply air is treated savings are not achieved using this control type. The fume

centrally and fed into the laboratories, while the exhaust hoods are not controlled and only have a fume hood mo-

air, depending on the structural conditions, is extracted via nitor (FM100), as stipulated by DIN EN 14175, which mo-

a central exhaust air fan or via individual fans. nitors whether the ventilation functions of the fume hoods

are working correctly.

Figure 6.10: Constant volume flow control

Exhaust air

Total exhaust

air = 6000m3/h

Exhaust fan

Supply air = 3240m3/h

Silencer CAV

VConst. = 600m3/h VConst. = 600m3/h VConst. = 600m3/h VConst. = 600m3/h VConst. = 600m3/h VConst. = 600m3/h CAV

FM100 FM100 FM100 FM100 FM100 FM100

Exhaust air

= 3600m3/h

Fume hood 1 Fume hood 2 Fume hood 3 Fume hood 4 Fume hood 5 Fume hood 6

Lab 1

Lab 2

Supply air = 2160m3/h

Silencer CAV

VConst. = 600m3/h VConst. = 600m3/h VConst. = 600m3/h VConst. = 600m3/h CAV

FM100 FM100 FM100 FM100

Exhaust air

= 2400m3/h

Fume hood 1 Fume hood 2 Fume hood 3 Fume hood 4

Legend:

Total supply air

= 5400m3/h

Manual damper

Supply air

FM100 Fume hood monitor

Air conditioning and fan

LabSystem Planning Manual ● Air technology for laboratories 9

Building ventilation systems and building services management

Chapter 6.0

The exhaust air volume flow of the fume hoods is measu- 7.1.1 Conclusion

red via the manual dampers and set in accordance with

the type of fume hood. In the example shown, all fume The simplicity of the system design must be weighed up

hoods are restricted to 600m³/h. The constant volume flow against the fact that air requirements may not be ideally

controller for the laboratory supply air and the laboratory accommodated.

exhaust air guarantees the defined room air exchange and

the required negative pressure in the laboratory. The total investment costs for the entire system are only

slightly less than for a fully variably controlled system, but

Table 6.1 shows a summary of the entire building supply the energy costs (for heating and cooling of the supply and

air and exhaust air with the room balances. exhaust air) are very high.

The decision in favour of fully variable systems is obvious,

Table 6.1: because such systems are amortised within 1 to 2 ye-

ars due to the savings potential of the lower energy and

VMIN in m³/h VMAX in m³/h construction costs (see Chapter 13.0, Economic efficiency

calculation).

Fume hood 1 600 600

Fume hood 2 600 600 Lower energy requirements reduce the operating costs

Fume hood 3 600 600 and preserve the environment.

Fume hood 4 600 600

Fume hood 5 600 600

Fume hood 6 600 600

Exhaust air 3600 3600

laboratory 1

Supply air 3240 3240

laboratory 2

Fume hood 1 600 600

Fume hood 2 600 600

Fume hood 3 600 600

Fume hood 4 600 600

Exhaust air 2400 2400

laboratory 2

Supply air 2160 2160

laboratory 2

Total exhaust air 6000 6000

Total supply air 5400 5400

The supply air volume flow is reduced by 10% in relation

to the exhaust air volume flow. This ensures that negative

pressure is maintained in the laboratory while at the same

time preventing contaminated air from flowing into adja-

cent rooms.

10 LabSystem Planning Manual ● Air technology for laboratories

Building ventilation systems and building services management

Chapter 6.0

8.1 Variable volume flow control

The exhaust air volume flow of the fume hoods is cont-

Figure 6.11 shows variable volume flow control of the la- rolled variably according to the demand and the position

boratory supply air. of the sash. In the example shown, all the fume hoods are

connected via the LON network and programmed with the

Optimum energy savings are achieved with this control following exhaust air volume flows: sash shut = 200 m³/h,

type. The fume hoods are controlled variably. The moni- sash open = 600 m³/h. At all other sash positions exhaust

toring unit stipulated by DIN EN 14175 to ensure proper air volume flows between > 200 m³/h and < 600 m³/h are

functioning of the ventilation functions of the fume hoods regulated.

is integrated in the FC500 and iCM controllers.

Variable exhaust air requires variable supply air, which

must be fed in at a correspondingly fast rate. The exhaust

Figure 6.11: Variable volume flow control air is regulated in < 3 sec and the supply air should be

regulated in < 5 sec in order to ensure a defined negative

pressure in the room at all times.

Exhaust air

Total exhaust air

VMAX = 6000m3/h

VMIN = 2000m3/h

Exhaust fan

Variabler Air Volume

VAV, LON

Room supply air

VMAX = 3240m3/h Silencer VAV-L-315-S

VMIN = 1080m3/h

VMAX = 600m3/h VMAX = 600m3/h VMAX = 600m3/h VMAX = 600m3/h VMAX = 600m3/h VMAX = 600m3/h

VMIN = 200m3/h VMIN = 200m3/h VMIN = 200m3/h VMIN = 200m3/h VMIN = 200m3/h VMIN = 200m3/h

M M M M M M

FC500- FC500- FC500- FC500- FC500- FC500-

p p p p p p

V-L V-L V-L V-L V-L V-L

Variabler Air Volume

VAV, LON

VAV-L-200-P

Fume hood 1 Fume hood 2 Fume hood 3 Fume hood 4 Fume hood 5 Fume hood 6

LON-network, FTT-10A

Room exhaust air

Lab 1 VMAX = 3600m3/h

VMIN = 1200m3/h

Lab 2

Variabler Air Volume

VAV, LON

Room supply air

VMAX = 2160m3/h Silencer VAV-L-315-S

VMIN = 720m3/h

VMAX = 600m3/h VMAX = 600m3/h VMAX = 600m3/h VMAX = 600m3/h

VMIN = 200m3/h VMIN = 200m3/h VMIN = 200m3/h VMIN = 200m3/h

Room exhaust air

M M M VMAX = 2400m3/h M

FC500- FC500- FC500- VMIN = 800m3/h FC500-

p p p p

V-L V-L V-L V-L

Variabler Air Volume

VAV, LON

VAV-L-200-P

Fume hood 1 Fume hood 2 Fume hood 3 Fume hood 4

LON-network, FTT-10A

Legend: Total supply air

VMAX = 5400m3/h

FC500-V-L

Variable fume hood VMIN = 1800m3/h

controller, LON-network Supply air

Air conditioning and supply fan

LabSystem Planning Manual ● Air technology for laboratories 11

Building ventilation systems and building services management

Chapter 6.0

The exhaust air actual values are available as SNVTs 8.1.1 Conclusion

(Standard Network Variable Type) on the LON network

and are summated in the VAV-L-315-S supply air control- Due to the very high savings potential with regard to the

ler and automatically regulated by this controller. energy costs, this system concept is amortised within a

very short period of time (see Chapter 13.0, economic ef-

The supply air volume flow is reduced by 10% in relation ficiency calculation).

to the exhaust air volume flow. This ensures that negative

pressure is maintained in the laboratory while at the same Compared with example 7.1 only 30% of the required ex-

time preventing contaminated air from flowing into adja- haust air volume flow is necessary when the sashes are

cent rooms. shut. This value is of course theoretical, as it cannot be

assumed that all sashes are always shut.

Table 6.2 shows a summary of the entire building supply

and exhaust air with the room balances. A diversity factor of 50 to 70% can be assumed as a practi-

cal value, whereby the entire central ventilation system for

supply air and exhaust air can also be on a smaller sca-

Table 6.2: le. This advantage considerably reduces the investment

costs for construction.

VMIN in m³/h VMAX in m³/h

Fume hood 1 200 600

Fume hood 2 200 600

Fume hood 3 200 600

Fume hood 4 200 600

Fume hood 5 200 600

Fume hood 6 200 600

Exhaust air 1200 3600

laboratory 1

Supply air 1080 3240

laboratory 1

Fume hood 1 200 600

Fume hood 2 200 600

Fume hood 3 200 600

Fume hood 4 200 600

Exhaust air 800 2400

laboratory 2

Supply air 720 2160

laboratory 2

Total exhaust air 2000 6000

Total supply air 1800 5400

The VAV-L-200-P LON exhaust air volume flow controller

serves to ensure that the minimum room air exchange rate

is maintained and automatically calculates the required dif-

ference value by subtracting the exhaust air actual values

from the required room air exchange rate and regulating

the difference automatically. The room air exchange rate is

not taken into account in table 6.2.

In the example shown, the LON network is limited to the

individual laboratory. If a connection should be made to a

building services management (BSM), the LON network

must be physically disconnected by means of a router. A

router should be installed every 25 to 30 nodes (network

subscribers) so that there is not too much data traffic on

the LON network. It is essential to connect a router every

64 nodes, because the specification of the FTT-10A trans-

ceiver requires this physical limitation.

12 LabSystem Planning Manual ● Air technology for laboratories

Building ventilation systems and building services management

Chapter 6.0

9.1 Ventilation system with speed 9.2 Ventilation system with speed controlled

controlled central supply air and central supply air and exhaust air

exhaust air with bypass

Figure 6.12 shows a ventilation system with speed cont- The ventilation system shown in Figure 6.13 is very similar

rolled supply and exhaust air. The flow rates of the supply to the design described in Figure 6.12. As in the example

and exhaust air fan are regulated so that the control va- already described, the supply air is regulated by the DPC

riable pressure (∆p) is centrally maintained at a constant duct pressure controller at a constant pressure level via

level. the frequency inverter, while the exhaust air fan is not re-

gulated and runs at a fixed speed. This guarantees that the

The SCHNEIDER DPC duct pressure controller is equip- exit speed of the discharged air, which may be well be over

ped with a PI controller and static differential pressure the required 7m/s for all operating states, remains con-

sensor (∆p) and directly actuates the frequency inverter stant. This safely prevents the contaminated discharge air

of the supply air fan with 0(2)...10V DC. The integrated from being partially drawn in again (e.g. if the inlet vents of

PI controller regulates the constant positive pressure (e.g. the outdoor air are inappropriately located or in inversion

400 Pa) via the supply air fan, the speed of which cont- weather conditions).

rolled by means of the frequency inverter.

Maintenance of constant pressure on the

suction side is achieved by the DPC duct

Figure 6.12: Ventilation system with speed controlled pressure controller actuating a damper with

central supply air and exhaust air a fast running servo motor, which works like

Heat a bypass.

exchanger DPC Filter

FI

p

If only a low exhaust air volume flow is re-

Exhaust air

quired by the connected fume hoods, be-

Exhaust fan cause the sashes are mostly closed, the

bypass is opened accordingly. The exhaust

air fan conveys a constant exhaust air volu-

FI

DPC me and maintains the differential value via

p

the bypass damper as outdoor air.

Supply air

If the maximum exhaust air is required by

Filter Heat

Air heating Air cooling Supply fan Silencer

the fume hoods, the bypass is shut comple-

exchanger

tely and thus ceases to have an effect. The

exhaust air fan now only conveys the con-

taminated exhaust air of the fume hoods.

Heat recovery must be installed in a different place and is

not taken into account in this example.

The exhaust air controller works in the same way as the This version of the exhaust air controller is preferred in

supply air controller. The only difference is in the mainte- Anglo-Saxon countries.

nance of constant pressure on the pressure side (supp-

ly air) and the suction side (exhaust air). The DPC duct

pressure controller regulates the constant negative pres- Figure 6.13: Ventilation system with speed controlled

sure (e.g. 450 pascal) via the exhaust air fan, the speed of central supply and exhaust air with bypass

which is controlled by means of the frequency inverter.

Damper with high

Outside air

The pressure control takes into account the pressure drop speed actuator

(Bypass)

in the system components and in the pipes of the branch

ducts.

DPC Filter

Exhaust fan

p

This control type is fully automatic and regulates

Exhaust air

changing load conditions (variable exhaust air vo-

lume flows) automatically. A building services ma-

nagement (BSM) is not required for central control

of the supply and exhaust air.

FU DPC

The fans are energy-optimised. However, particu- p

larly in the case of low exhaust air volume flows, it Supply air

must be ensured that the exit speed of the dischar-

ged air is not less than 7m/s (see DIN 1946, Part Filter Air heating Air cooling Supply fan Silencer

7). Only in this case is a sufficient emission height

of the discharged air guaranteed, which effectively

prevents partial intake of discharged air.

LabSystem Planning Manual ● Air technology for laboratories 13

Building ventilation systems and building services management

Chapter 6.0

9.2.2 Conclusion

Both system concepts are suitable for controlling the total

exhaust air. In smaller installations and ventilation sys-

tems, however, it must be ensured that with the control

type that uses a frequency inverter the entire unit builds

up the required duct negative pressure quickly enough, in

order to guarantee rapid exhaust air demand by the fume

hood (approx. 2-3 seconds). With the control type that

uses a bypass, a damper with a fast running servo motor

must be used.

Only then is a rapid exhaust air demand by the fume hood

guaranteed by an equally rapid increase of the duct nega-

tive pressure.

14 LabSystem Planning Manual ● Air technology for laboratories

Building ventilation systems and building services management

Chapter 6.0

10.1 Variable volume flow control of

4 laboratories in the LON network

Figure 6.14 shows variable volume flow control of 4 labo- Sections 9.1 and 9.2 describe in detail the functionality of

ratories with a central exhaust air fan and a central supply central, speed-controlled supply and exhaust air. These

air fan. Both fans are actuated by the SCHNEIDER DPC control circuits are fully automatic and regulate the re-

duct pressure controller and the frequency inverter in such quired total supply air and total exhaust air volume flows

a way that constant negative pressure (exhaust air) and automatically. Changing load conditions (variable exhaust

constant positive pressure (supply air) is regulated. air volume flows) are automatically recognised and regu-

lated. A building services management (BSM) is not re-

quired for central supply and exhaust air control.

Bild 6.14: Variable volume flow control of 4 Each laboratory also functions automatically and the VAV-

laboratories in the LON network L-250-S and VAV-L-315-S supply air volume flow control-

lers with LON interface summate the required laboratory

supply air from the individual laboratory exhaust air values,

Heat

Exchanger DPC Filter

FI

p

- +

Exhaust air

Exhaust fan

DPC Building management system

FI

p

+ -

Supply air

Filter Heat

Air heating Air cooling Supply fan Silencer

Exchanger

LON-network LON-network

LON-VAV LON-VAV

VAV-L-250-S VAV-L-315-S

M M M M M

FC500- FC500- FC500- FC500- FC500-

p p p p p

V-L V-L V-L V-L V-L

Lab 1 Lab 2

Router Router

Fume hood 1 Fume hood 2 Fume hood 1 Fume hood 2 Fume hood 3

LON-network

Router Router

LON-network LON-network

LON-VAV LON-VAV

VAV-L-250-S VAV-L-315-S

M M M M M

FC500- FC500- FC500- FC500- FC500-

p p p p p

V-L V-L V-L V-L V-L

Lab 3 Lab 4

Fume hood 1 Fume hood 2 Fume hood 1 Fume hood 2 Fume hood 3

LabSystem Planning Manual ● Air technology for laboratories 15

Building ventilation systems and building services management

Chapter 6.0

which are available as SNVTs (Standard Network Variable

Type) on the LON network. A VAV-L LON controller can

summate the exhaust air actual values of a maximum of

16 connected consumer loads (e.g. fume hoods). If more

than 16 fume hoods are present in a laboratory, the room

supply air is distributed over several VAV-L supply air vo-

lume flow controllers.

The supply air volume flow is programmable and is redu-

ced by e.g. 10% in relation to the exhaust air volume flow.

This ensures that negative pressure is maintained in the

laboratory while at the same time preventing contamina-

ted air from flowing into adjacent rooms.

To simplify matters, additional room exhaust air via a LON Figure 6.15: Control room

controller has not been included in this example. The ver-

sion described in detail in section 8.1 can also easily be Remote maintenance and diagnostics are also possible

integrated here. over the intranet and Internet and thus guarantee a high

level of durability and operating safety.

10.2 Connection to the building services

management

Connection to the building services management (BSM)

is done via routers. A router should be installed every 20

to 30 nodes (network subscribers) so that there is not too

much data traffic on the LON network and all required data

are transferred to the corresponding controllers at a satis-

factory speed. It is essential to connect a router every 64

nodes, because the specification of the FTT-10A transcei-

ver requires this physical limitation.

In the following example each laboratory is separated by

its own router. This version is somewhat more complex,

but clearly structured. If long cables are used, a router

must be included every 300 m in order to prevent cable

reflexions and therefore faulty data transfer.

Every fume hood and its specific data, such as exhaust

air actual values, operating status, malfunction notifica- Figure 6.16: Ventilation control in the whole building

tion, parameters, etc. can be visualised via the building

services management.

10.2.1 Conclusion

With the PAD-3000 software developed by SCHNEIDER,

the ideal prerequisites for visualisation of fume hoods are Due to the very high savings potential with regard to the

fulfilled. This program can also be included in existing busi- energy costs, this system concept is amortised within a

ness services management systems (e.g. ABB, Siemens, very short period of time (see Chapter 13.0, economic ef-

Honeywell, Sauter, Johnson Control, Kieback & Peter, etc.) ficiency calculation). Consistent LON networking makes

as a task. Similarly, every fume hood, entire laboratories or it possible to make efficient use of the building services

the whole laboratory building can be switched to reduced management and thus ensures a high energy savings

operation (night-time reduction or work-free time) via the potential while at the same time improving durability and

LON network. The consumer loads that have been swit- operating safety.

ched to reduced operation reduce the exhaust air volume

flow to a programmable, minimum value, which achieves The building services management can also record user

a considerable energy savings potential. behaviour at the fume hood. For example, the sash posi-

tion (closed or open) can be recorded. Measurement and

If the corresponding connections have been made, the accounting of air consumption data are easily possible for

fume hood lighting can also be switched off. each fume hood.

In addition to building and facility management, remote Depending on user behaviour, the entire system can be

maintenance and diagnostics are also possible. Thus, for amortised very quickly (approx. 1 to 2 years) due to the

example, the dampers of the exhaust air and supply air energy cost savings and if the diversity factor approach is

volume flow controllers can be opened or shut in order to used, the construction investment costs can be drastically

test the entire system and the sensors. reduced.

16 LabSystem Planning Manual ● Air technology for laboratories

Building ventilation systems and building services management

Chapter 6.0

11.1 Additional savings potential with the the exhaust air fan is regulated downwards until the "wea-

DPO duct pressure optimiser in the LON kest" damper is still at 80° (90° = damper fully open, 0° =

network damper fully shut) and thus is still in the control range.

Figure 6.17 shows variable volume flow control of 4 labo-

ratories in the LON network, which for the most part corre- 11.1.1 Conclusion

sponds to Figure 6.14.

Using two DPO duct pressure optimisers the entire buil-

Here the SCHNEIDER DPO duct pressure optimiser is ding ventilation system is optimised with the latest techno-

used instead of the DPC duct pressure controller, which logy and in such a way that as little energy as possible is

makes sense for LON-networked projects and which wasted and controllers are still within the control range.

achieves a further considerable savings potential with re-

gard to electrical energy. The supply air and exhaust air fans are always operated at

the ideal (minimum) operating point, which achieves con-

Via the LON network the damper positions of all controllers siderable savings with regard to electrical energy.

(fume hood, room exhaust air, etc.) are automatically che-

cked at regular intervals and the frequency inverter (FI) for

Figure 6.17: Variable volume flow control of 4

laboratories in the LON network

Building management system

LON-network

DPO-L

Heat

exchanger Filter

FI

Exhaust air

Exhaust fan

LON-network

DPO-L

FU

Supply air

Filter Heat

Air heating Air cooling Supply fan Silencer

exchanger

LON-network LON-network

LON-VAV LON-VAV

VAV-L-250-S VAV-L-315-S

M M M M M

FC500- FC500- FC500- FC500- FC500-

p p p p p

V-L V-L V-L V-L V-L

Lab 1 Lab 2

Router Router

Fume hood 1 Fume hood 2 Fume hood 1 Fume hood 2 Fume hood 3

LON-network

Router Router

LON-network LON-network

LON-VAV LON-VAV

VAV-L-250-S VAV-L-315-S

M M M M M

FC500- FC500- FC500- FC500- FC500-

p p p p p

V-L V-L V-L V-L V-L

Lab 3 Lab 4

Fume hood 1 Fume hood 2 Fume hood 1 Fume hood 2 Fume hood 3

LabSystem Planning Manual ● Air technology for laboratories 17

Building ventilation systems and building services management

Chapter 6.0

12.1 Product overview Duct pressure

controllers, Duct pressure optimisers

The diagram shows an overview of the products that are Technical data sheets, further information and tender

available from SCHNEIDER in the product group Duct specifications for the duct pressure controllers and duct

pressure controllers and Duct pressure optimisers. pressure optimisers CDP, DPC and DPO are available for

download on the Internet at www.schneider-elektronik.de.

See Chapter 1, Section 6.1 for the full LabSystem product

overview. www.schneider-elektronik.de.

Product group Product Short description Chapter

Duct pressure CDP Constant duct pressure controller with motor driven damper 6.0

controllers

DPC Duct pressure controller with actuation for frequency inverters of the 6.0

exhaust or supply air fan.

Duct pressure DPO Energy-optimised damper operating point through intelligent damper 6.0

optimiser management with actuation for frequency inverters of the exhaust or

supply air fan.

18 LabSystem Planning Manual ● Air technology for laboratories

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Labsystem Room Air Control in LaboratoriesDocument22 pagesLabsystem Room Air Control in LaboratoriesJulio AlceramNo ratings yet

- LabPlanningManual 04 enDocument8 pagesLabPlanningManual 04 enJulio AlceramNo ratings yet

- LabPlanningManual 02 enDocument12 pagesLabPlanningManual 02 enJulio AlceramNo ratings yet

- LabPlanningManual 03 enDocument16 pagesLabPlanningManual 03 enJulio AlceramNo ratings yet

- Constant Pressure Control Unit: Type CPCDocument8 pagesConstant Pressure Control Unit: Type CPCJulio AlceramNo ratings yet

- Chapter Overview: Labsystem Planning Manual Air Technology For LaboratoriesDocument2 pagesChapter Overview: Labsystem Planning Manual Air Technology For LaboratoriesJulio AlceramNo ratings yet

- DUC630 Jet Nozzle-2Document4 pagesDUC630 Jet Nozzle-2Julio AlceramNo ratings yet

- GB0813 Iris DampersDocument6 pagesGB0813 Iris DampersJulio AlceramNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Spun Pile Detail PDFDocument1 pageSpun Pile Detail PDFLavanyanNo ratings yet

- Chapter 3 RefrigerationDocument16 pagesChapter 3 RefrigerationPeter Ralph GaliciaNo ratings yet

- Ee8015-Unit-2-Refrigeration and Air ConditioningDocument30 pagesEe8015-Unit-2-Refrigeration and Air ConditioningS Jey RhajenNo ratings yet

- Article On Desuperheater 220709 PDFDocument5 pagesArticle On Desuperheater 220709 PDFlkumar4454No ratings yet

- Chvac 7 PDFDocument67 pagesChvac 7 PDFMohamedHany100% (2)

- BrochureDocument2 pagesBrochurebjohnNo ratings yet

- DaikinDocument117 pagesDaikinAbdo RezagNo ratings yet

- Performance Check Form Cooling Tower PDFDocument1 pagePerformance Check Form Cooling Tower PDFzar niNo ratings yet

- Variable Refrigerant Flow (VRF) Systems: Ir. Dr. Sam C. M. HuiDocument54 pagesVariable Refrigerant Flow (VRF) Systems: Ir. Dr. Sam C. M. HuiS Amit Rao100% (1)

- Energy Conservation Schemes: Sowrya MukkavilliDocument8 pagesEnergy Conservation Schemes: Sowrya MukkavilliSowrya SharmaNo ratings yet

- EPA Guidance On Moisture Control (Dragged)Document1 pageEPA Guidance On Moisture Control (Dragged)Mitesh KumarNo ratings yet

- ExHeat - HRF Flanged Industrial Immersion HeatersDocument2 pagesExHeat - HRF Flanged Industrial Immersion HeatersVictor PomboNo ratings yet

- BG Health Facilities Maintenance HLDocument5 pagesBG Health Facilities Maintenance HLChrisDcaNo ratings yet

- Refrigeration: U U W Q Du W QDocument20 pagesRefrigeration: U U W Q Du W QVandyck Mensah EmmanuelNo ratings yet

- Macquay AlsDocument92 pagesMacquay AlsCARLOSNo ratings yet

- Ata 21 I-Aea1Document97 pagesAta 21 I-Aea1Antonio CorteNo ratings yet

- Spare Parts ListDocument4 pagesSpare Parts ListAnoop Jacob KunnappuzhaNo ratings yet

- Balance CG SLB057 GB - 0820Document7 pagesBalance CG SLB057 GB - 0820Said ZubizaNo ratings yet

- SASO2663Document19 pagesSASO2663damaso taracenaNo ratings yet

- Product SpecificationDocument15 pagesProduct Specificationsonic8659No ratings yet

- ONLINE Training For NTPC-PMI: Preparatory Program For Energy Manager & Energy AuditorsDocument2 pagesONLINE Training For NTPC-PMI: Preparatory Program For Energy Manager & Energy AuditorsAMITAVA RAYNo ratings yet

- Hvac Layout DiagramDocument14 pagesHvac Layout DiagramPamellaNo ratings yet

- Jenis BlowerDocument3 pagesJenis BlowerMuhammad Ridwan TanjungNo ratings yet

- Black Book VCCDocument50 pagesBlack Book VCCRahul Pawar100% (2)

- Air-Conditioning & RefrigirationDocument36 pagesAir-Conditioning & RefrigirationMohamed Rizwan100% (1)

- Mec351 - Chapter 1Document97 pagesMec351 - Chapter 1MYlearn HazimiNo ratings yet

- Catalogo IbtDocument28 pagesCatalogo IbtGuizza GuizzaaNo ratings yet

- JZBFJZBS Series Semi Hermetic Compressor Condensing Units (Bitzer Compressor)Document9 pagesJZBFJZBS Series Semi Hermetic Compressor Condensing Units (Bitzer Compressor)Coolequipment CeeNo ratings yet

- Application of Penetration RequirementsDocument1 pageApplication of Penetration RequirementsjonongocoNo ratings yet