0% found this document useful (0 votes)

1K views27 pagesInverted Pendulum

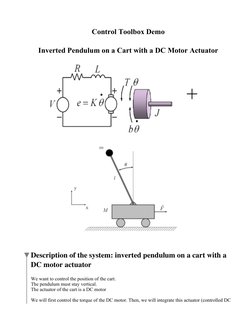

1) The document describes the control of an inverted pendulum on a cart with a DC motor actuator. It presents the equations of motion and parameters for the DC motor and the full cart-pendulum system.

2) The DC motor is first controlled in torque by identifying a transfer function from voltage input to current output. Then the motor is integrated into the full system.

3) Several control techniques are designed and tested in simulation for the full nonlinear system, including PID control, internal model control, and state feedback with pole placement combined with state estimation. All controllers achieve stability.

Uploaded by

zaccaro_86Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views27 pagesInverted Pendulum

1) The document describes the control of an inverted pendulum on a cart with a DC motor actuator. It presents the equations of motion and parameters for the DC motor and the full cart-pendulum system.

2) The DC motor is first controlled in torque by identifying a transfer function from voltage input to current output. Then the motor is integrated into the full system.

3) Several control techniques are designed and tested in simulation for the full nonlinear system, including PID control, internal model control, and state feedback with pole placement combined with state estimation. All controllers achieve stability.

Uploaded by

zaccaro_86Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

![Freq [rad/s]

Magnitude [dB]

Freq [rad/s]

Phase [deg.]

Automatic PID design

We design a PID controller to control the torque](https://screenshots.scribd.com/Scribd/252_100_85/326/48659465/9.jpeg)