Professional Documents

Culture Documents

SMAW-Fillet-AWS D1.1 WPS PDF

SMAW-Fillet-AWS D1.1 WPS PDF

Uploaded by

umeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMAW-Fillet-AWS D1.1 WPS PDF

SMAW-Fillet-AWS D1.1 WPS PDF

Uploaded by

umeshCopyright:

Available Formats

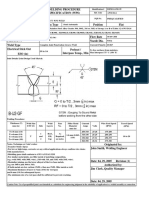

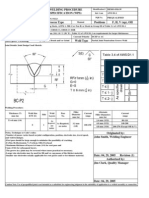

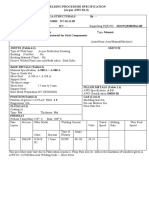

Prepared by: Identification # DEMO-SMAW

WPSAmerica.com

WELDING PROCEDURE

SPECIFICATION (WPS) Ref. Code AWS D1.1

Company Name: www.WPSAmerica.com

Address: info@WPSAmerica.com, Toll Free: 1 (877) WPS-WELD

PQR No. PREQUALIFIED

Process SMAW Process Type Manual Positions Flat, Horizontal

Base Metals Only Steels in Category A of Table 3.2 of AWS D1.1

Filler Metals AWS A5.1: E6010

Preheat/ Interpass Temp., Min Up to 20 mm (3/4): 0 °C (32 °F) ; Table 3.2 of AWS D1.1 on requirements for larger thicknesses

Interpass Temp., Max N/A Current/ Polarity DCEP

Interpass Cleaning Chip, File, Brush and/ or Grind Weld Type Fillet Weld

Joint Details/ Joint Design Used/ Sketch:

Welding Procedure:

Filler Alternate

Weld Size (S) Weld Pass Current Current

Side Diameter Filler Diameters

mm (in) Layers No. Amps Amps

mm (in) mm (in)

5 mm (3/16) 1 1

2.4 mm (3/32) 50-85

6 mm (1/4) 1 1

8 mm (5/16) 1 1, 2 1-3 (2 Flat)

4.0 mm (5/32) 120-170

10 mm (3/8) or 1, 2 1-3 (2 Flat) 3.2 mm (1/8) 90-140

12 mm (1/2) 2 1-3 1-6 (4 Flat)

4.8 mm (3/16) 140-215

16 mm (5/8) 1-4 1-8 (6 Flat)

>=20 mm (3/4) 1 to 5+ 1-12 (9 Flat)

Notes, Technique or Code’s rules: Originated by:

-Larger size electrodes may be used for fill and/ or cap passes of the thicker material.

-Smaller size electrodes usually applicable for root passes and/ or for thinner material. John Smith, Welding Engineer

Date: 04, 29, 2005 Revision (1)

Authorized by:

Jim Clark, Quality Manager

Date: 04, 29, 2005

Caution Note: Use of prequalified joint is not intended as a substitute for engineering judgment in the suitability of application to a welded assembly or connection.

You might also like

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification Sampleezdi2083% (23)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium Weldingvishal bailur50% (2)

- AWS D1-1 PQR-WPS Yes Pre QualifiedDocument2 pagesAWS D1-1 PQR-WPS Yes Pre QualifiedJRodengineer0% (1)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Sample Welding Procedure Specification (WPS) FormDocument1 pageSample Welding Procedure Specification (WPS) Formfallalovaldes50% (4)

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- LBW WOPQ REV. 2010a Interactive FormDocument1 pageLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document18 pagesWelder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)mahendraNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityNo ratings yet

- Wps Fillet AWSDocument4 pagesWps Fillet AWSMohd Ashraf100% (1)

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Welding Procedure Specification (WPS) of The ManufacturerDocument9 pagesWelding Procedure Specification (WPS) of The ManufacturerfallalovaldesNo ratings yet

- Welding Procedure Specification Review and Approval ProcessDocument4 pagesWelding Procedure Specification Review and Approval ProcessfallalovaldesNo ratings yet

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Silvia CardenasNo ratings yet

- Welding Qualification As Per AWS D1.1Document19 pagesWelding Qualification As Per AWS D1.1Ouni AchrefNo ratings yet

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- Welding Procedure Specification Register (Structural Steel) : AWS D1.1Document14 pagesWelding Procedure Specification Register (Structural Steel) : AWS D1.1murshid badshah100% (2)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- Welder and Welding Operator Performance Qualification RecordDocument1 pageWelder and Welding Operator Performance Qualification RecordAsif HameedNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- Procedure For WPSDocument7 pagesProcedure For WPSSatish KeskarNo ratings yet

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauniNo ratings yet

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuNo ratings yet

- WpsDocument39 pagesWpsAkhilesh Kumar100% (1)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Clad PQRDocument5 pagesClad PQRRinshadNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- WPQR SMAW EN-2 - 30mm (Under Modification)Document2 pagesWPQR SMAW EN-2 - 30mm (Under Modification)Mohamed Reda HusseinNo ratings yet

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- AL Wps PDFDocument4 pagesAL Wps PDFprem nautiyalNo ratings yet

- Comparison Between API-1104 21st Ed & 22nd EdDocument13 pagesComparison Between API-1104 21st Ed & 22nd EdsadashiwNo ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- Welding Procedure Specification (WPS) : Demo-SmawDocument1 pageWelding Procedure Specification (WPS) : Demo-SmawakranganNo ratings yet

- Welding Procedure Specification (As Per AWS D1.3) : With Preheat & PWHT (Auto/Semi-Auto/Manual/Machine) SketchDocument1 pageWelding Procedure Specification (As Per AWS D1.3) : With Preheat & PWHT (Auto/Semi-Auto/Manual/Machine) Sketchoomoom0% (1)

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Sample Forms AWS, ASME and APIDocument14 pagesSample Forms AWS, ASME and APIaamirtec301No ratings yet

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- XA00048720 Stainless HandbookDocument92 pagesXA00048720 Stainless HandbookThanis SurapapwongNo ratings yet

- Testing and Inspection of WeldsDocument20 pagesTesting and Inspection of Welds7harma V1swaNo ratings yet

- Penetrant TestingDocument43 pagesPenetrant TestingVineet JeswaniNo ratings yet

- Welding Procedure SpecificationDocument1 pageWelding Procedure Specificationfallalovaldes100% (1)

- Welding Procedure 2Document1 pageWelding Procedure 2lovaldes62No ratings yet

- RED Dye PenetrantDocument3 pagesRED Dye Penetrantlovaldes62No ratings yet

- Study of The Factors Affecting The Sensitivity of Liquid PenetrantDocument59 pagesStudy of The Factors Affecting The Sensitivity of Liquid PenetrantfallalovaldesNo ratings yet

- Visual Inspection of WeldDocument1 pageVisual Inspection of Weldfallalovaldes100% (1)

- CBIP Examination Paper - Liquid Penetrant Inspection Level 2 GeneralDocument4 pagesCBIP Examination Paper - Liquid Penetrant Inspection Level 2 GeneralfallalovaldesNo ratings yet

- Welding ProcedureDocument2 pagesWelding ProcedurefallalovaldesNo ratings yet

- Catalogo MagnafluxDocument78 pagesCatalogo MagnafluxfallalovaldesNo ratings yet