Professional Documents

Culture Documents

Cause & Effect Matrix-Rev2

Uploaded by

Steve WanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cause & Effect Matrix-Rev2

Uploaded by

Steve WanCopyright:

Available Formats

DHU-NOCL PROJECT

Cuddalore Refinery, Tamil Nadu

Nagarjuna Oil Corporation Limited, CB&I Lummus Crest

Cuddalore, TamilNadu, India Mauritius

Page 1 of 3

CAUSE & EFFECT MATRIX

140-H-001

02 2011-01-20 COMMENTS INCORPORATED RP AB AB

01 2010-08-12 COMMENTS INCORPORATED RP AB AB

00 2010-09-11 ISSUED FOR ENGINEERING RP AB AB

Rev Date Reason for Issue Prepared Checked Approved

Contractor Doc. No. : CS-140-XX-15-9004

DHU-NOCL Project Doc No : CS-140-XX-15-9004

Cuddalore Refinery, Tamil Nadu Rev: 02

Title

Page: 2 of 3

TABLE OF CONTENT

1 CAUSE & EFFECT MATRIX

DHU-NOCL Project Doc No : CS-140-XX-15-9004

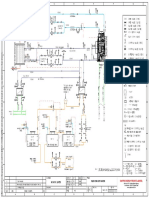

Cuddalore Refinery, Tamil Nadu CAUSE AND EFFECT MATRIX FOR 140-H-001 Rev: 02

Page: 3 of 3

Group

UZ-718

XZV-718A/718C XZV-718A/718C

XZV-718E/718F XZV-718E/718F

Tag No.

XZV-718W

XZV-718M

XZV-718G

XZV-718O

XZV-718Q

XZV-718N

XZV-718D

XZV-718H

XZV-718R

XZV-718U

XZV-718B

XZV-718P

XZV-718X

XZV-718S

XZV-718Y

XZV-718K

XZV-718V

XZV-718T

XZV-718Z

XZV-718L

XZV-718J

XZV-718I

HCV-830

Final Element

XZV-718W

XZV-718M

XZV-718G

XZV-718O

XZV-718Q

XZV-718N

XZV-718D

XZV-718H

XZV-718R

XZV-718U

XZV-718B

XZV-718P

XZV-718X

XZV-718S

XZV-718Y

XZV-718K

XZV-718V

XZV-718T

XZV-718Z

XZV-718L

XZV-718J

XZV-718I

HCV-830

Bleed valve at Fuel Gas supply line for Main Burner

CAUSE AND EFFECT DIAGRAM - SAFEGUARDING INTERLOCK NO - 140-UZ-718

STOP Fuel Gas Supply to Main Burner

STOP Fuel Gas Supply to Pilot Burner

STOP Fuel Oil Supply to Main Burner

FUEL Gas bleed valve for Burner-1

MAN/100%/P Heater Damper Valve Fully Open

FUEL OIL Supply To BURNER-1

FUEL OIL Supply To BURNER-2

FUEL OIL Supply To BURNER-3

FUEL OIL Supply To BURNER-4

FUEL Gas Supply To Burner-1

FUEL Gas Supply To Burner-2

FUEL Gas Supply To Burner-3

FUEL Gas Supply To Burner-4

MP Steam Supply To Burner-1

MP Steam Supply To Burner-2

MP Steam Supply To Burner-3

MP Steam Supply To Burner-4

FUEL Gas Supply To PILOT-1

FUEL Gas Supply To PILOT-2

FUEL Gas Supply To PILOT-3

FUEL Gas Supply To PILOT-4

FUEL Gas Bleed To PILOT-1

Bleed Valve of Pilot Burner

Stop Fuel Oil RETURN

Service Description

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

CLOSE

OPEN

OPEN

OPEN

OPEN

Action

Tag No. Service Description Tag No. UNIT NO INTERLOCK NO P & I D No.

Description of Safeguarding Block

140-PR-15-0004/140-

TZ-123 High high coil outlet Temperature 140-TT-123 A,B, C PR-15-0024/140-PR-15- x x x x x x x x x x x x x x x x

140 I-1 0026

PZ-821 Low low Pressure Fuel Gas to burner (2 OO 3) 140-PT-821 A,B,C 140-PR-15-0024 x x x x x x x

140 I-3

PZ-823 Low lowfuel gas pressure in pilot (2 OO 3) 140-PT-823 A,B,C 140-PR-15-0026 x x x x x x x x x x x x x x x x x x x x x x x x

140 I-5

140-PR-15-0026/ 140-

PZ-858 Low Low Pressure in heater of Fuel oil to Main burner 140-PT-858 A,B,C 140 x x x x x x x x x

I-4 PR-15-0024

Low Low Differential Pressure between fuel oil and atomised 140-PR-15-0026/ 140-

PDZ-860 140-PDT-60A,B,C 140 x x x x x x x x x

steam to burner (2 OO 3) I-2 PR-15-0024

PZ-900 Arch pressure High 140-PT-900A,B,C 140 I-6A 140-PR-15-0004 x

PZ-900 Arch pressure High high (2003 Voting) 140-PT-900A,B,C 140 I-6B 140-PR-15-0004 x x x x x x x x x x x x x x x x x

BZ-B-1 Flame Failure For Burner-1 140-BI-B-1 140 I-9 140-PR-15-0024 x x x x x x

BZ-B-2 Flame Failure For Burner-2 140-BI-B-2 140 I-10 140-PR-15-0024 x x x x

BZ-B-3 Flame Failure For Burner-3 140-BI-B-3 140 I-11 140-PR-15-0024 x x x x

BZ-B-4 Flame Failure For Burner-4 140-BI-B-4 140 I-12 140-PR-15-0024 x x x x

HZ-054 Emergency Trip Switch Local HZ-054 140 I-8 (Note-9) x x x x x x x x x x x x x x x x x x x x x x x

HZ-843 Emergency Trip Switch in Console Panel. HZ-843 140 I-8 (Note-9) x x x x x x x x x x x x x x x x x x x x x x x

Actuation of I3, I4 & I5 together I-15 x

Close of PCV-820/Malfunction Feedback from 140-PY-820 140 x x x x x x x x x

Feedback from 140-PY-

Close of PCV-823A/Malfunction 140 x x x x x x

823A

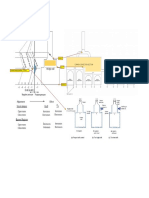

NOTES:

1. IN THE EVENT OF ACTUATION OF EMERGENCY HEATER SHUT DOWN PUSH BUTTON PROVIDED AT CONTROL ROOM, FUEL OIL, MAIN FUEL GAS & PILOT GAS TO THE FURNACE WILL BE CUT OFF AND STACK DAMPER OF THE FURNACE WILL OPEN EVEN IF INTERLOCKS ARE IN BYPASS MODE. A LOCAL

EMERGENCY PUSH BUTTON IS ALSO PROVIDED IN THE FIELD 15 METERS AWAY FROM FURNACE INSIDE A 'BREAK GLASS' ENCLOSURE.

2 FOR EACH INDIVIDUAL INTERLOCK MOS/BYPASS SOFT SWITCH WILL BE AVAILABLE IN THE PLC/SCADA. NO LAMP INDICATION IS AVAILABLE AT MAIN CONTROL ROMM PANEL FOR THE SAME.

3. INTERLOCK DESCRIPTION WITH CAUSE AND EFFECT ARE MENTIONED IN THE DOCUMENT. THIS IS BASED ON INTERLOCK DESCRIPTION DOCUMENT HOWEVER EFFECT AND ACTION OF BURNER ON/OFF VALVES ARE SHOWN IN THE C & E MATRIX.

4.IF STACK DAMPER DOES NOT OPEN FULLY WITHIN 20 SECONDS, ACTUATE I-6B

5. ACTUATION OF I-6A - START OPENING STACK DAMPER (10 SECONDS), IF PAH PERSISITS- START INTERLOCK TIMER I-6B 10SECS AND ACTUATE I-6B AFTER LAPSE OF 10 SECONDS IF PAH PERSISTS

6. I-15 INTERLOCK SHALL BE PROVIDED WITH START UP OVERRIDE

7. IN CASE OF ACTIVATION OF EMERGENCY DEPRESSURE, ALL FUEL OIL SUPPLY, AND FUEL GAS SUPPLY ON/OFF VALVES SHALL BE CLOSED AND CONTROLLERS 140-PC-820 AT FG LINE AND 140-PC-823 AT FO LINE SHALL BE FORCED TO CLOSED. (CONTROLLER OUTPUT - 0%)

8. IN CASE OF ACTIVATION OF INTERLOCKS I-3, I-4 & I-5, 140-PC-899 DAMPER VALVE SHALL BE FORCED TO OPEN. (CONTROLLER OUTPUT - 100%)

9. HZ-054 & HZ-843 ARE CLUBBED TOGETHER IN INTERLOCK I-8.

9. IN CASE OF ACTUATION OF INTERLOCK I-1, SEQUENCE AS MENTIONED IN CLAUSE 11.7 OF HEATER OPERATION PHILOSOPHY HAS TO BE FOLLOWED.

You might also like

- Final ExamDocument6 pagesFinal ExamTej ChoksiNo ratings yet

- Clean Coal Reference FGDDocument129 pagesClean Coal Reference FGDraharjoitb100% (1)

- High Integrity Protective SystemsDocument9 pagesHigh Integrity Protective SystemsAbhiyan Anala ArvindNo ratings yet

- Optimization of Water Reuse Network Using Water Pinch Technology WPT by Considering Single Contaminant For Kaduna Refinery and Pet 2375 4397 1000173Document6 pagesOptimization of Water Reuse Network Using Water Pinch Technology WPT by Considering Single Contaminant For Kaduna Refinery and Pet 2375 4397 1000173Brario AninditoNo ratings yet

- The Chemistry of COSDocument20 pagesThe Chemistry of COSsharkkingkingNo ratings yet

- Pid Engtech Pilot Plants v04pdfDocument20 pagesPid Engtech Pilot Plants v04pdfFaizan SarangNo ratings yet

- Introduction To Inherently Safer Design: Prepared For Safety and Chemical Engineering Education (SACHE) byDocument71 pagesIntroduction To Inherently Safer Design: Prepared For Safety and Chemical Engineering Education (SACHE) bySebastian iacopiNo ratings yet

- En Analysis of Thermal Efficiency Limit of Steam Methane Reforming ProcessDocument8 pagesEn Analysis of Thermal Efficiency Limit of Steam Methane Reforming ProcessAgam HanasichulaNo ratings yet

- Batch Processing Systems Engineering - Fundamentals and Applications For Chemical EngineeringDocument885 pagesBatch Processing Systems Engineering - Fundamentals and Applications For Chemical EngineeringitzelselNo ratings yet

- 06-449T R.1 PDFDocument76 pages06-449T R.1 PDFKhaqqul YaqinNo ratings yet

- Thermal Expansion FormulaDocument3 pagesThermal Expansion FormulaAnkur KoulNo ratings yet

- Gbhe-Peg-015 Practical Guide On The Reduction of DiscDocument87 pagesGbhe-Peg-015 Practical Guide On The Reduction of DiscjrfmlNo ratings yet

- Instrumentation and Process Control: Pamantasan NG Lungsod NG MaynilaDocument52 pagesInstrumentation and Process Control: Pamantasan NG Lungsod NG MaynilaAmiel DionisioNo ratings yet

- Flare Design EnglishDocument2 pagesFlare Design EnglishcyanpakNo ratings yet

- Chemical Plant Utility - Nitrogen System DesignDocument10 pagesChemical Plant Utility - Nitrogen System DesignIJRASETPublicationsNo ratings yet

- Alarm & ESD Set Point-R01Document5 pagesAlarm & ESD Set Point-R01Hossein Zohdi RadNo ratings yet

- Technical SpecificationDocument63 pagesTechnical SpecificationAmit AcharyaNo ratings yet

- Aspen-HYSYS Simulation of Natural Gas Processing PlantDocument4 pagesAspen-HYSYS Simulation of Natural Gas Processing PlantEsosaNo ratings yet

- EN TRACERTRACLOC SB DOC2213 - tcm505 35972 PDFDocument6 pagesEN TRACERTRACLOC SB DOC2213 - tcm505 35972 PDFermusatNo ratings yet

- CHE 503 Power Consumption in AgitatorDocument16 pagesCHE 503 Power Consumption in AgitatorNurtasha AtikahNo ratings yet

- Volume 3 Section 2 Process Requirements-FINAL 10062010Document63 pagesVolume 3 Section 2 Process Requirements-FINAL 10062010Pavle DimitrijevicNo ratings yet

- AB&CO Electrical Process Air Heaters: Preliminary Calculation of Prices & DimensionsDocument2 pagesAB&CO Electrical Process Air Heaters: Preliminary Calculation of Prices & DimensionsGeorge ConstantineNo ratings yet

- Simba B en Inctrl Ver4Document2 pagesSimba B en Inctrl Ver4Joao MinhoNo ratings yet

- Aeration Solutions Comparison Chart - VlightDocument2 pagesAeration Solutions Comparison Chart - VlightprannoyNo ratings yet

- Plant SpecificationsDocument4 pagesPlant SpecificationsjnmanivannanNo ratings yet

- Koch Modular ProcessDocument26 pagesKoch Modular ProcessKoch Modular ProcessNo ratings yet

- Updated Standard Operation Manual For Tank Vent Gas Recovery System Feb. 2013Document3 pagesUpdated Standard Operation Manual For Tank Vent Gas Recovery System Feb. 2013Steve WanNo ratings yet

- MA1Document49 pagesMA1aregawi selemonNo ratings yet

- Heat ExchangersDocument43 pagesHeat ExchangersSteve WanNo ratings yet

- Chen2010 Chapter ReferencesDocument6 pagesChen2010 Chapter Referencesahmed ramadanNo ratings yet

- Scale-Up of Chemical Engineering Process Chapter 1: Introduction of Scale-Up ProcessesDocument12 pagesScale-Up of Chemical Engineering Process Chapter 1: Introduction of Scale-Up ProcesseskayeNo ratings yet

- Aspen HTFS PDFDocument4 pagesAspen HTFS PDFQamar AbbasNo ratings yet

- Instrument IndexDocument2 pagesInstrument Indexyoonyoon1No ratings yet

- ECM Energy Audit ReportDocument4 pagesECM Energy Audit ReportJimit PatelNo ratings yet

- Deo Max N1Document2 pagesDeo Max N1Murrali Raj JeyagapalNo ratings yet

- Hyoffwind Power To Gas End ReportDocument68 pagesHyoffwind Power To Gas End Reportapi-267204600No ratings yet

- Project Report On Hgu & HDTDocument34 pagesProject Report On Hgu & HDTKamanasish BhattacharjeeNo ratings yet

- AkzoNobel - Hydrogen Peroxide Product Information Manual - December 2015 - tcm56-94028 - 2Document32 pagesAkzoNobel - Hydrogen Peroxide Product Information Manual - December 2015 - tcm56-94028 - 2PungkyRamadhaniPamungkasAminotoNo ratings yet

- LNG Liquefaction DocumentDocument6 pagesLNG Liquefaction Documentbaiju79No ratings yet

- Nioec SP 70 01Document55 pagesNioec SP 70 01Mohammad Amini100% (1)

- Pnid ExamplesDocument1 pagePnid Examplessecret soldierNo ratings yet

- 06 VR HadwacoDocument43 pages06 VR HadwacoLuis ValdezNo ratings yet

- Solvent Losses in Batch Distillation and Subsequent Condensation of Vapors and How To SaveDocument5 pagesSolvent Losses in Batch Distillation and Subsequent Condensation of Vapors and How To SavesrshahNo ratings yet

- Hydrogen Plant Design - 3DG-B42-00001Document8 pagesHydrogen Plant Design - 3DG-B42-00001snamprogNo ratings yet

- Evaluate Plant-Wide Safety of Your Interlock SystemDocument14 pagesEvaluate Plant-Wide Safety of Your Interlock SystemnavedscribdNo ratings yet

- Industrial: Western European Energy Conservation Technologies For EvaporatorsDocument33 pagesIndustrial: Western European Energy Conservation Technologies For EvaporatorsPhoe ChitNo ratings yet

- DistillationColumnDrawingAutoCAD PDFDocument3 pagesDistillationColumnDrawingAutoCAD PDFAbhijeet SahuNo ratings yet

- 1 CDB 4014 - Plant Design Project IDocument3 pages1 CDB 4014 - Plant Design Project Iharvin95No ratings yet

- Checal 1Document2 pagesChecal 1VaanNo ratings yet

- Choice of Runaway Reaction Scenarios For Vent Sizing Based Onpseudo Adiabatic Calorimetric TechniquesDocument48 pagesChoice of Runaway Reaction Scenarios For Vent Sizing Based Onpseudo Adiabatic Calorimetric TechniquesgiovanniNo ratings yet

- Friction Coefficient in PipesDocument16 pagesFriction Coefficient in PipesVanessa AyalaNo ratings yet

- Desmoke System p.155-173Document19 pagesDesmoke System p.155-173Just RysdanNo ratings yet

- Dryer Selection and DesignDocument43 pagesDryer Selection and DesignMuluken DeaNo ratings yet

- TO-HQ-02-013 Rev 00 Philosophy For Emergency Generator and S PDFDocument22 pagesTO-HQ-02-013 Rev 00 Philosophy For Emergency Generator and S PDFComsa CatalinNo ratings yet

- Fundamentals of Biological Wastewater Treatment - PrefaceDocument4 pagesFundamentals of Biological Wastewater Treatment - Prefaceabhi_nddNo ratings yet

- 5 Offer For Vertical Pyrolysis Plant 10TDocument5 pages5 Offer For Vertical Pyrolysis Plant 10TGaurav BihaniNo ratings yet

- Cakra 102, Esd Matrix 15 April 2014Document1 pageCakra 102, Esd Matrix 15 April 2014fearmanisNo ratings yet

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsFrom EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsNo ratings yet

- Selection PresentationDocument15 pagesSelection PresentationSteve WanNo ratings yet

- F 12102 Rules of CalculationDocument9 pagesF 12102 Rules of CalculationSteve WanNo ratings yet

- Esp 100 TPD Precicon 3 Drawing PDFDocument1 pageEsp 100 TPD Precicon 3 Drawing PDFSteve WanNo ratings yet

- Combustion CalculationDocument2 pagesCombustion CalculationSteve WanNo ratings yet

- Air Damper Control System671 PDFDocument1 pageAir Damper Control System671 PDFSteve WanNo ratings yet

- Pump Sizing Calculation SheetDocument10 pagesPump Sizing Calculation SheetSteve WanNo ratings yet

- Plano Rizzi Sopladores B 6102 FCCDocument2 pagesPlano Rizzi Sopladores B 6102 FCCSteve WanNo ratings yet

- Process Control BoilerDocument70 pagesProcess Control BoilerSteve WanNo ratings yet

- Steam Boilers VeloaDocument96 pagesSteam Boilers VeloaSteve WanNo ratings yet

- Boiler Safety Checklist &Document185 pagesBoiler Safety Checklist &Steve WanNo ratings yet

- Line List Ammonia Urea P1 RevisiDocument17 pagesLine List Ammonia Urea P1 RevisiSteve WanNo ratings yet

- Part 8 Exhaust FanDocument7 pagesPart 8 Exhaust FanSteve WanNo ratings yet

- Auxiliary BoilerDocument102 pagesAuxiliary BoilerSteve WanNo ratings yet

- Tank SizeDocument7 pagesTank SizeSteve WanNo ratings yet

- Chimney CalculationsDocument3 pagesChimney CalculationsSteve WanNo ratings yet

- Heat Recovery P Id Raymond RV 06Document1 pageHeat Recovery P Id Raymond RV 06Steve WanNo ratings yet

- Compensation (Gas) eDocument1 pageCompensation (Gas) eSteve WanNo ratings yet

- Furnace Typical Draft ProfileDocument1 pageFurnace Typical Draft ProfileSteve WanNo ratings yet

- Heat Loss Analysis 03Document3 pagesHeat Loss Analysis 03Steve WanNo ratings yet

- Hall Yarborough Z 1Document1 pageHall Yarborough Z 1Steve WanNo ratings yet

- T1001W6F011Document1 pageT1001W6F011Asim SaleemNo ratings yet

- Biology AS ClassifiedDocument209 pagesBiology AS ClassifiedMaaz Rashid100% (2)

- Manalaysay JPT Thesis With Approval PDFDocument103 pagesManalaysay JPT Thesis With Approval PDFTheresa Marie PrestoNo ratings yet

- Chebera Churchura National ParkDocument5 pagesChebera Churchura National ParkBeki Uje100% (1)

- Life of Tamav Irene (English)Document64 pagesLife of Tamav Irene (English)YonasNo ratings yet

- Benign Bone Tumours LectureDocument11 pagesBenign Bone Tumours Lecturekyliever100% (1)

- A Wideband Monopole Antenna DesignDocument67 pagesA Wideband Monopole Antenna DesignMohammad AlamsyahNo ratings yet

- 16 Tenses in English GrammarDocument5 pages16 Tenses in English Grammarnurtina samulaNo ratings yet

- Tutorial 8 Chapter 8: Carboxyl Compounds: Chm207 (Organic Chemistry)Document4 pagesTutorial 8 Chapter 8: Carboxyl Compounds: Chm207 (Organic Chemistry)Eqieyn JerrNo ratings yet

- Advanced IC Engines: Prof. R. Devaraj Dr. S. Ramachandran Dr. A. AndersonDocument61 pagesAdvanced IC Engines: Prof. R. Devaraj Dr. S. Ramachandran Dr. A. AndersonGopi KrishnanNo ratings yet

- Whitaker Test PDFDocument4 pagesWhitaker Test PDFKahn GenghisNo ratings yet

- Chapter 3 - Transducer and Sensors Part 1Document46 pagesChapter 3 - Transducer and Sensors Part 1Zersh EthioNo ratings yet

- Sheet 2 of 2: Turn TurnDocument2 pagesSheet 2 of 2: Turn TurnJesùs AlfaroNo ratings yet

- Mock 1 QP (PQ, Kine, Dyna)Document28 pagesMock 1 QP (PQ, Kine, Dyna)Tahmedul Hasan TanvirNo ratings yet

- 04 Gojko Subotic Visoki DecaniDocument42 pages04 Gojko Subotic Visoki DecaniJasmina S. Ciric100% (1)

- MahindraDocument44 pagesMahindraWuling PalembangNo ratings yet

- LG 47ld450-Ua Chassis La01bDocument71 pagesLG 47ld450-Ua Chassis La01belrudo11100% (1)

- Airports 14 EndDocument9 pagesAirports 14 EndMeedenken en Doen BVNo ratings yet

- BUAD 680 Group1 Final Project Marketing Audit TeslaDocument26 pagesBUAD 680 Group1 Final Project Marketing Audit TeslaAkaash HegdeNo ratings yet

- 0748640843Document273 pages0748640843Zia Ullah100% (1)

- Kingdoms of FlameDocument133 pagesKingdoms of Flamerobi255167% (3)

- Chapter 03 Two Dimensional Problems in Elasticity - Ugural, FensterDocument50 pagesChapter 03 Two Dimensional Problems in Elasticity - Ugural, Fensteracanerk100% (6)

- Chapter 3Document96 pagesChapter 3Sinclyr Valenciano100% (2)

- ComantDocument134 pagesComantsoniaxNo ratings yet

- Themes & Scriptures 2009 (Thumbnail)Document1 pageThemes & Scriptures 2009 (Thumbnail)Jenn100% (5)

- Tenda Catalogo 2020 PDFDocument24 pagesTenda Catalogo 2020 PDFTenda Región AndinaNo ratings yet

- ) Wikipe: Types of Anemometer - : 1 - Cup AnemometerDocument4 pages) Wikipe: Types of Anemometer - : 1 - Cup Anemometermahmoud osamaNo ratings yet

- Saturation Diving SystemsDocument4 pagesSaturation Diving SystemsekhwanhakimNo ratings yet

- Non Destructive TestingDocument9 pagesNon Destructive TestingAhmed KhanNo ratings yet

- Favipiravir Tablet Manual: Please Read The Instructions Carefully and Use Under The Guidance of A PhysicianDocument4 pagesFavipiravir Tablet Manual: Please Read The Instructions Carefully and Use Under The Guidance of A Physicianchard xuNo ratings yet