Professional Documents

Culture Documents

Understanding Boat Design 106 PDF

Uploaded by

Łukasz ZygielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Understanding Boat Design 106 PDF

Uploaded by

Łukasz ZygielCopyright:

Available Formats

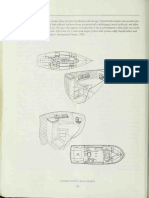

FIGURE 10-6

Typical cored hull layup.

Cieu co(^»

QvA-vee. \r\e.e.sa,C-,\-KSKS. ivcv^l

coeg E>oAE>

v(4iAt:c- F\se: B-<auASS S.yCifJ.

This is most often used as a stiffener in deck lami- size and may range from 'A inch to I inch. Ver}' large

nates, but it is also used in hulls, usually racing hulls, hulls may have two layers of coring with a thin layer

where stiffness and light weight are pnme considera- of fiberglass between to bond the cores together.

tions. There has been concern that the balsa core can A few boats have been built with a wood core,

rot if water gets to it through a crack in the outer usually a strip-planked hull with no framing and

laminate. However, the small squares of wood are fairly thin planking. The FRP covenng, both inside

separated from each other by resin if the work is and out, protects the wood core and provides suffi-

done properly, so that rot cannot spread easily cient additional strength to render the hull a solid,

Expanded PVC foam cores such as Airex, Ter- one-piece unit. Bulkheads are fitted and fastened to

manto, and Klegecell have proven themselves as well. the hull with FRP tape, similar to the system used in

They are inert materials and cannot absorb water and production craft. This construction lends itself to the

rot if the outer skin is broken. They also are available amateur builder because the large timbers of wood

m large panels that lend themselves to one-off con- boats and the intricate molds of fiberglass hulls are

struction over a relatively simple wood framework. eliminated.

Core materials vary in thickness according to boat

UNDERSTANDING BOAT DESIGN

94

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Mysterious Creatures (Time-Life Mysteries of The Unknown)Document152 pagesMysterious Creatures (Time-Life Mysteries of The Unknown)lancelimNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Understanding Boat Design 81 PDFDocument1 pageUnderstanding Boat Design 81 PDFŁukasz ZygielNo ratings yet

- Apollo's GoldDocument50 pagesApollo's GoldAndrea100% (1)

- Weeks 001-003 Cookery 2 Prepare and Cook Seafood Dishes (PartI)Document8 pagesWeeks 001-003 Cookery 2 Prepare and Cook Seafood Dishes (PartI)Mark John Paul Cabling100% (1)

- Milkfish (Bangus) Floating Cage Culture Project in Dauis, Bohol. PhilippinesDocument10 pagesMilkfish (Bangus) Floating Cage Culture Project in Dauis, Bohol. Philippinesedendereze6026100% (2)

- Dog Years by Gunter Grass 81988318Document382 pagesDog Years by Gunter Grass 81988318SFLD100% (4)

- Grade 5 - Las - Week 6Document16 pagesGrade 5 - Las - Week 6Jasmin CapitliNo ratings yet

- Not A Deck (From Boat Repair Manual, by Marine, 1988) : Areas of or Are Cored. Fiberglass Allan InternationalDocument1 pageNot A Deck (From Boat Repair Manual, by Marine, 1988) : Areas of or Are Cored. Fiberglass Allan InternationalŁukasz ZygielNo ratings yet

- Understanding Boat Design 102 PDFDocument1 pageUnderstanding Boat Design 102 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 92 PDFDocument1 pageUnderstanding Boat Design 92 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 95 PDFDocument1 pageUnderstanding Boat Design 95 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 98 PDFDocument1 pageUnderstanding Boat Design 98 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 101 PDFDocument1 pageUnderstanding Boat Design 101 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 93 PDFDocument1 pageUnderstanding Boat Design 93 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 104 PDFDocument1 pageUnderstanding Boat Design 104 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 103 PDFDocument1 pageUnderstanding Boat Design 103 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 90 PDFDocument1 pageUnderstanding Boat Design 90 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 87 PDFDocument1 pageUnderstanding Boat Design 87 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 75 PDFDocument1 pageUnderstanding Boat Design 75 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 88 PDFDocument1 pageUnderstanding Boat Design 88 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 80 PDFDocument1 pageUnderstanding Boat Design 80 PDFŁukasz ZygielNo ratings yet

- Understanding Boat Design 78 PDFDocument1 pageUnderstanding Boat Design 78 PDFŁukasz ZygielNo ratings yet

- Solutions Manual To Accompany College Physics 0321822420 9780321822420Document35 pagesSolutions Manual To Accompany College Physics 0321822420 9780321822420clowneryanileness.y7qst100% (55)

- Verbals Дистанційне з.ф.Document40 pagesVerbals Дистанційне з.ф.Anjela CelinNo ratings yet

- Xdabf 037 ADocument34 pagesXdabf 037 APatricia Mae Santos MañalacNo ratings yet

- Warren Sapp Bitten by Shark While LobsteringDocument3 pagesWarren Sapp Bitten by Shark While LobsteringHyldgaardFarrell4No ratings yet

- StoriesDocument17 pagesStoriesTJ VillalonNo ratings yet

- Green Landscape Advertising Trifold Brochure 1Document6 pagesGreen Landscape Advertising Trifold Brochure 1Rosedel BarlongayNo ratings yet

- Distance and DisplacementDocument1 pageDistance and DisplacementCarlCallosaNo ratings yet

- South America - Original Cultures Two - Ancient Man and His First CivilizationsDocument101 pagesSouth America - Original Cultures Two - Ancient Man and His First CivilizationsRoddy PfeifferNo ratings yet

- The Philippines and The West Philippine SeaDocument2 pagesThe Philippines and The West Philippine SeaMycz DoñaNo ratings yet

- Stability Safety and Operability of Small Fishing Vessels PDFDocument11 pagesStability Safety and Operability of Small Fishing Vessels PDFMANUEL HINOJOSANo ratings yet

- Divinity Original Sin 2 ScrollsDocument6 pagesDivinity Original Sin 2 Scrollsbeans54No ratings yet

- Fishing Guide - Harvest Moon - Light of Hope - NeoseekerDocument9 pagesFishing Guide - Harvest Moon - Light of Hope - NeoseekerJayjay PalomarNo ratings yet

- Conservation & Rehabilitation of LakesDocument31 pagesConservation & Rehabilitation of LakesjoshigautaNo ratings yet

- Joshietal2012 TunataxonomyDocument9 pagesJoshietal2012 TunataxonomyJarris MailuasNo ratings yet

- Elite-5 HDI Combo: Operation ManualDocument56 pagesElite-5 HDI Combo: Operation ManualluNo ratings yet

- The RingDocument2 pagesThe RingPablo César Tierradentro NavarreteNo ratings yet

- BÀI TẬP BUỔI 06 (unit 8)Document4 pagesBÀI TẬP BUỔI 06 (unit 8)Thuỳ TrangNo ratings yet

- Kall Et Al - 2022-From Good Intentions To Unexpected Results - Indonesian BSCDocument21 pagesKall Et Al - 2022-From Good Intentions To Unexpected Results - Indonesian BSCTita NopitawatiNo ratings yet

- Fisheries ManagementDocument29 pagesFisheries ManagementLeah NarneNo ratings yet

- What Are HomophonesDocument2 pagesWhat Are HomophonesmariencdNo ratings yet

- MOLUSKDocument10 pagesMOLUSKElizabeth B DiestroNo ratings yet

- Read This Text and Answer Questions 3 and 4Document9 pagesRead This Text and Answer Questions 3 and 4TarisPujoENo ratings yet

- UntitledDocument67 pagesUntitledCRISTIAN VILLOUTANo ratings yet

- Exam Questions: Exam Title: Chapter GSK 6Document17 pagesExam Questions: Exam Title: Chapter GSK 6Chandan Pal100% (1)