Professional Documents

Culture Documents

Concrete Construction Article PDF - D.C.-area Testing Labs Compare Compressive Strength Test-Result Differences

Uploaded by

Ramlan0 ratings0% found this document useful (0 votes)

13 views2 pagesconcrete

Original Title

Concrete Construction Article PDF_ D.C.-area Testing Labs Compare Compressive Strength Test-Result Differences

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentconcrete

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views2 pagesConcrete Construction Article PDF - D.C.-area Testing Labs Compare Compressive Strength Test-Result Differences

Uploaded by

Ramlanconcrete

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

D.C.

-area testing labs compare compressive

strength test-result differences

Annual program allows lab self-evaluation

any producers get the

M impression that,

while not nearly as

risky

as buying a lottery

ticket, testing labs often hold their

company’s future in a plastic mold.

Five years ago, when Teck Chua

tried to resolve test result differences,

he didn’t get the respect his Virginia

Concrete lab deserved. As a registered

professional engineer in charge of

QC/QA for Florida Rock Industries,

Concrete Engineering Inc.

which owns Washington, D.C.-area

ready-mix producer Virginia Con-

crete, Chua needed a way to validate

the quality of his own facility’s lab re-

sults to the engineering community.

Since Beltway-area municipal building

departments have adopted BOCA Another truckload of concrete departs from Virginia Concrete’s plant for a jobsite in the Washington,

#1705, producers and building owners D.C., area. With the documentation from its involvement in a round-robin lab testing program, the

have had to rely on the quality of producer demonstrates that its test breaks are as accurate as area engineering laboratories’.

third-party engineering labs to inspect

and test all aspects of the construction Cohn, executive director of the Wash- wanted to gather data on the subject,”

process. ington Area Council of Engineering says Cohn.

The absence of a municipal testing Laboratories. After a series of discus-

program created a void in the custom- sions, producer and testing lab repre- How the program works

ary cycle of checks and balances. sentatives agreed to cosponsor a The program evaluates variability in

“When I presented our lab-test results round-robin compressive strength test results attributable to differences

to engineers, I was constantly asked testing program according to the pro- in laboratory curing, capping and

how our results compared to local en- cedures established by ASTM C 802, cylinder testing methods. On the start-

gineering labs,” says Chua. “Standard Practice for Conducting an ing date for testing, drivers from Vir-

Frustrated by a lack of an interlabo- Interlaboratory Test Programs to De- ginia Concrete deliver two 4-cubic-

ratory precision standard in ASTM, termine the Precision of Test Methods yard loads of central-mixed concrete

Chua proposed that the Ready Mixed for Construction Materials.” Thirty to representing two strength levels to

Concrete Producers Technical Com- 40 testing facilities now participate an- Chua’s lab at the Edsall Road plant in

mittee initiate a program to generate nually. Springfield, Va. After discarding the

the precision standard. Members of Participants recognized the signifi- first two wheelbarrows from each

RMC-PTC, an ad hoc committee of cance of the round robin-testing re- truckload, volunteers use the rest of

local producers’ technical personnel, sults and realized that there was a need the batch to cast enough test cylinders

felt that participation of local com- for a qualified referee. “At the time, we for each participating lab.

mercial laboratories would be vital to were fortunate that Colin Lobo, the To satisfy the test’s requirements,

the program’s success. National Ready Mixed Concrete Asso- employees make as many as 180 cylin-

The committee contacted Tom ciation’s vice president of engineering, ders. To avoid rodding, technicians

keep slump below 3 inches so one vol-

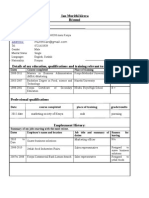

unteer can consolidate the cylinders D.C.-area labs’ round-robin

with a pencil vibrator.

Florida Rock technicians then cover

strength test results, 1991-98

the test cylinders with plastic and store Number Number Within-test Multilab

them for the first 24 hours at 70° F. Average of of S.D., C.V., S.D., C.V.,

Technicians from participating labs Year Batch strength cylinders labs psi %* psi %*

pick up assigned test cylinders, trans- 1991 1 4982 3 20 90.3 1.8 184.7 3.7

port them to their facilities and finally 2 7080 3 20 171.6 2.4 243.1 3.4

test them at a 28-day age on the as- 1993 1 3807 2 30 90.2 2.4 202.9 5.3

signed date. Lab technicians follow 2 7335 2 28 172.4 2.4 330.9 4.5

their normal company procedures in

1994 1 4584 2 25 94.8 2.1 261.7 5.7

curing, capping and breaking the test 2 7824 2 23 173.9 2.2 271.8 3.5

cylinders. Results are reported to the

1995 1 3344 2 28 86.2 2.6 177.7 5.3

NRMCA coordinator.

2 7170 2 27 124.7 1.7 272.2 3.8

Results 1996 1 4863 2 36 134.0 2.8 199.9 4.1

2 8323 2 34 170.4 2.0 433.6 5.2

“Program results provide lab man-

agers a baseline for quality,” says 1997 1 3899 2 38 89.8 2.3 194.3 5.0

Cohn. By comparing their individual 2 8082 2 36 247.6 3.1 387.2 4.8

3 11,740 2 14 304.4 2.6 608.8 5.2

results against the group’s precision,

managers can adjust their lab proce- 1998 1 4175 2 28 85.6 2.1 188.0 4.5

dures. 2 7255 2 29 177.0 2.4 349.0 4.8

Lobo says the round-robin test re- * precision factor

sults are useful when engineers have

A comparison of compressive strength in a round-robin testing program cosponsored by the

questions about the quality of testing.

Washington Area Council of Engineering Laboratories and the Ready Mixed Concrete Producers

First, questioners should review the

Technical Committee shows that test variability has been consistent.

range in strength of the two cylinders

from the same sample. Based on the the 1998 testing program, the multilab Test-precision estimates are also

C-39 precision statement, differences standard deviations were reasonably particularly important when compres-

should rarely exceed 500 psi for con- similar at 4.5% of the overall average sive-test results are used for acceptance

crete up to 5000 psi. for the low-strength batch and 4.8% of and payment decisions, since precision

The summary of the 1998 test results the overall average for the medium- is a major factor affecting the required

for the low- and medium-strength strength batch. overdesign needed to avoid penalties.

tests results are shown in the table on In ASTM terminology, the multilab Chua says the program has helped.

page 13. In accordance with ASTM C “d2s” are precision estimates deter- He now finds it easier to explain

802, the data coordinator next exam- mined from the multilab standard de- strength-test differences. “With the

ines the difference between each lab’s viation and are defined as the accept- round-robin results, I can explain to

two breaks. ASTM C 39, “Standard able difference between test results engineers that a 200-psi break differ-

Test Method for Compressive Strength obtained from two labs. This accept- ence is acceptable because it falls with-

of Cylindrical Concrete Specimens able difference between two individual in one standard deviation of precision

Guidelines” states that the single oper- test results would be exceeded only error,” says Chua.

ator precision of tests of individual one time in 20 (5%) under normal and But as successful as the program has

cylinders from the same sample of correct operation of the test method. been, Chua thinks there’s still work to

concrete is 2.37% (acceptable range of Based on the program’s multilab pre- be done. He points out that there’s al-

2 cylinders = 6.6%) for cylinders made cision factor, the test results from two ways one lab result that falls outside

in a laboratory environment. The labs testing concrete cylinders pre- two standard deviations. “If the culprit

within-test precision factor from the pared from the same concrete sample is a commercial lab, I hope it doesn’t

1998 data was 2.1% for the low- should not differ by more than about test my concrete,” says Chua. ■

strength batch and 2.4% for the medi- 12% to 13% of the average. — RICK YELTON

um-strength batch, comparable to the What is excluded in this variation

values in the C 39 precision statement. are initial 24-hour curing procedures;

The next comparison level comes therefore, unacceptable differences in

from the calculation of the multilab test results may sometimes be caused Publication #J99B011

Copyright© 1999, The Aberdeen Group,

standard deviation, an estimate of the by deviations from standard proce-

a division of Hanley-Wood, Inc.

variability of a large group of individ- dures in sample preparation and initial

All rights reserved

ual test results (average of two cylin- curing, which can invalidate test re-

ders) from different laboratories. In sults.

You might also like

- GMW14906Feb2012 PDFDocument59 pagesGMW14906Feb2012 PDFGustavo Pereira100% (2)

- Worldwide Engineering Standards: Stone Impact Resistance of CoatingsDocument6 pagesWorldwide Engineering Standards: Stone Impact Resistance of CoatingsAlondra CVNo ratings yet

- Aashto M288-06Document20 pagesAashto M288-06JuzonguyenNo ratings yet

- AASHTO T 134, 135, 136 DescripciónDocument7 pagesAASHTO T 134, 135, 136 DescripciónWalter Zegarra Herrera100% (1)

- Digital Circuit Testing: A Guide to DFT and Other TechniquesFrom EverandDigital Circuit Testing: A Guide to DFT and Other TechniquesNo ratings yet

- Guideline MD Listing and Authorization MDS-G5 PDFDocument153 pagesGuideline MD Listing and Authorization MDS-G5 PDFSyed SalmanNo ratings yet

- Oisd STD 175Document59 pagesOisd STD 175yandiNo ratings yet

- Syllabus Civil Qaqc Course Sdlinc 9600162099Document12 pagesSyllabus Civil Qaqc Course Sdlinc 9600162099Sridurgha Lakshmi Inc SDLINC NDT QA QC INSTITUTE100% (1)

- SR 2406 Supplemental Requirements - NACLA Recognized 17025 Construction Materials Testing-13027-7Document8 pagesSR 2406 Supplemental Requirements - NACLA Recognized 17025 Construction Materials Testing-13027-7Sreenath KooliyattuNo ratings yet

- KDP Well Test Procedures ManualDocument77 pagesKDP Well Test Procedures ManualJacob Keemink100% (2)

- Durability Index ManualDocument44 pagesDurability Index ManualSwathy ManoharNo ratings yet

- Mirafi PET Embankment Spec (JKR) - 190124Document9 pagesMirafi PET Embankment Spec (JKR) - 190124Norman SimNo ratings yet

- Laboratory Manual PDFDocument81 pagesLaboratory Manual PDFaman badashaalam100% (1)

- Fiber Decorticator - Methods of TestDocument18 pagesFiber Decorticator - Methods of TestRegan Roldan RolaNo ratings yet

- Testing Aggregate Adhesion to Predict Moisture DamageDocument4 pagesTesting Aggregate Adhesion to Predict Moisture DamageVenu GopalNo ratings yet

- Laboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationDocument6 pagesLaboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationAbid HussainNo ratings yet

- Durability Index Testing Procedure ManualDocument43 pagesDurability Index Testing Procedure ManualkarlNo ratings yet

- Ratings Packers PDFDocument10 pagesRatings Packers PDFsabilco13No ratings yet

- EVALUATION_OF_LUBRICANTS_FOR_COLD_FORMING_OF_STEELDocument113 pagesEVALUATION_OF_LUBRICANTS_FOR_COLD_FORMING_OF_STEELTrần Xuân HảiNo ratings yet

- GeotechDocument242 pagesGeotechAkhilesh Kumar SinghNo ratings yet

- FCC Catalyst EvaluationDocument40 pagesFCC Catalyst EvaluationvikasbadhanNo ratings yet

- Performance Monitoring Procedure - FinalDocument9 pagesPerformance Monitoring Procedure - FinalMuhammad Junaid KhanNo ratings yet

- British Standards Institution: Licensed by Information Handling Services Licensed by Information Handling ServicesDocument11 pagesBritish Standards Institution: Licensed by Information Handling Services Licensed by Information Handling ServiceskushanNo ratings yet

- Lab Manual For UTMDocument200 pagesLab Manual For UTMDesmond TongNo ratings yet

- Engineering Economy 14th EdDocument24 pagesEngineering Economy 14th EdMatthew ShieldsNo ratings yet

- Mte Research Report: The Development of Mixture Creep Performance Tests Using A Dynamic Shear RheometerDocument47 pagesMte Research Report: The Development of Mixture Creep Performance Tests Using A Dynamic Shear RheometergjaggaraoNo ratings yet

- Geo CreteDocument80 pagesGeo CreteRichard OonNo ratings yet

- Australian StandardDocument3 pagesAustralian StandardAnonymous jbvNLNANLINo ratings yet

- Concrete Rod Hanger Testing ResultsDocument9 pagesConcrete Rod Hanger Testing ResultsJuan Gutier CcNo ratings yet

- PDA Method StatementDocument22 pagesPDA Method StatementChezy629100% (2)

- BS 476 Part 6 - Test Report - KCL-unlockedDocument6 pagesBS 476 Part 6 - Test Report - KCL-unlockedArmağan DemirelNo ratings yet

- Materials Testing LabDocument3 pagesMaterials Testing LabBenNo ratings yet

- Evaluate CCPP EfficiencyDocument67 pagesEvaluate CCPP Efficiencytaha zafarNo ratings yet

- Materials Technical Report Analysis and SCC RedesignDocument25 pagesMaterials Technical Report Analysis and SCC RedesignJay MusaNo ratings yet

- GRP Pipe Joint ThesisDocument268 pagesGRP Pipe Joint ThesisA.Subin DasNo ratings yet

- CI4508 Concrete QADocument2 pagesCI4508 Concrete QAEng.Ahmad AbuFaraNo ratings yet

- CE205 Concrete Technology Lab Report: Compressive Strength of Cement MortarDocument12 pagesCE205 Concrete Technology Lab Report: Compressive Strength of Cement MortarRahand KawaNo ratings yet

- L 32Document7 pagesL 32Gustavo Suarez CoronadoNo ratings yet

- Laboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationDocument6 pagesLaboratories Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Laboratory EvaluationJesús Luis Arce GuillermoNo ratings yet

- Pruebas de Producción - Perforación No ConvencionalDocument15 pagesPruebas de Producción - Perforación No ConvencionalAna Cristina Soto GuerreroNo ratings yet

- Kilo Var Brief Issue 2Document4 pagesKilo Var Brief Issue 2kgskgmNo ratings yet

- Bagfilter Vs ESPDocument133 pagesBagfilter Vs ESPSushil KumarNo ratings yet

- Determining The Chemical Resistance of Concrete Products To Acid AttackDocument4 pagesDetermining The Chemical Resistance of Concrete Products To Acid AttackYoshi TaissonNo ratings yet

- Mechanical PropertiesDocument29 pagesMechanical PropertiesHéctor CartagenaNo ratings yet

- Bulletin 121 Testing Water Separation Properties of Jet Fuel Revised MSEP Protocol PDFDocument4 pagesBulletin 121 Testing Water Separation Properties of Jet Fuel Revised MSEP Protocol PDFPrakash JoshiNo ratings yet

- Stabilization Geotextile SpecificationDocument7 pagesStabilization Geotextile SpecificationDavid HongNo ratings yet

- C823C823MDocument7 pagesC823C823MLupita RamirezNo ratings yet

- WC059 AMG Metal Non Drainable Louver Test - MSRKDocument9 pagesWC059 AMG Metal Non Drainable Louver Test - MSRKAMG Co.No ratings yet

- Specification Package PlantDocument30 pagesSpecification Package PlantPrakash Kumar KumarNo ratings yet

- Polymer SpecifcatiionDocument7 pagesPolymer SpecifcatiionSunny RohillaNo ratings yet

- Mil STD 331 AmendDocument286 pagesMil STD 331 AmendGiridhar Rao SanaNo ratings yet

- Radio 4449 B13 B5Document45 pagesRadio 4449 B13 B5Ahmed Timraz100% (1)

- Srihari Katari 11 Jan 2022Document50 pagesSrihari Katari 11 Jan 2022Abhishek DevarajNo ratings yet

- Desenvolvimento de Um Processo de Tratamento Térmico Robusto para Rockwell B-Escala Blocos Teste de DurezaDocument108 pagesDesenvolvimento de Um Processo de Tratamento Térmico Robusto para Rockwell B-Escala Blocos Teste de DurezaJohnnyAntunesNo ratings yet

- Procedural Standards For Certified Testing of CleanroomsDocument140 pagesProcedural Standards For Certified Testing of CleanroomsDuc100% (1)

- Norma Astm d4110Document3 pagesNorma Astm d4110Manuel ContrerasNo ratings yet

- Harold M. Macusi: Career ObjectivesDocument3 pagesHarold M. Macusi: Career ObjectivesNick ValenzuelaNo ratings yet

- Bonding SOPDocument27 pagesBonding SOPLinh nguyễnNo ratings yet

- 4S-10 01Document27 pages4S-10 01Claudio Hernández PobleteNo ratings yet

- Scale Cavitation TestDocument9 pagesScale Cavitation TestCandy KendeeNo ratings yet

- QAP EWS & LIG Houses - AMC - R-0Document6 pagesQAP EWS & LIG Houses - AMC - R-0Vijay SinghNo ratings yet

- Design and Development of Injection Moulding MachiDocument6 pagesDesign and Development of Injection Moulding MachiRosanaNo ratings yet

- AGWA Guide GlazingDocument96 pagesAGWA Guide GlazingMoren AlfonsoNo ratings yet

- Assignment 7Document1 pageAssignment 7sujit kcNo ratings yet

- BG BG 202102080912862 User Manual - File (Long) BG BG-8Document1 pageBG BG 202102080912862 User Manual - File (Long) BG BG-8hofolo39No ratings yet

- Railway Reservation System - ConciseDocument38 pagesRailway Reservation System - ConciseTECH CodeNo ratings yet

- Spray Up MoldingDocument2 pagesSpray Up MoldingneelagaantanNo ratings yet

- CBSE KV Class VIII SA I Maths Sample Question Paper 2015Document3 pagesCBSE KV Class VIII SA I Maths Sample Question Paper 2015Amrita SenNo ratings yet

- CMO Olympiad Book For Class 3Document13 pagesCMO Olympiad Book For Class 3Srividya BaiNo ratings yet

- Occupational Health and Safety ProceduresDocument20 pagesOccupational Health and Safety ProceduresPRINCESS VILLANo ratings yet

- DIK 18A Intan Suhariani 218112100 CJR Research MethodologyDocument9 pagesDIK 18A Intan Suhariani 218112100 CJR Research MethodologyFadli RafiNo ratings yet

- Shimano 105 Gear Change ManualDocument1 pageShimano 105 Gear Change Manual1heUndertakerNo ratings yet

- Articulo SDocument11 pagesArticulo SGABRIELANo ratings yet

- Facts About SaturnDocument7 pagesFacts About SaturnGwyn CervantesNo ratings yet

- Einstein and Oppenheimer's Real Relationship Was Cordial and Complicated Vanity FairDocument1 pageEinstein and Oppenheimer's Real Relationship Was Cordial and Complicated Vanity FairrkwpytdntjNo ratings yet

- KireraDocument3 pagesKireramurithiian6588No ratings yet

- The School and The Community: Prepared By: Sen Xiao Jun Mohana Sundra Segaran Kaviyanayagi PonuduraiDocument26 pagesThe School and The Community: Prepared By: Sen Xiao Jun Mohana Sundra Segaran Kaviyanayagi PonuduraiKaviya SKTDSNo ratings yet

- Advantages of Chain Grate Stokers: Dept of Mechanical Engg, NitrDocument3 pagesAdvantages of Chain Grate Stokers: Dept of Mechanical Engg, NitrRameshNo ratings yet

- Net CallDocument2 pagesNet CallFerdinand Monte Jr.100% (2)

- Benevolent Assimilation Proclamation AnalysisDocument4 pagesBenevolent Assimilation Proclamation AnalysishgjfjeuyhdhNo ratings yet

- Os Ass-1 PDFDocument18 pagesOs Ass-1 PDFDinesh R100% (1)

- A Socio-Cultural Dimension of Local Batik Industry Development in IndoneisaDocument28 pagesA Socio-Cultural Dimension of Local Batik Industry Development in Indoneisaprihadi nugrohoNo ratings yet

- Pore and Formation PressureDocument4 pagesPore and Formation PressureramadhanipdNo ratings yet

- AR Ageing FinalDocument13 pagesAR Ageing FinalHAbbunoNo ratings yet

- Physics 8 - EnergyDocument54 pagesPhysics 8 - EnergyHakim AbbasNo ratings yet

- Methodology of Legal Research: Challenges and OpportunitiesDocument8 pagesMethodology of Legal Research: Challenges and OpportunitiesBhan WatiNo ratings yet

- API Training & ASNT NDT Level III Examination Preparatories From INDTT, Mumbia INDIADocument7 pagesAPI Training & ASNT NDT Level III Examination Preparatories From INDTT, Mumbia INDIAtraining6156No ratings yet

- 18.443 MIT Stats CourseDocument139 pages18.443 MIT Stats CourseAditya JainNo ratings yet

- PTE - Template - Essay All TypesDocument8 pagesPTE - Template - Essay All TypeskajalNo ratings yet

- Product Item Code Model Item Description MRP Count Down PricesDocument1 pageProduct Item Code Model Item Description MRP Count Down Pricesලහිරු විතානාච්චිNo ratings yet