Professional Documents

Culture Documents

MS-Pipe Laying by Open Cut (SHEET PILE)

MS-Pipe Laying by Open Cut (SHEET PILE)

Uploaded by

Roif SamsulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS-Pipe Laying by Open Cut (SHEET PILE)

MS-Pipe Laying by Open Cut (SHEET PILE)

Uploaded by

Roif SamsulCopyright:

Available Formats

UTIC SERVICES SDN. BHD.

THE PROPOSED SEWER NETWORK RECTIFICATION

AT INDAH WATER KONSORTIUM SDN BHD’S,

SEWAGE TREATMENT PLANT (ASSET NO. SAM058)

LOCATED AT JALAN NELAYAN, SEKSYEN 19, SHAH

ALAM, SELANGOR DARUL EHSAN

CONTRACT NO.: IWK/CW1/254/BSAM/C.SM.15.0013

PIPE LAYING WORK BY USING OPEN CUT

(USING SHEET PILE)

TABLE OF CONTENT

1. INTRODUCTION.................................................................................................................. 3

2. LIST OF VEHICLE MACHINERY AND EQUIPMENT..........................................................3

3. MANPOWER....................................................................................................................... 4

4. PROCEDURE...................................................................................................................... 4

4.1. Survey works........................................................................................................... 4

4.2. Removing of trees...................................................................................................4

4.3. Sheet Pile Installation.............................................................................................4

4.4. Excavation of line pipe............................................................................................5

4.5. Piling Work............................................................................................................... 5

4.6. Concreting work......................................................................................................7

4.7. Pipe Laying.............................................................................................................. 7

4.8. Backfilling and Compaction...................................................................................7

4.9. Manhole construction.............................................................................................7

4.10. Traffic Management.............................................................................................8

4.11. Dewatering........................................................................................................... 8

5. SAFETY HEALTH AND ENVIROMENT (SHE)...................................................................8

UTIC SERVICES SDN BHD (459079-W)

Head Office Klang Valley

No.12 Crossvent Subang, Jalan Lira U3/41, Pekan Baru Subang

Seksyen U3, 40150 Shah Alam, Selangor, MALAYSIA

Tel: (603) 78327030 Fax: (603) 78327830 www.uticservices.com

2

1. INTRODUCTION

Generally, this document is developed as a method used for the pipe laying work by using open

trench excavation and the shoring method is by using sheet pile.

2. LIST OF VEHICLE MACHINERY AND EQUIPMENT

2.1. Removal of trees

2.1.1. Boom Lift

2.1.2. Chainsaw

2.2. Sheet pile Installation

2.1.1. Excavator mounted vibrator

2.1.2. Sheet pile 9m

2.1.3. I beam Frame

2.3. Excavation line of pipe

2.3.1. Dump Truck

2.3.2. Excavator

2.3.3. Hand shovel

2.3.4. Box shoring with metal steel plate

2.4. Piling work

2.4.1. Piling Machine

2.4.2. Electric generator

2.4.3. Demolition hammer

2.5. Pipe laying

2.5.1. Excavator

2.5.2. Lifting hook

2.6. Safety equipment

2.6.1. Personnel protective equipment (PPE)

2.6.2. Safety cone / plastic barrier

2.6.3. Safety signage

UTIC SERVICES SDN BHD (459079-W)

Head Office Klang Valley

No.12 Crossvent Subang, Jalan Lira U3/41, Pekan Baru Subang

Seksyen U3, 40150 Shah Alam, Selangor, MALAYSIA

Tel: (603) 78327030 Fax: (603) 78327830 www.uticservices.com

3

3. MANPOWER

3.1. Site agent

3.2. Supervisor

3.3. Site Safety Supervisor

3.4. Excavator operator

3.5. Mobile crane operator for piling work

3.6. Skilled labour

3.7. General worker

4. PROCEDURE

4.1. Survey works

4.1.1. Before any works are commenced, Licensed Surveyor (LS) should be engaged

to verify the entire dimension and level as shown on drawings.

4.1.2. Data of existing structure such as pipe culvert, retaining wall, drains, road kerb

and underground utilities shall be checked and recorded

4.1.3. A joint survey shall be carried out in the presence of S.O. to confirm any

discrepancy, which may affect to the dimension, level or any part of the works.

4.2. Removing of trees

4.2.1. Before starting excavation work, trees that is higher than 3m had to be removed

for mobilization of machine purpose.

4.2.2. Tree branches will be cut to the point where there is only trunk and will be cut

using boom lift and chainsaw.

4.2.3. Trees that had been cut will then be planted at a site where it is approved by

MBSA.

4.3. Sheet Pile Installation

4.3.1. Machine will be mobilized to site with a 9m sheet pile.

4.3.2. An installation of sheet pile will be made by section whereby a section consists of

25m of length.

UTIC SERVICES SDN BHD (459079-W)

Head Office Klang Valley

No.12 Crossvent Subang, Jalan Lira U3/41, Pekan Baru Subang

Seksyen U3, 40150 Shah Alam, Selangor, MALAYSIA

Tel: (603) 78327030 Fax: (603) 78327830 www.uticservices.com

4

4.3.3. For the first point, a 2 section of sheet pile will be installed starting from MH 18Z

to MH 19 Z.

4.3.4. Next, installation of I beam at the top of sheet pile will be done. (Refer picture for

detail)

4.3.5. After finish 2 section of sheet pile, procedure 4.4 to 4.8 will be followed by.

4.3.6. After completion of procedure 4.8, the first section of sheet pile will be dismantled

and will be installed to continue to section 3 and continues the process until

MH8Z.

4.4. Excavation of line pipe

4.4.1. The trench for pipe shall be excavated to the requirement depth as per drawing.

4.4.2. Excavated earth shall be stored on one side of the trench for re-use in backfilling.

Temporary shoring of trenches will be using box shoring and steel plate at side of

the box shoring.

4.4.3. Excavation work by using excavator will scoop in between box shoring beam

which have clearance of 5m length in between.

4.4.4. Detail of box shoring is attached at Appendix A.

4.5. Piling Work

4.5.1. After excavation reached the required depth, piling work will start.

4.5.2. Before piling to peg location of piling whereby 1.5m distance between one pile to

another centre to centre pile as stated in construction drawing.

4.5.3. Finished pegging, piling work will start by using hammer pile method using

mobile crane.

4.5.4. We will carry out 2 points of pile for test with the same size of 230 x 230 mm

square pile. First point will be using 9 m initial and 6 m extension bar and second

point is only using 9 m initial pile.

4.5.5. PDA test will be carried out to test both point to achieve test load of 150 kN, we

will get consultant approval to propose with the balance works.

4.5.6. Next, excess pile will be left out 125mm (Lean con 50 mm, excess pile 75 mm)

from excavated ground level and reinforcement starter bar to be left out for

300mm.

UTIC SERVICES SDN BHD (459079-W)

Head Office Klang Valley

No.12 Crossvent Subang, Jalan Lira U3/41, Pekan Baru Subang

Seksyen U3, 40150 Shah Alam, Selangor, MALAYSIA

Tel: (603) 78327030 Fax: (603) 78327830 www.uticservices.com

5

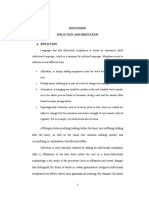

SHEET PILE

I BEAM

PIPE 375

RAF FOUNDATION

PILE

Figure 1: Diagram of box shoring with steel plate and lay of pipe

UTIC SERVICES SDN BHD (459079-W)

Head Office Klang Valley

No.12 Crossvent Subang, Jalan Lira U3/41, Pekan Baru Subang

Seksyen U3, 40150 Shah Alam, Selangor, MALAYSIA

Tel: (603) 78327030 Fax: (603) 78327830 www.uticservices.com

6

4.6. Concreting work

4.6.1. 50 mm lean concrete will be lay at the base of excavation before laying down 2

layers of A10 BRC.

4.6.2. 2 layers of BRC will be tied out with reinforcement starter bar of pile as shown in

Construction drawing.

4.6.3. Pile raft foundation will use concrete grade 30.

4.7. Pipe Laying

4.7.1. RCP size diameter 375mm will be laid in sequence after 200 mm base concrete

has harden and will continue concreting the remaining raft foundation to desired

height.

4.7.2. Joints on pipe shall be of slip-in type spigot and socket joint and flanged fittings.

4.7.3. All safety measures will be followed to keep the open trench free from accident.

4.8. Backfilling and Compaction

4.8.1. A layer of approved backfilling material i.e. Sand is spread above pipe.

4.8.2. Subsequent layer of approved backfill material is spread and compacted with

roller.

4.8.3. The remaining area shall be filled with compacted approved backfill material up

to bottom of pavement layers.

4.9. Manhole construction

4.9.1. Once invert level confirmed and checked by the surveyor; a 2100mm diameter or

1800 mm diameter of precast concrete chamber will be lowered down by caisson

method as a sleeve and shoring for the manhole.

4.9.2. Next, the concrete base should be lowered down.

4.9.3. Manhole chambering shall be fixed one by one up to the required level including

all the make-up pieces.

4.9.4. Grade 20 concrete shall be used as concrete surround using required sizes steel

mould to hold the chambering as per the drawings.

4.9.5. The completed manhole shall be backfilled and compact up to the required level.

UTIC SERVICES SDN BHD (459079-W)

Head Office Klang Valley

No.12 Crossvent Subang, Jalan Lira U3/41, Pekan Baru Subang

Seksyen U3, 40150 Shah Alam, Selangor, MALAYSIA

Tel: (603) 78327030 Fax: (603) 78327830 www.uticservices.com

7

4.10. Traffic Management

4.10.1. The objective is to minimize inconvenience and prevent potential hazard to the

public.

4.10.2. The road will be temporary closed during the delivery of machineries or

materials. The Scheme 2 will be applied upon loading and unloading of materials

and machineries as per Appendix A. The road will be re-open as soon as

practicable.

4.10.3. The precautions will be implemented as per following:

a) Subcontractors and suppliers adhere to the safety and traffic procedures

set out during the work.

b) Prevent unauthorized personnel parking and congest the traffic.

c) Maintain roads in a clean and safe condition.

4.11. Dewatering

4.11.1. Proper steps will be taken to ensure that all water disposals is done in line with

good engineering practices and is in compliance with local authorities laws.

4.11.2. Proper steps will be taken to ensure that the open cut works are free from water

until completion of works. This can be achieved by continually dewatering from

working area to the water tank.

4.11.3. The water pumps will be arranged sufficiently so that the dewatering process can

be proceeded with no obstruction.

5. SAFETY HEALTH AND ENVIROMENT (SHE)

5.1. Workers are compulsory to wear suitable PPE during working (especially during

handling of cement slurry).

5.2. Entry into the confined space (manhole), if any, shall strictly follow DOSH ICOP

2010 – Industrial code of practice to safe working in a confined space.

5.3. Vehicle, machinery and equipment shall be inspected and to insure in good working

condition prior to use at site.

5.4. If night work is required, site shall be equipped with enough lighting and proper

vehicles arrangement (TMP) to prevent disruption to the existing

UTIC SERVICES SDN BHD (459079-W)

Head Office Klang Valley

No.12 Crossvent Subang, Jalan Lira U3/41, Pekan Baru Subang

Seksyen U3, 40150 Shah Alam, Selangor, MALAYSIA

Tel: (603) 78327030 Fax: (603) 78327830 www.uticservices.com

8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Xstore Introduction Boot Camp Student WorkbookDocument251 pagesXstore Introduction Boot Camp Student Workbooklesay100% (1)

- Nms-Pipe Jacking Auger MethodDocument9 pagesNms-Pipe Jacking Auger MethodRoif SamsulNo ratings yet

- AASHTO Guide Manual For Bridge Element Inspection AASHTO ...Document17 pagesAASHTO Guide Manual For Bridge Element Inspection AASHTO ...fanfengliNo ratings yet

- NMS-Rehabilitation ManholeDocument6 pagesNMS-Rehabilitation ManholeRoif SamsulNo ratings yet

- MSIG Vol V 3edDocument64 pagesMSIG Vol V 3edjpmega004524No ratings yet

- MS-Slurry Jcking PDFDocument8 pagesMS-Slurry Jcking PDFRoif SamsulNo ratings yet

- Swot Analysis 123Document15 pagesSwot Analysis 123Roif SamsulNo ratings yet

- Non-Sway Frame Example: SolutionDocument5 pagesNon-Sway Frame Example: SolutionRoif SamsulNo ratings yet

- Colligative Properties of SolutionDocument8 pagesColligative Properties of SolutionJerome FernandezNo ratings yet

- NetVault Backup APM For Exchange Server Users GuideDocument88 pagesNetVault Backup APM For Exchange Server Users GuideClive GovindenNo ratings yet

- CRM Industry ClassificationDocument2 pagesCRM Industry ClassificationRenato LanaNo ratings yet

- Classroll Company ProfileDocument9 pagesClassroll Company ProfileMustafamobilyaprojeNo ratings yet

- 0032 CervicalCancerScreeningForm NCQA PDFDocument17 pages0032 CervicalCancerScreeningForm NCQA PDFkamayani_prNo ratings yet

- Fundamentals of Iron and SteelmakingDocument145 pagesFundamentals of Iron and SteelmakingMichela CarmeliNo ratings yet

- Chapter-2 Rectification of ErrorDocument8 pagesChapter-2 Rectification of ErrorprascribdNo ratings yet

- Steam Turbine Maintenance Inspections or Repairs: Turbine Restart After MajorDocument3 pagesSteam Turbine Maintenance Inspections or Repairs: Turbine Restart After Majordreamboy87No ratings yet

- How To Make Tiramisu - Recipe - Food - The GuardianDocument9 pagesHow To Make Tiramisu - Recipe - Food - The GuardianJu RiNo ratings yet

- Michelle - Chemical Equilibrium WS PDFDocument2 pagesMichelle - Chemical Equilibrium WS PDFLin Xian XingNo ratings yet

- Qm-Manyworlds A4Document26 pagesQm-Manyworlds A4Игор МиликићNo ratings yet

- Annex D. Local Development Information TemplateDocument3 pagesAnnex D. Local Development Information TemplateryanNo ratings yet

- Mudda Sai Aditya: Mobile: +91-703245-7377Document3 pagesMudda Sai Aditya: Mobile: +91-703245-7377Sai AdityaNo ratings yet

- J. Pierce, Et Al., - MIT RadLab (Complete Set) Vol 04 - Loran-McGraw-Hill (1948)Document490 pagesJ. Pierce, Et Al., - MIT RadLab (Complete Set) Vol 04 - Loran-McGraw-Hill (1948)Mari HaritonNo ratings yet

- Hec 101 VDocument50 pagesHec 101 VBeNobody293% (14)

- 9820gb180le 210Document31 pages9820gb180le 210BaggerkingNo ratings yet

- Heat Exchanger System Piping Design For A Tube Rupture EventDocument10 pagesHeat Exchanger System Piping Design For A Tube Rupture Eventmarco8garciaNo ratings yet

- Laura GirellaDocument35 pagesLaura GirellaRitaNo ratings yet

- Gage Repeatability and Reproducibility Data Sheet Variable Data ResultsDocument30 pagesGage Repeatability and Reproducibility Data Sheet Variable Data ResultsAlvaro FloresNo ratings yet

- Internal Assessment Criteria IODocument3 pagesInternal Assessment Criteria IORaghavNo ratings yet

- EE Assignments 2016Document8 pagesEE Assignments 2016manojNo ratings yet

- Makalah Morphology PDFDocument13 pagesMakalah Morphology PDFTiara WardoyoNo ratings yet

- Principles and Practices of Management & Organizational Behavior - Nikhil BabuDocument3 pagesPrinciples and Practices of Management & Organizational Behavior - Nikhil BabuNikhil BabuNo ratings yet

- Ann Rep 1415Document144 pagesAnn Rep 1415rizkiyahNo ratings yet

- Kfc3 - Senior CampDocument16 pagesKfc3 - Senior CampSam Ebarvia100% (2)

- Infants 2 Term 3Document24 pagesInfants 2 Term 3Adanna GrantNo ratings yet

- 1st Assignment of MMCDocument9 pages1st Assignment of MMCAwais Asghar KhanNo ratings yet

- CrystalMeth and Index PDFDocument53 pagesCrystalMeth and Index PDFAnthonyHansenNo ratings yet