Professional Documents

Culture Documents

Applications of Pretensioned Anchor Rods in Industrial Facilities

Uploaded by

André Luiz NogueiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Applications of Pretensioned Anchor Rods in Industrial Facilities

Uploaded by

André Luiz NogueiraCopyright:

Available Formats

Applications of Pretensioned Anchor

Rods in Industrial Facilities

SHU-JIN FANG

ABSTRACT

Base plate and anchor rod connections are key structural components. A great majority of anchor rods are designed, placed and installed

without pretensioning, usually because the structures are considered to be statically loaded. Applications of pretensioned anchor rods are

less common and generally limited to certain industrial facilities. This paper provides a brief overview of the current state of the practice re-

garding pretensioned anchor rods and reviews selected recent pretensioned anchor rod applications in power industry facilities.

Keywords: pretensioned anchor rods, column base connections.

INTRODUCTION experience and engineering judgment to develop a satisfac-

tory application. Information and design practices published

B ase plate and anchor rod connections are key structural

components of vital importance to the plumbness and

safety of structures. They are not only used as column base

in literature are not consistent, sometimes confusing and

conflicting. This paper is written with two objectives: (1)

to provide a brief review of the current state of the practice

support in every building structure, but also utilized for sup-

in pretensioned anchor rods; and (2) to present lessons and

porting nonbuilding structures and mounting of equipment

knowledge learned from selected recent project applications

in industrial facilities. Anchor rods, a relatively new termi-

in power industry facilities.

nology adopted by AISC, were referred to as anchor bolts in

For many years, AISC noted that the pretensioning of

the past. A great majority of anchor rods are designed, placed

anchor rods was not recommended for building structures.

and installed without pretensioning. Base plates are tied to

Commentary Section A3.4 of the 1999 Edition AISC LRFD

anchor rods by nut(s) and washer, as evidenced in typical

Specification noted concerns regarding prestressing re-

building column bases. Applications of pretensioned anchor

laxation due to concrete creep and the potential for stress

rods are less common and generally limited to certain indus-

corrosion damage. The author believes that the reason most

trial facilities. Design of column base plates and anchor rods

building structures do not have pretensioned anchor rods is

is governed by the AISC Specification for Structural Steel

that the structures are statically loaded. The Commentary

Buildings (AISC, 2005) and ACI 318 Appendix D (ACI,

note is not present in the 2005 AISC Specification. In view

2005). However, neither the AISC Specification nor ACI 318

of this historical background in the building industry, it

provide specific guidelines for pretensioned cast-in-place

would be very beneficial to examine the practices of pre-

anchors. An excellent guideline, AISC Design Guide 1, Base

tensioning of anchor rods outside the building industry.

Plate and Anchor Rod Design, second edition, second print-

ing (Fisher and Kloiber, 2006), is now available to guide en-

WHEN PRETENSIONING IS RECOMMENDED

gineers and fabricators for design, detailing, fabrication and

erection of column-base-plate and anchor rod connections. According to Design of Anchor Bolts in Petrochemical Fa-

Appendix 3 of the design guide provides limited but useful cilities (ASCE, 1997), pretensioning of anchor rods is rec-

discussions on pretensioned anchors. It appears that similar ommended for the following three situations:

guidelines or authoritative design codes/standards are still

• Tall vessels sensitive to wind such as towers with

lacking with respect to design, fabrication and installation of

a height-to-width ratio of 15 or more, or more than

pretensioned anchor rods, and little research has been done

100 feet tall.

in this area. Engineers often have to rely on their own past

• Dynamic machinery such as compressors or other pul-

sating equipment.

• High-strength anchor bolts to minimize load reversals.

Shu-Jin Fang, Ph.D., P.E., S.E., Senior Manager/Technical Advisor, Sargent &

Lundy, Chicago, IL. E-mail: shujin.fang@sargentlundy.com These three pretensioning applications all aim to improve

the long-term performance of anchor rods or to improve the

ENGINEERING JOURNAL / FIRST QUARTER / 2012 / 1

001-010_EJ1Q_2012_2010-02.indd 1 2/24/12 1:26 PM

performance of equipment or vessels. One common denomi- damage. Other shortcomings include lack of high assurance

nator among these applications is that the anchor supports that the anchor is properly installed and pretensioned in the

are subjected to frequent load fluctuations induced by wind, field. Periodic examination and testing may be needed to

thermal cycling or machine vibrations. Pretensioning helps monitor the loss of pretension over time caused by concrete

prevent fluctuation of the tensile stress in the anchors and creep and anchor relaxation.

therefore minimizes loosening of nuts and alleviates fatigue

concerns. Anchor pretensioning may also help decrease ma- CONFIGURATIONS OF THREE TYPES OF

chine vibrations and the drifts of process vessels under wind PRETENSIONED ANCHOR ROD JOINTS

or other lateral loads.

Three commonly used pretensioned anchor rod joints are

In addition, pretensioning of anchor rods will increase the

shown in Figures 1a, 1b and 1c.

frictional shear resistance at base plates, which is beneficial

Figure 1a represents a typical vibratory-machine joint in

for the design of anchorages for tall vessels and structures

which the sleeve is extended for the full depth of the an-

subjected to heavy wind and seismic forces. Certainly, wind-

chor. The sleeve is used for both precise alignment and

sensitive structures are not limited to tall process vessels.

pre-tensioning of anchor rods. The sleeve is usually made

Other examples include steel stacks, pipe rack supports, pip-

of metal pipes. Long metal sleeves can be substituted with

ing supports, crane column bases, transmission poles, wind

plastic (PVC) sleeves if no welding is required. Either sin-

turbine towers, telecommunication towers and cantilevered

gle or double nuts may be located beneath the embedment

signal- and light-support structures for highways.

plate. The space between the anchor rod and pipe sleeve

AISC Design Guide 1 (Fisher and Kloiber, 2006) states

can be filled with grout after the structure or equipment is

that vibratory machine joints and double-nut joints designed

set, aligned and pretensioned. Alternatively, sleeves may be

for high seismic applications (Seismic Design Category D, E

sealed on top or filled with appropriate elastomeric material

and F) or designed for fatigue require pretensioning accord-

to prevent water or grout from filling the sleeve. It should

ing to ASCE/SEI 7 (ASCE, 2005).

be noted that if sleeves are not grouted, anchor rods will

For each such application, engineers are advised to bal-

not be effective in resisting shear loads and will have to rely

ance the previously mentioned technical advantages against

on shear friction tension or shear lugs for shear resistance.

the possible cost increases, which could range from little to

The metal sleeves are generally at least 1.0 in. larger than

very substantial, depending on the size of anchor rods and

the anchor rod diameter. AISC Design Guide 1 (Fisher and

the pretension magnitude desired. There are a number of

Kloiber, 2006) recommends that full-depth steel sleeves be

other potential shortcomings caused by pretensioning that

used to minimize concrete creep/shrinkage. The full-depth

should not be overlooked. One of them is the damage to

steel sleeve permits elongation of the entire length of anchor

concrete and grout that may result from inadequate design

rod and should have adequate strength for transferring an-

or excessively high pretension loads. Improper tensioning

chor rod pretension from the embedment plate to the base

methods and/or improper tensioning sequences can cause

Notes:

1. Base plate and grout placed above concrete are not shown for clarity in Figure 1a and 1b.

2. If high strength anchor rods are used, welding of nuts to the anchor rods is typically not

recommended.

Fig. 1a. Pretensioned anchor rods for vibratory equipment support.

2 / ENGINEERING JOURNAL / FIRST QUARTER / 2012

001-010_EJ1Q_2012_2010-02.indd 2 2/24/12 1:26 PM

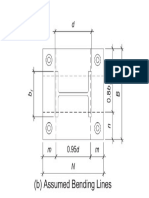

plate. The embedment plate should also be capable of resist- Figure 1c shows configuration of a typical double-nut-

ing the pretension force prior to placement of grout. Also, a moment joint at column base. The base plate is attached to

hardened plate washer with appropriate thickness may need anchor rods through double nuts (a leveling nut and a top

to be placed directly above the base plate when anchor pre- nut). Washers are typically used under both nuts. The base

tension is high. plate stands off from the concrete foundation and bearing

Figure 1b shows a pretensioned anchor rod design with on leveling nuts. Grout is not typically placed beneath the

a partial-depth sleeve. Partial-depth sleeves are primarily base plate. Anchor rods are designed for axial loads (tension

used for alignment purposes and are suitable only for ap- and compression), shear and moment. Double-nut-moment

plications where pretension is low or moderate. In order to joints are easy to level and plumb and are also very reliable

allow pretensioning of anchor rods, grout below the sleeve for transmitting moment to the foundation; therefore, they

must not be allowed to bond to the anchor rod. Typically, are satisfactory for nonredundant structures and seismic or

the portion of anchor rod shaft below the sleeve and within fatigue-loaded structures. This type of column base design

1 in. of the embedment plate is taped or coated with a bond- is commonly used in highway ancillary structures, towers

breaker for a distance at least six times anchor rod diameter and poles, which are subjected to significant moments and

above the embedment plate, so that the anchor rods can be shears. Double-nut joints are pretensioned between nuts

adequately stretched (ASCE, 1997). The sleeves are typi- only. Research performed for National Cooperative High-

cally positioned with a distance at least six times anchor rod way Research Program (NCHRP) Reports 469 and 412

diameter above the embedment plate. (Dexter and Ricker, 2002; Kaczinski et al., 1996) shows that

pretension in the rod between two nuts improves fatigue

strength by good load distribution among the anchor rods.

PRETENSIONING VALUE

For any pretensioned anchor application, the first question

raised by designers is how much pretension to apply. The

answers to this question vary with the intended application.

Table 1 gives a summary of various pretension practices in

power, petrochemical process and highway industries. It

can be seen from Table 1 that the pretension load desired

may vary from 0.15Fy (15% of the specified minimum yield

strength of anchor rod) to as high as 0.6Fu (60% of the speci-

fied minimum tensile strength of anchor rod), depending on

the design objectives.

Fig. 1b. Pretensioned anchor rod with partial-depth sleeve.

Fig. 1c. Typical double-nut-moment joint.

ENGINEERING JOURNAL / FIRST QUARTER / 2012 / 3

001-010_EJ1Q_2012_2010-02.indd 3 2/24/12 1:26 PM

Table 1. Summary of Various Anchor Rod Pretensioning Practices

AISC ASCE

Design ACI 351-3R Anchor

Vendor 1 Vendor 2 Vendor 3 Vendor 4 Vendor 4

Guide 1 (2004) Rod Design

(2006) (1997)

Double-

Nut-

Turbine Generator Turbine Generator ID/PA/FD ID/PA/FD Moment Vibratory See

Motor

Support Support Support Support Fan Fan Joint at Equipment Note 6

Column

Base

Anchor

2 in. to 1½ in. 2 in. to

Rod 1½ in. 1¾ in. 2 in. ≤ 4 in. No limit

2½ in. to 2 in. 2½ in.

Diameter

Ft = 0.3;

Fu unless

Sufficient

otherwise

Approx. 55 0.5 Fu for to resist dy-

required;

kips for 2-in. Gr. 36 and namic shear

Pretension 18,500 psi 30,000 psi 32,000 30,000 17,400 psi to

None anchor rod None 0.6 Fu for loads by

Load (0.18 Fy) (0.28 Fy) psi psi 18,000 psi

(17,500 psi higher shear friction;

for A36 or

or 0.5 Fy) strength 0.15 Fy ≤ Ft <

A307 Gr. C;

0.7 Fy

37,500 psi for

Gr. 105

1,100 ft-lb

for 2-in. Bolt torque

anchor rods Minimum should be

50 ft-lb

Installation and 840 ft-lb Not Not 1,560 1,900 nut determined

(Notes 2, 3 None

Torque for 1½-in. specified specified ft-lb ft-lb rotation based on

and 4)

anchor rods specified preload

(Notes 2 required

and 3)

Yes for

Not

Sleeves Yes Yes Yes Yes Yes Yes No Yes vibratory

Required

machine

No for

vibratory

applications;

Grouting Yes Yes Yes Yes Yes Yes Yes

N/A No fill sleeves

sleeves (Note 1) (Note 1) (Note 1) (Note 1) (Note 1) (Note 1) (Note 1)

with

elastomeric

materials

7,000 psi 7,000 psi

Minimum at 28 days at 28 days

Not

Grout and 5,000 and 5,000 7,500 psi 7,500 psi None None None None None

specified

Strength psi at 7 days psi at 7 days

(Note 5) (Note 5)

A307 Gr. C A307 Gr. C

(A36) stan- (A36) stan-

dard; use dard; use F1554 Gr.

Bolting A193

A449 Type A449 Type A193 B7 or No 36, 55, 105 No

(Rod) B7 or A193-B7 A193-B7 No restriction

1 anchor 1 anchor equivalent restriction and A615 restriction

Materials equivalent

rod when rod when Gr. 60

anchor rod anchor rod

size is large size is large

Notes

1. Fill sleeve completely with grout after equipment is set and aligned.

2. Tighten the nuts of anchor bolts to snug-tight where fixators are used.

3. Where anchor rods are subject to thermal movements (expansion or contraction), nuts are backed off from tightened torque to provide a 0.01-in. nominal

clearance between the bottom of nut and top of the washer; a nut-locking device or double-nutting should be provided.

4. Where thermal movement is not a concern, the anchor rods are generally tightened either snug-tight or with a 50 to 60 ft-lb final installed torque.

5. Use flowable, nonshrink, cementitious grout (ASTM C1107 Gr. A).

6. See page 1 for conditions recommended for pretensioning of anchor rods.

4 / ENGINEERING JOURNAL / FIRST QUARTER / 2012

001-010_EJ1Q_2012_2010-02.indd 4 2/24/12 1:26 PM

Vibratory Equipment Support Applications load reversal generated by wind induced vibrations. An ex-

Where pretensioned anchors are used for mounting of vi- cellent discussion of the minimum pretension loads is given

bratory equipment (sometimes referred as dynamic machin- in NCHRP Report 469 (Dexter and Ricker, 2002) for anchor

ery) and vibration performance is the primary objective, the rods used on highway ancillary structure supports. Exten-

pretension loads are generally set in the range of 0.15 Fy to sive fatigue testing has been performed on anchor rods in the

0.70 Fy. The size, material and pretension loads or pretension early 2000s, including NCHRP Report 412 (Kaczinski et al.,

stresses of anchor rods are typically specified by equipment 1996). The research in this report shows that the threshold

manufacturers. Pretensioning of the anchor rods enables the tensile fatigue stress range of anchor rods is 7 ksi, which is

equipment and foundation to act as an integral structure to very low. As a result, fatigue evaluation is not required if the

allow smooth transmission of machine unbalance force to stress in anchor rod remains in compression during the en-

the foundation. Proper pretension provides sufficient clamp- tire load cycle or if the stress range from applied loads is less

ing force to maintain critical alignment of the machine. than the threshold tensile stress range (7 ksi). This research

Others consider the pretension has a spring effect that will showed that column base plate–anchor rod connections sub-

absorb and dampen vibration levels. Unlike high-strength jected to more than 20,000 repeated application of axial ten-

bolts in steel-to-steel connections, the pretension loads in sion and/or flexure stress range must be checked for fatigue.

anchor rods required may be expressed either as tensile Their testing suggested that the allowable stress range of

stress or installation torque. Most rotary equipment such anchor rods at 20,000 cycles is approximately 27 ksi. Thus,

as gas turbines, steam turbines, generators, electric motors, pretensioning of anchor rods to minimize stress fluctua-

pumps and fans have a specified minimum pretension of tion can be extremely beneficial for base plate–anchor rod

0.15 Fy to 0.50 Fy. A minimum pretension load of 0.15 Fy connections that are subjected to large number of tensile

is the recommended value by ACI 351.3R (ACI, 2004) for stress cycles. Because highway cantilevered support struc-

foundation anchors supporting rotating equipment. Supports tures are subjected to many cycles of wind loads, includ-

for reciprocating equipment (compressors, hammers, diesel ing vortex shedding vibrations, natural wind gust, galloping

generators, etc.) generally require larger pretension loads and thrust gusts, NCHRP Report 469 recommends that all

because the machine produces large horizontal dynamic anchor rods in the double-nut moment base joints be preten-

forces. The pretension loads for these vibrating equipment sioned to a minimum value equal to 0.5 Fu (i.e., 50% of the

supports can be as high as 0.8 Fy. For precision machines, specified minimum tensile strength) for low-strength rod,

designing for a clamping force equal to 150% of the antici- namely, ASTM F1554 Rod Grade 36, and 0.6 Fu for anchor

pated normal operating bolt force is a common practice to rods made of higher-grade steel. These recommended mini-

account for uncertainty in bolt tensioning and creep/shrink- mum pretension loads are equivalent to 80% of the specified

age. Higher clamping force is typically achieved with more minimum tensile yield strength for Grade 36 rods, 0.818Fy

anchor bolts or larger pretension force. for Grade 55 rods, 0.714Fy for Grade 105 rods, and 0.8Fy for

In establishing anchor pretension, considerations Grade 60 ASTM A615 and A706 bars.

should be given to thermal friction and the use of fixators. Since the late 1970s, studies of tensile fatigue of anchor

Where anchor rods are subject to thermal movements due rods have been made at several major universities. A gen-

to expansion or contraction of equipment, some turbine eral study of anchor rod fatigue was made by Frank (1980)

manufacturers recommend that nuts to be backed off from at the University of Texas. This research showed that for

the tightened torque to provide a 0.01-in. nominal clearance double-nut moment base plate joints, tightening the double

between the bottom of nuts and top of the washer. In addi- nut connections 3 of a turn beyond snug-tight significantly

tion, a nut locking device or double nutting is often provided improved fatigue life. More research, including Van Dien et

to prevent loosening of the nuts. al. (1996), Richards (2004), and Hodge (1996) followed after

Leveling of mounting base for heavy machinery can the failures of cantilevered highway signs across the coun-

be challenging and time-consuming. To achieve efficient try, particularly in Michigan. Research further confirms the

mounting, many equipment manufacturers recommend the value of preloading the anchor bolts. An excellent summary

use of sliding shims or fixators. The later is a special an- of the tensile fatigue resistance of anchor rods and recom-

choring and leveling device that permits precise alignment mendations is given by NCHRP Report 469 (Kaczinski et

adjustments to be made after anchor nuts are tight. Where al., 1996). It states that the S-N fatigue curve for nonpreten-

fixators are employed, anchor rods are usually installed sioned anchor rods corresponds to the Fatigue Stress Cat-

snug-tight to avoid damage. egory E′ of Appendix 3 of the AISC Specification (AISC,

2005), except that the fatigue threshold is 7 ksi, which is

Highway Cantilever Structure Support Applications much higher than other Category E′ details. If the anchor

rod in double-nut-moment and vibratory-machinery joints

Anchor pretension higher than 0.5Fy may be necessary to is properly pretensioned, the rods will have tensile fatigue

maintain the tensile stress in the rod from fluctuating during

ENGINEERING JOURNAL / FIRST QUARTER / 2012 / 5

001-010_EJ1Q_2012_2010-02.indd 5 2/24/12 1:26 PM

resistance as good as Category E; however, the fatigue service environment and past industry experience. This in-

threshold is improved little. Because tests show that the cludes any one of the following conditions:

alignment eccentricity of anchor rods in the field can have

• Ensure the anchorage is capable of withstanding sig-

adverse effects on fatigue resistance, the report recommends

nificant cyclic stress fluctuations.

that Category E′ be used for design regardless of the pre-

tension. The anchor rod misalignment should be kept below • Keep anchorage tight and nuts from loosening that

1:40. These recommendations from NCHRP Report 469 can may be caused by operation vibrations.

serve as a guide to engineers for establishing the pretension

• Minimize the movement or drift of structures/vessels

needed for a specific application.

induced by foundation rotation.

Support of Tall Process Vessels, Process Towers, Steel • Follow the common tightening practice for a specific

Stacks and Wind Turbine Towers industry.

For tall process vessels, process towers, steel stacks and

wind turbine towers, there is no consensus on anchor rod For applications where anchor rods and base plates are to

pretension requirements. Some engineers choose to use a be subjected to a large number of significant stress cycles

very high pretension in anchor rods equal to the maximum from live loads, wind effects or other cyclic operating loads,

uplift forces caused by factored wind overturning moments. fatigue resistance is the single most important factor for de-

This conservative pretension is intended to ensure that ten- termination of anchor pretension. It is the responsibility of

sion in anchor rods will never exceed the initial anchor pre- foundation designers to select an adequate anchor pretension

tension force during the life of the structure. Others have load for their specific applications.

chosen to use a lower pretension equal to the maximum up-

lift that may be produced by the design wind (nonfactored) PRETENSIONING METHODS AND

or a fraction (50 to 70%) of the design (factored) wind mo- INSTALLATION SEQUENCE

ment. Past experience and research by Dexter and Ricker There are three methods commonly used for applying the

(2002) shows that fatigue is generally not a problem when required preload in the anchor rods: turn-of-the-nut method,

the number of cycles that exceed the anchor pretension force with a torque wrench and by hydraulic jacking. Among the

is small (less than 20,000 cycles) during the life of the struc- three, hydraulic jacking is the most accurate pretension-

ture. In any case, it will be prudent to evaluate the effect ing method and is used where the pretension load is criti-

of tensile fatigue on anchor rods and compression fatigue cal to the structural integrity of the support and/or to the

on concrete when pretension is not set to the maximum up- serviceability of the equipment. Hydraulic bolt tensioners

lift force. Where operating load spectra are not available, use an annular hydraulic jack placed around the anchor

a minimum pretension of 13 Fu is recommended by Design rod, stretching it axially. When the required stress level is

of Anchor Bolts in Petrochemical Facilities (ASCE, 1997). reached, the nut is tightened snugly and then the pressure re-

Steel stacks are another type of wind-sensitive struc- leased, resulting in a preloaded bolt without any frictional or

ture. Many stacks are susceptible to cross-wind (or vortex torsional stresses. The hydraulic jacking method can provide

shedding)-induced vibrations. According to the steel stack very accurate preload (±1%) on long bolts, but it is less accu-

design standard ASME STS-1 (ASME, 2006), anchor bolts rate on short bolts. The method is often used for mounting of

should be properly torqued and retightened 30 days after heavy vibratory machines with large-diameter anchor rods

stack erection. However, the standard is silent on the anchor or high-strength anchors (Grade 75, 105 or higher strength).

pretension requirements, and the engineer of record must The method is commonly used in the power industry, petro-

determine the pretension requirements. Where stacks are chemical industry and wind turbine industry. Calibrated

properly proportioned to preclude significant vibrations, hydraulic bolt pretensioners such as those manufactured by

anchor rods are typically tightened by 4 turn beyond the Boltech, Tantec and others have been used satisfactorily in

snug-tight condition. The 4 turn from snug-tight has also many applications.

been a standard industry practice for tightening of an- Torque wrench pretensioning only provides a rough

chor rods for building column base connections and static measure of anchor preload. The torque wrench method is

equipment supports. The pretension stresses obtained by a simple and easy method for field preloading. However,

tightening nuts 4 turn from snug-tight vary substantially, torque is not a reliable indicator of bolt tension and is sen-

depending on the anchor yield strength, embedment length, sitive to lubrication and condition of bolts and nuts. The

concrete strength, pitch of threads and the lubrication condi- torque coefficient used in common torque–tension relation-

tion of nuts and anchor rods. ships may vary from 0.1 to 0.3. AISC Design Guide 1 (Fish-

Thus, the level of pretension of anchor rods needed for a er and Kloiber, 2006) indicates that the coefficient is 0.12 for

given application is very much influenced by the expected common anchor rods. Others have suggested a larger value

6 / ENGINEERING JOURNAL / FIRST QUARTER / 2012

001-010_EJ1Q_2012_2010-02.indd 6 2/24/12 1:26 PM

of 0.2 for less-well-lubricated rods. For example, the torque Multiple anchor rods are used for mounting heavy equip-

needed for a pretension of 3 Fu of a 12-in.-diameter an- ment, large process vessels, cantilevered poles and tower

chor rod made of F1554 Grade 36 would be in the range of masts, and steel stacks. Anchor rods may be tightened in

408 to 680 ft-lb. If the rod is made of A193 B7 steel, the two or three stages. The three-stage tightening sequence

range will increase to 879 to 1,465 ft-lb based on the method is a more current trend in the industry, with 50% of full-

recommended by AISC Design Guide 1. Despite its inac- pretension applied to all anchors in the first stage, 90% in

curacy, the torque wrench method has been the method second stage and 100% full pretension applied in the last

of choice for many engineers for applications where the stage. Design of Anchor Bolts in Petrochemical Facilities

amount of pretension needed is either not essential or not recommends that anchor rods should be tightened in criss-

substantial. For anchor rods greater than 1 in. diameter, the cross or star pattern. Similar tightening sequence is also

torque required for anchor tightening would require the use followed in anchoring wind turbine towers.

of a slugging wrench or a hydraulic torque wrench. Installation sequence for pretensioned joints is provided

Turn-of-nut method is the easiest preloading method. It in Appendix A of AISC Design Guide 1 (Fisher and Kloiber,

gives preloads more reliable than the preceding torque wrench 2006). Due to creep and stress relaxation, anchor pretension

method. Anchor rods are first brought to the snug-tight should be monitored periodically and anchors should be

condition, followed by turning the nut from the snug-tight retightened if necessary. ACI 355.1R (ACI, 1997) reported

condition with a predetermined number of turns. The snug- that the final tension in headed anchors are typically in the

tight is generally conceived as the condition in which base range of 40 to 80% of the initial preload due to creep of

plate and grout are brought into good contact by tightening highly stressed concrete under the anchor head. The loss

nuts with a few impacts from common impact wrench. This of pretension depends on bearing stress under the anchor

is the method recommended by NCHRP Report 469 (Dex- head, concrete deformation and the anchor depth. It also re-

ter and Ricker, 2002) for tightening of the fatigue-sensitive ported that pretensioning the anchor 90 days after the initial

double-nut-moment base joints. The number of nut rotations tightening can reduce the pretension loss by more than 50%.

has been developed for double-nut-moment joints based on Anchors tightened 90 days after concrete placement then re-

extensive testing. For other pretensioned joints, the nut rota- tightened 1 year later can further reduce loss in pretension

tion required beyond the snug-tight condition is not known (80% less). For fatigue critical applications such as wind tur-

and may have to be established by testing. It is important to bine tower supports, engineers often specify that anchor rod

note that anchor rods are typically much longer than high- pretension be checked once within 6 months after anchor

strength structural bolts, varying from eight times the rod installation and every 3 years thereafter. Loosened anchors

diameter to 30 ft in length. Thus, the amount of nut rota- should be retightened with hydraulic jacking. AISC De-

tions beyond snug-tight to achieve pretension is substantially sign Guide 1 also recommends that all pretensioned anchor

larger than high-strength structural bolts. According to De- joints designed for Seismic Design Categories D, E or F be

sign of Anchor Bolts in Petrochemical Facilities (ASCE, inspected and maintained after a significant seismic event.

1997), the amount of nut rotation for the targeted pretension Where epoxy grout is used, creep under high compression

stress can be estimated by an approximate formula based can cause a significant loss in anchor bolt pretension, which

on displacement compatibility between anchor rod and nut reduces the ability of the anchor bolt to maintain high fric-

rotations. However, the amount of nut rotation for a given tional resistance to relative motion between vibrating equip-

preload estimated by the formula is often found to be too low ment and tie-downs. The effects of creep must be considered

because the compression deformation of concrete and grout in pretensioning of anchor bolts as well as in the engineering

is ignored in the approximation. Caution must be exercised of grout thickness, anchor bolt length and preload tension as

when using any approximate turn-of-nut formula. recommended by Design of Anchor Bolts in Petrochemical

Both torque wrench and turn-of-nut pretensioning method Facilities (ASCE, 1997) and PCI Design Handbook (PCI,

have been used for applications where anchor rods have a 2008).

diameter of 12-in. or smaller or where anchor rods have a

shallow embedment length (less than or equal to 15 times SPECIAL DESIGN CONSIDERATIONS

the anchor diameter). However, for anchor rods of larger

Designs of pretensioned anchor rods and regular anchor rods

diameter or greater embedment length, pretensioning by

have many common aspects. Anchor rods must be capable of

hydraulic tensioners will be more effective.

withstanding design loads (uplift tension loads, shear loads,

Aside from these three methods, load indicating mecha-

compression loads and pretension force) and allowing the

nisms, such as direct tension indicators (DTI), are getting

loads to be transferred to base plate, grout and concrete. An-

more popular. They are often used in verifying preloads

chor rods should possess adequate strength to guard against

installed by torque wrench and turn-of-nut method. They

bolt tensile failure and concrete pull out failure. Anchor

serve as an alternative means to hydraulic jacking to achieve

rods located near the edge of concrete piers or foundations

accurate pretension desired.

ENGINEERING JOURNAL / FIRST QUARTER / 2012 / 7

001-010_EJ1Q_2012_2010-02.indd 7 2/24/12 1:26 PM

should be designed for possible lateral (side) bursting fail- number of recent wind turbine foundation applications

ure. ACI 318 Appendix D (ACI, 2005) and AISC Design required the use of 12,000-psi grout and 7,000-psi

Guide 1 (Fisher and Kloiber, 2006) provide excellent provi- concrete.

sions/guidelines for design of nonpretensioned base plates

• Friction due to anchor pretension is available for shear

and anchor rods.

resistance. As a result, shear lugs are not often used in

There are, however, a few design aspects in which pre-

pretensioned anchors. According to Design of Anchor

tensioned anchors differ from nonpretensioned anchors

Bolts in Petrochemical Facilities, friction resistance

and would require special consideration. These include the

may also be considered for seismic shear if anchor

following:

rods are pretensioned to twice the seismic uplift force,

• Pretensioned anchors should have adequate fatigue except that no more than 50% of friction resistance

strength to resist cyclic loads (see Example 1), and should be provided by pretension.

bolt forces due to pry action should be included in the

fatigue evaluation. SELECTED EXAMPLES OF

• Embedment plate, sleeve and base plate should have PRETENSIONED ANCHOR APPLICATIONS

adequate static strength and stiffness for anchors with Example 1

large pretension as discussed in Design of Anchor

Bolts in Petrochemical Facilities (ASCE, 1997). This example involves the design of a spread footing with a

central pedestal to support a wind turbine tower as shown in

• Grout and concrete supporting base plates and anchors Figure 2. The turbine tower is anchored to the concrete ped-

are susceptible to localized bearing damage and con- estal via a base ring plate and 140 high-strength anchor rods.

crete splitting cracks when pretension force is high. A Anchor rods are to be fabricated from No. 10 A615 Grade

Fig. 2. Sketch of wind turbine foundation and tower anchorage to foundation for Example 1.

8 / ENGINEERING JOURNAL / FIRST QUARTER / 2012

001-010_EJ1Q_2012_2010-02.indd 8 2/24/12 1:26 PM

75 threaded bars. The anchor rods are arranged in two con- forces during their service life, and tensile fatigue of anchor

centric circles with 70 anchor rods evenly spaced along each rods is unlikely. Conversely, the tensile fatigue resistance

bolt circle. The diameter of the inner bolt circle is 13 ft 6 in.; of anchor rods should be evaluated for the other two cases

the diameter of the outer bolt circle is 14 ft 6 in. The tower where lower anchor pretension loads are selected.

anchorage is designed for an unfactored wind moment, Mw, According to the turbine manufacturer for this project, the

of 25,747 kip-ft, a horizontal shear load (V) of 118 kips, and turbine tower is expected to experience a mean overturning

a dead load, P, of 415 kips. In addition, the turbine manufac- moment of 10,873 kip-ft and a fatigue damage equivalent cy-

turer requires the anchorage to have adequate fatigue resis- clic moment range of 30,393 kip-ft at 1,000,000 cycles using

tance against operating load spectra with cyclic overturning a method recommended by Guidelines for Design of Wind

moment changes from nominal to a value as large as the de- Turbines (DNV/RSO, 2002). Therefore, the anchor rods will

sign wind moment. A complete design of this wind turbine be stressed to a tensile stress 1.3% higher than the initial

foundation will require a geotechnical evaluation, a static pretension at the maximum cyclic moment if pretension is

strength design, a structural stability analysis, a foundation set at 57 kips. Thus, the anchor rods should have adequate

dynamic stiffness analysis, and a static and fatigue strength fatigue strength. However, the anchor rods will be stressed

of anchorage. However, the focus of this example is limited to a maximum tensile stress 37.4% higher than the initial

to the determination of anchor rod pretension only. pretension if the anchor rod pretension load is set at 42 kips.

Note that Grade 75 threaded bars are the anchor rods most The tensile stress range is therefore equal to (0.374)(3)(100

commonly used in the wind turbine industry, although their ksi) = 12.5 ksi.

use at building column base is rare. The material has ex- Per AISC Specification (AISC, 2005) and ACI 351.3R-04

cellent strength: Fy = 75 ksi (minimum yield strength) and (ACI, 2004), the allowable stress range of the anchor rods

Fu = 100 ksi (minimum tensile strength) and excellent bond can be determined as follows:

strength to concrete. Grade 75 threaded rods are available

in many diameters (w to 32 in.) and in lengths up to 50 ft. 0.333

Cf

The net tensile area at the threads of a No. 10 threaded bar Fsr = ≥ 7 ksi = fatigue threshold

N

is 1.27 in.2

First, the maximum uplift force in anchor rods, Tb, due to

unfactored design moment can be estimated by the follow- where

ing approximation equation given by ASME STS-1 2006:

Cf = fatigue constant = 3.90 × 108

4 Mw P V N = 1,000,000 cycles

Tb = − +

NDb N (friction coefficient at grout × N ) 0.333

3.90 × 108

Fsr = = 7.3 ksi

1, 000, 000

where

Db = average diameter of the inner and outer bolt

The tensile stress range of 12.5 ksi from the operating

circles

load spectra will exceed the above allowable stress range by

N = number of anchor rods 70%. Therefore, the pretension of 42.0 kips is too low and

has to be adjusted to a higher value.

4 ( 25, 747 kip-ft ) 415 kips 118 kips

Tb = − + Note that the effective pretension in anchor rods with

(140 )(14 ft ) 140 ( 0.55) (140 ) an initial tension of 57.1 kips will decrease to 42.8 kips if

= 51.3 kips a 25% loss is considered. Hence, anchor rods with an ini-

tial pretension of 57.1 kips may not have adequate fatigue

strength unless the anchor tension is periodically monitored

A more accurate determination can be made on the basis and readjusted.

of moment of inertia considering exact locations of anchor This example shows that the fatigue strength of anchor

rods. Maximum tension in the outer anchor rods is 57.1 kips. rods is sensitive to anchor pretension. A proper selection of

There is no unique way for prescribing the pretension initial pretension is critical to the long-term fatigue perfor-

loads. One can set the pretension in the anchor rods equal to mance of wind sensitive structures.

57.1 kips (45% of the tensile strength of the rod) or 72.4 kips

at the factored moment (57% of the tensile strength of the Example 2

rod), or at a pretension of 42.0 kips (which is close to one- A compressor weighing 600 kips is supported on a con-

third of the rod tensile strength). If the pretension is set at crete block foundation via soleplate and epoxy grout. The

72.4 kips, the anchor rods will not be subjected to net uplift compressor is expected to produce a maximum dynamic

ENGINEERING JOURNAL / FIRST QUARTER / 2012 / 9

001-010_EJ1Q_2012_2010-02.indd 9 2/24/12 1:26 PM

horizontal force of 200 kips. Assume the machine will re- ACI (2005), Building Code Requirements for Structural

quire a total of eight 1w-in.-diameter anchor bolts and the Concrete and Commentary, ACI 318-05, American Con-

coefficient of friction at the critical interface is 0.15. This crete Institute, Farmington Hills, MI.

example will determine the preload tension required in the AISC (2005), Specification for Structural Steel Buildings,

anchor bolts and the bolt material required. American Institute of Steel Construction, Chicago, IL.

To avoid slippage under dynamic loads at any interface,

ASCE (2005), Minimum Design Loads for Buildings and

the friction force, F, at any interface between the compressor

Other Structures, ASCE/SEI 7-05, American Society of

frame and soleplate, or soleplate and epoxy grout, or grout

Civil Engineers, Reston, VA.

and foundation top surface must exceed the maximum hori-

zontal dynamic force, Hmax: ASCE (1997), Design of Anchor Bolts in Petrochemical

Facilities, Task Committee on Anchor Bolts, American

F = C f ( Wm + NTmin ) ≥ H max Society of Civil Engineers, New York, NY.

ASME (2006), Steel Stacks, STS-1 2006, American Society

of Mechanical Engineers, New York, NY.

where Dexter, R.J. and Ricker, M.J. (2002), “Fatigue-Resistant

Cf = friction coefficient = 0.15 Design of Cantilevered Signal, Sign and Light Supports,”

National Cooperative Highway Research Program

Tmin = minimum preload tension (NCHRP) Report 469, Transportation Research Board,

Wm = machine weight = 600 kips Washington, DC.

DNV/RSO (2002), Guidelines for Design of Wind Turbines,

Hmax = maximum horizontal load = 200 kips

Second Edition, Denmark.

N = number of bolts = 8 Fisher, J.M. and Kloiber L.A. (2006), Design Guide Series

No. 1: Base Plate and Anchor Rod Design, 2nd edition,

H max C f − Wm 2nd printing, American Institute of Steel Construction,

Tmin =

N Chicago, IL.

( 200 kips 0.15 ) − ( 600 kips ) Frank, K.H. (1980), “Fatigue Strength of Anchor Bolts,”

=

8 Journal of Structural Division, ASCE, Vol. 106, No. 6,

= 91.7 kips pp. 1279–1293.

Hodge, J.B. (1996), “Fatigue Analysis of High Mast Lumi-

naire Anchor Bolts,” MS Thesis, Texas A&M University,

Because the recommended clamping force is 150% of the College Station, TX.

required value, the minimum pretension is 137.5 kips. The

Kaczinski, M.R., Dexter, R.J. and Van Dien, J.P. (1996),

bolt stress due to pretension is 137,500 lb/1.90 in.2 = 72,368

“Fatigue-Resistant Design of Cantilevered Signal, Sign

psi, where net tensile area of anchor rod is 1.90 in.2 Per ACI

and Light Supports,” National Cooperative Highway Re-

351.3R, the ratio of prestress to yield stress should be be-

search Program (NCHRP) Report 412, Transportation

tween 0.15 and 0.8. Thus, the minimum required yield stress

Research Board, Washington, DC.

of anchor bolts is 72,368 psi/0.8 = 90,460 psi.

Select ASTM A193 B7 anchor bolts, which have a mini- PCI (2008), PCI Design Handbook, 7th edition, Precast/

mum yield strength of 105 ksi. Prestressed Concrete Institute, Chicago, IL.

Richards J.H. (2004), “Turn-of-the-nut Tightening of An-

REFERENCES chor Bolts,” MS Thesis, Texas A&M University, College

Station, TX.

ACI (1997), “Report on Anchorage to Concrete,” ACI

355.1R-91, reapproved 1997, American Concrete Institute, Van Dien, J.P. Kaczinski, M.R., and Dexter, R.J. (1996), “Fa-

Farmington Hills, MI. tigue Testing of Anchor Bolts,” Proceedings of the 14th

Structural Congress, American Society of Civil Engi-

ACI (2004), Foundations for Dynamic Equipment, ACI

neers, Reston, VA, pp. 337–344.

351.3R-04, American Concrete Institute, Farmington

Hills, MI.

10 / ENGINEERING JOURNAL / FIRST QUARTER / 2012

001-010_EJ1Q_2012_2010-02.indd 10 2/24/12 1:26 PM

You might also like

- On Drift Limits Associated With Different Damage Levels: June 2004Document13 pagesOn Drift Limits Associated With Different Damage Levels: June 2004RaviKanthSrivastavNo ratings yet

- Lateral Loads of 4 Level Shelving, With Hilti Anchorage, Based On ASCE 7-16Document12 pagesLateral Loads of 4 Level Shelving, With Hilti Anchorage, Based On ASCE 7-16kosdsdsNo ratings yet

- Bridge Technical NoteDocument5 pagesBridge Technical Noteপ্রিয়দীপ প্রিয়মNo ratings yet

- Analysis and Design of Prestressed Concrete SleepersDocument25 pagesAnalysis and Design of Prestressed Concrete SleeperspoezpietaNo ratings yet

- GW Byun Comparision Geotech Softwares PDFDocument52 pagesGW Byun Comparision Geotech Softwares PDFManiNo ratings yet

- Liquid Loads on a Tank Wall using PCA TablesDocument1 pageLiquid Loads on a Tank Wall using PCA TablesKevin YewNo ratings yet

- 4 Optimum Prestress of Tanks With Pinned BaseDocument6 pages4 Optimum Prestress of Tanks With Pinned BaseCarlotaGomesNo ratings yet

- Use of Flat Slabs in Multi-Storey Commercial Building Situated in High Seismic ZoneDocument14 pagesUse of Flat Slabs in Multi-Storey Commercial Building Situated in High Seismic ZoneZimit SukhadiaNo ratings yet

- Bridge vibration analysisDocument208 pagesBridge vibration analysisVan Cuong PhamNo ratings yet

- Shear Strength of Reinforced Concrete Beams Under Uniformly Distributed LoadsDocument10 pagesShear Strength of Reinforced Concrete Beams Under Uniformly Distributed LoadsMoataz M. M. Rizk100% (1)

- Elastomeric Bearing - Full Details PDFDocument11 pagesElastomeric Bearing - Full Details PDFm.ispasNo ratings yet

- Design of Partially Prestressed Concrete Beams Based On The CrackingDocument15 pagesDesign of Partially Prestressed Concrete Beams Based On The Crackingamino222No ratings yet

- 38 1 011-FundamentalsOfBeamBracing-YuraDocument16 pages38 1 011-FundamentalsOfBeamBracing-YuraengxyzNo ratings yet

- Sharma Et Al-2017-Structural Concrete As PublishedDocument9 pagesSharma Et Al-2017-Structural Concrete As PublisheddebiNo ratings yet

- VSL Strand Post Tensioning Systems Technical Catalogue - 2019 01Document55 pagesVSL Strand Post Tensioning Systems Technical Catalogue - 2019 01Frederick NaplesNo ratings yet

- Evaluation of Minimum Shear Reinforcement Requirements For Higher Strength ConcreteDocument9 pagesEvaluation of Minimum Shear Reinforcement Requirements For Higher Strength ConcreteHuda JawadNo ratings yet

- PT55 Article Seismic Considerations For New Quay CranesDocument3 pagesPT55 Article Seismic Considerations For New Quay Cranesalfatih1407497No ratings yet

- Management of Fatigue Cracking on Melbourne's Iconic West Gate BridgeDocument9 pagesManagement of Fatigue Cracking on Melbourne's Iconic West Gate BridgeAVSSSNo ratings yet

- Shear Strength of Reinforced Concrete Deep BeamsDocument4 pagesShear Strength of Reinforced Concrete Deep Beamsnevinkoshy100% (1)

- EC2 Strut and Tie DesignDocument69 pagesEC2 Strut and Tie DesignWai Hoong EngNo ratings yet

- Shear Behavior of Thick Slabs-ACIDocument12 pagesShear Behavior of Thick Slabs-ACIJoão Paulo MendesNo ratings yet

- Allowable Tensile Stress For Webs of Prestressed Segmental Concrete BridgesDocument8 pagesAllowable Tensile Stress For Webs of Prestressed Segmental Concrete BridgesShikhar SinghNo ratings yet

- Evaluation and Repair of Bridge Truss Gusset PlatesDocument16 pagesEvaluation and Repair of Bridge Truss Gusset PlatesLAM CONo ratings yet

- ACI 313R-97: Reported by ACI Committee 313Document20 pagesACI 313R-97: Reported by ACI Committee 313DIDIER ANGEL LOPEZ RINCONNo ratings yet

- Concept of STM Paper ACIDocument9 pagesConcept of STM Paper ACIshish0iitrNo ratings yet

- LEMESSURIER'S SECOND-ORDER ANALYSISDocument18 pagesLEMESSURIER'S SECOND-ORDER ANALYSISอภิรักษ์ มานะกิจศิริสุทธิNo ratings yet

- Seismic Design of Multi-Tiered Steel Braced Frames Including Gravity ColumnsDocument21 pagesSeismic Design of Multi-Tiered Steel Braced Frames Including Gravity ColumnsDiego Matias Burgos FuentesNo ratings yet

- Design and Analysis of Heavily Loaded RC Link BeamDocument17 pagesDesign and Analysis of Heavily Loaded RC Link BeamWasin WaiyasusriNo ratings yet

- The Analysis and Design of and The Evaluation of Design Actions For Reinforced Concrete Ductile Shear Wall StructuresDocument36 pagesThe Analysis and Design of and The Evaluation of Design Actions For Reinforced Concrete Ductile Shear Wall StructuresmamandaweNo ratings yet

- Bda - 4 CaltransDocument20 pagesBda - 4 CaltransalbertoxinaNo ratings yet

- ASCE Intermediate Diaphragms SC.1943-5576.0000272Document10 pagesASCE Intermediate Diaphragms SC.1943-5576.0000272jrhst36100% (1)

- Alberta Infrastructure Bridge AestheticsDocument70 pagesAlberta Infrastructure Bridge AestheticsShikhar SinghNo ratings yet

- Concrete Construction Article PDF - Mechanical vs. Lap SplicingDocument4 pagesConcrete Construction Article PDF - Mechanical vs. Lap SplicingGilven MedinaNo ratings yet

- Stonecutters BridgeDocument20 pagesStonecutters BridgeMarcos MorrisonNo ratings yet

- Don't Put Welds in BendingDocument2 pagesDon't Put Welds in BendingRune OveraasNo ratings yet

- Evaluating Structural Buildup at Rest of Self-Consolidating Concrete Using Workability TestsDocument10 pagesEvaluating Structural Buildup at Rest of Self-Consolidating Concrete Using Workability TestsHuaman Chavez Jesus AngelNo ratings yet

- (1963) Housner - The Bevavior of Inverted Pendulum Strtuctures During EarthquakesDocument15 pages(1963) Housner - The Bevavior of Inverted Pendulum Strtuctures During EarthquakesEdison GuzmanNo ratings yet

- Poulos Randolph 1983Document16 pagesPoulos Randolph 1983Enrique BarragánNo ratings yet

- Assessing Lateral Period of Building Frames Incorporating Soil-Flexibility by K.bhattacharya & S.C.duttaDocument27 pagesAssessing Lateral Period of Building Frames Incorporating Soil-Flexibility by K.bhattacharya & S.C.duttaNITBEHL77No ratings yet

- Prestressed Concrete Bridges With External PrestressingDocument9 pagesPrestressed Concrete Bridges With External PrestressingAsif HameedNo ratings yet

- ETCulvert V2 Brochure Web PDFDocument2 pagesETCulvert V2 Brochure Web PDFjorgesalinasengNo ratings yet

- Fib Model Code For Concrete Structures 2010:: Mastering Challenges and Encountering New OnesDocument7 pagesFib Model Code For Concrete Structures 2010:: Mastering Challenges and Encountering New Onesgsmrbharath_91No ratings yet

- Serviceability Behavior and Failure Mechanisms of Concrete Inverted T-Beam Bridge BentcapsDocument11 pagesServiceability Behavior and Failure Mechanisms of Concrete Inverted T-Beam Bridge BentcapspicottNo ratings yet

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDocument12 pagesThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelNo ratings yet

- Ramset AnchorsDocument60 pagesRamset Anchorsmercab15No ratings yet

- Designing Floor Openings in Two-Way Concrete SlabsDocument4 pagesDesigning Floor Openings in Two-Way Concrete SlabsnrnnadigNo ratings yet

- Errata: Transportation OfficialsDocument24 pagesErrata: Transportation OfficialsHector Enrique Reza ReyesNo ratings yet

- Study of Shear Wall With Circular Core Compared To Conventional Shear WallDocument8 pagesStudy of Shear Wall With Circular Core Compared To Conventional Shear WallTI Journals PublishingNo ratings yet

- Metric Threaded Inserts: Design GuideDocument26 pagesMetric Threaded Inserts: Design GuideKesavan DhuraiNo ratings yet

- As 1141.42-1999 Methods For Sampling and Testing Aggregates Pendulum Friction TestDocument2 pagesAs 1141.42-1999 Methods For Sampling and Testing Aggregates Pendulum Friction TestSAI Global - APACNo ratings yet

- Design of Curved Spliced Precast Concrete UBeam BridgesDocument284 pagesDesign of Curved Spliced Precast Concrete UBeam Bridgesmekkawi6650No ratings yet

- Minimum Shear Reinforcement in Normal, Medium, and High-Strength Concrete BeamsDocument9 pagesMinimum Shear Reinforcement in Normal, Medium, and High-Strength Concrete BeamsHuda JawadNo ratings yet

- Optimum Design of Launching Nose During Incremental Launching Construction of Same Span Continuous BridgeDocument6 pagesOptimum Design of Launching Nose During Incremental Launching Construction of Same Span Continuous BridgePenyair SufiNo ratings yet

- Elastomeric BearingsDocument20 pagesElastomeric Bearingsalperen52No ratings yet

- Kanis-The Riddle of Shear Failure and Its SolutionDocument28 pagesKanis-The Riddle of Shear Failure and Its SolutionHarish Kant SoniNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- NetKey GuideDocument9 pagesNetKey GuideMuhammad RizwanNo ratings yet

- Introducing The New Generation Hardox Wear PlateDocument2 pagesIntroducing The New Generation Hardox Wear PlateAndré Luiz NogueiraNo ratings yet

- Technical Data Sheet For HVU2 Adhesive Capsule With Rods Technical Information ASSET DOC 8000652Document17 pagesTechnical Data Sheet For HVU2 Adhesive Capsule With Rods Technical Information ASSET DOC 8000652Kovacs Zsolt-IstvanNo ratings yet

- Advance Steel BIM WorkflowDocument34 pagesAdvance Steel BIM WorkflowAndré Luiz NogueiraNo ratings yet

- Technical Data Sheet For Hilti HIT HY 170 Injectable Mortar For Anchors in Concrete and Masonry Technical Information ASSET DOC 4398553Document42 pagesTechnical Data Sheet For Hilti HIT HY 170 Injectable Mortar For Anchors in Concrete and Masonry Technical Information ASSET DOC 4398553Kovacs Zsolt-Istvan100% (1)

- AgaDocument6 pagesAgaAndré Luiz NogueiraNo ratings yet

- Easy Maintenance Retractable Idler: Video LinksDocument1 pageEasy Maintenance Retractable Idler: Video LinksAndré Luiz NogueiraNo ratings yet

- NetKey GuideDocument9 pagesNetKey GuideMuhammad RizwanNo ratings yet

- Column BaseplateDocument1 pageColumn BaseplateAndré Luiz NogueiraNo ratings yet

- SIM Full PDFDocument136 pagesSIM Full PDFjohn ed villasisNo ratings yet

- AfafafDocument3 pagesAfafafAndré Luiz NogueiraNo ratings yet

- Cen-Tc135 Clarification of Scope of en 1090-1Document4 pagesCen-Tc135 Clarification of Scope of en 1090-1bollascribdNo ratings yet

- BS 7608-2014 Guide To Fatigue Design and Assessment of Steel ProductsDocument152 pagesBS 7608-2014 Guide To Fatigue Design and Assessment of Steel ProductsAndré Luiz Nogueira86% (7)

- NSK CAT E1254f 184-188 PDFDocument3 pagesNSK CAT E1254f 184-188 PDFSavio FernandesNo ratings yet

- 5187901TechArticleWebDocLR PDFDocument7 pages5187901TechArticleWebDocLR PDFoggay94No ratings yet

- Base Plate ClassificationDocument3 pagesBase Plate ClassificationAndré Luiz NogueiraNo ratings yet

- Frederick PDFDocument56 pagesFrederick PDFAndré Luiz NogueiraNo ratings yet

- Catalog Paulstra Industry 2019 PDFDocument378 pagesCatalog Paulstra Industry 2019 PDFAndré Luiz NogueiraNo ratings yet

- XDT GB (10-10) PDFDocument2 pagesXDT GB (10-10) PDFAndré Luiz NogueiraNo ratings yet

- Calculate locking assembly dimensions for belt drum RF7015Document2 pagesCalculate locking assembly dimensions for belt drum RF7015André Luiz NogueiraNo ratings yet

- Substantiation of Parameters and Calculation of Vibration IsolatorsDocument8 pagesSubstantiation of Parameters and Calculation of Vibration IsolatorsAndré Luiz NogueiraNo ratings yet

- Apron FeederDocument4 pagesApron FeederAmérico Arone HuamaníNo ratings yet

- 9130643652638.pdf Mime Application/pdf&realname BIM LR+revCANDocument4 pages9130643652638.pdf Mime Application/pdf&realname BIM LR+revCANAndré Luiz NogueiraNo ratings yet

- 318-08 5th PrintingDocument1 page318-08 5th PrintingAndré Luiz NogueiraNo ratings yet

- 07 Delta Range: Construction BenefitsDocument2 pages07 Delta Range: Construction BenefitsAndré Luiz NogueiraNo ratings yet

- ISO 10684 Hot Dip Galvanized Fasteners PDFDocument27 pagesISO 10684 Hot Dip Galvanized Fasteners PDFAndré Luiz NogueiraNo ratings yet

- 07 Delta Range: Construction BenefitsDocument2 pages07 Delta Range: Construction BenefitsAndré Luiz NogueiraNo ratings yet

- Vibration Isolation - SimmonsDocument12 pagesVibration Isolation - SimmonsJoão Cavalcanti100% (1)

- Damage Identification of Belt Conveyors Using Periodic and Isolated Local Vibration ModesDocument250 pagesDamage Identification of Belt Conveyors Using Periodic and Isolated Local Vibration ModesAndré Luiz NogueiraNo ratings yet

- Gateway A2 Test 1BDocument3 pagesGateway A2 Test 1BNewteacher29100% (6)

- September/News/Septiembre 2013: P.O. Box 44 WWW - Hecatomberecords.esDocument7 pagesSeptember/News/Septiembre 2013: P.O. Box 44 WWW - Hecatomberecords.eshecatomberecordsNo ratings yet

- Delta ABAP Workbench 4.0 To 4.6Document313 pagesDelta ABAP Workbench 4.0 To 4.6aurber2013No ratings yet

- Late 18th and Early 19thDocument82 pagesLate 18th and Early 19thGrace CordelinNo ratings yet

- IN THE COURT OF - SUIT/APPEAL No. - JURISDICTION OF 2017Document1 pageIN THE COURT OF - SUIT/APPEAL No. - JURISDICTION OF 2017Adv Pooja AroraNo ratings yet

- B IngDocument2 pagesB IngsyfnanyNo ratings yet

- Pas 220Document71 pagesPas 220JuwitaNo ratings yet

- Sindhi 2020Document1 pageSindhi 2020Engr Javed AkhtarNo ratings yet

- Art of Public Speaking 11th Edition Lucas Test BankDocument25 pagesArt of Public Speaking 11th Edition Lucas Test BankBryanMillernicy100% (49)

- MEM05 Header R8.1Document388 pagesMEM05 Header R8.1andysupaNo ratings yet

- 285519-35126-30-case-studyDocument12 pages285519-35126-30-case-studyapi-737834018No ratings yet

- Trauma-Informed CounselingDocument1 pageTrauma-Informed Counselingapi-492010604No ratings yet

- Handout-Wisdom QuestionsDocument1 pageHandout-Wisdom Questionsapi-369459770No ratings yet

- Unit 10 Conic Sections ProjectDocument8 pagesUnit 10 Conic Sections Projectapi-290873974No ratings yet

- Race, Gender, and the Politics of Visible IdentityDocument21 pagesRace, Gender, and the Politics of Visible IdentityrebenaqueNo ratings yet

- Popular Telugu Novel "Prema DeepikaDocument2 pagesPopular Telugu Novel "Prema Deepikasindhu60% (5)

- Wonder Woman: Directed byDocument4 pagesWonder Woman: Directed byRoxana Ioana DumitruNo ratings yet

- Breakfast For Kirsten GillibrandDocument5 pagesBreakfast For Kirsten GillibrandSunlight FoundationNo ratings yet

- Sec. Gr. To BT History Temp Panel 2013Document50 pagesSec. Gr. To BT History Temp Panel 2013edwin_prakash75No ratings yet

- 100 transaction cycle in VisionPLUS banking systemDocument7 pages100 transaction cycle in VisionPLUS banking systemGoushik Balakrishnan100% (1)

- KCIS 2nd Semester Science Fair ProjectsDocument2 pagesKCIS 2nd Semester Science Fair ProjectsCaT BlAcKNo ratings yet

- Dell M1000e Install Admin TroubleshootingDocument78 pagesDell M1000e Install Admin Troubleshootingsts100No ratings yet

- CECB School Profile 23122020 1Document6 pagesCECB School Profile 23122020 1Anas SaadaNo ratings yet

- Lesson 7Document29 pagesLesson 7Khelly Joshua UyNo ratings yet

- Chapter 3 The Life of Jose Rizal PDFDocument11 pagesChapter 3 The Life of Jose Rizal PDFMelanie CaplayaNo ratings yet

- UntitledDocument421 pagesUntitledtunggal KecerNo ratings yet

- CAE Proposal Expressions and SamplesDocument6 pagesCAE Proposal Expressions and SamplesKimLiênNguyễnNo ratings yet

- Course Registration Slip MBA 2023Document3 pagesCourse Registration Slip MBA 2023Piyush RaghuwanshiNo ratings yet

- Royalstone ReadmeDocument2 pagesRoyalstone ReadmeAdnan BrianNo ratings yet

- Alcyone - Nietzsche On Gifts, Noise, and Women by Gary ShapiroDocument4 pagesAlcyone - Nietzsche On Gifts, Noise, and Women by Gary Shapirotaimur_orgNo ratings yet