Professional Documents

Culture Documents

Heat Recovery 233

Uploaded by

Rohit ShresthaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Recovery 233

Uploaded by

Rohit ShresthaCopyright:

Available Formats

Heat Recovery 233

Example: The average summer outside air (OA) temperature is

90°Fdb and the exhaust air (EA) temperature is 75°Fdb. The heat

recovery system operates at 20,000 cfm at 73 percent efficiency.

The sensible heat transferred from the outside air is 236,520

Btuhs (20,000 × 1.08 × 15 × 0.73).

In the winter, the energy recovered from the exhaust air is

709,560 Btuhs because the temperatures are 30°Fdb OA and

75°Fdb EA (45°Fdb ∆T).

For total (enthalpy) heat recovery systems, the equation used

is: Btuht = cfm × 4.5 × ∆h

Where:

Btuht = total heat transferred

cfm = quantity of airflow

4.5 = a constant for total heat equations, and

∆h = the enthalpy (total heat) difference between the

airstreams (from wet bulb and dry temperatures).

Example: The average summer outside air wet bulb (wb) tem-

perature is 70°Fwb (enthalpy 33.8 Btu/lb°F @ 90db and 70wb)

and the exhaust air wet-bulb temperature is 60°Fwb (enthalpy

26.3 Btu/lb°F @ 75db and 60wb). The heat recovery system oper-

ates at 20,000 cfm at 73 percent efficiency.

The total heat transferred from the outside air is 492,750 Btuh

(20,000 × 4.5 × 7.5 × 0.73).

In the winter, the energy recovered from the exhaust air is

1,261,440 Btuh because the temperatures are 20°Fwb OA (en-

thalpy 7.1 Btu/lb°F @ 30db and 20wb) and 60°Fwb EA (enthalpy

26.3 Btu/lb°F @ 75db and 60wb).

PROCESS-TO-COMFORT SYSTEMS

Process-to-comfort systems are generally sensible heat recov-

ery only. Therefore, they are used only during the spring, fall, and

winter months… there is no heat recovery during the summer

234 HVAC Fundamentals

months. When considering process-to-comfort heat-recovery sys-

tems, the process effluent must be evaluated for harmful materials

such as corrosives, condensibles (moisture or water vapor), con-

taminants, and noxious or toxic substances.

PROCESS-TO-PROCESS SYSTEMS

Process-to-process systems also perform sensible heat recov-

ery only, usually full recovery, but in some cases, partial recovery

can be performed if circumstances dictate. Determining when to

use a process-to-process system for partial sensible heat recovery

instead of full sensible recovery is based on the circumstances

under which the system will operate. For example, when the ex-

haust stream contains condensibles, such as moisture or water

vapor, and possible overcooling of the exhaust air stream could

occur with full recovery then a partial recovery system is more

appropriate. Keep in mind, that as with process-to-comfort sys-

tems, the process effluent must be evaluated for harmful sub-

stances such as corrosives, condensibles, contaminants, and

noxious or toxic materials.

HEAT EXCHANGERS

A heat exchanger is a device specifically designed to transfer

heat between two physically separated fluids. The term heat ex-

changer can describe any heat transfer device such as a coil or a

particular category of devices. Heat exchangers are made in vari-

ous sizes and types. The basic types of heat exchangers are shell

and tube, shell and coil, U-tube, helical, and plate. Typical HVAC

heat exchangers are designed for a number of fluid combinations

including:

• steam to water (converter, steam coil)

• water to steam (generator, boiler)

You might also like

- Air Conditioning Systems 51Document2 pagesAir Conditioning Systems 51rohitNo ratings yet

- Energy Savings Through Heat Recovery Systems in The PapermakingDocument4 pagesEnergy Savings Through Heat Recovery Systems in The PapermakingAneta HaziNo ratings yet

- Evaporative Cooling Technical Handbook - MuntersDocument20 pagesEvaporative Cooling Technical Handbook - MuntersradiopascalgeNo ratings yet

- Vapour Absorption SystemDocument21 pagesVapour Absorption Systemoyetunde ridwanNo ratings yet

- Assignment Thermal UiTMDocument26 pagesAssignment Thermal UiTMAmirul 'Pit'No ratings yet

- HVACDocument14 pagesHVACbagi1900No ratings yet

- Assignment Thermal UiTMDocument29 pagesAssignment Thermal UiTMiwe1234No ratings yet

- Economic Feasibility Study of Waste Heat To Power ConversionDocument43 pagesEconomic Feasibility Study of Waste Heat To Power ConversionajithvinuNo ratings yet

- Desiccant Wheel Regenerated by Thermal Energy From A Microcogenerator: Experimental Assessment of The Performances - Angrisani Et AlDocument12 pagesDesiccant Wheel Regenerated by Thermal Energy From A Microcogenerator: Experimental Assessment of The Performances - Angrisani Et AlDavid BroadfootNo ratings yet

- VIP06 Heat RecoveryDocument12 pagesVIP06 Heat RecoveryAdbhut KumarNo ratings yet

- Using Waste Heat For Energy Savings: Large Commercial, Institutional, Industrial FacilitiesDocument6 pagesUsing Waste Heat For Energy Savings: Large Commercial, Institutional, Industrial FacilitiesdomcristiniNo ratings yet

- Al 3419231934Document12 pagesAl 3419231934IJMERNo ratings yet

- Waste Heat Recovery: V. Shanthan MT21HPE001Document9 pagesWaste Heat Recovery: V. Shanthan MT21HPE001Shanthan VardelliNo ratings yet

- Limits of Feasibility and Energy Consumption of Desiccant and Evaporative Cooling in Temperate ClimatesDocument8 pagesLimits of Feasibility and Energy Consumption of Desiccant and Evaporative Cooling in Temperate Climatesd_muamer_116983894No ratings yet

- Cooling Tower InfoDocument78 pagesCooling Tower Infopitong_manning100% (1)

- Cooling Load CalculationsDocument6 pagesCooling Load CalculationssamuelNo ratings yet

- Chap # 07 Psychrometry-03Document18 pagesChap # 07 Psychrometry-03Aleena Amin KhuwajaNo ratings yet

- Tors Assignment 2Document14 pagesTors Assignment 2Leonard ZammitNo ratings yet

- WEAST HEAT RECOVERY Heating Purpose For Woldia University CaftiriaDocument10 pagesWEAST HEAT RECOVERY Heating Purpose For Woldia University CaftiriaMisge ChekoleNo ratings yet

- Advantages of Steam Heating Heating With Hot Water or OilDocument12 pagesAdvantages of Steam Heating Heating With Hot Water or OilEjub100% (1)

- CHPC PDFDocument6 pagesCHPC PDFsaliyarumesh2292No ratings yet

- Air ConditioningDocument19 pagesAir ConditioningNurul AkmamNo ratings yet

- REFRIGERATION EarlyDocument21 pagesREFRIGERATION EarlyIrfan FajriNo ratings yet

- King of PoemDocument9 pagesKing of PoemAlhaj MassoudNo ratings yet

- Latent HeatDocument2 pagesLatent HeatrohitNo ratings yet

- Indoor Pool Application Examples - Load CalculationDocument4 pagesIndoor Pool Application Examples - Load CalculationfireoniceNo ratings yet

- Application Guide: Air Systems - Energy SeriesDocument12 pagesApplication Guide: Air Systems - Energy SeriesJojolasNo ratings yet

- Lecture 3 - Refrigeration Basics 3Document23 pagesLecture 3 - Refrigeration Basics 3santiago ValleNo ratings yet

- Psychrometrics ProblemDocument7 pagesPsychrometrics ProblemPraveenkumar KashyabNo ratings yet

- Mollie ChartDocument15 pagesMollie ChartKriz EarnestNo ratings yet

- Evaporation Technolgy Mechanical Vapour Recompression - GEA - Wiegand - enDocument24 pagesEvaporation Technolgy Mechanical Vapour Recompression - GEA - Wiegand - enhardik033No ratings yet

- DheerajDocument7 pagesDheerajSaksham KakarNo ratings yet

- 68-Solar Waste Heat Driven Two-Stage AdsorptionDocument9 pages68-Solar Waste Heat Driven Two-Stage Adsorptionali105No ratings yet

- HRSG Design Tutorial - Heat BalanceDocument3 pagesHRSG Design Tutorial - Heat BalanceRavi KasaudhanNo ratings yet

- Cooling With Dehumidification PDFDocument9 pagesCooling With Dehumidification PDFKevin TsuiNo ratings yet

- Recuperator - Wikipedia, The Free EncyclopediaDocument3 pagesRecuperator - Wikipedia, The Free EncyclopediaAvijit DasNo ratings yet

- Study of Vapour Absorption System Using Waste Heat-F0283439Document6 pagesStudy of Vapour Absorption System Using Waste Heat-F0283439Anonymous NGXdt2BxNo ratings yet

- Unit Operations - 30 - 05 - 2019 AdobeDocument28 pagesUnit Operations - 30 - 05 - 2019 AdobesensamedicNo ratings yet

- +wang Et Al-2000-International Journal of Energy ResearchDocument8 pages+wang Et Al-2000-International Journal of Energy ResearchAngela Flores DiazNo ratings yet

- Climbing Film Evaporator: I. CHE 1014 II. SB92Document14 pagesClimbing Film Evaporator: I. CHE 1014 II. SB92Khalid M MohammedNo ratings yet

- AL-Qadisiyah University College of Engineering Mechanical DepartmentDocument11 pagesAL-Qadisiyah University College of Engineering Mechanical Departmentmuthana heidarNo ratings yet

- EvaporationDocument6 pagesEvaporationnoviantari87100% (1)

- CoolingDocument26 pagesCoolingShahrukh AnsariNo ratings yet

- Steam System Basics and Energy EfficiencyDocument100 pagesSteam System Basics and Energy EfficiencyJoelle SalamounNo ratings yet

- A Seminar Report On Water Cooled ChillerDocument15 pagesA Seminar Report On Water Cooled ChillerSudip Sharma100% (3)

- Rivera Et Al 2018, Experimental Assessment of Double Absorption Heat Transformer Operating With H2O LiBrDocument9 pagesRivera Et Al 2018, Experimental Assessment of Double Absorption Heat Transformer Operating With H2O LiBrRedees RedeesNo ratings yet

- Tabla 64Document1 pageTabla 64Fernando Rosales OleaNo ratings yet

- Industrial DehumidificationDocument16 pagesIndustrial Dehumidificationdax18003904100% (1)

- Munters System Design & Optimization ProblemsDocument62 pagesMunters System Design & Optimization Problemsmohd faisal jamilNo ratings yet

- Simulation and Optimization of Distillation Processes For Separating A Close-Boiling Mixture of N-Butanol and IsobutanolDocument6 pagesSimulation and Optimization of Distillation Processes For Separating A Close-Boiling Mixture of N-Butanol and IsobutanolZangNo ratings yet

- HVAC Cooling Load CalculationDocument98 pagesHVAC Cooling Load CalculationVishnupriya B.100% (3)

- Calculation of Boiler EfficiencyDocument14 pagesCalculation of Boiler EfficiencyBharat Choksi100% (1)

- Accepted Manuscript: Applied Thermal EngineeringDocument32 pagesAccepted Manuscript: Applied Thermal EngineeringPriamdanduNo ratings yet

- Instantaneous Determination of Heat Transfer Coefficients in A Steam Generator For An Alternative Energy Upgrade SystemDocument8 pagesInstantaneous Determination of Heat Transfer Coefficients in A Steam Generator For An Alternative Energy Upgrade SysteminderdipNo ratings yet

- An Introduction To Stirling-Cycle MachinesDocument11 pagesAn Introduction To Stirling-Cycle MachinessandigricNo ratings yet

- Self-Heat Recuperation: Theory and Applications: Yasuki Kansha, Akira Kishimoto, Muhammad Aziz and Atsushi TsutsumiDocument19 pagesSelf-Heat Recuperation: Theory and Applications: Yasuki Kansha, Akira Kishimoto, Muhammad Aziz and Atsushi TsutsumiJeff Anderson CollinsNo ratings yet

- Episode 3 MultipressuresystemsDocument75 pagesEpisode 3 MultipressuresystemsANTHONETTE BERNABENo ratings yet

- Evaporation 2Document18 pagesEvaporation 2Kuma Gloria100% (1)

- Compressors: Chapter FiveDocument2 pagesCompressors: Chapter FiveRohit ShresthaNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Figure 4-7. Cooling Tower. TR Is Tower Range (95 F - 85 F), CR Is Condenser Rise (85 Fto95 F)Document2 pagesFigure 4-7. Cooling Tower. TR Is Tower Range (95 F - 85 F), CR Is Condenser Rise (85 Fto95 F)Rohit ShresthaNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Air Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)Document2 pagesAir Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)rohitNo ratings yet

- Air Conditioning Systems 69: Heat Pump (Air-Air)Document2 pagesAir Conditioning Systems 69: Heat Pump (Air-Air)Rohit ShresthaNo ratings yet

- Heating and Ventilating Systems 43: MAT (%OA ×Document2 pagesHeating and Ventilating Systems 43: MAT (%OA ×rohitNo ratings yet

- Heating and Ventilating Systems 25Document2 pagesHeating and Ventilating Systems 25rohitNo ratings yet

- Figure 4-.2 Air Conditioning System ExampleDocument2 pagesFigure 4-.2 Air Conditioning System ExamplerohitNo ratings yet

- Air Conditioning Systems 55Document2 pagesAir Conditioning Systems 55rohitNo ratings yet

- Air Conditioning Systems 57Document2 pagesAir Conditioning Systems 57rohitNo ratings yet

- Air Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemDocument2 pagesAir Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemrohitNo ratings yet

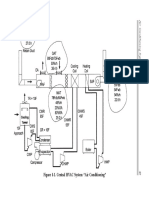

- Figure 4-1. Central HVAC System "Air Conditioning"Document2 pagesFigure 4-1. Central HVAC System "Air Conditioning"rohitNo ratings yet

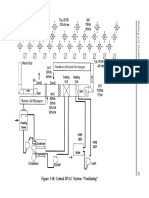

- Figure 3-10. Central HVAC System "Ventilating"Document2 pagesFigure 3-10. Central HVAC System "Ventilating"rohitNo ratings yet

- Heating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerDocument2 pagesHeating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerrohitNo ratings yet

- 1 PDFDocument2 pages1 PDFrohitNo ratings yet

- 1 PDFDocument2 pages1 PDFRohit ShresthaNo ratings yet

- Heating and Ventilating Systems 35Document2 pagesHeating and Ventilating Systems 35rohitNo ratings yet

- Figure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamDocument2 pagesFigure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamrohitNo ratings yet

- Heating and Ventilating Systems 41: Figure 3-8. Oil BurnerDocument2 pagesHeating and Ventilating Systems 41: Figure 3-8. Oil BurnerrohitNo ratings yet

- Heating and Ventilating Systems 29: Figure 3-2. Steam BoilerDocument2 pagesHeating and Ventilating Systems 29: Figure 3-2. Steam BoilerrohitNo ratings yet

- Heat Flow 15Document2 pagesHeat Flow 15rohitNo ratings yet

- Latent HeatDocument2 pagesLatent HeatrohitNo ratings yet

- Heating and Ventilating Systems 27Document2 pagesHeating and Ventilating Systems 27rohitNo ratings yet

- Heating and Ventilating Systems 33Document2 pagesHeating and Ventilating Systems 33rohitNo ratings yet

- Heat Flow 17: ConductionDocument2 pagesHeat Flow 17: ConductionrohitNo ratings yet

- Air Volume: HVAC Systems 11Document2 pagesAir Volume: HVAC Systems 11rohitNo ratings yet

- HVAC Systems 13: VentilatingDocument2 pagesHVAC Systems 13: VentilatingrohitNo ratings yet

- Fluent Combustion 15.0 L02-Non-PremixedDocument30 pagesFluent Combustion 15.0 L02-Non-PremixedrafsebeNo ratings yet

- Remote Controller Brc1c61Document12 pagesRemote Controller Brc1c61IGN SayogaNo ratings yet

- Footings and FoundationsDocument13 pagesFootings and Foundationsg4goharNo ratings yet

- Aluminum Design Manual-24Document1 pageAluminum Design Manual-24Mohammed AyeshNo ratings yet

- Printing On Proteinic FabricsDocument10 pagesPrinting On Proteinic FabricsDÃljït Sīñgh100% (1)

- Multi - 1 Drills: YE-ML20Document2 pagesMulti - 1 Drills: YE-ML20Michel DominguesNo ratings yet

- DOP3025 02 UkDocument60 pagesDOP3025 02 UkSegundo Francisco Jauregui ValenciaNo ratings yet

- Cryogenic CCDocument18 pagesCryogenic CCWayne MonneryNo ratings yet

- Noise and Vibration in PM Motors - Sources and RemediesDocument35 pagesNoise and Vibration in PM Motors - Sources and RemediesVirgilioNo ratings yet

- Basic Hydraulic SystemDocument142 pagesBasic Hydraulic SystemAlif Aizat Azman100% (1)

- Cassida Fluid CR 46 - SD - (Gb-En)Document9 pagesCassida Fluid CR 46 - SD - (Gb-En)Huu Tri HuynhNo ratings yet

- Saybrook: Pull-Down Filtered Kitchen FaucetDocument2 pagesSaybrook: Pull-Down Filtered Kitchen FaucetCasper John Nanas MuñozNo ratings yet

- Toyotomi FF V30TDocument24 pagesToyotomi FF V30TEnzoNo ratings yet

- ASCO Series 230 Automatic Transfer Switch 2017Document18 pagesASCO Series 230 Automatic Transfer Switch 2017Anonymous SDeSP1No ratings yet

- DLL - Science 5 - Q1 - W5Document9 pagesDLL - Science 5 - Q1 - W5HEVER TORRESNo ratings yet

- Determination of Vinyl Chloride Monomer in Food Contact Materials by Solid Phase Microextraction Coupled With Gas Chromatography/Mass SpectrometryDocument6 pagesDetermination of Vinyl Chloride Monomer in Food Contact Materials by Solid Phase Microextraction Coupled With Gas Chromatography/Mass SpectrometryPhuongthuy127No ratings yet

- Types and Design of The Towers TraysDocument12 pagesTypes and Design of The Towers TraysoluninjaaNo ratings yet

- Cooling Tower Lab ReportDocument9 pagesCooling Tower Lab ReportDinesh Kumar Vijeyan100% (6)

- SOURSERVICE Brochure PDFDocument8 pagesSOURSERVICE Brochure PDFshank100No ratings yet

- C1161 - 08 Flexural CeramicDocument16 pagesC1161 - 08 Flexural CeramicRedV1rusNo ratings yet

- Refrigeration Practical 1Document6 pagesRefrigeration Practical 1SamNo ratings yet

- Flange Gasket Basics GFDocument8 pagesFlange Gasket Basics GFSri DharNo ratings yet

- EC2 DesignDocument62 pagesEC2 Designmihaitimofte100% (1)

- 2017 - GFRP Laminates - Beams - Ansys - Thesis PDFDocument222 pages2017 - GFRP Laminates - Beams - Ansys - Thesis PDFNaga PhaneendraNo ratings yet

- Pumps and Compressors: Week 7Document20 pagesPumps and Compressors: Week 7ednsmnNo ratings yet

- Clay Treatment of Fuel White PaperDocument3 pagesClay Treatment of Fuel White PaperGiuliano Castellani CiodaroNo ratings yet

- ISO - 286-2 Shaft Limits TolerancesDocument2 pagesISO - 286-2 Shaft Limits TolerancesMixtli Garcia100% (1)

- A Review - Use of Clay in The Manufacture of Lightweight AggregateDocument8 pagesA Review - Use of Clay in The Manufacture of Lightweight AggregatesergioNo ratings yet

- Dehydration SugarDocument2 pagesDehydration SugarAyu Dara KharismaNo ratings yet

- RE7ML11BU TelemecaniqueDocument22 pagesRE7ML11BU TelemecaniqueHugo FermartiNo ratings yet