Professional Documents

Culture Documents

Membrane Pilot Unit Labbrain V3: Technical Data Cfu-Labbrain-Ver3

Uploaded by

Gabriel Montoya CorreaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Membrane Pilot Unit Labbrain V3: Technical Data Cfu-Labbrain-Ver3

Uploaded by

Gabriel Montoya CorreaCopyright:

Available Formats

FUTURE

MEMBRANE PILOT UNIT

LABBRAIN V3

The LabBrain pilot unit is designed for the CoMem membrane elements which includes

OD25x305/1016/1178mm, Hexa 28/31x1020mm* and Hexa 43/38x1020mm*.

Technical Data CFU-LABBRAIN-VER3

Test element (not included) OD25x305mm

(Standard configuration)

Feed pump capacity 1.5 m3/h / 6.6 gpm

Cross flow pump capacity 5 m3/h / 22 gpm

Valves Bürkert

Pump Grundfos

Piping Stainless Steel AlSl316L

Housing/ permeate tank Stainless Steel AlSl316L

PLC/transmitters Siemens

Temperature tolerance 85˚C / 185˚F

BPH maximum air pressure 6 bar / 87 psi

Power connection P+N+PE 230 V

Unit dimensions (LxWxH) 1500x932x945mm

4.9x3.0x3.1ft

Weight 125 kg / 275 lbs

*requires housing extension set

FUNCTION AND DESIGN

The LabBrain is a small and flexible unit design for pilot testing CoMem OD25mm elements and hexagonal

CoMem Hexa elements. With a volume of no more than one and a half cubic meter it can easily be

transported around and it is therefore ideal for on site testing.

The LabBrain pilot unit is equipped with a feed pump which pressurizes the system and a cross flow pump

which generates the cross-flow over the membrane element. The membrane can be operated both cross

flow and semi-dead end. In addition, the test unit is equipped with a Back Pulse Hammer (BPH). The BPH

system is a pulse generator, which delivers high frequency “block” pulses, from the permeate side, back

through the membrane in order to keep the membrane clean and free of foulants.

Transmitters and indicators makes it possible to measure and log the following data:

Pressure: at feed, retentate and permeate side of the membrane

Temperature: at retentate side of the membrane

Flow: the incoming feed flow, cross flow velocity and permeate flow

All data from pressure transmitters, flow transmitters, temperature

transmitter, pump settings and actual valve positions are stored in the

internal memory of the unit. The data can be reached by an USB port in

the unit. All features are displayed and be operated from the coloured

touch pad. Historical data and graphs can be presented on the screen.

The touch screen is connected to the skid by wire, which enables the

operator to place the unit on the floor, while operating from a laboratory HMI colour touch screen

desk or table.

ve r. 1 3 0 6 2 0 1 4

FUTURE

The PLC is preprogrammed with the following options: automatic backwash, automatic back pulse,

automatic semi-dead end operation, chemical enhanced backwash (CEB), automatic constant recovery

factor, constant permeate production etc.

Key properties of the lab scale unit:

Automated filtration modes (constant flow or constant pressure) – saves man hours to

adjust valves and eliminates human errors

Feed pump and cross flow pump for control of pressure and cross flow velocity independtly

Automated back-flush and back pulse procedures

Can run high recovery rate

Data logging of all vital parameters

Remote access (internet) to follow operation

Automatic shutdown for safety reasons

Small footprint/weight

Can be used for testing in laboratories and on-site

For operating manual please contact LiqTech

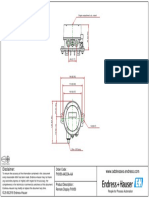

DIMENSIONS

Top-view

3D-view

Side-view

ve r. 1 3 0 6 2 0 1 4

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Ficha Tecnica de FermentadorDocument4 pagesFicha Tecnica de FermentadorOmar Yahen Reyes MedinaNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- AMS ANALITICA-AIRFLOW PUF BrochureDocument2 pagesAMS ANALITICA-AIRFLOW PUF BrochureShady HellaNo ratings yet

- Lachrom Elite: Hitachi High-Performance Liquid ChromatographDocument10 pagesLachrom Elite: Hitachi High-Performance Liquid ChromatographNaveen KamatNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Wax inhibitor testing loopDocument2 pagesWax inhibitor testing loopVu Van KhacNo ratings yet

- SUNpH Neutralisation Systems 2019 PDFDocument4 pagesSUNpH Neutralisation Systems 2019 PDFMAHENDAR SINGHNo ratings yet

- BRO3001 Hivol3000Document2 pagesBRO3001 Hivol3000documentos.envirotestNo ratings yet

- Cogent Ultrafiltración GrandeDocument6 pagesCogent Ultrafiltración GrandejmviaderNo ratings yet

- Product Specification: Model RefDocument6 pagesProduct Specification: Model RefHermawan HerryNo ratings yet

- AMS ANALITICA-AIRFLOW TSP-HVS BrochureDocument1 pageAMS ANALITICA-AIRFLOW TSP-HVS BrochureShady HellaNo ratings yet

- X10 X50 Data Sheet en E 0Document10 pagesX10 X50 Data Sheet en E 0Widayat WahyuNo ratings yet

- Pilodist: Petrodist 400 CCDocument7 pagesPilodist: Petrodist 400 CCWaheed ZebNo ratings yet

- High throughput closed microwave digestion system with 12 vessel capacityDocument6 pagesHigh throughput closed microwave digestion system with 12 vessel capacitywidyawatiNo ratings yet

- BF610Document4 pagesBF610Prasad KulkarniNo ratings yet

- High Pressure Cleaning MachinesDocument6 pagesHigh Pressure Cleaning MachinesNIKOSNo ratings yet

- Walchem Pump IX Series Brochure, IXC060, IXC150Document4 pagesWalchem Pump IX Series Brochure, IXC060, IXC150PromagEnviro.comNo ratings yet

- Life Support Test Facility LSTF100Document3 pagesLife Support Test Facility LSTF100Bojana MarinkovicNo ratings yet

- In-Situ Fermentors CatalogueDocument4 pagesIn-Situ Fermentors CatalogueVineet GuptaNo ratings yet

- Usg - 10060456 1.0Document228 pagesUsg - 10060456 1.0sahtekir0% (1)

- Maximum Adaptability: Electromagnetic Dosing PumpsDocument6 pagesMaximum Adaptability: Electromagnetic Dosing PumpsÁrpád VassNo ratings yet

- Reliance 380PG Pharmaceutical Grade Washer Technical DataDocument7 pagesReliance 380PG Pharmaceutical Grade Washer Technical DataNirbhayNo ratings yet

- KYMC Coating and Laminating Presses Offer Fully Automatic OperationDocument6 pagesKYMC Coating and Laminating Presses Offer Fully Automatic OperationValli MuthuNo ratings yet

- Infusion Pump 1Document27 pagesInfusion Pump 1Revati RadakisninNo ratings yet

- c221 E3490d Uh SeriesDocument20 pagesc221 E3490d Uh SeriesKokYee Chan100% (1)

- Versatile Hospital SterilizerDocument8 pagesVersatile Hospital Sterilizermohd shuib abd rahmanNo ratings yet

- AutoclaveDocument2 pagesAutoclaveSaif AliNo ratings yet

- Walchem Pump EH-HV Series Brochure, EWN, EHE35E1, EHE35E2Document2 pagesWalchem Pump EH-HV Series Brochure, EWN, EHE35E1, EHE35E2PromagEnviro.comNo ratings yet

- IV Infusion Pump, AMPALL: DescriptionDocument6 pagesIV Infusion Pump, AMPALL: DescriptionFem CruzNo ratings yet

- Vibronic Point Level Detection Liquiphant FTL50HDocument5 pagesVibronic Point Level Detection Liquiphant FTL50HPham Thien TruongNo ratings yet

- JESCO Product Range 48 2007Document16 pagesJESCO Product Range 48 2007Victor VignolaNo ratings yet

- FWT GENERAL CATALOGUE ENG Rev.1 - 1118 PRINT PDFDocument8 pagesFWT GENERAL CATALOGUE ENG Rev.1 - 1118 PRINT PDFPhilip Eusebio BitaoNo ratings yet

- Rapiline User ManualDocument216 pagesRapiline User ManualOlivier Martin67% (3)

- Partisol-Plus 2025Document2 pagesPartisol-Plus 2025bogdanberchiNo ratings yet

- BF3000Document6 pagesBF3000Jokanoe LertNo ratings yet

- ZZ - 1207652196 - Fast Loop Sampling System Specification-R2 PDFDocument4 pagesZZ - 1207652196 - Fast Loop Sampling System Specification-R2 PDFJohn PaulNo ratings yet

- Blastmate IIIDocument2 pagesBlastmate IIIHinawan Teguh SantosoNo ratings yet

- PROBHeDocument7 pagesPROBHeFernando BatistaNo ratings yet

- Vacuum KDocument6 pagesVacuum KSylvain AguedaNo ratings yet

- Universal Testing MachineDocument4 pagesUniversal Testing MachineTomy GeorgeNo ratings yet

- Space System Technical DataDocument7 pagesSpace System Technical DataMhini Baba JayNo ratings yet

- Air Filter Performance Test Bench - Specification (HCTE) 20221028Document5 pagesAir Filter Performance Test Bench - Specification (HCTE) 20221028Alberto SanchezNo ratings yet

- B) Galileo TP - Leak Test LineDocument2 pagesB) Galileo TP - Leak Test LinenairnavkrishNo ratings yet

- HiVol 3000Document2 pagesHiVol 3000Edwin E. YucraNo ratings yet

- Programma EGIL Circuit Breaker Analyzer Tests Up to 240kVDocument4 pagesProgramma EGIL Circuit Breaker Analyzer Tests Up to 240kVeng_mohammad78No ratings yet

- Aht84s AmqDocument1 pageAht84s AmqgmailNo ratings yet

- Dynamic Triaxial System DYNATRIAX EmSDocument6 pagesDynamic Triaxial System DYNATRIAX EmSkamelNo ratings yet

- TE3300 04 Level Process DatasheetDocument3 pagesTE3300 04 Level Process Datasheetsee aunNo ratings yet

- BF4500 Fermentor GuideDocument6 pagesBF4500 Fermentor Guideadnan_hashmi786No ratings yet

- Uop 4Document4 pagesUop 4mrkt1237247No ratings yet

- Centrifuge Manufacturers IndiaDocument14 pagesCentrifuge Manufacturers Indiasaurabh_acmasNo ratings yet

- Trace DSQ GC/MSDocument4 pagesTrace DSQ GC/MSjamilifreitasNo ratings yet

- 1-1-6 en Frese Optima Aug 10Document12 pages1-1-6 en Frese Optima Aug 10mymikeymikesNo ratings yet

- Product Information Hydraulic Power Pack GripcontrolDocument2 pagesProduct Information Hydraulic Power Pack GripcontrolOlly1989No ratings yet

- FOB4 Series TSDocument4 pagesFOB4 Series TSegomfricomNo ratings yet

- Biofuge Contifuge Stratos 120 200 208 240V DualDocument103 pagesBiofuge Contifuge Stratos 120 200 208 240V DualAndrew Holmes50% (2)

- Model 5617 Corrosion Test Apparatus BrochureDocument2 pagesModel 5617 Corrosion Test Apparatus BrochureBrenda OrtizNo ratings yet

- BURKERT Inf Tecnica 8692Document8 pagesBURKERT Inf Tecnica 8692luisNo ratings yet

- Data Sheet 6ES7241-1CH32-0XB0: General InformationDocument3 pagesData Sheet 6ES7241-1CH32-0XB0: General InformationGabriel Montoya CorreaNo ratings yet

- 9x18 AWG TC 600V Overall Shielded Control Cable - 8KMP109xxxDocument2 pages9x18 AWG TC 600V Overall Shielded Control Cable - 8KMP109xxxGabriel Montoya CorreaNo ratings yet

- Bus & Industrial Ethernet Cables GuideDocument18 pagesBus & Industrial Ethernet Cables GuideGabriel Montoya CorreaNo ratings yet

- 2x16 AWG TC 600V Shielded Control CableDocument2 pages2x16 AWG TC 600V Shielded Control CableRicardo GómezNo ratings yet

- 2x2x18 AWG 600V Individual and Overall Shielded Instrumentation Cable - 8PM3102xxxDocument2 pages2x2x18 AWG 600V Individual and Overall Shielded Instrumentation Cable - 8PM3102xxxGabriel Montoya CorreaNo ratings yet

- BUS-DOR 2X22/19 AWG SF/UTP ProFibus CableDocument2 pagesBUS-DOR 2X22/19 AWG SF/UTP ProFibus CableGabriel Montoya CorreaNo ratings yet

- 18x18 AWG TC 600V Overall Shielded Control Cable - 8KMP118xxxDocument2 pages18x18 AWG TC 600V Overall Shielded Control Cable - 8KMP118xxxGabriel Montoya CorreaNo ratings yet

- Pctel Bgyd890k 890-960 MHZ 10 DBD 7 Element Yagi Antenna - TesscoDocument2 pagesPctel Bgyd890k 890-960 MHZ 10 DBD 7 Element Yagi Antenna - TesscoGabriel Montoya CorreaNo ratings yet

- Bluewave Yagi - Guardian SeriesDocument1 pageBluewave Yagi - Guardian SeriesGabriel Montoya CorreaNo ratings yet

- PCTEL Heavy Duty Fiberglass Base Station Omnidirectional AntennasDocument1 pagePCTEL Heavy Duty Fiberglass Base Station Omnidirectional AntennasGabriel Montoya CorreaNo ratings yet

- Yagi Antennas, 890-960 MHZ, 12 DBD Gain: Bgyd890M SeriesDocument1 pageYagi Antennas, 890-960 MHZ, 12 DBD Gain: Bgyd890M SeriesGabriel Montoya CorreaNo ratings yet

- Bluewave BMY890O3025N1 Spec SheetDocument1 pageBluewave BMY890O3025N1 Spec SheetGabriel Montoya CorreaNo ratings yet

- Cat. 5e 4x2x241 AWG FUTP Outdoor PVCPVC UL (1581 VW 1) (UL) LISTED E211498 - 8393204101 - V - 1 - R - 7.'Document2 pagesCat. 5e 4x2x241 AWG FUTP Outdoor PVCPVC UL (1581 VW 1) (UL) LISTED E211498 - 8393204101 - V - 1 - R - 7.'Gabriel Montoya CorreaNo ratings yet

- PCTEL MYA93012 896-970 MHZ 11dB 12 Element Yagi Antenna - TESSCODocument1 pagePCTEL MYA93012 896-970 MHZ 11dB 12 Element Yagi Antenna - TESSCOGabriel Montoya CorreaNo ratings yet

- Surge Protection Connector - PT 5-HF-12DC-ST - 2838775: Key Commercial DataDocument7 pagesSurge Protection Connector - PT 5-HF-12DC-ST - 2838775: Key Commercial DataGabriel Montoya CorreaNo ratings yet

- Surge Protector For Off-Grid PV System, Imax 20ka, 100VdcDocument3 pagesSurge Protector For Off-Grid PV System, Imax 20ka, 100VdcGabriel Montoya CorreaNo ratings yet

- Pctel Carrier Grade 900Mhz Omnidirectional Base Station AntennasDocument1 pagePctel Carrier Grade 900Mhz Omnidirectional Base Station AntennasGabriel Montoya CorreaNo ratings yet

- Technical Data Installation InstructionsDocument2 pagesTechnical Data Installation InstructionsGabriel Montoya CorreaNo ratings yet

- POE Surge Protector Device, POE Surge Protector Device RJ45Document3 pagesPOE Surge Protector Device, POE Surge Protector Device RJ45Gabriel Montoya CorreaNo ratings yet

- 2 Poles DC Surge Protector For Off Grid PV SystemDocument2 pages2 Poles DC Surge Protector For Off Grid PV SystemGabriel Montoya CorreaNo ratings yet

- Surge Protector, Rj45 Surge ProtectorDocument4 pagesSurge Protector, Rj45 Surge ProtectorGabriel Montoya CorreaNo ratings yet

- P8AX Series: Technical Data Application ExampleDocument2 pagesP8AX Series: Technical Data Application ExampleGabriel Montoya CorreaNo ratings yet

- China Coaxial Surge Protective Device, DC-1800MHzDocument3 pagesChina Coaxial Surge Protective Device, DC-1800MHzGabriel Montoya CorreaNo ratings yet

- Scroll Compressors: SF 1-6 (1.5-5.5 kW/2-7.5 HP) / SF 2-22 (2.2-22 kW/3-30 HP)Document12 pagesScroll Compressors: SF 1-6 (1.5-5.5 kW/2-7.5 HP) / SF 2-22 (2.2-22 kW/3-30 HP)FRANCOISNo ratings yet

- Disclaimer:: Order Code: Fmr67-Aablbagpa5Xca2+AdDocument1 pageDisclaimer:: Order Code: Fmr67-Aablbagpa5Xca2+AdGabriel Montoya CorreaNo ratings yet

- China Coaxial Surge Arrester, DC-900MHzDocument3 pagesChina Coaxial Surge Arrester, DC-900MHzGabriel Montoya CorreaNo ratings yet

- Technical Data Installation InstructionsDocument2 pagesTechnical Data Installation InstructionsGabriel Montoya CorreaNo ratings yet

- Technical Information Micropilot FMR67: Free Space RadarDocument80 pagesTechnical Information Micropilot FMR67: Free Space RadarGabriel Montoya CorreaNo ratings yet

- Display RemotoDocument1 pageDisplay RemotoGabriel Montoya CorreaNo ratings yet

- Special Documentation Remote Display FHX50: Level and Flow MeasurementDocument24 pagesSpecial Documentation Remote Display FHX50: Level and Flow MeasurementGabriel Montoya CorreaNo ratings yet

- Roxtec Cable Seals: For Power Transmission and Distribution ApplicationsDocument24 pagesRoxtec Cable Seals: For Power Transmission and Distribution ApplicationsarifNo ratings yet

- Manual de Usuario Hidrolavadora Series DB 2323, 2324, 2527, 3030, 3835, 3540Document19 pagesManual de Usuario Hidrolavadora Series DB 2323, 2324, 2527, 3030, 3835, 3540RAUL CAVITANo ratings yet

- Smarter Washing Solutions: Modular Wash RangeDocument5 pagesSmarter Washing Solutions: Modular Wash RangeSujesh AnNo ratings yet

- Mushroom Packages An Ecovative Approach in Packaging IndustryDocument26 pagesMushroom Packages An Ecovative Approach in Packaging Industryvaidyaa pNo ratings yet

- Site Analysis Framework: A Comprehensive GuideDocument9 pagesSite Analysis Framework: A Comprehensive Guidebisrat meseretNo ratings yet

- Aspen SimulationDocument25 pagesAspen SimulationDineshNo ratings yet

- Surge protection arrestor for offices and homesDocument1 pageSurge protection arrestor for offices and homesSofia Rincon GomezNo ratings yet

- Lecture Notes on Temperature, Thermal Equilibrium, and the Microscopic Model of an Ideal GasDocument5 pagesLecture Notes on Temperature, Thermal Equilibrium, and the Microscopic Model of an Ideal GasDonald Ng Jer YiNo ratings yet

- Green FrameworkDocument22 pagesGreen Frameworkjalees23No ratings yet

- Liability For Payment. - X X X: It Shall Not Allow Unless The Commissioner Has Certified That The Taxes ImposedDocument31 pagesLiability For Payment. - X X X: It Shall Not Allow Unless The Commissioner Has Certified That The Taxes ImposedShaiNo ratings yet

- Sustainable Transport + TSM + TDMDocument64 pagesSustainable Transport + TSM + TDMAshabul KahfiNo ratings yet

- Crude Test: by Khazar HayatDocument27 pagesCrude Test: by Khazar HayatkhayatNo ratings yet

- Indian Economy Lecture Notes Unit IIDocument11 pagesIndian Economy Lecture Notes Unit IIAmit Kumar50% (2)

- Rr210205 Electro Mechanics IDocument8 pagesRr210205 Electro Mechanics ISrinivasa Rao GNo ratings yet

- Ts 1500Document2 pagesTs 1500cesar yunkeraNo ratings yet

- Question Bank - Module 2Document3 pagesQuestion Bank - Module 2Mohammed ElsheikhNo ratings yet

- VOLVO EXCAVATOR EC330B LCDocument12 pagesVOLVO EXCAVATOR EC330B LCyansenbarus0% (1)

- UNIT 5 - Special MachinesDocument33 pagesUNIT 5 - Special MachinesKapilachander ThangavelNo ratings yet

- English Test: Time Allowed: 45 MinutesDocument5 pagesEnglish Test: Time Allowed: 45 Minuteslele28891No ratings yet

- Railway Fire Protection Save Lives Reduce DamageDocument8 pagesRailway Fire Protection Save Lives Reduce DamageS.M.Touhidur RahmanNo ratings yet

- Manual MicrozoneDocument4 pagesManual MicrozoneEduardo PucNo ratings yet

- SPE GCS Well Integrity SymposiumDocument18 pagesSPE GCS Well Integrity SymposiumAshish AmarNo ratings yet

- Overiew of Comb Cycle Rev 6.0 - Part 1Document73 pagesOveriew of Comb Cycle Rev 6.0 - Part 1SamNo ratings yet

- Process Design QuestionnaireDocument30 pagesProcess Design QuestionnaireNguyen Anh TungNo ratings yet

- Suparco+ KRL Test Ques For Electrical EngrzDocument5 pagesSuparco+ KRL Test Ques For Electrical Engrzمحمد فصیح آفتابNo ratings yet

- XAT 2023 by CrackuDocument57 pagesXAT 2023 by CrackuRachit TripathiNo ratings yet

- Inspection Release Note: ChevronDocument3 pagesInspection Release Note: ChevronHassan M. OsmanNo ratings yet

- Essential Air Conditioning GuideDocument21 pagesEssential Air Conditioning GuideYASSERHENDY80No ratings yet

- Clean Energy Trainer - ContentDocument3 pagesClean Energy Trainer - ContentPedro HenriqueNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Biogas Production: Pretreatment Methods in Anaerobic DigestionFrom EverandBiogas Production: Pretreatment Methods in Anaerobic DigestionNo ratings yet

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)