Professional Documents

Culture Documents

Operational Qualification Report Aquabplus/Aquabplus B2/ Aquabplus HF

Operational Qualification Report Aquabplus/Aquabplus B2/ Aquabplus HF

Uploaded by

Magdi FarhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operational Qualification Report Aquabplus/Aquabplus B2/ Aquabplus HF

Operational Qualification Report Aquabplus/Aquabplus B2/ Aquabplus HF

Uploaded by

Magdi FarhanCopyright:

Available Formats

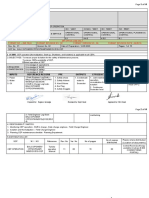

Chapter 3: Installation

AquaBplus/AquaBplus B2/

Operational Qualification Report

AquaBplus HF

Customer number/customer name: Inventory number:

Tester’s name: Operating hours:

Software version: Equipment code:

Service report number: Serial number:

No. Description Operating Measured value/ /NA

state correction

Information: = successful inspection item / NA = non-applicable inspection item

Options installed:

– AquaBplus B2 – – /

– AquaBplus HF – – /

– AquaBplus UF – – /

– RingBase – – /

– RingUnit / wall-mounted inlet unit Number of ring mains: /

– Housing – – /

– Emergency mode – – /

– Fluid Fly Loop – – /

Set units

– a) bar, L/h, °C, m – –

b) psi, gal/h, °F, ft

1 Tests/measures conducted with device switched off

1.1 Device unpacked. Off –

1.2 Delivery package is complete. Delivery package contents and Instructions for Use Off –

match the device.

1.3 No visible shipping damage or contamination on the device. Off –

1.4 Water pretreatment system correctly connected. Off –

1.5 All tube clamps and clamp connectors checked. Off –

1.6 Ferrite cores correctly installed. Off –

2 Preparation

2.1 AquaBplus prepared. Off –

2.2 AquaBplus B2 prepared. Off – /

2.3 AquaBplus HF prepared. Off – /

2.4 AquaBplus UF prepared. Off – /

Preparation options

Basic remote control option /

2.5 Basic remote control and AquaBplus correctly wired. Off –

Permeate tank control option /

2.6 Permeate tank connected. Off –

2.7 GENIUS® tank connected. Off – /

2.8 GRANUMIXplus connected. Off – /

AquaDETECTOR option /

2.9 AquaDETECTOR connected. Off –

3 Basic setting

Information: Turn the device on.

3.1 Configuration checked and recorded. On –

3.2 Direction of rotation of pumps P1 and P1s checked. On –

3.3 Pressure holding valve VR41 correctly set: On –

3.4 System rinsed according to specifications (if preserved). RINSE – /

3.5 Display values of the sensors called up on the display and checked for plausibility. SUPPLY –

3.6 Machine ID (serial number) and machine configuration correctly set. On –

4 Electrical safety check following (DIN) EN 62353:2015, IEC 62353:2014,

Information: Turn the device off.

Note: AquaBplus must be permanently connected.

4.1 Protective earth resistance measured and checked. Off / Ω

Target value: ≤ 0.3 Ω with power supply cord

5 Checking the sensors

5.1 Permeate conductivity (CD-P) checked. SUPPLY / µS/cm

5.2 Soft water conductivity (CD-F) checked. SUPPLY / µS/cm

5.3 Permeate temperature (T-P) checked. SUPPLY / °C / °F

5.4 Soft water temperature (T-F) checked. SUPPLY / °C / °F

5.5 Concentrate pressure stage 1 (P-C) checked. SUPPLY / bar/psi

Fresenius Medical Care AquaBplus SM-EN 9A-2019 3-5

Chapter 3: Installation

Service report number: Serial number:

No. Description Operating Measured value/ /NA

state correction

6 Checking the functions

6.1 Permeate pressure measured externally. Last supply ports ≥ 2.0 bar. SUPPLY / bar/psi

6.2 External alarm system checked. SUPPLY –

6.3 Leakage sensor checked. SUPPLY –

6.4 Emergency mode checked. EMERGEN- –

CY MODE

Testing the feed water

6.5 Activated carbon filter: Total chlorine checked at outlet. Off / mg/L /

Target value: Total chlorine < 0.1 mg/l ppm

6.6 Softener: Soft water checked at outlet. Off /

Target value: Hardness < 1° dH °dH/ppm CaCO3

6.7 SDI tested at outlet. Off /

Target value: SDI < 3

Testing options

AquaBplus B2 option /

Note: AquaBplus B2 must be permanently connected.

6.8 Protective earth resistance, maximum 0.3 Ω (with power supply cord). Off / Ω

6.9 Direction of rotation of the pump checked. SUPPLY –

6.10 Permeate conductivity (CD-Ps) checked. SUPPLY / µS/cm

6.11 Permeate temperature (T-Ps) checked. SUPPLY / °C / °F

6.12 Concentrate pressure (P-Cs) checked. SUPPLY / bar/psi

AquaBplus HF option /

Note: AquaBplus HF must be permanently connected.

6.13 Protective earth resistance, maximum 0.3 Ω (with power supply cord). Off / Ω

6.14 Temperature (T-Hin) checked (compared with T-P). SUPPLY / °C / °F

6.15 Temperature (T-Hout) checked (compared with T-P). SUPPLY / °C / °F

6.16 Temperature (T-sup) checked (compared with T-P). SUPPLY / °C / °F

6.17 Heat disinfection parameters adapted. STANDBY –

6.18 Direction of rotation of pump P5 checked. Heat –

disinfection

6.19 Heat disinfection performed without any errors and recorded accordingly. Heat / A

– Flow heaters checked for correct function. disinfection

RingBase option /

6.20 Permeate stop valve (V22) checked. SUPPLY –

Tank control option /

6.21 Tank sensors checked. SUPPLY –

6.22 Tank fill valve checked. SUPPLY –

AquaBplus UF option /

6.23 Rinse valves checked. RINSE –

Basic remote control option /

6.24 Start button pressed. System switches to SUPPLY. STANDBY –

6.25 Stop button pressed. System switches to STANDBY. SUPPLY –

6.26 Failure checked. On –

7 Disinfection

7.1 Disinfection performed and recorded as specified in the Disinfection Report. DISINFEC- –

TION

8 Final tasks

8.1 Procedure recorded on the machine record and in the Medical Device Register. STANDBY – /

8.2 All waste properly disposed of. STANDBY –

8.3 All documents completed. STANDBY –

3-6 Fresenius Medical Care AquaBplus SM-EN 9A-2019

Chapter 3: Installation

Confirmation of the inspection

Service report number: Serial number:

Test equipment used (type and serial number):

Inspection comments:

Date of inspection: Tester’s signature: Tester’s stamp:

#FMESIG_1##

Assessment of the inspection

The device is released for its intended use. Yes No Date of next inspection:

The inspection label has been attached to the device.

Assessment comments:

Date of assessment: Signature of representative of the responsible Stamp of the responsible organization:

organization:

#FMESIG_2##

Fresenius Medical Care AquaBplus SM-EN 9A-2019 3-7

You might also like

- Storm Boy Program - Year 3Document8 pagesStorm Boy Program - Year 3glen100% (1)

- Remote Control System Scanreco RC 400.: Instruction ManualDocument66 pagesRemote Control System Scanreco RC 400.: Instruction ManualCamilo Barrera100% (4)

- Understanding and Servicing Alarm SystemsFrom EverandUnderstanding and Servicing Alarm SystemsRating: 1 out of 5 stars1/5 (1)

- Ifr6000 Operations Manual Manual User Guide en PDFDocument320 pagesIfr6000 Operations Manual Manual User Guide en PDFbravo16893No ratings yet

- Aquabplus Disinfection: No. Disinfection Process Unit Measured ValueDocument2 pagesAquabplus Disinfection: No. Disinfection Process Unit Measured ValueMagdi FarhanNo ratings yet

- Tsc/Ma Report Aquabplus: Chapter 6: Technical Safety Checks / Maintenance ProceduresDocument2 pagesTsc/Ma Report Aquabplus: Chapter 6: Technical Safety Checks / Maintenance ProceduresMagdi Farhan0% (1)

- H145 Normal Checklist 1.3Document1 pageH145 Normal Checklist 1.3Pili Simon100% (1)

- Manual de Usuario BioClaveDocument15 pagesManual de Usuario BioClaveMJ DentalNo ratings yet

- Boiler O&M ManualDocument1,669 pagesBoiler O&M ManualLeonardo CoronadoNo ratings yet

- Maintenance Bypass Cabinet For Nfinity and GXT 10kvaDocument36 pagesMaintenance Bypass Cabinet For Nfinity and GXT 10kvaAhmedNo ratings yet

- IM AbsorptionChiller SteamType PDFDocument33 pagesIM AbsorptionChiller SteamType PDFمحمود متولىNo ratings yet

- Additional Sheet For Aquabplus Instructions For Use: 5.1 General Notes 10.2 TransportDocument2 pagesAdditional Sheet For Aquabplus Instructions For Use: 5.1 General Notes 10.2 TransportMagdi FarhanNo ratings yet

- Instruction Manual: Vertical Bypass/Non Bypass PanelDocument89 pagesInstruction Manual: Vertical Bypass/Non Bypass Panelrifky maulanaNo ratings yet

- Infant Incubator Service ManualDocument62 pagesInfant Incubator Service ManualevanNo ratings yet

- An Usm 719 - Tel InstrumentDocument2 pagesAn Usm 719 - Tel Instrumentnicole vargas ponceNo ratings yet

- DC AcDocument13 pagesDC AcPRAVINTH SNo ratings yet

- Liebert Psa5 500 1500va User GuideDocument26 pagesLiebert Psa5 500 1500va User GuidewilliamNo ratings yet

- AN 300 RT 4L2W ManualDocument100 pagesAN 300 RT 4L2W ManualGary GouveiaNo ratings yet

- SW70A1 Service ManualDocument35 pagesSW70A1 Service ManualAdi AdiyantoNo ratings yet

- Sorvall RC-28S - User ManualDocument71 pagesSorvall RC-28S - User ManualasdjoadreNo ratings yet

- FMEA Trial Checklist DP - ECRDocument4 pagesFMEA Trial Checklist DP - ECRsjsshipNo ratings yet

- SFC TroubleshootingDocument66 pagesSFC TroubleshootingTesting &Protection Electical Power SystemNo ratings yet

- Da3 - Uk3Document55 pagesDa3 - Uk3ldavidson358No ratings yet

- Service: ManualDocument76 pagesService: Manualdincina70No ratings yet

- mediadocumentLE05739AA PDFDocument36 pagesmediadocumentLE05739AA PDFtatone234No ratings yet

- VIAVI IFR6000-operations-manual-manuals-user-guides-enDocument322 pagesVIAVI IFR6000-operations-manual-manuals-user-guides-enAeromechanixNo ratings yet

- Avk Double Eccentric Butterfly Valves: Series 756Document15 pagesAvk Double Eccentric Butterfly Valves: Series 756Panagiotis PanagosNo ratings yet

- 2.0 Mock Drill - Power FailureDocument5 pages2.0 Mock Drill - Power Failure00083583rfNo ratings yet

- Clifton UltrasonicDocument19 pagesClifton UltrasonicSami Al SamowNo ratings yet

- Purificador Ultra 370 SeriesDocument35 pagesPurificador Ultra 370 SeriesmardonioandradeNo ratings yet

- 10 Cep SopDocument14 pages10 Cep SopSiddhant SatpathyNo ratings yet

- Operation Manual UC Midi 2015Document33 pagesOperation Manual UC Midi 2015Kiril Ackovski100% (3)

- Digital Energy Lp11uDocument48 pagesDigital Energy Lp11uMelLda UdjuNo ratings yet

- MiniMed ManualDocument132 pagesMiniMed ManualKiên Sơn NguyễnNo ratings yet

- General Tool OverviewDocument6 pagesGeneral Tool OverviewMuhammad ShahrukhNo ratings yet

- Absorption Chiller Heater: Installation ManualDocument35 pagesAbsorption Chiller Heater: Installation ManualSaad PathanNo ratings yet

- Ocean Rescue EPIRB1-user-manualDocument16 pagesOcean Rescue EPIRB1-user-manualrfpedleyNo ratings yet

- Breezaire XTR Exq ExsDocument24 pagesBreezaire XTR Exq ExsIan NowiczNo ratings yet

- WQ1 Work Order Details - Work Order: 20115: 13-Feb-2019 8:47 AMDocument42 pagesWQ1 Work Order Details - Work Order: 20115: 13-Feb-2019 8:47 AMaliALYASIRYNo ratings yet

- MC-0133 Uc-0060-0240 2012 (En)Document33 pagesMC-0133 Uc-0060-0240 2012 (En)Frank Lenin Ortiz GalarzaNo ratings yet

- 22 SOP of Vaccum PullingDocument18 pages22 SOP of Vaccum PullingSiddhant Satpathy100% (1)

- Apv Delta VPN Ii - Uk0Document17 pagesApv Delta VPN Ii - Uk0Deca2509No ratings yet

- Mus 593601Document41 pagesMus 593601anaialeNo ratings yet

- FLUKE 77 75 73 70 23 21 Series II Service TextDocument54 pagesFLUKE 77 75 73 70 23 21 Series II Service Textmzova production100% (1)

- H145 Normal Checklist 1.3 - Two PagesDocument2 pagesH145 Normal Checklist 1.3 - Two Pagesgabi maquettesNo ratings yet

- LAGB Checklist For Ammonia PDFDocument1 pageLAGB Checklist For Ammonia PDFSajith Kumar KNo ratings yet

- English. - . - . - . - . 2 Français. - . - . - . 38: Español. - . - . - . - 20Document19 pagesEnglish. - . - . - . - . 2 Français. - . - . - . 38: Español. - . - . - . - 20Akkara LekklaNo ratings yet

- 04-SEP660 REC670 REC650 Apparatus Control PDFDocument23 pages04-SEP660 REC670 REC650 Apparatus Control PDFIvana Vlade RadovanovicNo ratings yet

- Instruction Manual: E84111-K00060-00 Published Feb.2008 Ver.3-1.01Document36 pagesInstruction Manual: E84111-K00060-00 Published Feb.2008 Ver.3-1.01Kluzu Formaggio100% (1)

- Legrand UPSDocument68 pagesLegrand UPSCesar CausarenNo ratings yet

- HP 3476B Manual Operating ServiceDocument41 pagesHP 3476B Manual Operating ServiceSilvaa60No ratings yet

- Manual Usuario MVision ST5 MultilenguajeDocument84 pagesManual Usuario MVision ST5 Multilenguajepepekas100% (3)

- Fisher R FIELDVUE™ DVC6000 Digital Valve Controllers Instruction Manual (Supported)Document162 pagesFisher R FIELDVUE™ DVC6000 Digital Valve Controllers Instruction Manual (Supported)Agus TrionoNo ratings yet

- Gas Leak Detection Alarm: AKO-55624 AKO-55724Document16 pagesGas Leak Detection Alarm: AKO-55624 AKO-55724Amic BanatNo ratings yet

- ManualDocument24 pagesManualCarlos Manuel Arias RojasNo ratings yet

- HD4-R - Manual - J - 1VCD600900-1504 enDocument42 pagesHD4-R - Manual - J - 1VCD600900-1504 enferranrNo ratings yet

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentDocument5 pagesJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiNo ratings yet

- Arjo Maxi Sky 2 Maintenance and Repair ManualDocument140 pagesArjo Maxi Sky 2 Maintenance and Repair Manualass.biotecNo ratings yet

- Pipeline Capacity IncreaseDocument8 pagesPipeline Capacity IncreaseElendu Emmanuel ChigozieNo ratings yet

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlFrom EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNo ratings yet

- Sand Filter / Zeolite Filter / Birm Filter Settings Report / SERVICEDocument2 pagesSand Filter / Zeolite Filter / Birm Filter Settings Report / SERVICEMagdi FarhanNo ratings yet

- Aquabplus Training Record: Chapter 15: AppendixDocument4 pagesAquabplus Training Record: Chapter 15: AppendixMagdi FarhanNo ratings yet

- AK Filter - EngDocument28 pagesAK Filter - EngMagdi FarhanNo ratings yet

- Aquabplus/Aquabplus B2/ Aquabplus HF Settings Report: Chapter 12: AppendixDocument2 pagesAquabplus/Aquabplus B2/ Aquabplus HF Settings Report: Chapter 12: AppendixMagdi FarhanNo ratings yet

- Additional Sheet For The Remote Control Basic Option (Aquaa, Aquabplus, Cds3)Document6 pagesAdditional Sheet For The Remote Control Basic Option (Aquaa, Aquabplus, Cds3)Magdi FarhanNo ratings yet

- Interface Disinfection Aquabplus Disinfection With Puristeril 340 / Puristeril Plus Service ManualDocument32 pagesInterface Disinfection Aquabplus Disinfection With Puristeril 340 / Puristeril Plus Service ManualMagdi FarhanNo ratings yet

- Aquabplus Operational Data Acquisition Daily Report: General NotesDocument3 pagesAquabplus Operational Data Acquisition Daily Report: General NotesMagdi FarhanNo ratings yet

- Aquabplus Decalcification: Chapter 12: AppendixDocument1 pageAquabplus Decalcification: Chapter 12: AppendixMagdi FarhanNo ratings yet

- Additional Sheet For Aquabplus Instructions For Use: 5.1 General Notes 10.2 TransportDocument2 pagesAdditional Sheet For Aquabplus Instructions For Use: 5.1 General Notes 10.2 TransportMagdi FarhanNo ratings yet

- 1771 td182 - en P PDFDocument61 pages1771 td182 - en P PDFMagdi FarhanNo ratings yet

- Industrial Duty Commercial Door Operator: Owner'S ManualDocument36 pagesIndustrial Duty Commercial Door Operator: Owner'S ManualMagdi FarhanNo ratings yet

- Portable Quad-Band Mobile PhoneDocument259 pagesPortable Quad-Band Mobile PhoneMagdi FarhanNo ratings yet

- IFU - Delta Primo - 2019 - EN PDFDocument80 pagesIFU - Delta Primo - 2019 - EN PDFMagdi FarhanNo ratings yet

- Enraf-Nonius Endomed 484 ENDocument7 pagesEnraf-Nonius Endomed 484 ENMagdi FarhanNo ratings yet

- Enraf Nonius Endolaser 476 - Service Manual PDFDocument66 pagesEnraf Nonius Endolaser 476 - Service Manual PDFMagdi FarhanNo ratings yet

- Questions On Jajavava & SpringsDocument2 pagesQuestions On Jajavava & Springsjuni0001No ratings yet

- The Tile Industry in KeralaDocument40 pagesThe Tile Industry in KeralaNazanin SabetNo ratings yet

- 13 Interpolation - Lagrange NDDDocument23 pages13 Interpolation - Lagrange NDDمحمد خطباNo ratings yet

- Courses OfferedDocument60 pagesCourses OfferedAditya Raj GuptaNo ratings yet

- Sage Publications, Inc. Johnson Graduate School of Management, Cornell UniversityDocument21 pagesSage Publications, Inc. Johnson Graduate School of Management, Cornell UniversitysabaNo ratings yet

- C 2.1.5 Huawei Global Corporate Fact Sheet AnnexDocument4 pagesC 2.1.5 Huawei Global Corporate Fact Sheet AnnexHassanghasemiNo ratings yet

- Corporate Social Responsibility: 1. Attock Sahara Foundation (Asf) 2. Community Welfare by The CompanyDocument3 pagesCorporate Social Responsibility: 1. Attock Sahara Foundation (Asf) 2. Community Welfare by The Companyshrizvi14No ratings yet

- SOP124 Use and Maintenance of The Galaxy 170R Co2 IncubatorDocument7 pagesSOP124 Use and Maintenance of The Galaxy 170R Co2 IncubatorAntonio PorchedduNo ratings yet

- Chapter 1: Introduction To CompanyDocument27 pagesChapter 1: Introduction To CompanyarunNo ratings yet

- Pfeiffer Work With TurboDocument44 pagesPfeiffer Work With TurbozayerirezaNo ratings yet

- MUÑEQUITA LINDA - Partitura CompletaDocument8 pagesMUÑEQUITA LINDA - Partitura CompletaFernando Fernandez PérezNo ratings yet

- Examiners' Reports 2016: LA3017 Commercial Law - Zone BDocument15 pagesExaminers' Reports 2016: LA3017 Commercial Law - Zone BFahmida M RahmanNo ratings yet

- Letter of Motivation NewDocument2 pagesLetter of Motivation NewTchinda Steve100% (2)

- Math 4 Q2 Module 2 Week 2 PresentationDocument46 pagesMath 4 Q2 Module 2 Week 2 Presentationsusana mohilloNo ratings yet

- 5.6 Water Purification: I. Natural Sources of WaterDocument8 pages5.6 Water Purification: I. Natural Sources of WaterWillie ChitNo ratings yet

- Assessing Classroom Management Practices Setting The Stage For Effective and Equitable InterventionAssessment For Effective InterventionDocument5 pagesAssessing Classroom Management Practices Setting The Stage For Effective and Equitable InterventionAssessment For Effective Interventionzgr2yhf7wpNo ratings yet

- Logcat Home Fota Update LogDocument37 pagesLogcat Home Fota Update Logwalteroscch2010No ratings yet

- Study Guide Unit 2.2 - Dna Replication & Protein SynthesisDocument35 pagesStudy Guide Unit 2.2 - Dna Replication & Protein SynthesisGraceNo ratings yet

- Steel Stairs, Ladders and Platforms - MSTDocument13 pagesSteel Stairs, Ladders and Platforms - MSTwafikmh4No ratings yet

- g6 Math 2015Document14 pagesg6 Math 2015jian tongNo ratings yet

- Thesis Statement On VanityDocument7 pagesThesis Statement On Vanitysandraahnwashington100% (2)

- GSK Sotrovimab Fact Sheet For HCP 12222021Document34 pagesGSK Sotrovimab Fact Sheet For HCP 12222021Jillian SmithNo ratings yet

- Infill Pattern Lab PDFDocument10 pagesInfill Pattern Lab PDFCHAITANYA GHARAPURKARNo ratings yet

- A Tamilarasan-20uba1852Document71 pagesA Tamilarasan-20uba1852Maheswaran MahiNo ratings yet

- Listening To CustomersDocument31 pagesListening To CustomersKumar AbhishekNo ratings yet

- The Islamia University of Bahawalpur: Interview Time and Venue Financial Crisis ScholarshipDocument26 pagesThe Islamia University of Bahawalpur: Interview Time and Venue Financial Crisis ScholarshipAbubakar RiazNo ratings yet

- Namin PDFDocument162 pagesNamin PDFDhananjay KumarNo ratings yet

- LIRN NapoliDocument12 pagesLIRN NapoliDiegoNo ratings yet

- Getting Started With SAP Roadmap ViewerDocument15 pagesGetting Started With SAP Roadmap ViewerGiomNo ratings yet