Professional Documents

Culture Documents

2004 Oil Country Catalog 052504 PDF

2004 Oil Country Catalog 052504 PDF

Uploaded by

Nubia BarreraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2004 Oil Country Catalog 052504 PDF

2004 Oil Country Catalog 052504 PDF

Uploaded by

Nubia BarreraCopyright:

Available Formats

Oil Country Manufacturing

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Master Tubing Tongs

Models 55000, 56800, 55700 and 57800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Open-Head Tubing Tongs

Model 45000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Models RS, BTS and CTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Backup Tongs

Models Three-Jaw and MS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Closed-Head Tubing Tongs

Model CH-58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Model CH-93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power Sucker Rod Tongs

Models M-20, M-40, M-50 and M-75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hooks and Links

100-Ton Tubing Hooks and Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Weldless Elevator Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Tubing Spiders

Models B, C, HD and E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Model G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Inverted Snubbing Spiders

Models C and HD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Center-Latch Tubing Elevator

Models CL-65 and CL-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Side-Door Tubing Elevator

Models SD-65 and SD-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Tubing Elevator

Model YC Slip-Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Heavy-Duty Rod Hooks

Models RH-20 and RH-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Heavy-Duty Rod Elevators

Models RES-1 and REP-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Rod Handling Accessories

Rod Swivel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

35-Ton Rod Hook Clevis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Miscellaneous

Depthometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Sucker Rod Wrenches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

The products in this catalog may be covered by one

or more United States and/or international patents.

Please address all intellectual property inquiries to:

Weatherford International Ltd

Legal Department

515 Post Oak Blvd., Suite 600

Houston, Texas 77027 USA

Tel.: +1-713-693-4000 © 2004. Weatherford. All rights reserved.

Fax: +1-713-693-4300

Introduction

Oil Country Manufacturing (OCM), committed to the success of well

servicing contractors worldwide, supplies state-of-the-art well servicing

equipment of the highest quality. Our innovative product designs represent

many years of field research, and our dedication to quality and service result

in lower operational costs, less downtime and better safety records for our

clients.

From our headquarters and main manufacturing facilities in Ventura,

California, USA, we promptly and efficiently process your equipment orders.

Our easy access to international air and ocean freight terminals ensures

prompt shipment to anywhere in the world.

A Complete Line of Well Serving Equipment

Our complete line of high-quality well service equipment combines

field-proven features with innovative designs, developed in response

to client needs. From tongs, spiders and elevators to hooks, OCM can

deliver the equipment you need to be more productive. And we're

available 24 hours a day to service what we sell.

© 2004. Weatherford. All rights reserved. 2

American Petroleum

Institute (API)

Certificates

Practical Design and Quality Manufacturing

The quality of OCM products attests to our management and engineering staff's extensive experience

in the well servicing industry. Field-proven features and innovative design distinguish our superior well

servicing equipment.

OCM's manufacturing facility includes state-of-the-art CNC machines for precise manufacture of our

product line components. We understand that proper fit and function of high-quality equipment give

you confidence and peace of mind.

OCM products are quality inspected for materials, dimensions, function and load test. Our quality

assurance program meets API standards, ensuring superior inspection methods, materials,

processes, procedures, testing, engineering and product design.

With OCM's commitment to quality, you know you are receiving the best well servicing equipment in

the industry, equipment that is consistently reliable, cost-effective and safe.

At OCM, we do one thing better than anyone else: We build the best well servicing equipment on the

market. Count on OCM equipment for efficiency, dependability and safety!

3 © 2004. Weatherford. All rights reserved.

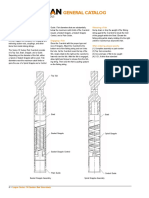

Master Tubing Tongs

Models 55000, 56800, 55700 and 57800

Key Features

! Increased size range to 5-1/2 in. ! Makeup pressure control valve

(Models 55700/57800) mounted on tong (optional)

! Higher-torque open-head tong ! Flip-top lid for easy access to brake

band

! Combination top cast case and

bottom fabricated plate for greater ! Three-jaw power backup for

strength greater safety (optional)

! Gears, roller pins and bearings ! Gear-driven, chainless design

redesigned to provide greater

! Proven planetary gear transmission

strength required for higher torque

! Integrated load cell and torque

gauge mounted with backup for

increased makeup torque accuracy

(optional)

Master Tubing

Tong with Hydraulic

Backup and Load Cell

Dimensions

Mode ls: 55000 56800 56801 56802

Le ngth: 42-1/2 in. (1 079.5 mm) 42-1/2 in. (1 079.5 mm) 42-1/2 in. (1 079.5 mm) 42-1/2 in. (1 079.5 mm)

Width: 30 in. (762 mm) 30 in. (762 mm) 30 in. (762 mm) 30 in. (762 mm)

He ight: 29-1/4 in. (743 mm) 29-1/4 in. (743 mm) 29-1/4 in. (743 mm) 29-1/4 in. (743 mm)

We ight: 716 lb (324.77 kg) 716 lb (324.77 kg) 716 lb (324.77 kg) 716 lb (324.77 kg)

Tong Arm Le ngth: 29 in. (736.6 mm) 29 in. (736.6 mm) 29 in. (736.6 mm) 29 in. (736.6 mm)

Mode ls: 55700 57800 57801 57802

Le ngth: 42-1/2 in. (1 079.5 mm) 42-1/2 in. (1 079.5 mm) 42-1/2 in. (1 079.5 mm) 42-1/2 in. (1 079.5 mm)

Width: 30 in. (762 mm) 30 in. (762 mm) 30 in. (762 mm) 30 in. (762 mm)

He ight: 29-1/4 in. (743 mm) 29-1/4 in. (743 mm) 29-1/4 in. (743 mm) 29-1/4 in. (743 mm)

We ight: 675 lb (306.18 kg) 780 lb (353.8 kg) 780 lb (353.8 kg) 780 lb (353.8 kg)

Tong Arm Le ngth: 29 in. (736.6 mm) 29 in. (736.6 mm) 29 in. (736.6 mm) 29 in. (736.6 mm)

© 2004. Weatherford. All rights reserved. 4

Master Tubing Tongs

Models 55000, 56800, 55700 and 57800

Specifications

Mode ls: 55000 56800 56801 56802

1.05 to 4-3/4 in. 1.05 to 4-3/4 in. 1.05 to 4-3/4 in. 1.05 to 4-3/4 in.

Pipe Size Range :

(26.6 to 120.6 mm) (26.6 to 120.6 mm) (26.6 to 120.6 mm) (26.6 to 120.6 mm)

Tor que in Low Ge ar @ 2,500 PSI 8,740 f t-lb 11,750 f t-lb 12,680 f t-lb 14,500 f t-lb

(172 bar ): (11 850 N•m) (15 931 N•m) (17 191 N•m) (19 659 N•m)

Tor que in Low Ge ar @ 2,000 PSI 7,023 f t-lb 9,390 f t-lb 10,000 f t-lb 11,750 f t-lb

(138 bar ): (9 521 N•m) (12 730 N•m) (13 558 N•m) (15 930 N•m)

Rate d Spe e d in High Ge ar ,

93 RPM 76 RPM 67 RPM 61 RPM

35 GPM (133 LPM ):

Rate d Spe e d in Low Ge ar : 20.6 RPM 15.4 RPM 13.7 RPM 12.5 RPM

Tor que Arm Le ngth: 29 in. (737 mm) 29 in. (737 mm) 29 in. (737 mm) 29 in. (737 mm)

Nom inal Pow e r Re quir e m e nts : 2,000 PSI (35 GPM) 2,000 PSI (35 GPM) 2,000 PSI (35 GPM) 2,000 PSI (35 GPM)

Mode ls: 55700 57800 57801 57802

1.05 to 5-1/2 in. 1.05 to 5-1/2 in. 1.05 to 5-1/2 in. 1.05 to 5-1/2 in.

Pipe Size Range :

(26.6 to 139.7 mm) (26.6 to 139.7 mm) (26.6 to 139.7 mm) (26.6 to 139.7 mm)

Tor que in Low Ge ar @ 2,500 PSI 8,740 f t-lb 11,750 f t-lb 12,680 f t-lb 14,500 f t-lb

(172 bar ): (11 850 N•m) (15 931 N•m) (17 191 N•m) (19 659 N•m)

Tor que in Low Ge ar @ 2,000 PSI 7,023 f t-lb 9,390 f t-lb 10,000 f t-lb 11,750 f t-lb

(138 bar ): (9 521 N•m) (12 730 N•m) (13 558 N•m) (15 930 N•m)

Rate d Spe e d in High Ge ar ,

93 RPM 76 RPM 67 RPM 61 RPM

35 GPM (133 LPM ):

Rate d Spe e d in Low Ge ar : 20.6 RPM 15.4 RPM 13.7 RPM 12.5 RPM

Tor que Arm Le ngth: 29 in. (737 mm) 29 in. (737 mm) 29 in. (737 mm) 29 in. (737 mm)

Nom inal Pow e r Re quir e m e nts : 2,000 PSI (35 GPM) 2,000 PSI (35 GPM) 2,000 PSI (35 GPM) 2,000 PSI (35 GPM)

Ba ckup Type : M anual M S Pne um atic/Hydr aulic Pne um atic/Hydr aulic

1.05 to 6-1/8 in. 1.05 to 5-9/16 in. 1.05 to 6-1/8 in.

Pipe Size Range :

(26.6 to 155.6 mm) (26.6 to 141.3 mm) (26.6 to 155.6 mm)

We ight: 53 lb (24 kg) 148 lb (67.1 kg) 148 lb (67.1 kg)

5 © 2004. Weatherford. All rights reserved.

Open-Head Tubing Tongs

Model 45000

Key Features

! Safety door: Operational lock-out ! Flip-top lid for easy access to brake

device prevents tong from band

operating with door open

! Three-jaw power backup for

! Load-bearing door minimizes case greater safety (optional)

spreading effect

! Gear-driven, chainless design

! Integrated load cell and torque

! Proven planetary gear transmission

gauge mounted with backup for

increased makeup torque accuracy

(optional)

Dimensions

Mode l 45000

Le ngth: 42-1/2 in. (1 079.5 mm)

Width: 30 in. (762 mm)

He ight: 29-1/4 in. (743 mm)

We ight: 672 lb (304.82 kg)

Tong Arm Le ngth: 29 in. (736.6 mm)

Specifications

Mode l 45000

1.05 to 4-3/4 in.

Pipe Size Range : Model 45000

(26.6 to 120.6 mm)

Tor que in Low Ge ar @ 2,500 PSI 6,670 f t-lb

(172 bar ): (9 043 N•m)

Tor que in Low Ge ar @ 2,000 PSI 5,440 f t-lb

(138 bar ): (7 375 N•m)

Rate d Spe e d in High Ge ar ,

93 RPM

35 GPM (133 LPM ):

Rate d Spe e d in Low Ge ar : 27 RPM

Tor que Arm Le ngth: 29 in. (737 mm)

Nom inal Pow e r Re quir e m e nts : 2,000 PSI (35 GPM)

Back up Type : M anual M S Pne um atic/Hydr aulic

1.05 to 4-1/2 in. 1.05 to 5-9/16 in.

Pipe Size Range :

(26.6 to 114.3 mm) (26.6 to 141.3 mm)

We ight: 53 lb (24 kg) 148 lb (67.1 kg)

© 2004. Weatherford. All rights reserved. 6

Backup Tongs

Models Three-Jaw and MS

OCM can provide the three-jaw or MS backup tongs for use with our open-head tubing tongs and

master tubing tongs. Backup tongs hang below the power tubing tong for making and breaking

threaded tubular connections. The three-jaw backup tong is available with pneumatic or hydraulic

operation. The MS backup tong is available only for manual operations.

Three-Jaw Power MS Manual Backup

Backup System Tong

Key Features Key Features

! Increased safety: Helps keep rig ! Increased safety: Helps keep rig

crew's hands clear of potential crew's hands clear of potential

danger danger

! Easy operation: Straightforward ! Easy operation: Straightforward

design for ease of use design for ease of use

! Increased strength: Significantly

stronger than traditional manual

backups

Specifications Model Air Backup

Mode ls: Ma nua l MS 3-Ja w Pne um a tic 3-Ja w Hydra ulic

Par t Num be r : 45700- 55510-102* 55520-202*

1.05 to 6-1/8 in. 1.05 to 5-9/16 in. 1.05 to 5-9/16 in.

Pipe Size Range :

(26.6 to 155.57 mm) (26.6 to 141.3 mm) (26.6 to 141.3 mm)

We ight: 53 lb (24 kg) 148 lb (67.1 kg) 170 lb (77.11 kg)

Jaw s for M S Back up Size Range : Par t Num be r

1.310 to 2.060 in. (33.27 to 52.32 mm) 45420 Lug Jaw

2-3/8 to 3.668 in. (60.32 to 93.17 mm) 45422 Lug Jaw

3-1/2 to 4-1/2 in. (88.9 to 114.3 mm) 45424 Lug Jaw

4-1/2 to 6-1/8 in. (114.3 to 155.57 mm) 45577 Short Latch Jaw

Jaw Se ts for Both Air and Hydr aulic Back up Size Range :

1.050 to 3.69 in. (26.67 to 93.17 mm) Diamond Tooth 55152-100

1.900 to 4-1/2 in. (48.26 to 114.3 mm) Straight Tooth 55177-100

Model MS

2-7/8 to 5-9/16 in. (73.02 to 141.3 mm) Straight Tooth 55157-100

*Also availab le in sizes up to 6-1/8 in. (155.6 mm)

7 © 2004. Weatherford. All rights reserved.

Open-Head Tubing Tongs

Models RS, BTS and CTS

Key Features

! More steel weight in case to reduce

potential of case spreading

! Gussets added to bottom case to

reduce potential of case spreading

! Integral sprocket and outer ring

(sprocket teeth machined on outer

ring)

! Traditional chain-driven design

! Uses the familiar jaw-and-bushing

biting system

Model RS

Model BTS

Dimensions

Mode ls: RS BTS CTS

Le ngth: 51-1/2 in. (1 308.1 mm) 41-1/4 in. (1 047.7 mm) 51-1/2 in. (1 308.1 mm)

Width: 27-3/4 in. (704.8 mm) 27-3/4 in. (704.8 mm) 27-3/4 in. (704.8 mm)

He ight: 25 in. (635 mm) 24-1/4 in. (615.9 mm) 25 in. (635 mm)

We ight: 658 lb (298.47 kg) 648 lb (293.93 kg) 658 lb (298.47 kg)

Tong Arm Le ngth: 39-1/2 in. (1 003.3 mm) 29-1/4 in. (742.9 mm) 39-1/2 in. (1 003.3 mm)

© 2004. Weatherford. All rights reserved. 8

Open-Head Tubing Tongs

Models RS, BTS and CTS

Specifications

Mode ls: RS RS Hi-Torque BTS BTS Hi-Torque

1.05 to 4-1/2 in. 1.05 to 4-1/2 in. 1.05 to 4-1/2 in. 1.05 to 4-1/2 in.

Pipe Size Range :

(26.6 to 114.3 mm) (26.6 to 114.3 mm) (26.6 to 114.3 mm) (26.6 to 114.3 mm)

Tor que in Low Ge ar @ 2,000 PSI 4,650 f t-lb 6,600 f t-lb 4,650 f t-lb 6,600 f t-lb

(136 bar ): (6 305 N•m) (8 813 N•m) (6 305 N•m) (8 813 N•m)

Rate d Spe e d in High Ge ar ,

100 RPM 80 RPM 100 RPM 80 RPM

35 GPM (133 LPM ):

Tor que Arm Le ngth: 39.5 in. (1 003 mm) 39.5 in. (1 003 mm) 29.25 in. (743 mm) 29.25 in. (743 mm)

Nom inal Pow e r Re quir e m e nts ,

2,000 PSI (138 bar) 2,000 PSI (138 bar) 2,000 PSI (138 bar) 2,000 PSI (138 bar)

35 GPM (133 LPM ):

Mode ls: CTS CTS Hi-Torque

1.05 to 5-1/2 in. 1.05 to 5-1/2 in.

Pipe Size Range :

(26.6 to 139.7 mm) (26.6 to 139.7 mm)

Tor que in Low Ge ar @ 2,000 PSI 4,650 f t-lb 6,600 f t-lb

(136 bar ): (6 305 N•m) (8 813 N•m)

Rate d Spe e d in High Ge ar ,

100 RPM 80 RPM

35 GPM (133 LPM ):

Tor que Arm Le ngth: 39.5 in. (1 003 mm) 39.5 in. (1 003 mm)

Nom inal Pow e r Re quir e m e nts ,

2,000 PSI (138 bar) 2,000 PSI (138 bar)

35 GPM (133 LPM ):

Back up Type : M anual M S Pne um atic/Hydr aulic

1.05 to 4-1/2 in.* 1.05 to 5-9/16 in.*

Pipe Size Range :

(26.6 to 114.3 mm) (26.6 to 141.3 mm)

We ight: 53 lb (24 kg) 148 lb (67.1 kg)

*Also availab le to 6-1/8 in. (155.6 mm)

9 © 2004. Weatherford. All rights reserved.

Closed-Head Tubing Tongs

Model CH 58

Key Features

! Increased safety. Drag button ! For higher-torque versions, backup

adjustments made from outside the uses same full-size jaws as in the

tong. Hands are never placed tong for greater strength.

inside the drag ring for

! Integrated load cell and torque

adjustments.

gauge mounted with backup for

! Gear-driven, chainless design increased makeup torque accuracy

eliminates need for oil bath (optional)

lubrication.

! Uses the familiar five-jaw and drag

! No oil seals to leak fluid gripping system

! Fabricated case for easier ! Optional hydraulic lift and stiff arm

maintenance

Dimensions

Mode ls: CH 58-1 CH 58-2

Le ngth: 50 in. (1 270 mm) 50 in. (1 270 mm)

Width: 30 in. (762 mm) 30 in. (762 mm)

He ight: 38 in. (965 mm) 38 in. (965 mm)

We ight*: 1,196 lb (542.51 kg) 1,196 lb (542.51 kg)

Tong Arm Le ngth: 36 in. (914.4 mm) 36 in. (914.4 mm)

*Excluding b ackup

Specifications Model CH 58-1

Mode ls: CH 58-1 CH 58-2 CH 58-5

1.312 to 7.0 in. 1.312 to 7.0 in. 1.312 to 7.0 in.

Pipe Size Range :

(33 to 178 mm) (33 to 178 mm) (33 to 178 mm)

Tor que in Low Ge ar @ 2,500 PSI 8,210 f t-lb 11,200 f t-lb 15,824 f t-lb

(172 bar ): (11 117 N•m) (15 185 N•m) (21 454 N•m)

Tor que in Low Ge ar @ 2,000 PSI 6,580 f t-lb 9,180 f t-lb 12,700 f t-lb

(138 bar ): (8 921 N•m) (12 446 N•m) (17 219 N•m)

Rate d Spe e d in High Ge ar ,

106 RPM 76 RPM 55 RPM

35 GPM (133 LPM ):

Tor que Arm Le ngth: 36 in. (914 mm) 36 in. (914 mm) 36 in. (914 mm)

Nom inal Pow e r Re quir e m e nts ,

2,000 PSI (138 bar) 2,000 PSI (138 bar) 2,000 PSI (138 bar)

35 GPM (133 LPM ):

Back up Type : Pne um atic Hydr aulic Hydr aulic

1.05 to 6-1/8 in. 1.05 to 6-1/8 in. 1.05 to 6-1/8 in.

Pipe Size Range :

(26.6 to 155.6 mm) (26.6 to 155.6 mm) (26.6 to 155.6 mm)

© 2004. Weatherford. All rights reserved. 10

Closed-Head Tubing Tongs

Model CH 93

Key Features

! Traditional chain-driven, oil-bath

lubrication system

! Uses the familiar five-jaw and jaw

carrier gripping system

! Optional manual, air or hydraulic

backup

! Optional hydraulic lift cylinder

! Optional torque arm (stiff arm)

Dimensions

Model CH 93

Mode l CH 93

Le ngth: 51 in. (1 295.4 mm)

Width: 22 in. (558.8 mm)

He ight: 32 in. (812.8 mm)

We ight: 1,173 lb (532.07 kg)

Tong Arm Le ngth: 36 in. (914.4 mm)

Specifications

Mode l CH 93

1.312 to 7.0 in.

Pipe Size Range :

(33 to 178 mm)

Tor que in Low Ge ar @ 2,000 PSI 6,000 f t-lb

(138 bar ): (8 135 N•m)

Rate d Spe e d in High Ge ar ,

126 RPM

35 GPM (133 LPM ):

Tor que Arm Le ngth: 22 in. (559 mm)

Nom inal Pow e r Re quir e m e nts ,

2,000 PSI (138 bar)

35 GPM (133 LPM ):

Back up Type : Pne um atic Hydr aulic

1.05 to 6-1/8 in. 1.05 to 6-1/8 in.

Pipe Size Range :

(26.6 to 155.6 mm) (26.6 to 155.6 mm)

11 © 2004. Weatherford. All rights reserved.

Power Sucker Rod Tongs

Models M-20, M-40, M-50 and M-75

Key Features

! Safer than manual rod wrenches

! Optional pressure control valve and

gauge mounted on tong for greater

accuracy of makeup torque

! Reduced incidence of cross

threading

! Increased accuracy and

consistency of makeup torque

Safety Installation and

Removal Tool

! Installs and removes

the rod tong inner ring

assembly when

changing rod sizes.

! Optional safety

installation tool

eliminates need for

placing hands inside

the tong to change

inner rings.

Model M-40

Specifications

Mode ls: M-20 M-40 M-50 M-75

Par t Num be r : 27841 2784 -1 27841-5 27841-7

1,290 f t-lb 1,620 f t-lb 2,040 f t-lb 2,830 f t-lb

M axim um Tor que :

(1 750 N•m) (2 197 N•m) (2 767 N•m) (3 838 N•m)

M axim um Spe e d: 130 RPM 105 RPM 80 RPM 65 RPM

Hydr aulic Re quir e m e nts : 2,000 PSI @ 30 GPM (137.6 bar @ 114 LPM)

348 lb 321 lb 366 lb 366 lb

Es tim ate d We ight:

(157.85 kg) (145.61 kg) (166.02 kg) (166.02 kg)

Rod Size : 0.5 to 1.125 in. (12.7 to 28.6 mm)

API Pipe Range * 1.05 to 1.9 in. (26.7 to 48.3 mm)

*W hen using special jaw assemb ly

© 2004. Weatherford. All rights reserved. 12

Hooks and Links

100-Ton Tubing Hooks and Blocks

Key Features

! Available in the 80 Series

(solid shaft) or the 70 Series

(spring-loaded shaft)

! Solid side plates available in

standard or weighted versions

! Manufactured to API Specification 8C

Dimensions

Mode ls: 70 Se rie s 80 Se rie s

Le ngth: 76 in. (1 930.4 mm) 57 in. (1 447.8 mm)

Width: 27-1/2 in. (698.5 mm) 27-1/2 in. (698.5 mm)

He ight: 15-1/4 in. (387.35 mm) 15-1/4 in. (387.35 mm)

We ight: 2,672 lb (1 120 kg) 2,120 lb (961.32 kg)

80 Series

Weldless Elevator Links

Key Features

! All 1 3/4-in., 150-ton rated

! Available in 36-, 48-, 60-, 72-, 84-

and 96-in. lengths

! Manufactured to API Specification 8C

Dimensions

Mode ls: 36 in. 48 in. 60 in.

Le ngth (ove r all): 42-1/2 in. (1 079.5 mm) 53-1/2 in. (1 358.9 mm) 65-1/2 in. (1 663.7 mm)

Width: 8-1/2 in. (215.9 mm) 8-1/2 in. (215.9 mm) 8-1/2 in. (215.9 mm)

We ight (s e t): 165 lb (74.84 kg) 184 lb (83.46 kg) 220 lb (99.8 kg)

Mode ls: 72 in. 84 in. 96 in.

Le ngth (ove r all): 77-1/4 in. (1 962.1 mm) 90 in. (2 286 mm) 101 in. (2 565.4 mm)

Width: 8-1/2 in. (215.9 mm) 8-1/2 in. (215.9 mm) 8-1/2 in. (215.9 mm)

We ight (s e t): 265 lb (120.2 kg) 308 lb (139.71 kg) 350 lb (158.76 kg)

13 © 2004. Weatherford. All rights reserved.

Tubing Spiders

Models B, C, HD and E

OCM Models B, C, HD and E tubing spiders can handle various tubing sizes and load ratings. Tubing

spiders use two slip body assembly halves. (Slip inserts fit into the slip body assembly elements.)

A safety latch can engage a shoulder on the link to prevent movement of the link and shaft arms.

This feature traps the slips in the down and engaged positions, preventing accidental release of the

tubing string.

Key Features

! Choice of models for varying size

ranges and tonnage ratings for

single-string operations

! Interchangeable doors

(within a model size)

! 360° replaceable inserts

! Air or hydraulic operation

Model C

Model E Model B

Dimensions

Models: B C HD E

He ight to Guard: 14 in. (355.6 mm) 17-1/8 in. (434.97 mm) 17-3/4 in. (450.85 mm) 21-1/2 in. (546.1 mm)

12 to 16 in. 18-3/4 to 18-1/2 in. 19-1/4 to 18-1/2 in. 24-1/2 to 23-1/2 in.

Bas e :

(304.8 to 406.4 mm) (476.25 to 469.9 mm) (488.95 to 469.9 mm) (622.3 to 596.9 mm)

Gate Ope ning: 4-1/4 in. (107.95 mm) 6 in. (152.4 mm) 6 in. (152.4 mm) 7-1/2 in. (190.5 mm)

Bow l Ope ning: 4-3/4 in. (120.65 mm) 6-5/8 in. (168.27 mm) 6-5/8 in. (168.27 mm) 9-1/8 in. (231.77 mm)

We ight: 206 lb (93.44 kg) 346 lb (156.95 kg) 376 lb (170.55 kg) 856 lb (388.28 kg)

© 2004. Weatherford. All rights reserved. 14

Tubing Spiders

Models B, C, HD and E

Specifications

Models: B C HD E

110,000 lb 165,000 lb 250,000 lb 350,000 lb

Capacity:

(49 887 kg) (74 830 kg) (113 379 kg) (158 730 kg)

Tubing Spide r As s e m bly w /o Slips : Part Num be r

Domestic Pneumatic 60000-100 65000-100 65000HD-100 66000-100

Domestic Hydraulic 60000H-100 65000H-100 65000HDH-100 66000H-100

Manual Operation 60000-101

Slip Body As s e m bly, 3-1/2 in. Nom inal*: 60622-100 65622-100 65622-100 66621-100

Slip Ins e rt Se t, 3-1/2 in. Nom inal:

1.315-in. (33.4-mm) tubing 65652-1.315 65652-1.315 65652-1.315

1.660-in. (42.2-mm) tubing 65652-1.660 65652-1.660 65652-1.660

1.900-in. (48.3-mm) tubing 65652-1.900 65652-1.900 65652-1.900

2.060-in. (52.3-mm) tubing 65652-2.060 65652-2.060 65652-2.060

2 3/8-in. (60.3-mm) tubing 65652-1 65652-1 65652-1 66651-1ST

2 7/8-in. (73.0-mm) tubing 65652-2 65652-2 65652-2 66651-2ST

3 1/8-in. (79.4-mm) tubing 65652-3.125 65652-3.125 65652-3.125

3 1/2-in. (88.9-mm) tubing 65652-3 65652-3 65652-3 66651-3ST

Slip Body As s e m bly, 4-1/2 in. Nom inal*: 65623-100 65623-100

Slip Ins e rt Se t, 4-1/2 in. Nom inal:

3 1/2-in. (88.9-mm) tubing 65653-1 65653-1

4-in. (101.6-mm) tubing 65653-2 65653-2

4 1/2-in. (114.3-mm) tubing 65653-3 65653-3

Solid Slip Body As s e m bly:

4.75-in. (120.7-mm) tubing 65624-4.75 65624-4.75

5-in. (127.0-mm) tubing 65624-1 65624-1

5 1/2-in. (139.7-mm) tubing 65624-2 65624-2

7 5/8-in. (193.7-mm) tubing 66625-100ST

Slip Body As s e m bly, 5-1/2 in. Nom inal*: 66623-100

Slip Ins e rt Se t, 5-1/2 in. Nom inal*:

4-in. (101.6-mm) tubing 66653-1

4 1/2-in. (114.3-mm) tubing 66653-2

5-in. (127.0-mm) tubing 66653-3

5 1/2-in. (139.7-mm) tubing 66653-4

Slip Body As s e m bly, 7 in. Nom inal*: 66624-100

Slip Ins e rt Se t, 7 in. Nom inal:

5 1/2-in. (139.7-mm) tubing 66654-1ST

6 5/8-in. (168.3-mm) tubing 66654-2ST

7-in. (177.8-mm) tubing 66654-3ST

*W ithout slip insert set

15 © 2004. Weatherford. All rights reserved.

Inverted Snubbing Spiders

Models C and HD

These spiders can be manufactured to operate in the inverted (or upside-down) position for use in

snubbing operations.

Key Features

! Choice of models for varying size

ranges and tonnage ratings for

single-string operations

! Interchangeable doors

(within a model size)

! 360° replaceable inserts

! Operates pneumatically or

hydraulically

Model HD

Model C

© 2004. Weatherford. All rights reserved. 16

Tubing Spiders

Model G

OCM's Model G tubing spider uses a hinged, three-element, slip body assembly, which accepts slip

inserts. The center element of the slip assembly pivots from a moveable arm, which moves the slips

up and out of the way or down for engagement with the tubing. A pneumatic cylinder enables the

movable arm to pivot. In case of pneumatic pressure failure, the slips will set automatically.

Key Features Dimensions

! Optional three-body slip system Mode l G

uses OCM FCI-type inserts for 270° He ight to Guar d: 9-5/16 in. (236.5 mm)

pipe gripping Bas e : 15-1/4 to 21-1/4 in. (387 to 540 mm)

! One body size runs 2-3/8 to Gate Ope ning: 4-1/2 in. (114 mm)

3-1/2 in.-OD tubulars Bow l Ope ning: 5-7/8 in. (149 mm)

We ight: 136 lb (61.69 kg)

! Operates pneumatically or

hydraulically

Specifications

M ode l G

120,000 l b

Capacity:

(54 431 k g)

Tubing Spide r As s e m bly w /o Slips : Part Num be r

Domestic Pneumatic 61000-100

International Pneumatic 61000

Slip Body As s e m bly, 3-1/2 in. Nom inal*: 61003-100

Slip Ins e rt Se t, 3-1/2 in. Nom inal:

1.050-in. (26.7-mm) tubing 61041-101

1.315-in. (33.4-mm) tubing 61041-102

1.660-in. (42.2-mm) tubing 61041-103

1.900-in. (48.3-mm) tubing 61041-104

Model G

2.060-in. (52.3-mm) tubing 61041-105

2 3/8-in. (60.3-mm) tubing 61006-101

2 7/8-in. (73.0-mm) tubing 61006-102

3 1/2-in. (88.9-mm) tubing 61006-103

Slip Body As s e m bly, 4-1/2 in. Nom inal*: 61039-100

Slip Ins e rt Se t, 4-1/2 in. Nom inal:

3 1/2-in. (88.9-mm) tubing 61040-101

4-in. (101.6-mm) tubing 61040-102

4 1/2-in. (114.3-mm) tubing 61040-103

*W ithout slip insert set

17 © 2004. Weatherford. All rights reserved.

Center-Latch Tubing Elevator

Models CL-65 and CL-100

OCM's center-latch tubing elevator can handle plain or upset collar-type tubing, drill pipe and casing.

The elevator is designed for various tubing sizes and for 65- and 100-ton load ratings. The two

halves of the elevator are of about equal weight, providing proper balance for easier opening and

closing. A safety latch prevents accidental opening of the elevator. Pulling on the latch disengages it

and opens the elevator. Closing the two halves of the elevator automatically resets the latch in the

locked position.

Key Features Dimensions

! Safety latch and latch lock design Models: CL-65 2-7/8 in. CL-65 4-1/2 in.

! Raised load-bearing surface versus Length: 17-3/8 in. (441.3 mm) 17-3/8 in. (441.3 mm)

Width: 16-1/4 in. (412.8 mm) 16-1/4 in. (412.8 mm)

traditional elevators. When

repairing, this surface can be Height: 9-3/4 in. (247.6 mm) 9-7/8 in. (250.8 mm)

machined instead of being forced to Weight: 120 lb (54.43 kg) 160 lb (72.58 kg)

build up elevator body.

Models: CL-100 2-7/8 in. CJ-100 4-1/2 in.

! Rear handle for safer handling Length: 17-1/4 in. (438.1 mm) 19-1/4 in. (488.9 mm)

! Available in 65- and 100-ton Width: 16-1/4 in. (412.7 mm) 18-1/4 in. (463.5 mm)

versions Height: 10-1/4 in. (260.3 mm) 11 in. (279.4 mm)

Weight: 128 lb (58.06 kg) 172 lb (78.02 kg)

! Manufactured to API Specification 8C

Specifications

Models: CL-65 CL-100

Capacity: 65 ton (59.0 tonne) 100 ton (90.7 tonne)

Tubing Size and Type : Part Num be r

1.660-in. (42.2-mm) plain 100063-100 --

1.660-in. (42.2-mm) upset 100064-100 --

1.900-in. (48.3-mm) plain 100065-100 --

1.900-in. (48.3-mm) upset 100066-100 --

2 3/8-in. (60.3-mm) plain 100067-100 100017-100

2 3/8-in. (60.3-mm) upset 100068-100 100018-100

2 7/8-in. (73.0-mm) plain 100070-100 100019-100

2 7/8-in. (73.0-mm) upset 100071-100 100020-100

3 1/2-in. (88.9-mm) plain 100072-100 100021-100

3 1/2-in. (88.9-mm) upset 100073-100 100022-100

4-in. (101.6-mm) plain 100074-100 100023-100

4-in. (101.6-mm) upset 100075-100 100024-100

Model CL-100

4 1/2-in. (114.3-mm) plain 100076-100 100025-100

4 1/2-in. (114.3-mm) upset 100077-100 100026-100

© 2004. Weatherford. All rights reserved. 18

Side-Door Tubing Elevator

Models SD-65 and SD-100

OCM's side-door tubing elevator can handle plain or upset collar-type tubing, drill pipe and casing.

The elevator is designed for various tubing sizes and for 65- and 100-ton load ratings. A built-in safety

feature prevents the door from opening when a load is on the elevator. Front and rear handles

enhance safety and ease of operation.

Key Features

! Safety lock design ! Rear handle for safer handling

! Raised load-bearing surface versus ! Available in 65- and 100-ton

traditional elevators allows for versions

multiple refacing rather than

! Manufactured to API Specification 8C

building up elevator body.

Dimensions

Mode ls: SD-65 SD-100

Le ngth: 21-13/16 in. (554 mm) 23 in. (584.2 mm)

Width: 11 in. (279.4 mm) 12 in. (304.8 mm)

He ight: 8-3/8 in. (212.7 mm) 10-1/2 in. (266.7 mm)

We ight: 82 lb (37.19 kg) 138 lb (62.6 kg)

Specifications

Model SD-100

Models: SD-65 SD-100

Capacity: 65 ton (59.0 tonne) 100 ton (90.7 tonne)

Tubing Size and Type : Part Num be r

1.900-in. (48.3-mm) plain 20296-156 12600-156

1.900-in. (48.3-mm) upset 20296-157 12600-157

2-3/8-in. (60.3-mm) plain 20296-158 12600-158

2-3/8-in. (60.3-mm) upset 20296-159 12600-159

2 7/8-in. (73.0-mm) plain 20296-160 12600-160

2 7/8-in. (73.0-mm) upset 20296-161 12600-161

3 1/2-in. (88.9-mm) plain 20296-162 12600-162

3 1/2-in. (88.9-mm) upset 20296-163 12600-163

Es tim ate d We ight: 82 lb (37.2 kg) 138 lb (62.6 kg)

19 © 2004. Weatherford. All rights reserved.

Tubing Elevator

Model YC Slip-Type

Key Features

! Rated at 75 ton

! Size range 3-1/2 in. to 7 in.-OD

tubulars

! Manufactured to API Specification 8C

Dimensions

Mode l YC Ele va tor

Le ngth: 29-1/2 in. (749.3 mm)

Width: 27-3/4 in. (704.85 mm)

He ight: 12 in. (304.8 mm)

We ight: 450 lb (204.12 kg)

Model YC Slip Body

Specifications

Mode l YC

Capacity: 75 ton (68 tonne)

YC Slip-Type Ele vator ,

Par t Num be r Es tim ate d We ight

Le s s Slips and Guide Plate s

24140-100 455 lb (206.38 kg)

Slip Body Se t As s e m bly,

Le s s Guide Plate s

4-1/2 x 3-1/2 in. (114.3 x 88.9 mm) 34931-200 130 lb (58.97 kg)

4-1/2 x 4 in. (114.3 x 101.6 mm) 26830-200 120 lb (54.43 kg)

4-1/2 x 4-1/2 in. (114.3 x 114.3 mm) 24072-5-200 116 lb (52.62 kg)

5-1/2 x 5 in. (139.7 x 127.0 mm) 24072-7-200 112 lb (50.80 kg)

5-1/2 x 5-1/2 in. (139.7 x 139.7 mm) 24072-2-200 108 lb (48.99 kg)

7 x 6-5/8 in. (177.8 x 168.3 mm) 24077-7-200 101 lb (45.81 kg)

7 x 7 in. (177.8 x 177.8 mm) 24077-1-200 97 lb (43.99 kg)

Bottom Guide Plate Se ts :

3-1/2 in. (88.9 mm) 26827-1-100 7.5 lb (3.4 kg)

4 in. (101.6 mm) 26827-100 8.75 lb (3.97 kg)

4-1/2 in. (114.3 mm) 24071-4-100 8.5 lb (3.85 kg)

5 in. (127.0 mm) 24071-100 8 lb (3.63 kg)

5-1/2 in. (139.7 mm) 24071-1-100 5.75 lb (2.61 kg)

6-5/8 in. (168.3 mm) 24071-3-100 5.25 lb (2.38 kg)

7 in. (177.8 mm) 24071-2-100 3.75 lb (1.70 kg)

© 2004. Weatherford. All rights reserved. 20

Heavy-Duty Rod Hooks

Models RH-20 and RH-35

OCM rod hooks are available with a load rating of either 20 or 35 tons and with a choice of locking

mechanism. The standard locking mechanism operates with a one-hand grip at the hook's center of

balance. This capability allows the operator to steady the hook, open the latch, and engage or remove

the bail of the rod elevator in one smooth, continuous motion on or off the hook. The alternative to the

standard lock is a new latching mechanism that further enhances operator safety.

Both models feature a structural guard on the rod hook that protects the operator's hand. The RH-35

rod hook uses a spring support for easier stabbing, makeup, and disengagement of sucker rod

threads; however, some operators prefer the shorter length of the RH-20 model.

Key Features

! Choice of 20- and 35-ton models

! Both models available in standard

locking version or with new safety

latch mechanism for increased

safety

! Manufactured to API Specification 8C

Specifications

Mode ls: RH-20 RH-35

Capacity: 20 ton (18.1 tonne) 35 ton (31.8 tonne)

Par t Num be r : 22040 - 100 21982 - 100

Le ngth: 25-1/2 in. (648mm) 39 in. (991 mm)

We ight: 51 lb (23.1 kg) 88 lb (39.9 kg)

Model RH-20

Model RH-35

21 © 2004. Weatherford. All rights reserved.

Heavy-Duty Rod Elevators

Models RES-1 and REP-1

Key Features

! Available in solid or plate-type body

style

! Reversible body styles

! Front and rear latches for easier

operation

! Manufactured to API Specification 8C

Specifications

RES-1 REP-1

Mode ls:

(Solid) Body (Pla te -Type ) Body

50,000 lb 50,000 lb

Capacity:

(19 501.1 kg) (19 501.1 kg) Model RES-1

We ight: 32 lb (14.5 kg) 31 lb (14.1 kg)

Size Range : Par t Num be r

1/2 to 5/8 in. (13 to 16 mm) -- 27728-100

5/8 to 3/4 in. (16 to 19 mm) 27725-100 27729-100

3/4 to 7/8 in. (19 to 22 mm) 27726-100 27730-100

1 in. (25 mm) 27727-100 27731-100

1-1/8 in. (29 mm) 27750-100 27732-100

Mode l PRE (Solid) Body for Polishe d Rods

50,000 lb

Capacity:

(19 501.1 kg)

We ight: 32 lb (14.5 kg)

Size Range : Par t Num be r

1in. (25 mm) 27736-100

1-1/8 in. (29 mm) 27733-100

1-1/4 in. (31.75 mm) 27734-100

1-1/2 in. (38 mm) 37735-100 Model REP-1

© 2004. Weatherford. All rights reserved. 22

Rod Handling Accessories

Rod Swivel

OCM rod swivels create a safer working environment by greatly reducing the effects of potentially

dangerous operations, such as releasing sanded-up rods in standard pump wells. In a progressive

cavity pump application, once the downhole pump is initially unseated, the rods will spin within the rod

swivel, and that action is contained within the tubing elevator. After the danger has passed, the rod

swivel is removed, and normal operations can resume. The rod swivel works in either a 2 7/8- or

3 1/2-in. collar-type tubing elevator.

Dimensions

Rod Sw ive l

Width: 7 in. (177.8 mm)

He ight: 18 in. (457.2 mm)

We igh: 53 lb (24.04 kg)

35-Ton Rod Hook Clevis

Key Features

! For installation of rod hook onto

blocks

! Manufactured to API Specification 8C

23 © 2004. Weatherford. All rights reserved.

Miscellaneous

Depthometer

OCM's depthometer gives quick and accurate wireline measurements when performing bailing,

cleaning out, swabbing or similar operations.

Key Features

! Available in either ball-bearing or

bronze-bearing design

Specifications

Mode ls: Bronze Be a ring Ba ll Be a ring

(units in f t) (units in mm) (units in f t) (units in mm)

Par t Num be r :

14000-200 14000-202 14000-201 14000-203

We ight: 11 lb (5 kg) 11 lb (5 kg)

Model DP-200

Sucker Rod Wrenches

Specifications

Suck e r Rod Wr e nch

Rod/Coupling** Size of Suck e r Handle Le ngth Wr e nch He ad Spr ing Kit***

As s e m bly

Squar e Size (in.) Rod* (in.) (in.) Par t Num be r Par t Num be r

Par t Num be r

QA 1-19 7/8 in. 5/8 in. SR 19 in. 27609 800026

QA 2-19 1 in. 3/4 to 7/8 in. SR 19 in. 27610 800026

QA 2-19R 1-1/8 in. 7/8 in. EL SR 19 in. 27611 800026

QA 4-19 1-5/16 in. 1 in. SR 19 in. 27612 800026

QA 5-19 1-1/2 in. 1-1/8 in. SR 19 in. 27613 800026

*SR = Sucker rod

**RC = Rod coupling

***Spring kit includes 1 spring, 1 pivot pin and 2 retainer rings.

© 2004. Weatherford. All rights reserved. 24

Manufacturing Facility

Ventura, CA, USA

800-338-5889

805-643-1200

Regional Offices

Bakersfield, CA, USA

661-322-5966

Oklahoma City, OK, USA

405-206-7158

Odessa, TX, USA

800-364-9140

432-362-0339

Edmonton, Alberta, Canada

780-448-1721

515 Post Oak Blvd., Suite 600

Houston, Texas 77027

Phone: 713-693-4000 Weatherford products and services are subject to Weatherford’s standard terms and

conditions. For more information concerning the full line of Weatherford products and

Fax: 713-693-4300 services, please contact your authorized Weatherford representative. Unless noted

www.weatherford.com otherwise, trademarks and service marks noted herein are the property of Weatherford.

© 2004. Weatherford. All rights reserved. Brochure 483.01

You might also like

- Bowen Fishing Tools CatalogDocument4 pagesBowen Fishing Tools Cataloghamid nobakhtNo ratings yet

- Critical Area Inspection From Vaco BJDocument76 pagesCritical Area Inspection From Vaco BJHassan KhalidNo ratings yet

- Catalog PDFDocument222 pagesCatalog PDFLeandro100% (1)

- FMS 275 ManualDocument62 pagesFMS 275 ManualRagesh Raghavan100% (2)

- Lecture 12 FatigueDocument23 pagesLecture 12 Fatigueantoine demeire100% (2)

- Cameron BOP Parts CatalogueDocument142 pagesCameron BOP Parts CatalogueRodrigo AbbaNo ratings yet

- Spider Elevator B+V Forum CatalogDocument40 pagesSpider Elevator B+V Forum CatalogIRWIN_DSOUZA100% (1)

- Catálogo Cameron Bop Novo 2004-2005Document162 pagesCatálogo Cameron Bop Novo 2004-2005Edmo Virgens100% (1)

- Doc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualDocument12 pagesDoc. 20-1715 Rev D (9/12/1005) Pneumatic Spider Operating Procedure ManualGregory StewartNo ratings yet

- Master Bushing-Bowls - DENCON ToolDocument5 pagesMaster Bushing-Bowls - DENCON ToolcristinelbNo ratings yet

- B+V Manual - VES-HCL 350Document62 pagesB+V Manual - VES-HCL 350osvaldoNo ratings yet

- Swivel King Oil ToolsDocument48 pagesSwivel King Oil ToolsLuis Aparcana100% (1)

- Cameron EB 538 D Rev D2 - Shear Rams - Op & MaintDocument7 pagesCameron EB 538 D Rev D2 - Shear Rams - Op & MaintCanrig RamdeNo ratings yet

- Rotary Slips "RDL" "RD" "RDS": Side Door Elevator 150 TON 250 TON 350 TONDocument11 pagesRotary Slips "RDL" "RD" "RDS": Side Door Elevator 150 TON 250 TON 350 TONShaikh Sabir HussainNo ratings yet

- Maintenance Y SERIESDocument10 pagesMaintenance Y SERIESStowartNo ratings yet

- Annular Bop Packing Elements: Otu Se (Axs)Document2 pagesAnnular Bop Packing Elements: Otu Se (Axs)JoseManuelDominguezHuertaNo ratings yet

- Min - TJL API RP 7G-2 - For MSDocument1 pageMin - TJL API RP 7G-2 - For MSQuality controllerNo ratings yet

- AAX Tong MaintenanceDocument7 pagesAAX Tong MaintenanceBahman Matouri100% (1)

- 9 - Single Joint ElevatorDocument2 pages9 - Single Joint ElevatorleoNo ratings yet

- DL Annular Blowout Preventer 21-1/4" 3000 Psi WPDocument27 pagesDL Annular Blowout Preventer 21-1/4" 3000 Psi WPJeneesh Shanmughan100% (1)

- 2-36, TMC Jar, OpDocument15 pages2-36, TMC Jar, OpAli HosseiniNo ratings yet

- Manual: CDQ (S) Sucker Rod ElevatorsDocument5 pagesManual: CDQ (S) Sucker Rod ElevatorsDarshan MakwanaNo ratings yet

- TW514Document32 pagesTW514Rafael Charry AndradeNo ratings yet

- Deadline Anchors BrochureDocument3 pagesDeadline Anchors Brochurejlmunozv100% (3)

- Shearing Blind Rams SBRDocument8 pagesShearing Blind Rams SBRDavid OrtegaNo ratings yet

- Nov Mission Drilling SolutionsDocument24 pagesNov Mission Drilling SolutionsahnafNo ratings yet

- Shaffer NOV Type 72 ShearsDocument2 pagesShaffer NOV Type 72 ShearsTitanBOP100% (1)

- Den Con Cat 2012Document36 pagesDen Con Cat 2012rage7No ratings yet

- Safety Clamp: Operation ManualDocument21 pagesSafety Clamp: Operation ManualDavid Venegas AndradeNo ratings yet

- Araña BJ 350 Ton 13 3-8Document60 pagesAraña BJ 350 Ton 13 3-8ceciliachableNo ratings yet

- Part Number 26-62 Revision A: Illustrated Parts ListDocument276 pagesPart Number 26-62 Revision A: Illustrated Parts ListAndres NavarroNo ratings yet

- Den Con 2006 2007 CatalogDocument28 pagesDen Con 2006 2007 CatalogazeazeazeNo ratings yet

- Contitech HP HosesDocument65 pagesContitech HP HosesRobert FlateråsNo ratings yet

- 00-24 Proper Clamps Mud HoseDocument2 pages00-24 Proper Clamps Mud Hoseforajistu100% (1)

- H Tong Maintenance ManualDocument8 pagesH Tong Maintenance ManualBahman MatouriNo ratings yet

- 13.625 10000 15mbtm Hydril GK Screwed Annular Bop Spec SheetDocument1 page13.625 10000 15mbtm Hydril GK Screwed Annular Bop Spec SheetJoel SNo ratings yet

- Spider Varco 375Document1 pageSpider Varco 375Hany AhmedNo ratings yet

- Barco BJ PDFDocument9 pagesBarco BJ PDFJose CamachoNo ratings yet

- TPWSD Catalog 2010Document36 pagesTPWSD Catalog 2010miguel mendozaNo ratings yet

- Access Manual ToolsDocument72 pagesAccess Manual ToolsJinhichi Molero Rodriguez0% (1)

- Mast Leg Weight Indicator: Part Number TW1001 Revision ADocument20 pagesMast Leg Weight Indicator: Part Number TW1001 Revision ALuis Eduardo Albarracin RugelesNo ratings yet

- Section 4: Pressure Control EquipmentDocument47 pagesSection 4: Pressure Control Equipmentgonzalito777No ratings yet

- Swivel Joints, Interchangeable FMC and SPMDocument3 pagesSwivel Joints, Interchangeable FMC and SPMAlice MiNo ratings yet

- HH SwivelDocument3 pagesHH SwivelHoracio LafuenteNo ratings yet

- Tubular Running Services ItemisedDocument10 pagesTubular Running Services ItemisedNoel JenningsNo ratings yet

- General Catalog: Midco Petroleum PartsDocument44 pagesGeneral Catalog: Midco Petroleum PartsabdulNo ratings yet

- Westco Model5500 Tubing TongDocument51 pagesWestco Model5500 Tubing Tong000No ratings yet

- Chart Drives: Technical DataDocument4 pagesChart Drives: Technical DataJohn Suarez100% (1)

- Den Con 2009 2010 CatalogDocument36 pagesDen Con 2009 2010 CatalogAdrian Cantaragiu100% (1)

- COS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronDocument5 pagesCOS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronYudaNo ratings yet

- Annular Bops D Bop DL Bop: To Contents PageDocument6 pagesAnnular Bops D Bop DL Bop: To Contents PageDavid OrtegaNo ratings yet

- Catalog 2Document44 pagesCatalog 2Enrique HortaNo ratings yet

- Axon-Type50u Ram BopDocument4 pagesAxon-Type50u Ram BopMohie Khosravani0% (1)

- Api Flange Bolt & Ring Chart: PO BOX 639 - Bakersfield, CA 93302Document1 pageApi Flange Bolt & Ring Chart: PO BOX 639 - Bakersfield, CA 93302Prasetiyo SholehNo ratings yet

- Gardner Denver - Bomba de Lodos PZJ-9 Part ListDocument29 pagesGardner Denver - Bomba de Lodos PZJ-9 Part ListAngel LunaNo ratings yet

- 13.62 5K Model 7022 Manual PDFDocument30 pages13.62 5K Model 7022 Manual PDFPato GonzalezNo ratings yet

- Tc1001 06 Cameron TopDocument151 pagesTc1001 06 Cameron TopTopoilServNo ratings yet

- Cameron Hydraulic Gate Valves Type F & FCDocument3 pagesCameron Hydraulic Gate Valves Type F & FCJuan Sebastian Diaz CuadrosNo ratings yet

- Oil ContryDocument28 pagesOil ContryMauricio CordiNo ratings yet

- VMQ PDFDocument78 pagesVMQ PDFoleg-spbNo ratings yet

- B+V-Manual - Tongs BV & WRT Models PDFDocument58 pagesB+V-Manual - Tongs BV & WRT Models PDFYina Useche100% (2)

- Copertina Commercial PDFDocument1 pageCopertina Commercial PDFYina UsecheNo ratings yet

- B+V Manual - Elevator Links PDFDocument10 pagesB+V Manual - Elevator Links PDFYina UsecheNo ratings yet

- Allison CLBT, CLT, VCLBT, 5861, AL 6061 2Document45 pagesAllison CLBT, CLT, VCLBT, 5861, AL 6061 2Yina Useche100% (1)

- Operate Pumping Systems and Associated Control SystemsDocument16 pagesOperate Pumping Systems and Associated Control SystemsCharles Adorador VillaricoNo ratings yet

- Requirements For Occupancy Permit For PEZADocument4 pagesRequirements For Occupancy Permit For PEZAAllan Ydia100% (1)

- Managing Innovation Within Firm Chap-2Document48 pagesManaging Innovation Within Firm Chap-29904152180No ratings yet

- Local Site Effects and Design Ground Motions (Lectures 23 To 26)Document8 pagesLocal Site Effects and Design Ground Motions (Lectures 23 To 26)YHTRTRNo ratings yet

- System ModelsDocument18 pagesSystem ModelsgurugksNo ratings yet

- My IT ReportDocument21 pagesMy IT Reportemmanuelezekulie2No ratings yet

- Alpago Daily Report 36 RevDocument2 pagesAlpago Daily Report 36 RevKHALID NAZKINo ratings yet

- LEcture 9 (Software Evolution)Document17 pagesLEcture 9 (Software Evolution)umer farooqNo ratings yet

- Admission Requirements For The Building DisciplineDocument13 pagesAdmission Requirements For The Building Disciplineresearchtemp3No ratings yet

- Sequential ControlDocument6 pagesSequential ControlPurushoth ReddyNo ratings yet

- The Golden Gate BridgeDocument3 pagesThe Golden Gate BridgeMikel CordovaNo ratings yet

- Carrier 38ANDocument30 pagesCarrier 38ANeeooaaiiNo ratings yet

- Sampling, Testing Inspection For Structural Works: CE157 Group 5Document40 pagesSampling, Testing Inspection For Structural Works: CE157 Group 5Annerose GaleraNo ratings yet

- 5.01 Cold Water Pipe Sizing Testing and Commissioning 2Document3 pages5.01 Cold Water Pipe Sizing Testing and Commissioning 2Khiem LeNo ratings yet

- Impact of Hybrid FACTS Devices On The STDocument10 pagesImpact of Hybrid FACTS Devices On The STyhonatan_21No ratings yet

- Notification Supervisor (Mechanical)Document2 pagesNotification Supervisor (Mechanical)sivagnanam sNo ratings yet

- Kurt Crawford ResumeDocument1 pageKurt Crawford Resumequiksilver4727No ratings yet

- Pipe Section Technical Papers - Aug 28 2009Document8 pagesPipe Section Technical Papers - Aug 28 2009Vân Anh TrầnNo ratings yet

- Sir Syed University of Engineering & Technology, Karachi: Rubrics For FYDP Final AssessmentDocument2 pagesSir Syed University of Engineering & Technology, Karachi: Rubrics For FYDP Final AssessmentHey MarkoNo ratings yet

- JNTUK BT 3-1 Sem R16 TT Aug 2021Document5 pagesJNTUK BT 3-1 Sem R16 TT Aug 2021SreelekhaNo ratings yet

- Day 12 Earthquake Load AnalysisDocument49 pagesDay 12 Earthquake Load AnalysisV.m. RajanNo ratings yet

- NUSE AR2018spreadsDocument22 pagesNUSE AR2018spreadsGlenden KhewNo ratings yet

- Model-Based Software ArchitecturesDocument13 pagesModel-Based Software Architecturesshibhi100% (1)

- NBA PG SAR 2013 Computer Science Engg PDFDocument123 pagesNBA PG SAR 2013 Computer Science Engg PDFjeevan gNo ratings yet

- SAEP 1610 (Oct 2017)Document9 pagesSAEP 1610 (Oct 2017)nadeem shaikhNo ratings yet

- References ThesisDocument4 pagesReferences ThesisMohammad Zohaib Khan KambohNo ratings yet

- Mix Design LogDocument8 pagesMix Design LogpratimwhiteNo ratings yet

- Introduction To Process Plant Layout and Piping DesignDocument39 pagesIntroduction To Process Plant Layout and Piping DesignJohn Jhay Canlas100% (2)

- SACTIP-Q-001-05 Rev.01 Precast Concrete at Fabrication YardsDocument3 pagesSACTIP-Q-001-05 Rev.01 Precast Concrete at Fabrication YardsMuhammad AbrarNo ratings yet