Professional Documents

Culture Documents

Aht84s Amq

Uploaded by

gmailOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aht84s Amq

Uploaded by

gmailCopyright:

Available Formats

Capacity 0-60 l/min up to 210 bar, reduced flow up to 280 bar Structure

High-pressure pump drive AC motor, 19 kW, 440 V, 60 Hz, 3 phase, 2935 rpm Electrically driven, compact, mobile, single pump dual system

Fluid specification MIL-H-5606 (NATO code H-515) or alternatives aircraft hydraulics tester.

High-pressure pump Axial piston, variable stroke, pressure controlled

Boost pump Separate, constant-volume pump (G-rotor)

Cooler Oil-to-air, 14 kW, 2 speed Operation

Pressure & flow control Computer-controlled valves / pump Easy, safe and reliable operation complying with

Indication Display of flow, temperature and pressures, plus other military and civil aircraft specifications and low-level

relevant information on a portable, monochrome display maintenance requirement. Automatic test sequences possible.

Fluid reservoir 50 l; de-aeration with 0.7 bar abs. reservoir pressure

High-pressure filter 3-micron outlet filtration, replaceable element SARLC

Boost system filter 3-micron filtration, replaceable element

The AHT is prepared for the Sun Aircraft Reservoir Level

Cleanliness level according to NAS 1638, Class 5

Piping High-pressure lines: stainless steel Control system. This system controls the level of hydraulic

Low-pressure lines: aluminium fluid in the aircraft reservoir whilst running the tests.

Hoses Non-elastomer hoses (except for ext. and HP hoses) De-aeration of the test stand reservoir remains operational.

Outlet system Two pressure- and flow-controlled outlets This system supersedes a dual “closed loop” system.

Return system Two pressure-controlled inlets

SARLC Sun Aircraft Reservoir Level Control System Functions

External connections Two ½” supply pressure hoses, length 8 m and The tester is designed to perform the following

two 1” return pressure hoses, length 8 m functions and test procedures:

Power supply cable: length 10 m, on a spring-loaded • Provide a source of hydraulic power to operate the

cable reel. Connector: 63 A. aircraft hydraulics system and controls for functional and

Average noise level 70 dB (A) at a distance of 3.65 m from the test stand operational tests without the necessity of starting the

Dimensions (L x W x H) 1950 x 1080 x 1255 mm aircraft engines.

Weight 980 kg • Test the aircraft hydraulics system for function checks,

Construction Stainless steel and aluminium, vibration tested for indication of malfunctions, for flow and pressure

according to German Navy standards. checks, leakage, etc.

Dimensioned for up to 140 G. • Filter, de-aerate and dehydrate the aircraft hydraulic fluid.

Mobility 4-wheel hydrostatic drive with joy stick control. • Drain, flush and refill the aircraft hydraulics system.

Dynamic slopes up to 15°. Static slopes up to 35°.

Options

• Automatic calibration

• Oil contamination measurement

You might also like

- Hacking Ultimate Hacking Guide Hacking For Beginne 1Document90 pagesHacking Ultimate Hacking Guide Hacking For Beginne 1lalalibrary73% (11)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Neca Labor Factor Score SheetDocument1 pageNeca Labor Factor Score SheetEng Waseem SamsodienNo ratings yet

- Statement-Jan 2019 PDFDocument4 pagesStatement-Jan 2019 PDFPatricio Rodriguez Jr100% (1)

- How To Knit SocksDocument10 pagesHow To Knit SocksHolly Robles100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Mobile Hydraulic Test Stands For Aircraft Maintenance: Ht2000-Single SystemDocument2 pagesMobile Hydraulic Test Stands For Aircraft Maintenance: Ht2000-Single SystemJohn LeeNo ratings yet

- Yarway Valve DesignDocument12 pagesYarway Valve DesignwaqashabibNo ratings yet

- LTE Feature Up To FL15ADocument146 pagesLTE Feature Up To FL15AYoucef BelhadiaNo ratings yet

- Brochure Sennebogen 870 M E enDocument16 pagesBrochure Sennebogen 870 M E enMauro TognocchiNo ratings yet

- Circuit RecommendationsDocument37 pagesCircuit RecommendationsTatiana Mancera100% (1)

- Control Loop Hardware and TroubleshootingDocument51 pagesControl Loop Hardware and TroubleshootingAhmed ElsayedNo ratings yet

- MKT202 - Group 6 - Marketing Research ProposalDocument9 pagesMKT202 - Group 6 - Marketing Research ProposalHaro PosaNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Compact High-Pressure Hydraulic TesterDocument1 pageCompact High-Pressure Hydraulic TestergmailNo ratings yet

- AHT95 Leaflet - Issue June 2005Document1 pageAHT95 Leaflet - Issue June 2005gmailNo ratings yet

- Model MS-RV: Workshop ContainerDocument6 pagesModel MS-RV: Workshop Containerjose ocanaNo ratings yet

- Aq-1000 Feature Specification Sheet 131201Document1 pageAq-1000 Feature Specification Sheet 131201api-305625208No ratings yet

- Features Aq-1270 131201Document1 pageFeatures Aq-1270 131201api-305625208No ratings yet

- Features Aq-F270 131201Document1 pageFeatures Aq-F270 131201api-305625208No ratings yet

- Aq-1500 Feature Specification Sheet 140601Document1 pageAq-1500 Feature Specification Sheet 140601api-305625208No ratings yet

- Hobart ft1000 PDFDocument12 pagesHobart ft1000 PDFhernan espitiaNo ratings yet

- Quadruplex Stack Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPDocument2 pagesQuadruplex Stack Mounted Lubricated Rotary Vane Medical Vacuum Systems 7.5 AND 10 HPEng.Gihad EladlNo ratings yet

- Triplex Stack Mounted Scroll Medical Air Plants With Desiccant Air Dryers 5 HPDocument2 pagesTriplex Stack Mounted Scroll Medical Air Plants With Desiccant Air Dryers 5 HPEng.Gihad EladlNo ratings yet

- Triplex Systems 4Document2 pagesTriplex Systems 4Eng.Gihad EladlNo ratings yet

- Features Aq-2000 131201Document1 pageFeatures Aq-2000 131201api-305625208No ratings yet

- Triplex Systems 3Document2 pagesTriplex Systems 3Eng.Gihad EladlNo ratings yet

- Triplex Systems 2 PDFDocument2 pagesTriplex Systems 2 PDFEng.Gihad EladlNo ratings yet

- Duplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPDocument2 pagesDuplex Tank Mounted Lubricated Rotary Vane Medical Vacuum Systems 1 Through 5 HPEng.Gihad EladlNo ratings yet

- SATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFDocument20 pagesSATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFuserscribd2011No ratings yet

- Sts ChloromaticDocument8 pagesSts Chloromaticahmsa.morsyNo ratings yet

- Features, Specification and Application of Reducing StationsDocument6 pagesFeatures, Specification and Application of Reducing StationsPeter JonesNo ratings yet

- 30rbsy - RqsyDocument27 pages30rbsy - RqsyErick SebeNo ratings yet

- Quadruplex Systems 3 PDFDocument2 pagesQuadruplex Systems 3 PDFEng.Gihad EladlNo ratings yet

- ZZ - 1207652196 - Fast Loop Sampling System Specification-R2 PDFDocument4 pagesZZ - 1207652196 - Fast Loop Sampling System Specification-R2 PDFJohn PaulNo ratings yet

- R950Document20 pagesR950equipment9278No ratings yet

- Series CH4200: Chemical Feed Equipment Floor-Mounted Gas DispenserDocument5 pagesSeries CH4200: Chemical Feed Equipment Floor-Mounted Gas DispenserCandra Tier'z100% (1)

- TRITORC Насосные установки для проведения гидротестов - ENDocument12 pagesTRITORC Насосные установки для проведения гидротестов - ENjason forsythNo ratings yet

- 5-EN 4050-A (Dig) - 2F1CDocument9 pages5-EN 4050-A (Dig) - 2F1Cabuzer1981No ratings yet

- Laundry DesignDocument11 pagesLaundry DesignrajevskumarNo ratings yet

- Manual OyM - Compresor 900hDocument2 pagesManual OyM - Compresor 900hCARLOSNo ratings yet

- Duplex Systems 6Document2 pagesDuplex Systems 6Eng.Gihad EladlNo ratings yet

- Duplex Systems 19Document2 pagesDuplex Systems 19Eng.Gihad EladlNo ratings yet

- Triplex Systems 3Document2 pagesTriplex Systems 3Eng.Gihad EladlNo ratings yet

- Triplex Stack Mounted Systems 1Document2 pagesTriplex Stack Mounted Systems 1Eng.Gihad EladlNo ratings yet

- HFD Catalog SentinelDocument12 pagesHFD Catalog SentinelGuido Moreno PeredoNo ratings yet

- Spraymec 8100 VC: FeaturesDocument12 pagesSpraymec 8100 VC: FeaturesSanjeev Roy100% (1)

- Hose Test Unit SpecsDocument4 pagesHose Test Unit Specsศุภกฤต รักในหลวงNo ratings yet

- High Pressure Cleaning MachinesDocument6 pagesHigh Pressure Cleaning MachinesNIKOSNo ratings yet

- Duplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 3 Through 7.5 HPDocument2 pagesDuplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 3 Through 7.5 HPEng.Gihad EladlNo ratings yet

- Duplex "Space SaverDocument2 pagesDuplex "Space SaverEng.Gihad EladlNo ratings yet

- Reliance 380PG Pharmaceutical Grade Washer Technical DataDocument7 pagesReliance 380PG Pharmaceutical Grade Washer Technical DataNirbhayNo ratings yet

- Saveon Water Level ControllerDocument4 pagesSaveon Water Level ControllerRajesh S100% (3)

- Duplex Systems 4Document2 pagesDuplex Systems 4Eng.Gihad EladlNo ratings yet

- Duplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 1 Through 2 HPDocument2 pagesDuplex "Space Saver" Dry Rotary Vane Medical Vacuum Systems 1 Through 2 HPEng.Gihad EladlNo ratings yet

- Quadruplex Stack Mounted Scroll Medical Air Plants With Desiccant Air Dryers 5 HPDocument2 pagesQuadruplex Stack Mounted Scroll Medical Air Plants With Desiccant Air Dryers 5 HPEng.Gihad EladlNo ratings yet

- Calibration RigDocument5 pagesCalibration RigBijoy AyyagariNo ratings yet

- Features Aq-3000 141001Document1 pageFeatures Aq-3000 141001api-305625208No ratings yet

- CHOKE MANIFOLD 3Document2 pagesCHOKE MANIFOLD 3fabianmed83No ratings yet

- 3-Variable Process Control Training System - Hands-On Industrial SkillsDocument4 pages3-Variable Process Control Training System - Hands-On Industrial SkillseugeneNo ratings yet

- Damper Testing: The World of Damper Test MachinesDocument11 pagesDamper Testing: The World of Damper Test MachinesFajarNo ratings yet

- Remote Hydraulically Operated Monitor 03 RCHM299: System Package Valve Box / Hydraulic SourceDocument1 pageRemote Hydraulically Operated Monitor 03 RCHM299: System Package Valve Box / Hydraulic SourceKrishna N HNo ratings yet

- K & T Style Hydraulic System Test Analysers - ManualDocument16 pagesK & T Style Hydraulic System Test Analysers - Manualpravesh bhartiNo ratings yet

- Cat 30RB 2013Document10 pagesCat 30RB 2013Denise Koh Chin HuiNo ratings yet

- Air-Cooled Liquid Chillers for Commercial and Industrial ApplicationsDocument16 pagesAir-Cooled Liquid Chillers for Commercial and Industrial Applicationsrudagochav3096No ratings yet

- Xl3210iii-Ficha TecnicaDocument2 pagesXl3210iii-Ficha TecnicaRicardo Faundez SanchezNo ratings yet

- Global Solution For Aerospace Maintenance: Dedienne Aerospace TEST BENCH 150 TonnesDocument12 pagesGlobal Solution For Aerospace Maintenance: Dedienne Aerospace TEST BENCH 150 TonnesgmailNo ratings yet

- SLIDE Presentation CompressedDocument20 pagesSLIDE Presentation CompressedgmailNo ratings yet

- Tripod PresentationDocument20 pagesTripod PresentationgmailNo ratings yet

- DPAX150TADocument2 pagesDPAX150TAgmailNo ratings yet

- Le Garric Facilities PresentationDocument8 pagesLe Garric Facilities PresentationgmailNo ratings yet

- 6 Ton Hydraulic Axle Jack Maintenance ManualDocument1 page6 Ton Hydraulic Axle Jack Maintenance ManualgmailNo ratings yet

- DPAX150TADocument2 pagesDPAX150TAgmailNo ratings yet

- Presentation 2007Document13 pagesPresentation 2007gmailNo ratings yet

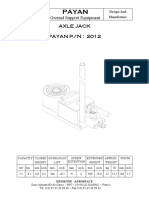

- Payan: Axle Jack PAYAN P/N: 2012Document38 pagesPayan: Axle Jack PAYAN P/N: 2012gmailNo ratings yet

- DPTR035C1280004500Document2 pagesDPTR035C1280004500gmailNo ratings yet

- Global Solution For Aerospace Maintenance: Dedienne Aerospace TEST BENCH 150 TonnesDocument12 pagesGlobal Solution For Aerospace Maintenance: Dedienne Aerospace TEST BENCH 150 TonnesgmailNo ratings yet

- Presentation 2007Document13 pagesPresentation 2007gmailNo ratings yet

- DPAX036RM215710180Document2 pagesDPAX036RM215710180gmailNo ratings yet

- DPAX030RA00Document2 pagesDPAX030RA00gmailNo ratings yet

- Le Garric Facilities PresentationDocument8 pagesLe Garric Facilities PresentationgmailNo ratings yet

- Global Solution For Aerospace Maintenance: Dedienne Aerospace TEST BENCH 150 TonnesDocument12 pagesGlobal Solution For Aerospace Maintenance: Dedienne Aerospace TEST BENCH 150 TonnesgmailNo ratings yet

- ACT95C MFAGE Introduction-New Logo VersionDocument21 pagesACT95C MFAGE Introduction-New Logo VersiongmailNo ratings yet

- EFI4000 LeafletDocument2 pagesEFI4000 LeafletgmailNo ratings yet

- Engine Stand Capability PresentationDocument16 pagesEngine Stand Capability PresentationgmailNo ratings yet

- ACT95C MFAGE-shortFeb09Document10 pagesACT95C MFAGE-shortFeb09gmailNo ratings yet

- Presentation de TLD Groupe: January 2008Document50 pagesPresentation de TLD Groupe: January 2008gmailNo ratings yet

- Chiarlone Aeronautical PresentazioneDocument30 pagesChiarlone Aeronautical PresentazionegmailNo ratings yet

- 3294-04 Beam Aiport BrochureDocument12 pages3294-04 Beam Aiport BrochuregmailNo ratings yet

- Key Loader Air Force 1PM 1200: For Technical and Operational Features Ask For Specification N° 1353Document2 pagesKey Loader Air Force 1PM 1200: For Technical and Operational Features Ask For Specification N° 1353gmailNo ratings yet

- FRESIA Company Presentation 05Document21 pagesFRESIA Company Presentation 05gmailNo ratings yet

- Export Promotion Capital Goods Scheme PresentationDocument32 pagesExport Promotion Capital Goods Scheme PresentationDakshata SawantNo ratings yet

- Final E-Portfolio AssignmentDocument7 pagesFinal E-Portfolio Assignmentapi-302594281No ratings yet

- Tablets TextDocument18 pagesTablets TextarunbaskaranjNo ratings yet

- Courts CP, XO CP, Circumvention - DDI 2015 SWSDocument311 pagesCourts CP, XO CP, Circumvention - DDI 2015 SWSdavidsi325No ratings yet

- Study of HRM Practices in Public SectorDocument82 pagesStudy of HRM Practices in Public SectorvishalNo ratings yet

- Notes On ME (2) Unit 1Document16 pagesNotes On ME (2) Unit 1Shashwat SinhaNo ratings yet

- Kumba Resources: Case StudiesDocument12 pagesKumba Resources: Case StudiesAdnan PitafiNo ratings yet

- MCIAA Tax Exemption CaseDocument4 pagesMCIAA Tax Exemption CaseJep Echon TilosNo ratings yet

- Managing People and OrganisationsDocument50 pagesManaging People and OrganisationsOmkar DesaiNo ratings yet

- Definition (Art. 1458)Document10 pagesDefinition (Art. 1458)Fatima SladjannaNo ratings yet

- Permalex CatalogDocument24 pagesPermalex CataloggbricksphNo ratings yet

- Practical Research 2: Quarter 1 Module 1: Nature of Inquiry and ResearchDocument406 pagesPractical Research 2: Quarter 1 Module 1: Nature of Inquiry and ResearchJohn Michael Reyes RamosNo ratings yet

- Buses and PortsDocument3 pagesBuses and PortsHuma Rashid80% (5)

- Change-oriented leadership impacts team climate & potencyDocument17 pagesChange-oriented leadership impacts team climate & potencyAkhwand Abdur Raffi SaulatNo ratings yet

- Supply Chain Analysis of PRAN GroupDocument34 pagesSupply Chain Analysis of PRAN GroupAtiqEyashirKanakNo ratings yet

- MAD Lab Manual - List of ExperimentsDocument24 pagesMAD Lab Manual - List of Experimentsmiraclesuresh67% (3)

- Group7 Sula Wine IBDocument16 pagesGroup7 Sula Wine IBFenny ShahNo ratings yet

- KS 94 DatasheetDocument8 pagesKS 94 Datasheetbaananou nizarNo ratings yet

- Process Flow Diagram (For Subscribers Who Visits Merchant Business Premises)Document2 pagesProcess Flow Diagram (For Subscribers Who Visits Merchant Business Premises)Lovelyn ArokhamoniNo ratings yet

- Chap 010Document147 pagesChap 010Khang HuynhNo ratings yet

- Court of Appeals decision on Batara family land disputeDocument19 pagesCourt of Appeals decision on Batara family land disputeKhanini GandamraNo ratings yet

- Digital Business Communication in The Global Era ) : Digitalization Culture Based CultureDocument16 pagesDigital Business Communication in The Global Era ) : Digitalization Culture Based CulturejjruttiNo ratings yet

- Chapter 4 Review QuestionsDocument5 pagesChapter 4 Review Questionschiji chzzzmeowNo ratings yet