Professional Documents

Culture Documents

Distillation Column

Uploaded by

Ranjani J Deepak0 ratings0% found this document useful (0 votes)

95 views23 pagesDistillation is a process that separates mixtures into individual components based on differences in their boiling points. It works by heating the mixture to vaporize components with lower boiling points, which are then condensed and collected.

There are two main types of distillation columns: batch columns which process feed intermittently, and continuous columns which process a steady stream of feed. Distillation columns contain trays, packings, or valves to facilitate vapor-liquid contact during separation.

Key components of distillation equipment include the reboiler for vaporization, condenser for condensation, and reflux drum to collect and recycle condensed vapor back to the column for improved separation.

Original Description:

Original Title

Distillation column

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDistillation is a process that separates mixtures into individual components based on differences in their boiling points. It works by heating the mixture to vaporize components with lower boiling points, which are then condensed and collected.

There are two main types of distillation columns: batch columns which process feed intermittently, and continuous columns which process a steady stream of feed. Distillation columns contain trays, packings, or valves to facilitate vapor-liquid contact during separation.

Key components of distillation equipment include the reboiler for vaporization, condenser for condensation, and reflux drum to collect and recycle condensed vapor back to the column for improved separation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

95 views23 pagesDistillation Column

Uploaded by

Ranjani J DeepakDistillation is a process that separates mixtures into individual components based on differences in their boiling points. It works by heating the mixture to vaporize components with lower boiling points, which are then condensed and collected.

There are two main types of distillation columns: batch columns which process feed intermittently, and continuous columns which process a steady stream of feed. Distillation columns contain trays, packings, or valves to facilitate vapor-liquid contact during separation.

Key components of distillation equipment include the reboiler for vaporization, condenser for condensation, and reflux drum to collect and recycle condensed vapor back to the column for improved separation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 23

Module 6

Distillation –An Introduction

a process in which a liquid or vapour mixture of two or

more substances is separated into its component

fractions of desired purity, by the application and

removal of heat.

distillation is the most common separation technique

Distillation is based on the fact that the vapour of a

boiling mixture will be richer in the components that

have lower boiling points.

Types of Distillation Columns

Batch Columns:

the feed to the column is introduced batch-wise

the column is charged with a 'batch' and then the

distillation process is carried out

When the desired task is achieved, a next batch of feed

is introduced.

Continuous Columns

continuous columns process a continuous feed stream

capable of handling high throughputs

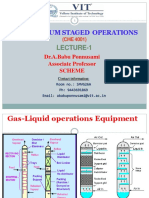

BASIC DISTILLATION EQUIPMENT AND OPERATION

Main Components of Distillation Columns

A vertical shell - separation of liquid components is carried out

Column internals- trays/plates and/or packings

Reboiler - provide the necessary vaporisation for the distillation

process

Condenser - cool and condense the vapour leaving the top of the

column

Reflux drum - hold the condensed vapour from the top of the

column so that liquid (reflux) can be recycled

back to the column

Distillation Column - Schematic

Basic Operation and Terminology

Feed is introduced usually somewhere near the

middle of the column to a tray known as the feed

tray

Feed tray divides the column into a top enriching or

rectification section and a bottom stripping section.

The feed flows down the column where it is

collected at the bottom in the re-boiler – feed

vapours formed.

The vapour raised in the reboiler is re-introduced

into the unit at the bottom of the column.

The liquid removed from the reboiler is known as

the bottoms

Basic Operation and Terminology

The vapour moves up the column,

and as it exits the top of the unit, it

is cooled by a condenser.

The condensed liquid is stored in a

holding vessel known as the reflux

drum.

Some of this liquid is recycled

back to the top of the column and

this is called the reflux.

The condensed liquid that is

removed from the system is known

as the distillate or top product.

COLUMN INTERNALS

Bubble cap trays:

has riser or chimney fitted over each hole,

and a cap that covers the riser.

The cap is mounted so that there is a

space between riser and cap to allow

the passage of vapour.

Vapour rises through the chimney

and is directed downward by the cap,

finally discharging through slots in the

cap, and finally bubbling through the

liquid on the tray.

Valve Trays

• Perforations are covered by liftable

caps.

• Vapour flows lifts the caps, thus self

creating a flow area for the passage of

vapour.

• The lifting cap directs the vapour to

flow horizontally into the liquid, thus

providing better mixing than is possible

in sieve trays.

Sieve trays

• Sieve trays are simply metal plates with

holes in them.

•Vapour passes straight upward through the

liquid on the plate.

• The arrangement, number and size of the

holes are design parameters.

• Because of their efficiency, wide operating

range, ease of maintenance and cost factors,

sieve and valve trays have replaced bubble

cap trays in many applications.

Liquid and Vapour Flows in a Tray Column

Each tray has 2 conduits, one on each

side, called ‘downcomers’.

Liquid falls through the downcomers

by gravity from one tray to the one

below it.

Being lighter, vapour flows up the

column and is forced to pass through

the liquid, via the openings on each

tray.

The area allowed for the passage of

vapour on each tray is called the active

tray area.

Liquid and Vapour Flows in a Tray Column

Liquid and Vapour Flows in a Tray Column

The frothing of the liquid on the active tray area is due to both passage

of vapour from the tray below as well as boiling.

As the hotter vapour passes through the liquid on the tray above, it

transfers heat to the liquid. In doing so, some of the vapour condenses

adding to the liquid on the tray.

The condensate is richer in the less volatile components than is in the

vapour.

Because of the heat input from the vapour, the liquid on the tray boils,

generating more vapour.

This vapour, which moves up to the next tray in the column, is richer in

the more volatile components.

This continuous contacting between vapour and liquid occurs on each

tray in the column and brings about the separation between low

boiling point components and those with higher boiling points.

Packings

increase the interfacial area for vapour-liquid contact

impart good vapour-liquid contact

packings provide extra inter-facial

area for liquid-vapour contact

efficiency of separation is

increased for the same column height

packed columns are shorter than trayed columns

Packed columns are called continuous-contact

columns while trayed columns are called staged-

contact columns because of the manner in which

vapour and liquid are contacted.

COLUMN REBOILERS

heat-exchangers to bring the liquid at the bottom of

the column to boiling point

COLUMN REBOILERS

DISTILLATION PRINCIPLES

Vapour Pressure and Boiling

energy input raises vapour pressure

a liquid is said to ‘boil’ when its vapour pressure equals the

surrounding pressure

the ease with which a liquid boils depends on its volatility

liquids with high vapour pressures (volatile liquids) will

boil at lower temperatures

the vapour pressure and hence the boiling point of a liquid

mixture depends on the relative amounts of the

components in the mixture

distillation occurs because of the differences in the

volatility of the components in the liquid mixture

The Boiling Point Diagram

shows how the equilibrium compositions of the

components in a liquid mixture vary with temperature

at a fixed pressure

Relative Volatility

measure of the differences in volatility between 2

components, and hence their boiling points.

indicates how easy or difficult a particular separation will

be

The relative volatility of component ‘i’ with respect to

component ‘j’ is defined as

yi = mole fraction of component ‘i’ in the vapour

xi = mole fraction of component ‘i’ in the liquid

VAPOUR LIQUID EQUILIBRIA

Vapour-Liquid-Equilibrium (VLE) Curves

Constant pressure VLE data is obtained from boiling point diagrams

The VLE plot expresses the bubble-point and the dew-point of a binary

mixture at constant pressure.

VLE CURVES

You might also like

- Selection of Column Type: Plate or PackedDocument52 pagesSelection of Column Type: Plate or Packedsai charanNo ratings yet

- DISTILLATION COLUMN Nida Baigk124Document28 pagesDISTILLATION COLUMN Nida Baigk124Shifa ShaikhNo ratings yet

- Chemical Reactor Analysis and Applications for the Practicing EngineerFrom EverandChemical Reactor Analysis and Applications for the Practicing EngineerNo ratings yet

- DistillationDocument48 pagesDistillationSneha 10-DNo ratings yet

- Handbook of Vapor Pressure: Volume 4: Inorganic Compounds and ElementsFrom EverandHandbook of Vapor Pressure: Volume 4: Inorganic Compounds and ElementsNo ratings yet

- Ahmed Deyab: Senior Process Engineer Process Simulation ConsultantDocument154 pagesAhmed Deyab: Senior Process Engineer Process Simulation ConsultantHamza AliNo ratings yet

- Distillation Column InternalsDocument16 pagesDistillation Column InternalsBon Joey BernestoNo ratings yet

- Introduction To BoilersDocument36 pagesIntroduction To BoilersAdel SukerNo ratings yet

- Bubble ColumnDocument34 pagesBubble ColumnAfroz MohammedNo ratings yet

- Packed TowersDocument44 pagesPacked Towersnawazkhan98482No ratings yet

- 2017.08.28 - Gas - Liquid Contacting Equipments PDFDocument37 pages2017.08.28 - Gas - Liquid Contacting Equipments PDFdankshavali shaikNo ratings yet

- Mass Transfer EquipmentsDocument32 pagesMass Transfer EquipmentsAjaykumarNo ratings yet

- Gas-Liquid Operations Equipment: Mr. Chintan K. Modi Asst. Professor Chemical Engineering Department SrictDocument76 pagesGas-Liquid Operations Equipment: Mr. Chintan K. Modi Asst. Professor Chemical Engineering Department SrictSoma BerwariNo ratings yet

- Flow-Induced Fatigue Failure in Tubular Heat ExchangersDocument7 pagesFlow-Induced Fatigue Failure in Tubular Heat ExchangersVelpandian ManiNo ratings yet

- TraysDocument9 pagesTraysElladaNo ratings yet

- Push Valve ExperienceDocument13 pagesPush Valve ExperienceIan Mann100% (1)

- Anone PlantDocument2 pagesAnone PlantAbijith100% (1)

- Ese652 - Process Control Ii Chapter 5.2 - Distillation ColumnDocument5 pagesEse652 - Process Control Ii Chapter 5.2 - Distillation ColumnJennifer HughesNo ratings yet

- Chapter 5Document70 pagesChapter 5Husnain AliNo ratings yet

- Liquid Liquid ExtractionTechnologyDocument12 pagesLiquid Liquid ExtractionTechnologyBrandonQuisiNo ratings yet

- FALLSEM2021-22 CHE4001 ETH VL2021220100382 Reference Material I 17-Aug-2021 Lecture-1 (Tray Vs Packed Column)Document62 pagesFALLSEM2021-22 CHE4001 ETH VL2021220100382 Reference Material I 17-Aug-2021 Lecture-1 (Tray Vs Packed Column)sanyukta sinhaNo ratings yet

- Koch Glitsch Conventional Trays BrochureDocument12 pagesKoch Glitsch Conventional Trays Brochureunknownx_XNo ratings yet

- Extractive DistillationDocument10 pagesExtractive DistillationAlya NazarochkinaNo ratings yet

- Why A Shell and Tube Heat Exchanger?Document17 pagesWhy A Shell and Tube Heat Exchanger?Avishek KumarNo ratings yet

- Reactive Distillation ProcessesDocument9 pagesReactive Distillation ProcessesAndrew TanNo ratings yet

- Boilers & Thermal Fluid HeatersDocument53 pagesBoilers & Thermal Fluid HeatersannasitNo ratings yet

- Destilation Column InfoDocument33 pagesDestilation Column InfokumarNo ratings yet

- Interfacial Heat Transfer Coefficients of Various Vapors in Direct Contact CondensationDocument11 pagesInterfacial Heat Transfer Coefficients of Various Vapors in Direct Contact CondensationJesse Haney IIINo ratings yet

- Spo 19-07-19Document21 pagesSpo 19-07-19kissorek3g0% (1)

- Room Temperature Synthesis of Copper Oxide Nanoparticles Morphological Evaluation and Their Catalytic Applications For Degradation of Dyes and C-N Bond Formation Reaction PDFDocument11 pagesRoom Temperature Synthesis of Copper Oxide Nanoparticles Morphological Evaluation and Their Catalytic Applications For Degradation of Dyes and C-N Bond Formation Reaction PDFAshpavi ArunNo ratings yet

- Use and Importance of Furnaces in Oil RefineriesDocument6 pagesUse and Importance of Furnaces in Oil RefineriesMusa KaleemNo ratings yet

- Ped CB208 P8 1Document57 pagesPed CB208 P8 1Siddhant SoymonNo ratings yet

- Distillation Column-3Document36 pagesDistillation Column-3Sana BashirNo ratings yet

- Plate Hydraulic Design ExampleDocument53 pagesPlate Hydraulic Design ExampleChristopher RileyNo ratings yet

- Modelling of Naphtha Cracking For Olefins Production - Joao MarcosDocument9 pagesModelling of Naphtha Cracking For Olefins Production - Joao MarcosBahar MeschiNo ratings yet

- P 475188Document33 pagesP 475188Parth PatelNo ratings yet

- BubbleCap Distillation Manuals - FINAL 29082018 - 17PgsDocument17 pagesBubbleCap Distillation Manuals - FINAL 29082018 - 17PgsSagar MorjeNo ratings yet

- Pages From Centrifugal Pumps HandbookDocument4 pagesPages From Centrifugal Pumps HandbookSHINo ratings yet

- Distillation ColumnsDocument12 pagesDistillation ColumnsJade RanteNo ratings yet

- Piping CodesDocument47 pagesPiping CodesSankar MukaNo ratings yet

- A Comprehensive Program For Calculation of Flame Radiation LevelsDocument6 pagesA Comprehensive Program For Calculation of Flame Radiation LevelsStefano BelliniNo ratings yet

- Plate Contractor Design FundamentalsDocument21 pagesPlate Contractor Design FundamentalsMiraj savaniNo ratings yet

- RESIDUE CURVE MAPS GUIDEDocument5 pagesRESIDUE CURVE MAPS GUIDEWali AhsanNo ratings yet

- History of Catalyst HandlingDocument3 pagesHistory of Catalyst HandlingElvi HernandezNo ratings yet

- Determining PZC of Oxides for Catalyst ImpregnationDocument2 pagesDetermining PZC of Oxides for Catalyst ImpregnationchemistkamalNo ratings yet

- Boiling and CondensationDocument13 pagesBoiling and CondensationPrithvi de VilliersNo ratings yet

- Distillation PresentationDocument38 pagesDistillation PresentationMohamed BalbaaNo ratings yet

- Columns: An Introductory Guide To Columns For Chemical EngineersDocument53 pagesColumns: An Introductory Guide To Columns For Chemical EngineersHerawan Mulyanto100% (1)

- Heat ExchangersDocument36 pagesHeat ExchangersSyukri ShahNo ratings yet

- Gas Sweetening Processes and ApplicationsDocument6 pagesGas Sweetening Processes and ApplicationsEdwin AguilarNo ratings yet

- Dynamic Mesh Handling in OpenFOAMDocument34 pagesDynamic Mesh Handling in OpenFOAMAmr HitchNo ratings yet

- Valve TrayDocument3 pagesValve TrayfurqonmaNo ratings yet

- Lecture 14-15 - Gas-Liquid Contact EquipmentDocument11 pagesLecture 14-15 - Gas-Liquid Contact EquipmentMihir Kumar MechNo ratings yet

- Heat ExchangersDocument7 pagesHeat ExchangersAgustin Gago LopezNo ratings yet

- Vacuum Distillation Colume: Mass Transfer Lab AssignmentDocument4 pagesVacuum Distillation Colume: Mass Transfer Lab AssignmentMalik HamidNo ratings yet

- Cheg Process ControlDocument279 pagesCheg Process Controltesfay gebreNo ratings yet

- Column PresentationDocument27 pagesColumn PresentationTaifurNo ratings yet

- CorrosionDocument9 pagesCorrosionhesampirNo ratings yet

- How To Use HTRI For Shell & Tube Exchanger DesignDocument38 pagesHow To Use HTRI For Shell & Tube Exchanger Designirshaad_s88% (17)

- CONSERVATION OF PLANTS AND ANIMALSDocument13 pagesCONSERVATION OF PLANTS AND ANIMALSpankaj_bsnlNo ratings yet

- Chapter 4Document12 pagesChapter 4anil.gelra5140No ratings yet

- Maths CH 1Document20 pagesMaths CH 1Ranjani J DeepakNo ratings yet

- HTRI Input Design Basis - Rev. 0Document33 pagesHTRI Input Design Basis - Rev. 0Swath M Murali100% (2)

- L&T Interview QuestionsDocument5 pagesL&T Interview QuestionsRanjani J DeepakNo ratings yet

- Instrument Design CriteriaDocument41 pagesInstrument Design CriteriasanthaNo ratings yet

- 06 Qa CRT 0001 0Document29 pages06 Qa CRT 0001 0Ranjani J DeepakNo ratings yet

- 02 Linear EquationDocument16 pages02 Linear EquationmanjuramuNo ratings yet

- 2004A Rev.9Document75 pages2004A Rev.9Ranjani J DeepakNo ratings yet

- History French Revolution NotesDocument4 pagesHistory French Revolution NotesRanjani J Deepak100% (1)

- BPVC Viii 1interp STND 62 2013 JanDocument1 pageBPVC Viii 1interp STND 62 2013 JanRanjani J DeepakNo ratings yet

- What's The Difference Between Parallel Flow, Counter Flow and Crossflow Heat ExchangersDocument7 pagesWhat's The Difference Between Parallel Flow, Counter Flow and Crossflow Heat ExchangersRanjani J DeepakNo ratings yet

- Piping Design CriteriaDocument15 pagesPiping Design CriteriaSubash Chandrabose0% (1)

- 3 Shell and Tube Heat Exchanger Features That Affect Shell-Side Pressure DropDocument10 pages3 Shell and Tube Heat Exchanger Features That Affect Shell-Side Pressure DropRanjani J DeepakNo ratings yet

- 3 Types of Mechanical Failures in Shell and Tube Heat Exchangers and How To Prevent ThemDocument6 pages3 Types of Mechanical Failures in Shell and Tube Heat Exchangers and How To Prevent ThemRanjani J DeepakNo ratings yet

- Resistoflex 1Document106 pagesResistoflex 1Ranjani J DeepakNo ratings yet

- Scanned Documents by TapScannerDocument7 pagesScanned Documents by TapScannerRanjani J DeepakNo ratings yet

- How to convert a gas burner from LPG to natural gasDocument35 pagesHow to convert a gas burner from LPG to natural gasRanjani J DeepakNo ratings yet

- Academia Summary - Selection of Heat Exchanger TypesDocument3 pagesAcademia Summary - Selection of Heat Exchanger TypesRanjani J DeepakNo ratings yet

- Horizontal vs. Vertical Baffles - Which To Choose For Your Shell and Tube Heat ExchangerDocument6 pagesHorizontal vs. Vertical Baffles - Which To Choose For Your Shell and Tube Heat ExchangerRanjani J DeepakNo ratings yet

- Fluoro Polymers Lined Pipe, Fittings, Valves, Vessels, & ColumnsDocument4 pagesFluoro Polymers Lined Pipe, Fittings, Valves, Vessels, & ColumnsRanjani J DeepakNo ratings yet

- Mechanical Constraints on Thermal Design of Shell and Tube ExchangersDocument3 pagesMechanical Constraints on Thermal Design of Shell and Tube ExchangersRanjani J DeepakNo ratings yet

- Resistoflex Plastic Lined Pipe Ptfe Pfa PVDF PP Chemical Resistance ChartDocument14 pagesResistoflex Plastic Lined Pipe Ptfe Pfa PVDF PP Chemical Resistance ChartRanjani J DeepakNo ratings yet

- Pipes and FittingsDocument7 pagesPipes and FittingsRanjani J DeepakNo ratings yet

- ACAD Air Cooled Heat Exchanger Design SummaryDocument2 pagesACAD Air Cooled Heat Exchanger Design SummaryRanjani J DeepakNo ratings yet

- Academia Summary - Shell and Tube Heat Exchangers Using Cooling WaterDocument3 pagesAcademia Summary - Shell and Tube Heat Exchangers Using Cooling WaterRanjani J DeepakNo ratings yet

- Ethylene EJ PDFDocument24 pagesEthylene EJ PDFMahmoud Al HomranNo ratings yet

- Strainer Screens Technical BulletinDocument1 pageStrainer Screens Technical BulletinRanjani J DeepakNo ratings yet

- Fluoroline ANSI 150 DataDocument31 pagesFluoroline ANSI 150 DataRanjani J DeepakNo ratings yet

- Tribhuvan University Institute of Engineering Pulchowk CampusDocument23 pagesTribhuvan University Institute of Engineering Pulchowk CampusSujan BaralNo ratings yet

- Displacement and Double Decomposition ReactionDocument22 pagesDisplacement and Double Decomposition ReactionSaksham GuptaNo ratings yet

- Increasing Profits in Jet Fighter Manufacturing - BCG CaseDocument3 pagesIncreasing Profits in Jet Fighter Manufacturing - BCG CaseAkhilGovindNo ratings yet

- Drawings - 37163, 37164Document23 pagesDrawings - 37163, 37164intecNo ratings yet

- Earthquake AlarmDocument11 pagesEarthquake AlarmDILIP KUMARNo ratings yet

- Summary of Changes in ASME Section IX, 1998 EditionDocument5 pagesSummary of Changes in ASME Section IX, 1998 EditionTeguh Setiono100% (1)

- McCulloch Late ModelsDocument10 pagesMcCulloch Late Modelsbell8388No ratings yet

- Shape Memory AlloysDocument11 pagesShape Memory AlloysAnonymous oOBXlaNo ratings yet

- Interface GSKTMTRLBRCHR A4 Int 4webDocument7 pagesInterface GSKTMTRLBRCHR A4 Int 4webROGERIO GUILHERME DE OLIVEIRA MARQUESNo ratings yet

- Blastrite BeadsDocument1 pageBlastrite BeadsAsad AhmedNo ratings yet

- ISA Standard 71.04Document12 pagesISA Standard 71.04Luis Alberto Chable GarciaNo ratings yet

- Technical Data Sheet for Road Marking PaintDocument3 pagesTechnical Data Sheet for Road Marking PaintfluretNo ratings yet

- Metalcraft Metrib 750: PurposeDocument2 pagesMetalcraft Metrib 750: PurposeAshleyHammondNo ratings yet

- Performance Analysis of Separating and Throttling Calorimeter To DetermineDocument5 pagesPerformance Analysis of Separating and Throttling Calorimeter To DetermineDaniel LauNo ratings yet

- Otto Primer 1216: The Primer For Natural Stone and MetalDocument2 pagesOtto Primer 1216: The Primer For Natural Stone and MetalJoeNo ratings yet

- Record Power SDS150 ManualDocument20 pagesRecord Power SDS150 Manualrobberry99No ratings yet

- Automation of Instrument Air Dryer Control UsingDocument4 pagesAutomation of Instrument Air Dryer Control UsingiaetsdiaetsdNo ratings yet

- MR Aviation Turbine Fuel (Def Stan 91 91 Issue 6)Document4 pagesMR Aviation Turbine Fuel (Def Stan 91 91 Issue 6)Karthik BalajiNo ratings yet

- Sy335 365CDocument10 pagesSy335 365CJeremy Espinoza0% (1)

- Propaver: An Innovative Design, Built To The Highest Standards To Meet and Exceed The Customer'S DemandsDocument4 pagesPropaver: An Innovative Design, Built To The Highest Standards To Meet and Exceed The Customer'S Demandswalk002No ratings yet

- 2010 HSC Exam ChemistryDocument38 pages2010 HSC Exam ChemistryFiras AhmadNo ratings yet

- Ball ValveDocument14 pagesBall Valveaamer6789No ratings yet

- Sikalastic®-560 GCC Eco-friendly Liquid Roof WaterproofingDocument7 pagesSikalastic®-560 GCC Eco-friendly Liquid Roof WaterproofingDarwin SagiNo ratings yet

- Preflex GirderDocument10 pagesPreflex GirderkklisaNo ratings yet

- Midea 2nd-Generation Centralized Controller Installation and Operation ManualDocument15 pagesMidea 2nd-Generation Centralized Controller Installation and Operation ManualAgustin CesanNo ratings yet

- How To Design Concrete Structures Using Eurocode 2 PDFDocument83 pagesHow To Design Concrete Structures Using Eurocode 2 PDFbarbiesmilez100% (1)

- MSDS Vooki Hand Sanitizer MSDS PDFDocument9 pagesMSDS Vooki Hand Sanitizer MSDS PDFarun100% (2)

- A Clear & Present Danger 2 - The Use of QT or TMT Rebars in Seismic Zone 4Document12 pagesA Clear & Present Danger 2 - The Use of QT or TMT Rebars in Seismic Zone 4friends_y2k5No ratings yet

- Microtechnology and Nanotechnology For Semiconductor DevisesDocument43 pagesMicrotechnology and Nanotechnology For Semiconductor DevisesbhawnaNo ratings yet