Professional Documents

Culture Documents

Bentoax Earth Powder PDF

Uploaded by

Nimish TaterhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bentoax Earth Powder PDF

Uploaded by

Nimish TaterhCopyright:

Available Formats

BENTOAX- BENTONITE EARTHING POWDER

Sodium based bentonite is used as Earth (Ground) Enhancement Material contains rich

montmorillonite. It is treated with special chemicals making it ideal for electron earthing. Bentonite being

hygroscopic & moisture absorbing clay with various advantages is being widely used for Ground

Enchaining Compound. Our product has a good water holding capacity which ensure good ion by

means of ion exchange with electron

Bentonite protects earth conductor from direct contamination and corrosion. It’s a type of clay which

has high tendency to absorb, retain water and swells. This property makes it desirable for applications

in grounding system improvement as they could result in lowering as well as minimizing the fluctuation

of ground resistance over a long period of time.

Several commercially forms of earthing enhancement material are available such as , powder and

granules.

SPECIFICATIONS FOR EARTHING GRADE POWDER

Physical Properties

Parameters Specifications

1. Moisture 12 – 14%

2. pH value 7.5 – 9

3. Base Exchange capacity 90 meq min

4. Particle size < 200 mesh 70% min.

5. Water Absorption Capacity 300 min

6. Expandability / Swellability 15 – 20%

Chemical Properties

Parameters Specifications

LOI 8 – 10%

SiO2 48 – 54%

Fe2O3 10 – 15%

Al2O3 14 – 17%

CaO 1.5 – 2.5%

MgO 2 – 3%

Na2O 1.2 – 2%

Applications:

Preparation of Slurry is the most important aspect for getting the best result out of BENTOAX. The

slurry is prepared in the following Proportion (BENTOX: Water Ratio) • For areas that receive good

annual rainfall, the mixing ratio is 1:1, i.e. for each bag of BENTOAX (25 Kg), mix 25 Liters of water. •

For dry areas that does not receive good annual rainfall, the water part in the slurry is increased to 1.4

– 1.5 times i.e. for each bag of BENTOAX (25 Kg), mix around 35-38 Liters of water depending upon

the severity of dryness.

Note: Application ratios are mention on basis of our shared experiences from our valued customers.

Self evaluation of product behavior on your process and end product is advisable. Mixing BENTOAX

with water properly to make homogenous & swelling thick slurry is EXTREMELY important in achieving

the required results from the product.

You might also like

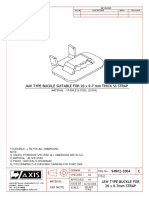

- Jaw Type Buckle Suitable For 20 X 0.7 MM Thick Ss Strap: Material: Stainless Steel (Ss304)Document1 pageJaw Type Buckle Suitable For 20 X 0.7 MM Thick Ss Strap: Material: Stainless Steel (Ss304)Nimish TaterhNo ratings yet

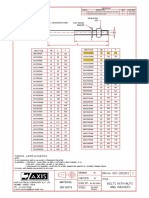

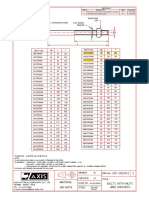

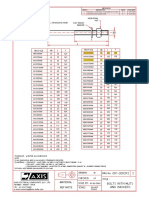

- Ref Note: Rev # Description Appv. Rev DateDocument1 pageRef Note: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- Material: Ref Note: Rev # Description Appv. Rev DateDocument1 pageMaterial: Ref Note: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- Dead End Clamp: Rev # Description Appv. Rev DateDocument1 pageDead End Clamp: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- WIDTH 20 MM: Stainless Steel (Ss202) Strap in Coil Form (50 MTRS)Document1 pageWIDTH 20 MM: Stainless Steel (Ss202) Strap in Coil Form (50 MTRS)Nimish TaterhNo ratings yet

- WIDTH 20 MM: Stainless Steel (Ss202) Strap in Coil Form (50 MTRS)Document1 pageWIDTH 20 MM: Stainless Steel (Ss202) Strap in Coil Form (50 MTRS)Nimish TaterhNo ratings yet

- Jaw Type Buckle Suitable For 20 X 0.7 MM Thick Ss Strap: Material: Stainless Steel (Ss304)Document1 pageJaw Type Buckle Suitable For 20 X 0.7 MM Thick Ss Strap: Material: Stainless Steel (Ss304)Nimish TaterhNo ratings yet

- Material: Ref Note: Rev # Description Appv. Rev DateDocument1 pageMaterial: Ref Note: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- Copper Clad Steel Stranded ConductorDocument2 pagesCopper Clad Steel Stranded ConductorNimish TaterhNo ratings yet

- Material: Ref Note: Rev # Description Appv. Rev DateDocument1 pageMaterial: Ref Note: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- Material: Ref Note: Rev # Description Appv. Rev DateDocument1 pageMaterial: Ref Note: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- Jaw Type Buckle Suitable For 20 X 0.7 MM Thick Ss Strap: Material: Stainless Steel (Ss304)Document1 pageJaw Type Buckle Suitable For 20 X 0.7 MM Thick Ss Strap: Material: Stainless Steel (Ss304)Nimish TaterhNo ratings yet

- WIDTH 20 MM: Stainless Steel (Ss202) Strap in Coil Form (50 MTRS)Document1 pageWIDTH 20 MM: Stainless Steel (Ss202) Strap in Coil Form (50 MTRS)Nimish TaterhNo ratings yet

- Ref Note: Rev # Description Appv. Rev DateDocument1 pageRef Note: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- Jaw Type Buckle Suitable For 20 X 0.7 MM Thick Ss Strap: Material: Stainless Steel (Ss304)Document1 pageJaw Type Buckle Suitable For 20 X 0.7 MM Thick Ss Strap: Material: Stainless Steel (Ss304)Nimish TaterhNo ratings yet

- PDF Created With Pdffactory Trial VersionDocument1 pagePDF Created With Pdffactory Trial VersionNimish TaterhNo ratings yet

- Material: Ref Note: Rev # Description Appv. Rev DateDocument1 pageMaterial: Ref Note: Rev # Description Appv. Rev DateNimish TaterhNo ratings yet

- Metric Exothermic PDFDocument45 pagesMetric Exothermic PDFNimish TaterhNo ratings yet

- Switchgears: Tested Power... Trusted SolutionDocument2 pagesSwitchgears: Tested Power... Trusted SolutionNimish TaterhNo ratings yet

- Conduit Fitting Catalog.Document5 pagesConduit Fitting Catalog.Nimish TaterhNo ratings yet

- Din RailsDocument4 pagesDin RailsNimish TaterhNo ratings yet

- Conduit Fitting Catalog.Document5 pagesConduit Fitting Catalog.Nimish TaterhNo ratings yet

- AxiWeld Exothermic Welding System PDFDocument24 pagesAxiWeld Exothermic Welding System PDFNimish TaterhNo ratings yet

- A Total Solution: An ISO 9001: 2015 CompanyDocument14 pagesA Total Solution: An ISO 9001: 2015 CompanyNimish TaterhNo ratings yet

- AXIS Handout PDFDocument14 pagesAXIS Handout PDFNimish TaterhNo ratings yet

- Aerial Bundled Conductor Solutions: Product CatalogDocument44 pagesAerial Bundled Conductor Solutions: Product CatalogNimish TaterhNo ratings yet

- PV Solar Clips Axis PDFDocument10 pagesPV Solar Clips Axis PDFNimish TaterhNo ratings yet

- PV Solar Clips Axis PDFDocument10 pagesPV Solar Clips Axis PDFNimish TaterhNo ratings yet

- A Total Solution: An ISO 9001: 2015 CompanyDocument14 pagesA Total Solution: An ISO 9001: 2015 CompanyNimish TaterhNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 4 5929483715435561135Document44 pages4 5929483715435561135Anonymous cKdbnUH100% (1)

- Epoxy LabDocument4 pagesEpoxy LabRosni hasanNo ratings yet

- ConsbeamDocument4 pagesConsbeamtraisimdoNo ratings yet

- InternalPainting PDFDocument9 pagesInternalPainting PDFPhilip LonerganNo ratings yet

- CIP 01 - Dusting Concrete SurfacesDocument2 pagesCIP 01 - Dusting Concrete Surfacesedward the iiiNo ratings yet

- Reparación de Casco de Horno RotativoDocument13 pagesReparación de Casco de Horno RotativoErick OlavarriaNo ratings yet

- Bunnings Store Map - Padstow NSW - PFO - WebDocument2 pagesBunnings Store Map - Padstow NSW - PFO - WebsdfsdfsdfNo ratings yet

- ARMY - Chapter Eight Explosive BreachingDocument25 pagesARMY - Chapter Eight Explosive Breachingrsreeth100% (1)

- Potential and Electric Field Distribution Associated With HVDC Insulators Under Different Pollution ConditionsDocument121 pagesPotential and Electric Field Distribution Associated With HVDC Insulators Under Different Pollution ConditionsFaridah HassanNo ratings yet

- MDS Report Substances of Assemblies and Materials: 1. Company and Product NameDocument3 pagesMDS Report Substances of Assemblies and Materials: 1. Company and Product NameMohamed HarisNo ratings yet

- Article Chemical Engineering July 2017 Activated Carbon Fundamentals and New ApplicationsDocument10 pagesArticle Chemical Engineering July 2017 Activated Carbon Fundamentals and New ApplicationsHonguito WebNo ratings yet

- ME8491 - Unit1 PDFDocument44 pagesME8491 - Unit1 PDFSenthilkumar SivasankaranNo ratings yet

- Preparation For Loading LNG CargoDocument78 pagesPreparation For Loading LNG CargopradeepNo ratings yet

- Different Types of Wood JointDocument2 pagesDifferent Types of Wood Joint[AP-STUDENT] Resty GarciaNo ratings yet

- Silicate IndustryDocument40 pagesSilicate IndustryTamiru DerejeNo ratings yet

- As 1366.3-1992 Rigid Cellular Plastics Sheets For Thermal Insulation Rigid Cellular Polystyrene - Moulded (RCDocument7 pagesAs 1366.3-1992 Rigid Cellular Plastics Sheets For Thermal Insulation Rigid Cellular Polystyrene - Moulded (RCSAI Global - APAC100% (1)

- "The Comparison of Stamicarbon and Saipem Urea Technology": October 2016Document11 pages"The Comparison of Stamicarbon and Saipem Urea Technology": October 2016Anonymous iuFpXLNo ratings yet

- AISC-ASD-Anchor Bolt CapacityDocument1 pageAISC-ASD-Anchor Bolt CapacityUmar FarooqueNo ratings yet

- Infineum - Used Oil Elemental Analysistable 1599925859367Document2 pagesInfineum - Used Oil Elemental Analysistable 1599925859367PedroNo ratings yet

- PIP pnsc0035 Steam Tracing SpecificationDocument57 pagesPIP pnsc0035 Steam Tracing Specificationsenthilkumar rangaraj100% (1)

- Technical Data Sheet For HIT HY 270 Injectable Anchor Mortar For Masonry Technical Information ASSET DOC 4098527Document26 pagesTechnical Data Sheet For HIT HY 270 Injectable Anchor Mortar For Masonry Technical Information ASSET DOC 4098527H (Chief11)No ratings yet

- CCM Corporate Overview - v2Document37 pagesCCM Corporate Overview - v2Mohammed Hammoudeh100% (2)

- Singapore-Cambridge GCE A Levels Exam Practice Paper IIDocument5 pagesSingapore-Cambridge GCE A Levels Exam Practice Paper IIChong56No ratings yet

- Astm E1131Document6 pagesAstm E1131Erick IvánNo ratings yet

- Apavisa Catalogo General 16Document438 pagesApavisa Catalogo General 16ggestrudesNo ratings yet

- Zinga Brochure EN - 09.2017-V6Document4 pagesZinga Brochure EN - 09.2017-V6Edmar Tomines BangayanNo ratings yet

- 3M Double Coated Tape 9731Document7 pages3M Double Coated Tape 9731Lucas HenriqueNo ratings yet

- Proguard CN 100 Iso TDSDocument3 pagesProguard CN 100 Iso TDSm_f_deathNo ratings yet

- SHRH DMW FailuresDocument1 pageSHRH DMW FailuresNandaNo ratings yet

- Determination of Hardness of WaterDocument2 pagesDetermination of Hardness of WaterNitinSrivastavaNo ratings yet