Professional Documents

Culture Documents

Characterization of Phenol-Formaldehyde Prepolymer Resins by in Line FT-IR Spectros

Uploaded by

kkkkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Characterization of Phenol-Formaldehyde Prepolymer Resins by in Line FT-IR Spectros

Uploaded by

kkkkCopyright:

Available Formats

238 Acta Chim. Slov.

2005, 52, 238–244

Scientific Paper

Characterization of Phenol-Formaldehyde Prepolymer

Resins by In Line FT-IR Spectroscopy†

Ida Poljanšek and Matjaž Krajnc*

University of Ljubljana, Faculty of Chemistry and Chemical Technology, Aškerčeva 5, P. O. Box 537, SI-1001 Ljubljana,

Slovenia. E-mail: matjaz.krajnc@fkkt.uni-lj.si

Received 03-06-2005

†

Dedicated to the memory of Prof. Dr. Tatjana Malavašič

Abstract

Different resol phenol-formaldehyde prepolymer resins have been synthesized with different formaldehyde / phenol

ratios. The phenolic resin composition depends on monomer ratio, catalyst, reaction conditions, and residual

free monomers. Temperature and pH conditions under which reactions of phenols with formaldehyde are carried

out have a profound effect on the characteristics of the resulting products. Three reaction sequences must be

considered: formaldehyde addition to phenol, chain growth or prepolymer formation and finally the crosslinking

or curing reaction. Two prepolymer types are obtained depending on pH, novolacs in an acidic pH region whereas

resols by alkaline reaction. Resol resins are synthesized with a molar excess of formaldehyde (1<F/P<3). These

are mono- or polynuclear hydroxymethylphenols which are stable at room temperatures, but are transformed

into three dimensional, cross linked, insoluble and infusible polymers by the application of heat.

An ATR-FTIR spectrometry technique (ReactIR 4000) with light conduit and diamond-composite sensor was

used to perform in-line monitoring of phenol-formaldehyde prepolymer synthesis. This technique was found to

be ideal for determining residual free phenol and formaldehyde, individual phenol and formaldehyde conversions

and prepolymer composition changes as a function of time when the condensation reaction was carried out.

The kinetics data obtained through the ReactIR 4000 in-line reaction analysis system agreed well with those

determined by the traditional titration method. ReactIR technology replaces time consuming and inaccurate

off-line methodology.

Key words: phenol-formaldehyde resin, in-line IR spectroscopy

Introduction to improve their curing, to lower the content of free

formaldehyde and to reduce the cost of the resin.9,10 To

Since their introduction in 1910 the relatively clarify the complicated relationship between the phenol

inexpensive and highly versatile family of phenolic ring and amino functional group our research work

resins has played a vital role in construction, automotive, started with the study of phenol-formaldehyde resins.

electrical and appliance industries.1,2,3 Temperature and The aim of our work was to study the PF resin

pH conditions under which reactions of phenols with preparation process. The influence of molar ratio

formaldehyde are carried out have a profound effect between phenol and formaldehyde on the PF synthesis

on the characteristics of the resulting products. Three and on the composition of the synthesized product was

reaction sequences must be considered: formaldehyde investigated. Furthermore, the pH value of the reaction

addition to phenol, chain growth or prepolymer formation mixture was varied to study their influence on the

and finally the crosslinking or curing reaction.4– 8 Two structure of PF resin. An ATR-FTIR spectrometry was

prepolymer types are obtained depending on pH, found to be a successful and informative analytical tool

novolacs in an acidic pH region whereas resols by for determining individual phenol and formaldehyde

alkaline reaction. Resol resins are synthesized with a conversions and prepolymer composition changes as a

molar excess of formaldehyde (1<F/P<3). These are function of time when the condensation reaction was

mono-or polynuclear hydroxymethylphenols which are carried out.11,12,13 We detected the different bridges

stable at room temperatures, but are transformed into formations during the reaction of two hydroxymethyl

three dimensional, crosslinked, insoluble and infusible groups under alkaline conditions. According to review

polymers by the application of heat. Recently, urea has of the literature available to us, the in-line ATR-FTIR

been introduced into phenol-formaldehyde (PF) resins technique has not been applied in the studies of PF

Poljanšek and Krajnc Characterization of Phenol-Formaldehyde Prepolymer Resins

Acta Chim. Slov. 2005, 52, 238–244 239

Table 1. Reaction conditions of phenol-formaldehyde resin synthesis, concentrations of phenol and formaldehyde at t=0 and free

formaldehyde in the resin at the end of reaction synthesis.

Synthesis Molar ratio Phenol:Formaldehyde CA0 Phenol mol/L CA0 Form. mol/L T*, °C t, h pH % Free Form.

Synthesis 1 1:1.6 4.05 6.22 61,5 3 8 3.35%

Synthesis 2 1:1.8 3.78 6.58 55 3 8 2.32%

Synthesis 3 1:1.8 3.78 6.58 21,3 3 7 8.86%

Synthesis 4 1:1.8 3.78 6.58 62 3 8 2.77%

Synthesis 5 1:1.9 3.68 6.5 65 3 8 5.77%

Synthesis 6 1:2 3.57 6.90 70 3 8 3.75%

* Temperature at which we started to collect mid FTIR spectra of the condensation components.

resins synthesis. Different resol prepolymer resins composite) insertion probe was used to collect mid-

have been synthesized with different F/P ratios. An FTIR spectra of the condensation components. IR

important structural factor determined quantitatively spectra were collected every three minutes in the

for resol prepolymer resins is the F/P ratio after the wavenumber range between 4000 and 650 cm–1 at

reaction. In order to evaluate the ability of the ATR- resolution 8 cm–1. These spectra were used to calculate

FTIR spectroscopic method, the kinetic data obtained the amounts of free phenol and free formaldehyde

through the IR in-line analysis were compared to results and to some extent the PF resin composition. At the

from the traditional titration method.14 end of the synthesis the traditional titration method

for determining free formaldehyde was carried out as

well as residual phenol content was determined by gas

Experimental chromatography. 15

Materials

Phenol (99+ %), 37% formaldehyde aqueous Results and discussion

solution and sodium hydroxide (98%) were used. All

the chemicals were supplied by Aldrich. ATR-FTIR spectrometry was utilized to monitor

the condensation reaction in real time. In-line

Resin synthesis data acquisition was performed by immersing the

Different resol prepolymer resins (Table 1) were transmission probe directly into the reactor. Assignment

prepared with the same amount of catalyst (NaOH) but of the characteristic peaks of phenol and formaldehyde

with different F/P ratios: R1, R2, R3 and R4 with F/P was done using the previously collected spectra of both

ratios of 1.6, 1.8, 1.9 and 2.0, respectively. PF resin was reactants in aqueous solution. The spectra of phenol and

synthesized in a 500 ml batch reactor fitted with a reflux formaldehyde solutions are presented in Figure 1 and

condenser, a mechanical stirrer, a digital thermometer collected in Table 2. The assignment of characteristic

and an IR probe. Several batch condensations of phenol peaks was done on the basis of relevant literature.16,17 In

and formaldehyde were conducted at 90 °C. Reaction Figure 1 a typical IR spectrum of a phenol-formaldehyde

vessels were heated to the same reaction temperature. resin (synthesis 2) is also represented.

The recipes used are shown in Table 1.

All resins were prepared by reacting the required

amounts of phenol (80% solution in water) with varying

amounts of formaldehyde (37% solution in water,

Merck) in the presence of the catalyst. The resulting

reaction mixture was stirred and heated to 90–95 °C

until the mixture became cloudy. Afterwards, the resin

is used as it is or it is neutralized. In the first set of

experiments the reproducibility of the resin synthesis

was investigated to determine the amounts of free

phenol and free formaldehyde.

FTIR spectroscopy Figure 1. FTIR specta at the wavelengths in the range of interest

A ReactIRTM 4000 reaction analysis system for phenol, formaldehyde and phenol-formaldehyde resin type

equipped with a light conduit and DiComp (diamond resol (synthesis 2, no.61).

Poljanšek and Krajnc Characterization of Phenol-Formaldehyde Prepolymer Resins

240 Acta Chim. Slov. 2005, 52, 238–244

Table 2. Functional groups and observed wavenumbers for Table 3. Functional groups and observed wavenumbers for

phenol and formaldehyde and their literature values. phenol-formaldehyde resin type resol and their literature values.

Literature data Observed Literature data Observed

of wavenumber, wavenumber, Functional group of wavenumber, wavenumber, Functional group

cm–1 cm–1 cm–1 cm–1

Phenol 3400 3389 OH

3400 3308 OH stretch 2925 in phase stretching vibration

2953

/ 3026 CH unsaturated stretch of -CH2- alkane

1605 1594 C = C aromatic ring 2850 out of phase stretching

2895

vibration of -CH2- alkane

1510 1498 C = C aromatic ring

1633 C = C aromatic ring

1485 1475 C = C aromatic ring

1610 1610* C = C aromatic ring

1380 1370 OH in-plane bend

1517 1552 C = C aromatic ring

1240 1224 C-C-O asymmetric stretch

1504 1513 C = C aromatic ring

1180 1170 CH aromatic, in-plane

1480 1478 C-H aliphatic

1160 1153 C-O stretch

1460 / -CH2- deformaton vibration

1060 1073 single bond C-O stretching

vibrations of -C-OH group 1450 C = C benzene ring obscured

1451*

by -CH2- methylene bridge

1020 1023 -C-OH

1390 1370 OH in plane

990 999.7 -C-H

1378

880 887.8 -C-H

1237 asymmetric stretch of

800 810.6 asymmetric stretch of 1235

phenolic C-C-OH

phenolic C-C-OH

1153 1154 C-O stretch

747 748.8 CH aromatic, out-of-plane

1100 asymmetric stretching

680 690.9 ring bend

1116 vibration of C – O-C

aliphatic ether

Formaldehyde 1045 single bond C-O stretching

1058*

3400 3350 OH stretch vibrations of -CH2OH group

2822 2980 CH stretch, general 1000 1019 aliphatic hydroxyl

2724 2914 CH bend overtone 976 1,2,4-substituted benzene

976*

1722 1644* C = O stretch (overlapped ring

with OH scissors of water) 885 887.8 CH out-of-plane, isolated H

1390 1447 C-H bend 835 CH out-of-plane, para-

826

/ 1158 C-O stretch substituted

/ 1108 -C-OH 760 CH out of plane, ortho-

756.6

/ 1023 -C-OH substituted

/ 992 C-H 694 694.8 adjacent 5H

/ 911 *observed IR spectral frequencies of 2,4,6-trihydroxymethyl

/ 671 phenol

Characteristic absorbances of the phenolic resin peaks at 1594 and 1498 cm–1 corresponded to the C=C

are assigned in Table 3 using the literature.18,19,20 These aromatic ring vibrations. The peaks at 1224 and 1170

signals were helpful in identifying the components of cm–1 corresponded to the C-C-O asymmetric stretch and

the condensation reaction of phenol and formaldehyde. C-H in plane deformations, respectively, while the 999.7,

We do have to emphasize that the literature assigned and 748.8 cm–1 peaks belonged to the C-H out of plane

absorption bands to the various chemical groups did vibrations. The peak at 1370 cm–1 which corresponded

vary, as might have been expected.19 to the phenol O-H in plane bend (Figures 1 and 2)

The normalized phenol-formaldehyde resin was also detected for phenol-formaldehyde resin. The

spectra at the wavelengths in the range of interest for width of the band at 1370 cm–1 indicates it is due to an

the PF resin synthesis are shown in Figure 2. The spectra O-H rather than C-H or C-C bond. The formaldehyde

were recorded at a resolution of 8 cm–1 with 128 scans for aqueous solution was added into the reactor at the

each spectrum. The reaction mixture spectra of PF resin beginning of the process, therefore the characteristic

run were collected every 3 minutes for a total of 180 peaks of methylene glycol C-O, O-H, and C-H bends

minutes at wavenumbers from 4000–650 cm–1. As shown at 1108 cm–1, 1023 cm–1, and 992 cm–1 were observed in

in Figure 2, the characteristic peaks of phenol at 1594, the first spectrum, respectively (Figure 2, Table 2). After

1498, 1224, 1170, 999.7, and 748.8 cm–1 diminished with the reactor content heated to preferred temperature a

increasing reaction time, while the absorbance band of sharp decrease of phenol and formaldehyde peaks was

hydroxymethyl and methylene groups increased. The observed as a result of the reaction.

Poljanšek and Krajnc Characterization of Phenol-Formaldehyde Prepolymer Resins

Acta Chim. Slov. 2005, 52, 238–244 241

methylene-ether bridges continued to react till the end

of experiment.

Figure 2. Reaction profile shows significant changes as the

polymerization of PF resin (molar ratio F / P= 1.8 / 1) occurs in

range of 1800 cm–1 – 650 cm–1.

At the beginning the characteristic peak of the

formaldehyde at 911 cm–1 decreased with increasing

reaction time and afterwards slightly increased due

to the conversion of methylene ether bridges into

Figure 3. The concentration profiles for formaldehyde (F),

methylene bridges with the loss of formaldehyde mono-hydroxymethyl groups (MHMP), di-hydroxymethyl groups

and water. The absorbances for other characteristic (DHMP) and methylene bridges (MeB) during PF synthesis.

groups were less observable because they overlapped

with other absorbances of the product. It can be

observed (Figures 2) that an additional peak occurred Figures 4 and 5 present the time evolution of

at 1610 cm–1. This peak was attributed to C=C band phenol and formaldehyde consumption determined

vibrations of the product aromatic ring. In the phenol- by means of the in-line IR measurements. At the end

formaldehyde resin spectrum additional characteristic of the synthesis the traditional titration method for

signals of methylene bridge C-H bend at 1478 cm–1 determining free formaldehyde was carried out as

and methylene-ether bridge C-O-C bend at 1116 cm–1 well as residual phenol content was determined by gas

were present. chromatography. The calculated residual phenol content

In Figure 3 the concentration profiles for of final products was compared with those observed by

phenol, formaldehyde, and the reaction product were GC. In spite of the different principle of measurements

generated by the use of ConcIRTTM Opus I software. the agreement between the results is satisfactory, within

The decrease of free formaldehyde and on the other ± 10% error. The consumption of monomers (phenol

hand, the increase of methylene bridges (MeB) as well and formaldehyde) during the reaction was estimated

as the formation of mono-hydroxymethyl (MHMP) by calculating the ratio between the absorbance at

and di-hydroxymethyl phenols (DHMP) was observed 1594 cm–1 (phenol) and the absorbance at 911 cm–1

from the concentration profiles. The concentration (formaldehyde) at reaction time t and the corresponding

of mono-hydroxymethyl phenols increased and then peaks at the start of the polymerization reaction

decreased due to the formation of di-hydroxymethyl (t = 0), according to Equation (1).

phenols and methylene bridges. The reaction rate

of the formation of methylene bridges increased peak height at time t

X (mol %) = (1 − ) × 100 (1)

when the mono-hydroxymethyl groups reached the peak height at time t = 0

maximum. In the first 50 minutes the concentration

of hydroxymethyl groups increased and afterwards, The absorbance of the characteristic peak

when methylene-ether bridges or methylene bridges was measured as the peak height referred to a

were formed, the concentration started to decrease. two point baseline. The in-line end values of the

In the same time di-hydroxymethyl groups were also formaldehyde consumption (conversion) agreed well

formed. The concentration of di-hydroxymethyl groups with those from the off-line traditional titration method

increased till the maximum in 75 minutes and then (Table 1). In Table 1 the reaction conditions of phenol-

started to decrease due to the formation of methylene formaldehyde resin synthesis, concentrations of phenol

bridges. The concentration of formaldehyde began to and formaldehyde and free formaldehyde at the end of

decrease from the beginning of the experiment. It was reaction synthesis are listed. The ATR-FTIR probe also

estimated that almost all the free formaldehyde reacted detected the oscillation of the temperature as a change

in 75 minutes of the reaction, while the methylene and in the ATR-FTIR absorbance peak heights.

Poljanšek and Krajnc Characterization of Phenol-Formaldehyde Prepolymer Resins

242 Acta Chim. Slov. 2005, 52, 238–244

formaldehyde was 0.56 mol/L. The in-line end values of

the formaldehyde consumption agreed well with those

from the off-line traditional titration method.

Figure 4. Concentration profile of phenol in the synthesis

of phenol-formaldehyde resin at different molar ratios

formaldehyde : phenol.

The concentration profiles for phenol in the Figure 5. Concentration profile of formaldehyde in the syn-

synthesis of phenol-formaldehyde resin at different thesis of phenol-formaldehyde resin at different molar ratios

formaldehyde : phenol.

molar ratios formaldehyde : phenol agreed with the well

known theory that in the synthesis of PF resin the pH

value of the reaction mixture has a great influence as The concentration profiles for hydroxymethyl-

well as the temperature. For the synthesis of PF resin at phenols and for methylene bridges are shown in Figures

pH=7 the decrease of phenol is lower regarding to the 6 and 7, respectively. The profiles were generated by the

synthesis of PF resin at pH=8. At higher temperatures use of Conc IRTTM Opus I software. The concentration

the consumption of phenol is higher. profiles of hydroxymethylphenols in the synthesis of PF

The weight % of free formaldehyde in the synthesis resins for different molar ratios of F/P are shown in

3 and 5 are higher due to the lower temperature and Figure 6. The reaction rate of hydroxymethylphenols

lower pH value of the reaction mixture. The influence of increased with the increasing ratio between F/P. The

the pH value of the reaction mixture prevailed over the maximum of hydroxymethylphenol concentration was

influence of the reaction temperature. The lower rate of reached in 38 minutes for the molar ratio of 2/1 and

consumption of formaldehyde in the synthesis 5 (1 : 1.9) in 48 minutes for the molar ratio of 1.8/1 and then

can be ascribed to the lower pH value of the reaction started to decrease due to the formation of methylene

mixture due to the higher amount of formaldehyde at and methylene-ether bridges. For the synthesis 3 with

the start of the reaction and on the other hand due to the molar ratio of 1.8/1 it is obvious that the reaction

the lower starting temperature. The concentration of rate of hydroxymethylphenol is actually the same but

formaldehyde (Figure 5) in the synthesis of PF resin the reaction temperature was too low for the formation

with the F/P ratio 2/1 decreased for 35 minutes, when of methylene or methylene-ether bridges. The PF

it reached the minimum and started to increase due to resin synthesized under the conditions mentioned was

the formation of methylene bridges from the methylene- soluble in water which corresponds to the PF resins

ether bridges. In this reaction free formaldehyde is with a high concentration of hydroxymethyl groups. The

a side product. In order to observe the influence of polymerization of hydroxymethyl phenols was hindered

pH on the synthesis of PF resins the reaction was by lower pH values while the influence of lower starting

proceeded at pH=7 and pH=8. From the Figure 5 it temperatures was not so significant.

can be observed that the concentration of formaldehyde The concentration profiles of methylene bridges

for the reaction condition of pH=7 slowly decreased, in the synthesis of PF resins with different molar

regarding to the concentration of formaldehyde for the ratio between F/P are represented in Figure 7. The

synthesis at pH=8. The concentration of the catalyst is end concentration of methylene bridges increased as

very important for the reaction rate. For the synthesis the molar ratio between formaldehyde and phenol

of PF resin with a molar ratio of 1.8/1 at pH=8 the increased. The concentration of methylene bridges is

concentration of free formaldehyde decreased from the lowest in synthesis 3 with the molar ratio of 1.8/1

6.58 mol/L to 1.74 mol/L after the first hour and at because the temperature and pH value of the reaction

the end of the experiment the concentration of free mixture were too low.

Poljanšek and Krajnc Characterization of Phenol-Formaldehyde Prepolymer Resins

Acta Chim. Slov. 2005, 52, 238–244 243

Figure 6. Concentration profiles of hydroxymethylphenols in the Figure 7. Concentration profiles of methylene briges in the

synthesis of PF resins: synthesis 3 (molar ratio 1 : 1.8, pH=7); synthesis of PF resins: synthesis 6 (molar ratio 2 : 1); synthesis

synthesis 4 (molar ratio 1 : 1.8, pH=8); synthesis 6 (molar ratio 1 : 2). 2 (molar ratio 1.8 : 1);synthesis 3 (molar ratio 1.8 : 1, pH=7);

synthesis 1 (molar ratio 1.6:1).

Conclusions 3. J. E. Shafizadeh, S. Guionnet, M. S. Tillman, J. C. Seferis,

J. Appl. Polym. Sci. 1999, 73 (4), 505–514.

Different PF resins were synthesized at different 4. M. V. Alonso, M. Oliet, J. M. Perez, F. Rodriguez, J.

molar ratios. The characterization of the chemical Echeverria, Thermochimica Acta 2004, 419, 161–167.

structure of resole prepolymers and their intermediates 5. A. H. Conner, L. F. Lorenz, K. C. Hirth, J. Appl. Polym.

is very complex because of the many closely related Sci. 2002, 86, 3256–3263.

isomers available. Firstly, hydroxymethylphenols are 6. K. Lenghaus, G. G. Qiao, D. H. Solomon, Polymer, 2000,

formed by the initial substitution reactions between 41, 1973–1979.

formaldehyde and phenol. Secondly, condensation 7. K. Lenghaus, G. G. Qiao, D. H. Solomon, Polymer, 2001,

reactions take place between hydroxymethylphenols 42, 3355–3362.

themselves, as well as between hydroxymethylphenols 8. A. Pizzi, A. Stephanou, J. Appl. Polym. Sci. 1993, 49,

and phenol. Methylene and methylene-ether bridges are 2157–2170.

formed in this step. These prepolymers contain many 9. G. He, B. Riedl, J. Polym. Sci. Part B: Polym. Phys. 2003,

active hydroxymethyl groups. It was observed that the 41, 1929–1938.

structure of the PF resin depends on the initial molar 10. S. So, A. Rudin, J. Appl. Polym. Sci., 1990, 41, 205–232.

ratio of F/P, temperature and pH value. 11. T. Holopainen, L. Alvila, T. T. Pakkanen, J. Rainio, J.

In-line ATR-FTIR spectroscopy was found to Appl. Polym. Sci. 2003, 89, 3582–3586.

be a successful and informative analytical tool for 12. J. J. Lindberg, U. Brotherus, V. A. Era, Angew. Makromol.

determining individual phenol and formaldehyde Chem. 1975, 45, 77–83.

conversions as well as intermediate and final product 13. M. Panetti, A. Cangelosi, F. Ferrero, Annali di Chimica,

composition. Absorbance bands which correspond 1981, 743–749.

to the PF resins are 1633, 1478 and 1116 cm–1 for the 14. M. F. Grenier-Loustalot, S. Larroque, P. Grenier, J. P.

C=C aromatic ring, C-H methylene bridge and C-O-C Leca, D. Bedel, Polymer 1994, 35, 3046–3054.

methylene-ether bridge, respectively. 15. European standard, EN ISO 8974.

16. T. Holopainen, L. Alvila, J. Rainio, T. T. Pakkanen, J.

Acknowledgments Appl. Polym. Sci. 1998, 69, 2175–2185.

17. V. A. Erä, J. J. Linndberg, A. Mattila, L. Vauhkonen, T.

The financial support of this work by the Slovenian Linnahalme, Angew. Makromol. Chem. 1976, 50, 43–52.

Ministry of Education, Science and Sport (Grant P2- 18. V. A. Erä, H. Salo, T. Kaps, J. J. Linndberg, Angew.

0191 and Grant L2-6686) is gratefully acknowledged. Makromol. Chem. 1975, 48, 185–187.

19. R. O. Ebewele, B. H. River, J. A. Koutsky, J. Appl. Polym.

Sci. 1986, 31, 2275–2302.

References

20. G. Carotenuto, L. Nicolais, J. Appl. Polym. Sci. 1999, 74,

1. A. Knop, L. A. Pilato: Phenolic resins, Springer-Verlag, 2703–2715.

Berlin, 1985.

2. H. Pasch, M. Schrod, Macromol. Rapid Commun. 2004,

25, 224–230.

Poljanšek and Krajnc Characterization of Phenol-Formaldehyde Prepolymer Resins

244 Acta Chim. Slov. 2005, 52, 238–244

Povzetek

Sintetizirali smo različne fenol-formaldehidne prepolimere s spreminjanjem razmerja med formaldehidom in

fenolom. Sestava fenolne smole je odvisna od začetnega razmerja monomerov, vrste katalizatorja, reakcijskih

pogojev in koncentracije prostih monomerov na koncu reakcije. Pomemben vpliv na značilnosti sintetizirane

smole imata tudi temperatura in pH vrednost pod katerimi poteka reakcija fenola s formaldehidom. Upoštevati

moramo tri zaporedne reakcije : adicijo formaldehida na fenol, rast verige ali tvorbo prepolimera in končno

zamreževanje ali reakcijo utrjevanja. Glede na pH vrednost dobimo dve vrsti prepolimera, novolak v kislem

območju pH vrednosti, medtem ko dobimo rezol pod alkalnimi reakcijskimi pogoji. Rezolno smolo sintetiziramo

z molarnim prebitkom formaldehida (1<F/P<3). Produkti so mono - ali poli - jedrski hidroksimetil fenoli, ki

so stabilni pri sobni temperaturi, vendar se pri povišani temperaturi zamrežijo v tridimenzionalen, netopen in

netaljiv polimer.

Potek sinteze fenol - formaldehidnega prepolimera smo spremljali s pomočjo "in-line" ATR-FTIR spektroskopske

analitske tehnike (ReactIR 4000), ki je opremljena z optičnim vodnikom in diamantnim kompozitnim senzorjem.

Ta tehnika se je izkazala kot idealna za določanje prostega fenola in formaldehida, kot tudi njunih konverzij,

prav tako pa tudi sprememb v sestavi prepolimera v odvisnosti od reakcijskega časa kondenzacije. Kinetični

podatki, ki smo jih dobili s pomočjo ReactIR 4000 "in-line" reakcijskega analiznega sistema se dobro ujemajo s

podatki določenimi s tradicionalnimi titracijskimi metodami. ReactIR tehnologija nadomešča časovno potratno

in nenatančno "off-line" metodologijo.

Poljanšek and Krajnc Characterization of Phenol-Formaldehyde Prepolymer Resins

You might also like

- NNResinDocument8 pagesNNResinNonny Dwitasari SiregarNo ratings yet

- Structure and Curing Mechanism of Resol Phenol-Formaldehyde Prepolymer ResinsDocument8 pagesStructure and Curing Mechanism of Resol Phenol-Formaldehyde Prepolymer Resinsmahdavian76No ratings yet

- Determination of Paraformaldehyde Reactivity and Its Relationship To PRF Resin GelationDocument6 pagesDetermination of Paraformaldehyde Reactivity and Its Relationship To PRF Resin GelationNam Phạm VănNo ratings yet

- Properties of RTF Copolymer Resins from Taiwan Acacia and China Fir BarkDocument8 pagesProperties of RTF Copolymer Resins from Taiwan Acacia and China Fir BarkFirman Rangga WinataNo ratings yet

- Phenol-Formaldehyde Resols Modified by Boric Acid: 386 POLIMERY 2006, 51, NR 5Document3 pagesPhenol-Formaldehyde Resols Modified by Boric Acid: 386 POLIMERY 2006, 51, NR 5cera primaNo ratings yet

- Development and Characterization of Phenol - Formaldehyde Molding PowderDocument8 pagesDevelopment and Characterization of Phenol - Formaldehyde Molding PowderAmir Surya HidayahNo ratings yet

- Quantification of The Maleic Anhydride Grafted Onto Polypropylene by Chemical and Viscosimetric Titrations, and FTIR Spectros PDFDocument11 pagesQuantification of The Maleic Anhydride Grafted Onto Polypropylene by Chemical and Viscosimetric Titrations, and FTIR Spectros PDFThinh DangNo ratings yet

- Average Structural Analysis of Tar Obtained From Pyrolysis of WoodDocument8 pagesAverage Structural Analysis of Tar Obtained From Pyrolysis of WoodHailey17No ratings yet

- Synthesis and Characterization of Highly Soluble Uorescent Main Chain Copolyimides Containing Perylene UnitsDocument6 pagesSynthesis and Characterization of Highly Soluble Uorescent Main Chain Copolyimides Containing Perylene UnitsMuhammad Faisal AminNo ratings yet

- Development and Characterization of PhenolDocument10 pagesDevelopment and Characterization of PhenolHardeep BrarNo ratings yet

- 10 1002@pola 22191Document9 pages10 1002@pola 22191tigharaNo ratings yet

- 1 s2.0 S0141813017344562 MainDocument8 pages1 s2.0 S0141813017344562 MainZAKARIA EL KHABBABINo ratings yet

- Structure of Resorcinol, Phenol, and Furan Resins by MALDI TOF Mass Spectrometry and 13C NMRDocument10 pagesStructure of Resorcinol, Phenol, and Furan Resins by MALDI TOF Mass Spectrometry and 13C NMRראול אפונטהNo ratings yet

- Development and Characterization of Phenol - Formaldehyde Molding PowderDocument8 pagesDevelopment and Characterization of Phenol - Formaldehyde Molding PowderUma MaheshwarNo ratings yet

- Syn Final Helen MDocument8 pagesSyn Final Helen Mapi-509765936No ratings yet

- The Chemistry of Novolac Resins. I A Review On The Use of ModelsDocument9 pagesThe Chemistry of Novolac Resins. I A Review On The Use of ModelsELIZANo ratings yet

- Changiz Karami, Keivan Ghodrati, Mina Izadi, Azita Farrokh, Sedigheh Jafari, Maryam Mahmoudiyani, and Nahid HaghnazariDocument4 pagesChangiz Karami, Keivan Ghodrati, Mina Izadi, Azita Farrokh, Sedigheh Jafari, Maryam Mahmoudiyani, and Nahid HaghnazariMiriam GarciaNo ratings yet

- A Novel Method For Determination of Polyester End-Groups by NMR SpectrosDocument7 pagesA Novel Method For Determination of Polyester End-Groups by NMR SpectrosLucas Del PretteNo ratings yet

- Effect of F P and OH P Molar Ratios and Condensation Viscosity On The Structure of Phenol Formaldehyde Resol Resins For Overlays A Statistical StudyDocument7 pagesEffect of F P and OH P Molar Ratios and Condensation Viscosity On The Structure of Phenol Formaldehyde Resol Resins For Overlays A Statistical StudyRobert RicardoNo ratings yet

- Pembuatan Resin Fenol Formaldehid Sebagai Prekursor Untuk Preparasi Karbon BerporiDocument6 pagesPembuatan Resin Fenol Formaldehid Sebagai Prekursor Untuk Preparasi Karbon BerporiInda AlwanNo ratings yet

- Assessment of Resin Formulations by Infrared Spectroscopy and Multivariate AnalysisDocument11 pagesAssessment of Resin Formulations by Infrared Spectroscopy and Multivariate Analysispato-locoNo ratings yet

- Synthesis of Paracetamol Via Acetylation and Analysis of ProductDocument4 pagesSynthesis of Paracetamol Via Acetylation and Analysis of Productdione.njokuNo ratings yet

- Thermal Degradation Study of New Polymer Derived From 8 Hydroxyquinoline 5sulphonic Acid and CatecholDocument9 pagesThermal Degradation Study of New Polymer Derived From 8 Hydroxyquinoline 5sulphonic Acid and Catecholsunaina agarwalNo ratings yet

- Calcium Phosphate Apatites With Variable Ca/P Atomic Ratio I. Synthesis, Characterisation and Thermal Stability of PowdersDocument8 pagesCalcium Phosphate Apatites With Variable Ca/P Atomic Ratio I. Synthesis, Characterisation and Thermal Stability of PowdersMaximimilianoNo ratings yet

- Kubicka Different SolventsDocument10 pagesKubicka Different SolventscligcodiNo ratings yet

- Reactions 03 00040Document13 pagesReactions 03 00040Ibtissame AbbadNo ratings yet

- Control of Reactivity of Novolac Resins: The Use of 3,4-Dihydro-2h-Pyran As A Labile Protecting GroupDocument7 pagesControl of Reactivity of Novolac Resins: The Use of 3,4-Dihydro-2h-Pyran As A Labile Protecting GroupQuế NghiNo ratings yet

- Kinetics of Polyesterification: Modelling and Simulation of Unsaturated Polyester Synthesis Involving 2-Methyl-1,3-PropanediolDocument7 pagesKinetics of Polyesterification: Modelling and Simulation of Unsaturated Polyester Synthesis Involving 2-Methyl-1,3-PropanediolMamoon ShahidNo ratings yet

- Acacia Resin PDFDocument8 pagesAcacia Resin PDFMaria Dolores Landete RuizNo ratings yet

- Tuneable Thermal Properties of PTHF-based Copolymers by Incorporation ofDocument12 pagesTuneable Thermal Properties of PTHF-based Copolymers by Incorporation ofSimon LeluyerNo ratings yet

- Immobilization of Metalloporphyrin Complexes in Molecular Sieves and Their Catalytic ActivityDocument8 pagesImmobilization of Metalloporphyrin Complexes in Molecular Sieves and Their Catalytic Activityauro55No ratings yet

- Synthesis and Structure Characterization of Phenol-Urea-Formaldehyde Resins in The Presence of Magnesium Oxide As CatalystDocument11 pagesSynthesis and Structure Characterization of Phenol-Urea-Formaldehyde Resins in The Presence of Magnesium Oxide As CatalystEzequiel BarilliNo ratings yet

- Diwate Madam PaperDocument7 pagesDiwate Madam PaperShivaji GhodkeNo ratings yet

- Enzymatic Electrochemical Detection - MatlabDocument9 pagesEnzymatic Electrochemical Detection - MatlabCARMEN JOVINA ARAVENA GONZALEZNo ratings yet

- Ionic Liquids for Propyne/Propylene SeparationDocument6 pagesIonic Liquids for Propyne/Propylene SeparationSendy Arfian SaputraNo ratings yet

- 22 (2012 Friedrich) (JBCS) Mechanistic Implications of Zinc (II) Ions On The Degradation of Phenol by The Fenton ReactionDocument6 pages22 (2012 Friedrich) (JBCS) Mechanistic Implications of Zinc (II) Ions On The Degradation of Phenol by The Fenton ReactionVolnir SilvaNo ratings yet

- Synthesis of Anisole by Vapor Phase Methylation of Phenol With Methanol Over Catalysts Supported On Activated AluminaDocument3 pagesSynthesis of Anisole by Vapor Phase Methylation of Phenol With Methanol Over Catalysts Supported On Activated AluminaNitish Singh SengarNo ratings yet

- Molecules: Synthesis and Bioactivity of A-Aminophosphonates Containing FluorineDocument7 pagesMolecules: Synthesis and Bioactivity of A-Aminophosphonates Containing FluorineThomas CharmNo ratings yet

- The Total Synthesis of Natural ProductsFrom EverandThe Total Synthesis of Natural ProductsJohn ApSimonNo ratings yet

- Drozdov LimoneneDocument7 pagesDrozdov LimoneneElizaveta SeleznevaNo ratings yet

- Synthesis and Characterization of Some Novel Coumarin Based Pyrazoles, Isoxazole and Pyrimidyl DerivativesDocument6 pagesSynthesis and Characterization of Some Novel Coumarin Based Pyrazoles, Isoxazole and Pyrimidyl DerivativesNalla Umapathi ReddyNo ratings yet

- Kyambogo University: Phenol Formaldehyde Polymer Synthesis AIMDocument8 pagesKyambogo University: Phenol Formaldehyde Polymer Synthesis AIMNkugwa Mark WilliamNo ratings yet

- EPL-0009812 ArticleDocument14 pagesEPL-0009812 Articlerajesh kothariNo ratings yet

- Effects of Dye Dopants On The Conductivity and Optical Absorption Properties of PolypyrroleDocument32 pagesEffects of Dye Dopants On The Conductivity and Optical Absorption Properties of PolypyrroleAndré MacedoNo ratings yet

- The Flame-Retardant Effect of Diethyl Vinyl Phosphonate in Copolymers With Styrene, Methyl Methacrylate, Acrylonitrile and AcrylamideDocument4 pagesThe Flame-Retardant Effect of Diethyl Vinyl Phosphonate in Copolymers With Styrene, Methyl Methacrylate, Acrylonitrile and AcrylamideThinh DangNo ratings yet

- Lee1996 PDFDocument10 pagesLee1996 PDFMateus PinheiroNo ratings yet

- Optimization of Time Reaction and Hydroxide Ion Concentration On Flavonoid Synthesis From Benzaldehyde and Its DerivativesDocument6 pagesOptimization of Time Reaction and Hydroxide Ion Concentration On Flavonoid Synthesis From Benzaldehyde and Its DerivativesAnonymous 3hPHKsFUYNo ratings yet

- Menzel 2011Document9 pagesMenzel 2011マルワNo ratings yet

- Natarajan and Murugavel - 2017 - Thermal stability and thermal degradation kineticsDocument22 pagesNatarajan and Murugavel - 2017 - Thermal stability and thermal degradation kineticsmartina.cirronis96No ratings yet

- Phosphazene PublicationDocument6 pagesPhosphazene Publicationanon_963545076No ratings yet

- Materials Today: Proceedings: Sachin S. Bangade, Vivek M. Raut, Subodh E. Bhandarkar, Deepali P. GulwadeDocument4 pagesMaterials Today: Proceedings: Sachin S. Bangade, Vivek M. Raut, Subodh E. Bhandarkar, Deepali P. GulwadeCarlos CarranzaNo ratings yet

- Ribeiro Et Al-2013-Journal of Applied Polymer ScienceDocument13 pagesRibeiro Et Al-2013-Journal of Applied Polymer ScienceDiana BejaranoNo ratings yet

- Czerwinski 1999Document8 pagesCzerwinski 1999Bijon GuhaNo ratings yet

- Phenols in FuelDocument12 pagesPhenols in Fuelvzimak2355No ratings yet

- Spectroscopic Study of The Molecular Structure of A Lignin-Polymer SystemDocument5 pagesSpectroscopic Study of The Molecular Structure of A Lignin-Polymer SystemLata DeshmukhNo ratings yet

- Urea Formaldehyde and Alkylated Urea For PDFDocument11 pagesUrea Formaldehyde and Alkylated Urea For PDFNam Phạm VănNo ratings yet

- Lab Report: 01 Lab Report On Course Name: Polymer Science and Engineering Sessional Course Code: CEP 354Document7 pagesLab Report: 01 Lab Report On Course Name: Polymer Science and Engineering Sessional Course Code: CEP 354Sourav SutradharNo ratings yet

- 54754-Article Text-89653-1-10-20100526Document7 pages54754-Article Text-89653-1-10-20100526nurizzaatiNo ratings yet

- Dyes and Pigments-2016-New Class of Hyperpolarizable Push-Pull Organic Chromophores by Applying A Novel and Convenient Synthetic StrategyDocument5 pagesDyes and Pigments-2016-New Class of Hyperpolarizable Push-Pull Organic Chromophores by Applying A Novel and Convenient Synthetic StrategyELKIN ALFONSO RODRIGUEZ AGUALIMPIANo ratings yet

- Phenol Formaldehyde Resin. BakeliteDocument7 pagesPhenol Formaldehyde Resin. BakeliteSO R ANNo ratings yet

- Compal La-3361p r1Document44 pagesCompal La-3361p r1Wellington ReisNo ratings yet

- GB1516 Sac 240 CV MS 0003 - DDocument18 pagesGB1516 Sac 240 CV MS 0003 - DkkkkNo ratings yet

- GB1516 Sac 240 CV MS 0003 - DDocument18 pagesGB1516 Sac 240 CV MS 0003 - DkkkkNo ratings yet

- GB1516 Sac 240 CV RP 0002 - ADocument66 pagesGB1516 Sac 240 CV RP 0002 - AkkkkNo ratings yet

- Features Description: Lt1999-10/Lt1999-20/ Lt1999-50 High Voltage, Bidirectional Current Sense AmplifierDocument24 pagesFeatures Description: Lt1999-10/Lt1999-20/ Lt1999-50 High Voltage, Bidirectional Current Sense AmplifierkkkkNo ratings yet

- Comparative Study of K-NN, Naive Bayes and Decision Tree Classification TechniquesDocument4 pagesComparative Study of K-NN, Naive Bayes and Decision Tree Classification TechniquesElrach CorpNo ratings yet

- Flowserve Hydrocarbon Processing FPD 4 eDocument16 pagesFlowserve Hydrocarbon Processing FPD 4 eLUKAS3589100% (1)

- Kinetic Modeling of Methanol Synthesis From Carbon Monoxide CarbDocument84 pagesKinetic Modeling of Methanol Synthesis From Carbon Monoxide CarbkkkkNo ratings yet

- Influence of Iron Furnaces Slag On Collapsibility and Shear Strength of Gypseous SoilDocument7 pagesInfluence of Iron Furnaces Slag On Collapsibility and Shear Strength of Gypseous SoilkkkkNo ratings yet

- Certificate of Physical Fitness: IA. History of Any Known Illness / SurgeryDocument2 pagesCertificate of Physical Fitness: IA. History of Any Known Illness / SurgerykkkkNo ratings yet

- Methanol Synthesis Over A Zn-Deposited Copper Model CatalystDocument7 pagesMethanol Synthesis Over A Zn-Deposited Copper Model CatalystkkkkNo ratings yet

- RC Flat Slab Fire AnalysisDocument5 pagesRC Flat Slab Fire AnalysiskkkkNo ratings yet

- Influence of Iron Furnaces Slag On Collapsibility and Shear Strength of Gypseous SoilDocument7 pagesInfluence of Iron Furnaces Slag On Collapsibility and Shear Strength of Gypseous SoilkkkkNo ratings yet

- DSC Kinetics Methods ReviewDocument6 pagesDSC Kinetics Methods ReviewChanin NgudsuntearNo ratings yet

- Peter2012 PDFDocument12 pagesPeter2012 PDFkkkkNo ratings yet

- HDMIDocument11 pagesHDMIAnil BpsNo ratings yet

- LM2596 DDocument25 pagesLM2596 DMartadhi DendraNo ratings yet

- Timer 555 DatasheetDocument11 pagesTimer 555 DatasheetMissael Lavado MarquezNo ratings yet

- DatasheetDocument2 pagesDatasheetAndreza AzevedoNo ratings yet

- Data Overview - SR. OPERATORDocument1 pageData Overview - SR. OPERATORAli Gohar RaoNo ratings yet

- Shift Supervisor Job in Qatar Petroleum RefiningDocument1 pageShift Supervisor Job in Qatar Petroleum RefiningkkkkNo ratings yet

- 11 AppendixDocument5 pages11 AppendixkkkkNo ratings yet

- Fitness Aziz AlhaidariDocument2 pagesFitness Aziz Alhaidariabdulaziz saif ali mansoorNo ratings yet

- Syria 2012Document28 pagesSyria 2012kkkkNo ratings yet

- DatasheetDocument2 pagesDatasheetAndreza AzevedoNo ratings yet

- Informe de Produccion de Biodiesel en CHEMCADDocument7 pagesInforme de Produccion de Biodiesel en CHEMCADGustavo BarciaNo ratings yet

- 11 AppendixDocument5 pages11 AppendixkkkkNo ratings yet

- 8.1 There Is Vs It Is PDFDocument4 pages8.1 There Is Vs It Is PDFgoodreziNo ratings yet

- Shift Supervisor Job in Qatar Petroleum RefiningDocument1 pageShift Supervisor Job in Qatar Petroleum RefiningkkkkNo ratings yet

- Multi-stage compression power calculationsDocument8 pagesMulti-stage compression power calculationsallovid0% (1)

- QCS 2010 Section 28 Part 2Document38 pagesQCS 2010 Section 28 Part 2Saif Abdulla0% (1)

- 9.2 Electrochemical CellsDocument39 pages9.2 Electrochemical CellsRose ChanNo ratings yet

- Integrated Wellbore Assurance FlowchartDocument1 pageIntegrated Wellbore Assurance FlowchartLoganBohannonNo ratings yet

- NEBOSH GC3 Observations Sheet SampleDocument12 pagesNEBOSH GC3 Observations Sheet SampleShezi Bhatti100% (3)

- 4600cl StepperDocument37 pages4600cl StepperJEREMEE MICHAEL TYLERNo ratings yet

- Normal Wash, Pigment Wash, Caustic WashDocument9 pagesNormal Wash, Pigment Wash, Caustic WashTauhidurRChowdhuryNo ratings yet

- Chemical Composition, Phytochemical and Antioxidant Activity From Extract of Etlingera Elatior Flower From IndonesiaDocument6 pagesChemical Composition, Phytochemical and Antioxidant Activity From Extract of Etlingera Elatior Flower From IndonesiaFadhil Muhammad AwaluddinNo ratings yet

- Maximizing Alternative Fuel Use in Cement ProductionDocument4 pagesMaximizing Alternative Fuel Use in Cement Productionmohamadi42100% (1)

- Amberlite Ira743Document2 pagesAmberlite Ira743Gregorio Antonio Valero VerdeNo ratings yet

- WCH11 01 2024 Jan QPDocument20 pagesWCH11 01 2024 Jan QPbmaniafuNo ratings yet

- Lutz PVDF Pump Tube: For Highly Aggressive LiquidsDocument2 pagesLutz PVDF Pump Tube: For Highly Aggressive LiquidsEnrique Monzon BeltranNo ratings yet

- 06-Civil Engineering Materials (CE)Document2 pages06-Civil Engineering Materials (CE)Darya MemonNo ratings yet

- CompostingDocument26 pagesCompostingVarenya MehtaNo ratings yet

- Ip Part 9 Liquefied Petroleum Gas Volume 1 Large Bulk Pressure Storage and Refrigerated LPGDocument100 pagesIp Part 9 Liquefied Petroleum Gas Volume 1 Large Bulk Pressure Storage and Refrigerated LPGminhy100% (2)

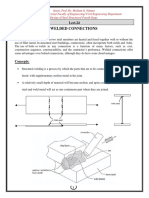

- Welded Connections: Lect.24Document15 pagesWelded Connections: Lect.24sanketNo ratings yet

- Ger Eng 2013Document1 pageGer Eng 2013Vijaya AcharNo ratings yet

- Road Map Organic PDFDocument5 pagesRoad Map Organic PDFS SquareNo ratings yet

- BO-0475 - Const - Work - Pro - For Gasket Install (Rev 0) - 20150605Document35 pagesBO-0475 - Const - Work - Pro - For Gasket Install (Rev 0) - 20150605Rijwan MohammadNo ratings yet

- Opioid AnalgesicsDocument38 pagesOpioid AnalgesicslinggarNo ratings yet

- Ebcs 11 - Ventilation and Air Condition'IngDocument92 pagesEbcs 11 - Ventilation and Air Condition'IngMebratuNo ratings yet

- Identifying of Fats of Halal and Non Halal Animals Using A GeometricDocument192 pagesIdentifying of Fats of Halal and Non Halal Animals Using A GeometricMuhammad Khairulnizam100% (1)

- Corrosion Prediction Models Industrial SystemsDocument73 pagesCorrosion Prediction Models Industrial Systems_Asylum_100% (3)

- Royal Botanic Gardens Victoria: Cranbourne Gardens Water Treatment PlantDocument40 pagesRoyal Botanic Gardens Victoria: Cranbourne Gardens Water Treatment PlantHenry OkoyeNo ratings yet

- SCIENCE 8 Q3 - WEEK 3 - LAS 1 Phase ChangeDocument2 pagesSCIENCE 8 Q3 - WEEK 3 - LAS 1 Phase ChangeGlin BarrientosNo ratings yet

- STMDocument11 pagesSTMRohit SatheshNo ratings yet

- Spruing and Investing HandoutDocument23 pagesSpruing and Investing HandoutMariam SherifNo ratings yet

- Using ESD Valves As SafeguardsDocument11 pagesUsing ESD Valves As SafeguardsHector Javier Cruz CampaNo ratings yet

- Common Causes of Premature Failure of Hadfield Steel Crushers and Hammers Used in The Mining IndustryDocument3 pagesCommon Causes of Premature Failure of Hadfield Steel Crushers and Hammers Used in The Mining IndustryLaboratorio CalidadNo ratings yet

- ACB10 Technical Data April10Document12 pagesACB10 Technical Data April10RK TekNo ratings yet