Professional Documents

Culture Documents

O-Ring O-Ring Sold by Package: - P Series - P Series

Uploaded by

namOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

O-Ring O-Ring Sold by Package: - P Series - P Series

Uploaded by

namCopyright:

Available Formats

50

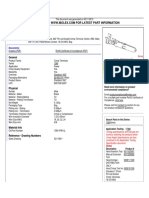

O-Ring O-Ring Sold by Package

- P Series - - P Series -

Similar

ཕٛ൰ᇋݞProducts Comparison Points CAD Data Folder Name: 45_Pipes_Fittings_Valves Similar Products Comparison Points

ཕٛ൰ᇋݞ CAD Data Folder Name: 45_Pipes_Fittings_Valves

1Dimension and hardness are complaint with JIS Standard. 1dimension tolerance compliant to JIS Standards; Hardness Tolerance widened in accordance with JIS Standards

2Sold by Single Item 2Sold by Package (200 pcs. per Package)

3RoHS Compliant 3Not RoHS Compliant

Part Number (Type ∙ No.) Part Number (Type ∙ No.)

NPA10 PACK-NPA10

Type MMaterial HHardness (JIS Hs) Color Operable Temperature Range JIS Symbol Application Type MMaterial HHardness (JIS Hs) Color Operable Temperature Range JIS Symbol Application

NPA Nitrile Rubber 70±5 Black -30 ~ 100°C Class 1 A Mineral Oil Resistant PACK-NPA Nitrile Rubber 70±8 Black -30 ~ 100°C Equivalent to Class 1 Grade A Mineral Oil Resistant

* Most representative material with superior oil / abrasion resistance and heat stability. * Most representative material with superior oil / abrasion resistance and heat stability.

W W

0.1 or Less

0.1 or Less

do do

0.15 or Less 0.15 or Less

W W

Q JIS B 2401 P Series (For Mounting, Dynamic) Q P Series (For Mounting, Dynamic)

Part Number Nominal

JIS I.D. Matching Material Days Part Number Nominal

JIS I.D. Matching Material Days Part Number Nominal

JIS I.D. Matching Material Pcs. per Part Number Nominal

JIS I.D. Matching Material Pcs. per

W to Ship W to Ship W W

Type No. Number do Tolerance d Tolerance D Tolerance Type No. Number do Tolerance d Tolerance D Tolerance Type No. Number do Tolerance d Tolerance D Tolerance Package Type No. Number do Tolerance d Tolerance D Tolerance Package

3 P3 2.8 3 6 31 P31 30.7 ±0.30 31 37 3 P3 2.8 3 6 16 P16 15.8 ±0.20 16 20

±0.14 3 Days ±0.14

4 P4 3.8 4 7 31.5 P31.5 31.2 31.5 37.5 4 P4 3.8 4 7 18 P18 17.8 ±0.21 18 22

±0.31

5 P5 4.8 5 8 32 P32 31.7 32 38 5 P5 4.8 5 8 20 P20 19.8 ±0.22 20 24

±0.15 ±0.15

6 P6 1.9 5.8 6 0 9 +0.05 34 P34 33.7 ±0.33 34 40 Stock 6 P6 1.9 5.8 6 0 9 +0.05 21 P21 2.4 20.8 ±0.23 21 0 25 +0.06

7 P7 ±0.08 6.8 7 -0.05 10 0 35 P35 34.7 35 41 7 P7 ±0.08 6.8 7 -0.05 10 0 22 P22 ±0.09 21.8 22 -0.06 26 0

±0.16 ±0.16

8 P8 7.8 8 11 35.5 P35.5 35.2 ±0.34 35.5 41.5 3 Days 8 P8 7.8 8 11 22A P22A 21.7 ±0.24 22 28

9 P9 8.8 9 12 36 P36 35.7 36 42 9 P9 8.8 9 12 24 P24 23.7 24 30

10 P10 9.8 ±0.17 10 13 38 P38 37.7 38 44 PACK- 10 P10 9.8 ±0.17 10 13 200 PACK- 25 P25 24.7 ±0.25 25 31 200

3.5 Stock NPA NPA

10A P10A 9.8 10 14 39 P39 38.7 ±0.37 39 0 45 +0.08 10A P10A 9.8 10 14 26 P26 25.7 ±0.26 26 32

±0.1 -0.08 0

11 P11 10.8 11 15 40 P40 39.7 40 46 11 P11 10.8 11 15 28 P28 27.7 ±0.28 28 34

±0.18 ±0.18 3.5 0

11.2 P11.2 11 11.2 15.2 41 P41 40.7 ±0.38 41 47 3 Days 11.2 P11.2 11 11.2 15.2 30 P30 ±0.01 29.7 ±0.29 30 -0.08 36 +0.08

0

2.4 0 +0.06

12 P12 11.8 12 16 42 P42 41.7 ±0.39 42 48 12 P12 ±0.09 11.8 12 -0.06 16 0 32 P32 31.7 ±0.31 32 38

12.5 P12.5 12.3 ±0.19 12.5 16.5 44 P44 43.7 44 50 12.5 P12.5 12.3 ±0.19 12.5 16.5 44 P44 43.7 ±0.41 44 50

±0.41

14 P14 2.4 13.8 14 0 18 +0.06 45 P45 44.7 45 51 14 P14 13.8 14 18 5.7 49.7 ±0.45 0

Stock 50A P50A ±0.13 50 -0.1 60 +0.1

0

15 P15 ±0.09 14.8 15 -0.06 19 0 46 P46 45.7 ±0.42 46 52 Stock 15 P15 14.8 ±0.20 15 19

NPA ±0.20

16 P16 15.8 16 20 48 P48 47.7 ±0.44 48 54

NPA Q P Series Detailed Fitting Size

18 P18 17.8 ±0.21 18 22 50 P50 56

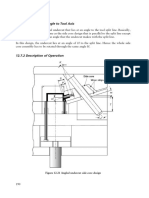

49.7 ±0.45 50 1To fix a plane: If an internal pressure is exerted, install O-Ring so that the perimeter of the O-ring

20 P20 19.8 ±0.22 20 24 50A P50A 60 G Dimension (Tolerance+0.25

0 ) H R contacts with the external wall of the groove; If an external pressure is exerted, install O-ring so that

21 P21 20.8 ±0.23 21 25 52 P52 51.6 ±0.47 52 62 Type No. No Back-Up Back-Up Ring Back-Up Rings

Dimension Dimension the internal circumference of the O-Ring contacts with the internal wall of the groove.

22 P22 21.8 22 26 53 P53 52.6 ±0.48 53 63 Ring on One Side on Both Sides H ±0.05 Max. Value 2To fix a plane in consideration of the internal pressure, provide a margin of 0.2~0.3mm for Dimension

D where Dimension D is 30mm or less.

22A P22A 21.7 22 28 55 P55 54.6 ±0.49 55 65 3 Days NPA NPB 3~10 2.5 3.9 5.4 1.4 0.4 3Slot Dimension is for reference only.

±0.24

22.4 P22.4 22.1 22.4 28.4 56 P56 55.6 ±0.50 56 66 NPSW NPS 10A~22 3.2 4.4 6.0 1.8 0.4

24 P24 23.7 24 30 58 P58 57.6 ±0.52 58 68 NPF NPFH 22A~44 4.7 6.0 7.8 2.7 0.8

25 P25 24.7 25 31 60 P60 59.6 ±0.53 60 70 Stock

±0.25 5.7 0 +0.1 NPEG NPBR 50A~80 7.5 9.0 11.5 4.6 0.9

25.5 P25.5 3.5 25.2 25.5 0 31.5 +0.08 62 P62 ±0.13 61.6 ±0.55 62 -0.1 72 0

26 P26 ±0.1 25.7 ±0.26 26 -0.08 32 0 63 P63 62.6 ±0.56 63 73 For Plane Fixing / External Pressure For Plane Fixing / Internal Pressure For Fixing Cylinder Surface G

For Dynamic G

28 P28 27.7 ±0.28 28 34 65 P65 64.6 ±0.57 65 75 D

29 P29 28.7 29 35 67 P67 66.6 ±0.59 67 77 3 Days d G G

29.5 P29.5 29.2 ±0.29 29.5 35.5 3 Days 70 P70 69.6 ±0.61 70 80

H

H

30 P30 29.7 30 36 Stock 71 P71 70.6 ±0.62 71 81 G

D

d

D

D

d

d

d

EFor Detailed Fitting Size, refer to DP.2244. 75 P75 74.6 ±0.65 75 85 G

eStock lineup may vary by country. 80 P80 79.6 ±0.69 80 90 Stock

eStock: Same day shipping available upon request. Order by THA: 16:00, SGP: 12:00, MYS: 15:00

DP.75

No Back-Up Ring Back-Up Ring on One Side Back-Up Rings on Both Sides

Order Standard Service Non-Standard Service

Quantity Regular Quantity Large Quantity

90+5°

W

W

Quantity 1~500 501~ 0.1~0.2R -0 0.1~0.2R 0.1~0.2R 0.1~0.2R

*Rotating can be applied only in axial direction, reduces 0.1~0.2R 0.1~0.2R

H

H

H

Days to ship Standard To be quoted time for attaching or detaching the press processing, 90+5°

-0

and improves operating efficiency.

R R R R R R

O-Ring G G G

Order Standard Service Non-Standard Service

Quantity Regular Quantity Large Quantity

Enlarged View EStock lineup may vary by country. Quantity 1 ~ 10 Package(s) 11 Packages ~

ESame day shipping available upon request. Order by Days to ship Standard To be quoted

THA: 16:00, SGP: 12:00, MYS: 15:00 DP.75

2243 2244

You might also like

- 120 Ielts Speaking Topics Parts 1 2 3Document50 pages120 Ielts Speaking Topics Parts 1 2 3JohnSon93% (41)

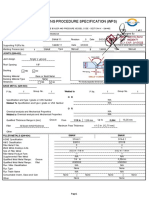

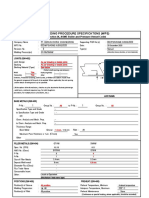

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin Romero100% (1)

- AE lv4 Listening & Speaking TB PDFDocument70 pagesAE lv4 Listening & Speaking TB PDFnamNo ratings yet

- Full Isolation of M-State ElementsDocument2 pagesFull Isolation of M-State ElementsWigwammanNo ratings yet

- How Different Colors of Light Affect Plant GrowthDocument5 pagesHow Different Colors of Light Affect Plant Growthmaybell pamaNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- 2nd 2020 IELTS Speaking GuessworkDocument290 pages2nd 2020 IELTS Speaking Guessworknam100% (2)

- Chapter 3 Hydraulic SystemDocument88 pagesChapter 3 Hydraulic SystemAhmad Anas100% (1)

- Deck CrainDocument540 pagesDeck Crainpraveen67% (3)

- WPS For P1 MaterialDocument1 pageWPS For P1 Materialasirul_meNo ratings yet

- Pamphlet 94 - Edition 5 - January 2018Document76 pagesPamphlet 94 - Edition 5 - January 2018Carlos Bermejo Alvarez100% (1)

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 pagesWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNo ratings yet

- Draft Wps Astm A 743 GR - Ca6nmDocument2 pagesDraft Wps Astm A 743 GR - Ca6nmIlham PaneNo ratings yet

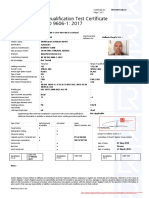

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauniNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Simon - 40 TIPS For IELTS Speaking Part 2Document35 pagesSimon - 40 TIPS For IELTS Speaking Part 2namNo ratings yet

- Biogas Production SystemsDocument22 pagesBiogas Production SystemsEmiliano Rodriguez TellezNo ratings yet

- Welding Metallurgy - Unit 12 - WEEK 11 PDFDocument3 pagesWelding Metallurgy - Unit 12 - WEEK 11 PDFDilipNo ratings yet

- O-Rings: Back-Up Rings / P SeriesDocument1 pageO-Rings: Back-Up Rings / P SeriesRian PratamaNo ratings yet

- LED Battens: Version: 1018.C.1 Price Validation: December, 2018Document1 pageLED Battens: Version: 1018.C.1 Price Validation: December, 2018Khuzaim KhanNo ratings yet

- Ficha Tecnica de MECH - Valvula Mariposa Ranurada X381DXDocument1 pageFicha Tecnica de MECH - Valvula Mariposa Ranurada X381DXCarmen Frances Arquinigo DonayreNo ratings yet

- General: Part Number: Status: Overview: DescriptionDocument2 pagesGeneral: Part Number: Status: Overview: DescriptionFredNo ratings yet

- PIPELINERS LIMITED-Chevron Bangladesh Project Welder Register (Update On Dec, 05. 2020) Welder Test Information Qualified Welder NameDocument1 pagePIPELINERS LIMITED-Chevron Bangladesh Project Welder Register (Update On Dec, 05. 2020) Welder Test Information Qualified Welder NameJakir HossainNo ratings yet

- Data Sheet 4.11 Issue ADocument6 pagesData Sheet 4.11 Issue Amy.work.ksabNo ratings yet

- Oil-Free Bushings (Copper Alloy Straight Standard) Oil-Free Bushings (Copper Alloy With Oil Groove)Document1 pageOil-Free Bushings (Copper Alloy Straight Standard) Oil-Free Bushings (Copper Alloy With Oil Groove)Shinya Takeda(武田 慎也)No ratings yet

- ExpressDocument2 pagesExpressabhi.c01487No ratings yet

- General: Part Number: Status: Overview: DescriptionDocument2 pagesGeneral: Part Number: Status: Overview: DescriptionEdgarNo ratings yet

- Shoe Brakes N.hyd - NV - HydDocument1 pageShoe Brakes N.hyd - NV - HydNajib KiwanNo ratings yet

- Πιννας - BW 111 PE PF bsDocument1 pageΠιννας - BW 111 PE PF bsLHYT NTUANo ratings yet

- RS Pro Black Heat Shrink Tubing 3 - 1, 91mm Dia X 91Document1 pageRS Pro Black Heat Shrink Tubing 3 - 1, 91mm Dia X 91Ahmed GhreebNo ratings yet

- DatasheetDocument6 pagesDatasheetsongdashengNo ratings yet

- Lases00113 1Document3 pagesLases00113 1henrykwolek15No ratings yet

- MTA Megacompact Technical Data Sheet v00Document1 pageMTA Megacompact Technical Data Sheet v00muhammetNo ratings yet

- VQ20 Tf2z304enDocument2 pagesVQ20 Tf2z304enChin YongkaiNo ratings yet

- R-216G-311 - 0 Manual Valve With Limit SwitchDocument3 pagesR-216G-311 - 0 Manual Valve With Limit SwitchFahmi HaidiNo ratings yet

- Molex 0002081201 - CRIMP - TERMINALSDocument2 pagesMolex 0002081201 - CRIMP - TERMINALSSadeq NeiroukhNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetGeorge DonosaNo ratings yet

- Multi - 1 Drills: YE-ML20Document2 pagesMulti - 1 Drills: YE-ML20Michel DominguesNo ratings yet

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2013Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2013LeonNo ratings yet

- MTA powerVAL Technical Data Sheet v01Document1 pageMTA powerVAL Technical Data Sheet v01Ali HNo ratings yet

- O-Rings O-Rings: S Series G SeriesDocument1 pageO-Rings O-Rings: S Series G SeriesRian PratamaNo ratings yet

- Welding Procedure Specification: JOINTS (QW-402)Document3 pagesWelding Procedure Specification: JOINTS (QW-402)Nitin KurupNo ratings yet

- P-Qac-Pro-200-38242 Welding Procedure Specification (WPS) Register Rev BDocument1 pageP-Qac-Pro-200-38242 Welding Procedure Specification (WPS) Register Rev BRamzi ZoghlamiNo ratings yet

- WPS RegDocument1 pageWPS RegRamzi ZoghlamiNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationHasan AhmedNo ratings yet

- TGS TDS Ci NBR 6160Document1 pageTGS TDS Ci NBR 6160Chang MikeNo ratings yet

- Crimp Terminals-133239Document3 pagesCrimp Terminals-133239vandat2tNo ratings yet

- PSP Profile, TPU Piston Cap SealDocument3 pagesPSP Profile, TPU Piston Cap SealSamira 1986No ratings yet

- Engineered Plastics GuideDocument1 pageEngineered Plastics GuideKmgsa BandaraNo ratings yet

- Welding Tubing CatalogDocument4 pagesWelding Tubing Catalogthanh_121No ratings yet

- Firekill: Model: OH-L2Document2 pagesFirekill: Model: OH-L2Canberk KarahanNo ratings yet

- Standard Sprockets Standard Sprockets / Double Sprockets: 60B Series 80B Series 40SD, 50SD SeriesDocument1 pageStandard Sprockets Standard Sprockets / Double Sprockets: 60B Series 80B Series 40SD, 50SD SeriesTomi KazuoNo ratings yet

- TGS TDS NBR Dia 6165Document1 pageTGS TDS NBR Dia 6165Chang MikeNo ratings yet

- Datasheet - Burndy - YA6CTC10Document2 pagesDatasheet - Burndy - YA6CTC10Ariel MendozaNo ratings yet

- Hardness Testing On Metallic MaterialsDocument1 pageHardness Testing On Metallic MaterialsThe KeymasterNo ratings yet

- Hose Clamp SMCDocument7 pagesHose Clamp SMCjtamilanbanNo ratings yet

- Bolt Grade Markings and Strength Chart - Head Markings, Material, Proof, Yield, Tensile StrengthDocument2 pagesBolt Grade Markings and Strength Chart - Head Markings, Material, Proof, Yield, Tensile StrengthHamilton Fábio Borges50% (2)

- Hamamatsu R7400UDocument8 pagesHamamatsu R7400UJaeYeon ParkNo ratings yet

- 03 VEX SpotDocument2 pages03 VEX SpottemamNo ratings yet

- Welder'S Qualification Test Certificate: Plate TO Plate Plate and Pipe Dia 500Document3 pagesWelder'S Qualification Test Certificate: Plate TO Plate Plate and Pipe Dia 500Er Pralabh ShahNo ratings yet

- D11N PDFDocument2 pagesD11N PDFJhon Richard Chambi PacoNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- OML 58 Phase 1 Project Welders Qualification Log: Candiate IdDocument9 pagesOML 58 Phase 1 Project Welders Qualification Log: Candiate IdTheophilus OrupaboNo ratings yet

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocument2 pagesPetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNo ratings yet

- MTA uniVAL Technical Data Sheet v00Document1 pageMTA uniVAL Technical Data Sheet v00muhammetNo ratings yet

- 01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InDocument2 pages01 25284124-8230-26-000-0008 REV.02 Piping List Tie-InRajeev KumarNo ratings yet

- Down LightersDocument1 pageDown LightersKhuzaim KhanNo ratings yet

- Stress ST DiagramsDocument1 pageStress ST DiagramsMinh LeNo ratings yet

- LC1 EE3706 C1 Basic ConceptsDocument16 pagesLC1 EE3706 C1 Basic ConceptsnamNo ratings yet

- 1lessons - For - Ielts - Advanced - Speaking 1 PDFDocument156 pages1lessons - For - Ielts - Advanced - Speaking 1 PDFMohammed El AsriNo ratings yet

- 2017 2018chuyen10ththdhspDocument12 pages2017 2018chuyen10ththdhspnamNo ratings yet

- Eatary Review (Rain Bow)Document2 pagesEatary Review (Rain Bow)namNo ratings yet

- The Day Music Died - Michael Jackson (Rain Bow)Document2 pagesThe Day Music Died - Michael Jackson (Rain Bow)namNo ratings yet

- 3rd 2020 Topic-Based Answers - Vietnam IELTS SPEAKING PART 2Document23 pages3rd 2020 Topic-Based Answers - Vietnam IELTS SPEAKING PART 2namNo ratings yet

- TIẾNG ANH 11 - CHLDocument17 pagesTIẾNG ANH 11 - CHLnamNo ratings yet

- IELTS Fighters - Transcript audio + Answers giáo trình IELTS Listening band 5.0 - 6.5 (học tại trung tâm)Document167 pagesIELTS Fighters - Transcript audio + Answers giáo trình IELTS Listening band 5.0 - 6.5 (học tại trung tâm)namNo ratings yet

- IELTS Recent Actual Test With Answers Volume 6Document15 pagesIELTS Recent Actual Test With Answers Volume 6namNo ratings yet

- Word Building PrefixesDocument4 pagesWord Building PrefixesnamNo ratings yet

- 12.7.3 Key Design Features: 12.8 Curved UndercutsDocument3 pages12.7.3 Key Design Features: 12.8 Curved UndercutsnamNo ratings yet

- 04 PDFDocument24 pages04 PDFnamNo ratings yet

- Pref PDFDocument1 pagePref PDFnamNo ratings yet

- Can Siet Luc KINGTONYDocument1 pageCan Siet Luc KINGTONYnamNo ratings yet

- 2undercuts at Angle To Tool Axis PDFDocument2 pages2undercuts at Angle To Tool Axis PDFnamNo ratings yet

- 2form Pins PDFDocument3 pages2form Pins PDFnamNo ratings yet

- Mould Design Guide: Figure 12.9 Offset Dowel DesignDocument3 pagesMould Design Guide: Figure 12.9 Offset Dowel DesignnamNo ratings yet

- Guidelines For The Establishment of Pharmaceutical Retail BusinessDocument19 pagesGuidelines For The Establishment of Pharmaceutical Retail BusinessFranc100% (1)

- Sgs Port Klang Ann Joo Integrated Steel 03653-03731 (79samples)Document8 pagesSgs Port Klang Ann Joo Integrated Steel 03653-03731 (79samples)Jasni JalaludinNo ratings yet

- Routine and Special Core AnalysisDocument33 pagesRoutine and Special Core AnalysisInfinix UserNo ratings yet

- Great DesignomicsDocument95 pagesGreat DesignomicsChristopher Allen VarsoviaNo ratings yet

- ANEXO 5 - Catalogo Sumideros JR Smith PDFDocument22 pagesANEXO 5 - Catalogo Sumideros JR Smith PDFCamilo VelásquezNo ratings yet

- Gherciu AntonelaDocument2 pagesGherciu AntonelaPetruNo ratings yet

- Avicel ® RC-591 Suspension MTR Bpna enDocument7 pagesAvicel ® RC-591 Suspension MTR Bpna enRaedMoh100% (1)

- Chem 155 Quiz 3 Review Topics and Questions With AnswersDocument6 pagesChem 155 Quiz 3 Review Topics and Questions With Answersuvir iitmNo ratings yet

- Copper CorrosionDocument2 pagesCopper CorrosionDonatas BertasiusNo ratings yet

- Done By: Neha Jain Priya Upadhyay Saanchi AroraDocument13 pagesDone By: Neha Jain Priya Upadhyay Saanchi AroraPriya UpadhyayNo ratings yet

- PLANTILLA para Diagrama TernarioDocument8 pagesPLANTILLA para Diagrama TernarioHernan Yucra GeronimoNo ratings yet

- Insoluble Ions EssayDocument2 pagesInsoluble Ions EssayDarshan Meghji100% (1)

- 3d Printing Materials PropertiesDocument51 pages3d Printing Materials PropertiesAmy GaoNo ratings yet

- SPT2021 Butadiene AAMDocument29 pagesSPT2021 Butadiene AAMTasneem MNo ratings yet

- Yellow Passion Fruits Headspace Werkhoff1998Document18 pagesYellow Passion Fruits Headspace Werkhoff1998mapollo2000No ratings yet

- Adrif Vision List New 11.02.2021Document2 pagesAdrif Vision List New 11.02.2021rahsreeNo ratings yet

- 20 eDocument57 pages20 eakanksha vermaNo ratings yet

- VSEPR ShortcutDocument3 pagesVSEPR ShortcutSubhojyotiDasNo ratings yet

- Fatigue BasicsDocument30 pagesFatigue BasicsABY.SAAJEDI879No ratings yet

- Avian Urolithiasis EngDocument4 pagesAvian Urolithiasis Engwaseem234No ratings yet

- Presentation On Nutmeg Oil For IPB NOV 2022Document34 pagesPresentation On Nutmeg Oil For IPB NOV 2022KushDaiwikNo ratings yet

- Paracetamol e Ibuprofeno Como Contaminantes EmergentesDocument27 pagesParacetamol e Ibuprofeno Como Contaminantes EmergentesElmer VargasNo ratings yet

- ConcreteDocument23 pagesConcreteHein ZanNo ratings yet