Professional Documents

Culture Documents

Electrodag 725a (6s-61) - en

Uploaded by

jccaleffi0 ratings0% found this document useful (0 votes)

41 views2 pagesOriginal Title

electrodag 725a (6s-61)-en

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

41 views2 pagesElectrodag 725a (6s-61) - en

Uploaded by

jccaleffiCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Technical Data Sheet

Electrodag™ 725A (6S-61)™

August-2009

PRODUCT DESCRIPTION TYPICAL CURING PERFORMANCE

Electrodag™ 725A (6S-61)™ provides the following product Recommended Drying Cycle

characteristics: 15 minutes @ 120°C

Technology Thermoplastic

Appearance Silver The above cure profile is a guideline recommendation. Cure

conditions (time and temperature) may vary based on customers'

Filler Type Silver

experience and their application requirements, as well as customer

Product Benefits • Conductive curing equipment, oven loading and actual oven temperatures.

• Process ease

• Screen printable

• Long shelf life

• Good printability TYPICAL PROPERTIES OF CURED MATERIAL

• Excellent flexibility Dry Coating on Polyester foil, dried 15 minutes @ 120ºC

• No thinning required Physical Properties

• Low electrical resistance Adhesion , grade 5B

• Excellent adhesion strength Cohesion test (resistance change), % <3

• Good screen residence time

Cure Heat cure

Electrical Properties

Application Conductive Ink

Sheet Resistivity @ 25µm, ohms/sq 0.008 to 0.014

Operating Temperature- 100ºC

Maximum

Typical Assembly Membrane keyboards, membrane touch

Applications switches and Flexible circuits

GENERAL INFORMATION

For safe handling information on this product, consult the

Material Safety Data Sheet, (MSDS).

Electrodag™ 725A (6S-61)™ is designed for use in the

DIRECTIONS FOR USE

production of low voltage circuitry on polyester film.

1. Mix thoroughly with plastic spatula or mechanical stirrer

from bottom of container , careful not to whip air in to the

TYPICAL PROPERTIES OF UNCURED MATERIAL product. Using a plastic spatula will decrease the

Solids Content (3 hours @ 110°C), % 60 to 63 possibility of introducing plastic grindings from the

Viscosity, Brookfield , mPa·s (cP): container sidewalls into the product, which could damage

Speed 20 rpm, @ 20ºC 15,000 to 18,000 the screen.

2. Bring product to room temperature prior to use.

Density, , Kg/cm³ 2,100 3. Electrodag™ 725A (6S-61)™ is supplied ready for use.

Theoretical coverage, m²/kg: Should thinning become necessary, dilute 1 to 3% by

@ 10μm dry coating thickness 12

weight with Electrodag™ DBE.

Shelf Life @ 4 to 8ºC , year:

From date of qualification in original seal 1

Clean-up

To clean screen and equipment, use Methylethylketone (MEK)

Flash Point , Tag Closed Cup Flash Tester, ºC 94 or similar solvents

Storage

Store product in the unopened container in a dry location.

TYPICAL SCREEN PRINTING PROCESS Storage information may be indicated on the product container

Emulsion Thickness labeling.

Solvent resistant emulsion , μm 10 to 40 Optimal Storage: 4 to 8 °C

Recommended Squeegee Material removed from containers may be contaminated during

Shore Hardness 70 to 80 use. Do not return product to the original container. Henkel

Recommended Screen Type Corporation cannot assume responsibility for product which

Monofilament polyester screen , threads/cm 64 to 80 has been contaminated or stored under conditions other than

Stainless steel screen , threads/cm 68 to 130 those previously indicated. If additional information is required,

Printing Equipment Type please contact your local Technical Service Center or

Manual Customer Service Representative.

Semi-automatic

High speed reel-to-reel

TDS Electrodag™ 725A (6S-61)™, August-2009

Not for product specifications

The technical data contained herein are intended as reference

only. Please contact your local quality department for

assistance and recommendations on specifications for this

product.

Conversions

(°C x 1.8) + 32 = °F

kV/mm x 25.4 = V/mil

mm / 25.4 = inches

N x 0.225 = lb

N/mm x 5.71 = lb/in

N/mm² x 145 = psi

MPa x 145 = psi

N·m x 8.851 = lb·in

N·m x 0.738 = lb·ft

N·mm x 0.142 = oz·in

mPa·s = cP

Note

The data contained herein are furnished for information only

and are believed to be reliable. We cannot assume

responsibility for the results obtained by others over whose

methods we have no control. It is the user's responsibility to

determine suitability for the user's purpose of any production

methods mentioned herein and to adopt such precautions as

may be advisable for the protection of property and of persons

against any hazards that may be involved in the handling and

use thereof. In light of the foregoing, Henkel Corporation

specifically disclaims all warranties expressed or implied,

including warranties of merchantability or fitness for a

particular purpose, arising from sale or use of Henkel

Corporation’s products. Henkel Corporation specifically

disclaims any liability for consequential or incidental

damages of any kind, including lost profits. The discussion

herein of various processes or compositions is not to be

interpreted as representation that they are free from

domination of patents owned by others or as a license under

any Henkel Corporation patents that may cover such

processes or compositions. We recommend that each

prospective user test his proposed application before repetitive

use, using this data as a guide. This product may be covered

by one or more United States or foreign patents or patent

applications.

Trademark usage

Except as otherwise noted, all trademarks in this document

are trademarks of Henkel Corporation in the U.S. and

elsewhere. ® denotes a trademark registered in the U.S.

Patent and Trademark Office.

Reference 0.0

Americas Europe Asia

+1.310.764.4600 +44.1223.893.771 +86.21.3898.4800

For the most direct access to local sales and technical support visit: www.henkel.com/electronics

You might also like

- Astm C-494 PDFDocument9 pagesAstm C-494 PDFvelmurug_bala100% (5)

- Sikacem®-711 Elastic: Provisional Product Data SheetDocument4 pagesSikacem®-711 Elastic: Provisional Product Data SheetDavid V. BaltazarNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- SN2 RXDocument25 pagesSN2 RXGebby FebriliaNo ratings yet

- Principles of Wool Spinning ProcessesDocument68 pagesPrinciples of Wool Spinning ProcessesCẩm Tú100% (1)

- CoolThermTC 2002Document2 pagesCoolThermTC 2002pranavNo ratings yet

- TDS LF-375Document2 pagesTDS LF-375Ofer ShochetNo ratings yet

- TDS LF-300Document1 pageTDS LF-300Ofer ShochetNo ratings yet

- TDS LF-370Document2 pagesTDS LF-370ofershochetNo ratings yet

- TDS LF-370Document1 pageTDS LF-370Ofer ShochetNo ratings yet

- TDS LF-350Document1 pageTDS LF-350Ofer ShochetNo ratings yet

- TDS LF-390Document1 pageTDS LF-390Ofer ShochetNo ratings yet

- TDS LF-301Document1 pageTDS LF-301Ofer ShochetNo ratings yet

- TDS LF-361Document2 pagesTDS LF-361ofershochetNo ratings yet

- TDS LF-371Document1 pageTDS LF-371Ofer ShochetNo ratings yet

- tds-hd5403pdfDocument2 pagestds-hd5403pdfAthonioMourinhoNo ratings yet

- TDS LF-371 - Dec22Document2 pagesTDS LF-371 - Dec22ofershochetNo ratings yet

- ShaliProtek PuR 40Document3 pagesShaliProtek PuR 40Rana MahatoNo ratings yet

- Ps 700Document2 pagesPs 700Maurício LopesNo ratings yet

- Loctite Stycast 2651MM Cat 9 TDS 1Document2 pagesLoctite Stycast 2651MM Cat 9 TDS 1steffan.henryNo ratings yet

- Sikagard - 62 EngDocument3 pagesSikagard - 62 Engbassem kooliNo ratings yet

- Aluminum Filled Epoxy Resin Cement: Product OverviewDocument2 pagesAluminum Filled Epoxy Resin Cement: Product OverviewAli KhezeliNo ratings yet

- Eci 1010 Ec-EnDocument2 pagesEci 1010 Ec-EnPRATIKPATELNo ratings yet

- Technical Data Sheet: Page 1 of 5 HCD-10316 (Rev. 2012-04-24 2:24 PM)Document5 pagesTechnical Data Sheet: Page 1 of 5 HCD-10316 (Rev. 2012-04-24 2:24 PM)Sami LAHMIDINo ratings yet

- LOCTITE 3811 Eccobond Uf 3811 enDocument2 pagesLOCTITE 3811 Eccobond Uf 3811 enHector GarciaNo ratings yet

- TDS - Ew 6325H - enDocument2 pagesTDS - Ew 6325H - enAnthony GalindoNo ratings yet

- Xylan 80-510-G3196 Pfa BeDocument2 pagesXylan 80-510-G3196 Pfa BeSYED MAZHARNo ratings yet

- Aquasmart Hybrid PDFDocument3 pagesAquasmart Hybrid PDFmeena nachiyarNo ratings yet

- Tds 8330 2partsDocument2 pagesTds 8330 2partsgrasia77No ratings yet

- Condictive EpoxyDocument3 pagesCondictive EpoxyashfaqNo ratings yet

- Aquasmart PBDocument3 pagesAquasmart PBmeena nachiyarNo ratings yet

- Masterprotect 1813: Amine-Cured, Pitch Free EpoxyDocument2 pagesMasterprotect 1813: Amine-Cured, Pitch Free EpoxyGavriel Ng100% (1)

- Product Data Sheet: Sumitomo Polyethylene LdpeDocument2 pagesProduct Data Sheet: Sumitomo Polyethylene LdpeMd Abdul SalamNo ratings yet

- Hyperdesmo S 2k - v2.0Document3 pagesHyperdesmo S 2k - v2.0rasasiNo ratings yet

- Hyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane SealantDocument2 pagesHyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane Sealantsasikumar durairajanNo ratings yet

- HT 521 84054 800 ENDocument5 pagesHT 521 84054 800 ENEdward AguillónNo ratings yet

- Scotchkote: Fusion-Bonded Epoxy Coating 206N LGDocument1 pageScotchkote: Fusion-Bonded Epoxy Coating 206N LGSohail TisekarNo ratings yet

- Ablestik 2114 BiPax-EN-1761143Document3 pagesAblestik 2114 BiPax-EN-1761143نور محمد وحيد القدسيNo ratings yet

- Loctite 7232 High Temperature Wear Resistant Putty: Product Description SheetDocument1 pageLoctite 7232 High Temperature Wear Resistant Putty: Product Description SheetjohnNo ratings yet

- Epoxy Technical SheetDocument2 pagesEpoxy Technical SheetLuan TranNo ratings yet

- Sikamelt 700Document2 pagesSikamelt 700Ionut StoicaNo ratings yet

- Sikagrout®-200 PT Id: Product Data SheetDocument3 pagesSikagrout®-200 PT Id: Product Data SheetCbeztNo ratings yet

- Epoxylite 578EB - TDS - 2008Document3 pagesEpoxylite 578EB - TDS - 2008beemer5No ratings yet

- Sabic PP 575P: Polypropylene Homopolymer For Injection MoldingDocument2 pagesSabic PP 575P: Polypropylene Homopolymer For Injection MoldingDynamic SaravananNo ratings yet

- Loctite Eccobond Fp4530 en GLDocument2 pagesLoctite Eccobond Fp4530 en GLHalilibrahim CanNo ratings yet

- Cooltherm Tc-2002 Thermally Conductive Structural Adhesive: Technical Data SheetDocument2 pagesCooltherm Tc-2002 Thermally Conductive Structural Adhesive: Technical Data SheetpronavNo ratings yet

- Transclean 801Document2 pagesTransclean 801carmaNo ratings yet

- KCC DataSheet WH3350 (ENG)Document2 pagesKCC DataSheet WH3350 (ENG)Trịnh Minh KhoaNo ratings yet

- Anabond 652c Heat Sink Compound Thermally ConductiveDocument2 pagesAnabond 652c Heat Sink Compound Thermally ConductiveRohit MahaleNo ratings yet

- Mea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaDocument2 pagesMea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaMuhammad hussainNo ratings yet

- Technical Data: P/S 870 Class B Corrosion Inhibitive SealantDocument2 pagesTechnical Data: P/S 870 Class B Corrosion Inhibitive Sealantlucas laraNo ratings yet

- Cardolite NX 2016Document2 pagesCardolite NX 2016Lê TiếnNo ratings yet

- TDS of Metlok 703Document2 pagesTDS of Metlok 703idrees.theheroNo ratings yet

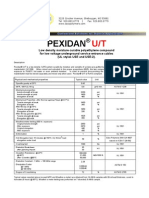

- Pexidan Ut Saco 0510Document2 pagesPexidan Ut Saco 0510Eddy BrentonNo ratings yet

- Technical Data Sheet - CPE HG100 - 03012019Document1 pageTechnical Data Sheet - CPE HG100 - 03012019AngelNo ratings yet

- Epoxylite® E478Document4 pagesEpoxylite® E478pedro maiaNo ratings yet

- Technical Data Sheet for 1-Part Silicone Sealant Silcoset 151Document2 pagesTechnical Data Sheet for 1-Part Silicone Sealant Silcoset 151Arun VaideeswaranNo ratings yet

- Hyperseal 50 FCSDocument3 pagesHyperseal 50 FCSmeena nachiyarNo ratings yet

- Sikagrout - 200 PtidDocument3 pagesSikagrout - 200 Ptidfandy sipataNo ratings yet

- Scotch-Weld: Cyanoacrylate Adhesive PR100Document3 pagesScotch-Weld: Cyanoacrylate Adhesive PR100Marco AurélioNo ratings yet

- Macal® 8200 Pro: Technical Data SheetDocument2 pagesMacal® 8200 Pro: Technical Data SheetMOHAMEDNo ratings yet

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- Nusil CV2-2646 - 29017393Document3 pagesNusil CV2-2646 - 29017393Joaquin Sanchez MagariñosNo ratings yet

- Tds csp-5210 (Dieletrico Uv)Document1 pageTds csp-5210 (Dieletrico Uv)jccaleffiNo ratings yet

- V-Series Mixer End User GuideDocument22 pagesV-Series Mixer End User GuidejccaleffiNo ratings yet

- Cleaning Polycarbonate Sheet: Supplier Product Application MethodDocument2 pagesCleaning Polycarbonate Sheet: Supplier Product Application MethodjccaleffiNo ratings yet

- Guia de Laminas OlfaDocument1 pageGuia de Laminas OlfajccaleffiNo ratings yet

- 50 555circuitsDocument76 pages50 555circuitsmmkenoNo ratings yet

- En Technical Information PDFDocument160 pagesEn Technical Information PDFjccaleffiNo ratings yet

- Paraffin Test ActivityDocument2 pagesParaffin Test ActivityCapal Anna MarieNo ratings yet

- Lutensol CS 6250Document4 pagesLutensol CS 6250ARTHA -LESTARINo ratings yet

- Sikalastic®-871 JW (A)Document10 pagesSikalastic®-871 JW (A)Haris RisdianaNo ratings yet

- Masil EM 350: Product Type 35% Silicone Emulsion Product DescriptionDocument2 pagesMasil EM 350: Product Type 35% Silicone Emulsion Product DescriptionCARMEN LINARESNo ratings yet

- 22602-Sample-Question-Paper (Msbte Study Resources) Maintenance and Repairs of Structures (MRS)Document4 pages22602-Sample-Question-Paper (Msbte Study Resources) Maintenance and Repairs of Structures (MRS)Roshan Kinholkar100% (1)

- Project Report On Manures and Chemical FertilizersDocument5 pagesProject Report On Manures and Chemical FertilizersAvishekNo ratings yet

- Vermiculite Filler 835 Spiral Wound Gasket - 957562Document1 pageVermiculite Filler 835 Spiral Wound Gasket - 957562deden okNo ratings yet

- Implementing Air Drilling for Higher ProductivityDocument7 pagesImplementing Air Drilling for Higher ProductivityLok Bahadur RanaNo ratings yet

- X Ray Crystallography: Presented By: Ayesha Kabeer University of Gujrat Sialkot SubcampusDocument12 pagesX Ray Crystallography: Presented By: Ayesha Kabeer University of Gujrat Sialkot SubcampusRahulNo ratings yet

- Additivity Rules For The Estimation of Molecular Properties. Thermodynamic PropertiesDocument28 pagesAdditivity Rules For The Estimation of Molecular Properties. Thermodynamic Propertieswesileh981No ratings yet

- At First Crush Cheek Palette ColourPopDocument1 pageAt First Crush Cheek Palette ColourPopmNo ratings yet

- Components of FoodDocument37 pagesComponents of FoodSunil KumarNo ratings yet

- Act 2 - DIgestive SystemDocument37 pagesAct 2 - DIgestive Systemisabellamarie.castillo.crsNo ratings yet

- A-Level Biology Question and Answers 20 20/2021Document76 pagesA-Level Biology Question and Answers 20 20/2021FireFrostNo ratings yet

- Chem 256Document109 pagesChem 256Richard LarbiNo ratings yet

- Klubertemp HM 83 402Document2 pagesKlubertemp HM 83 402AlfredNo ratings yet

- Biogeochemical Cycles For APESDocument42 pagesBiogeochemical Cycles For APESjohnosborneNo ratings yet

- Grade-9-Science Q2 Wk2 GLAKDocument24 pagesGrade-9-Science Q2 Wk2 GLAKMorana TuNo ratings yet

- Acrylic Acid - MohitDocument42 pagesAcrylic Acid - MohitvickuNo ratings yet

- Safety Data Sheet Cotton Products: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument5 pagesSafety Data Sheet Cotton Products: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingAhmed and Gaser KnawyNo ratings yet

- Electronics For Electricians 7th Edition Herman Test BankDocument3 pagesElectronics For Electricians 7th Edition Herman Test Bankjessicataylorqcpdbkxsat100% (15)

- Electrochemistry: Galvanic Cells and Cell PotentialDocument79 pagesElectrochemistry: Galvanic Cells and Cell PotentialTuna ShinNo ratings yet

- Bosmans Et Al. (2013) - The Crucial Role of Waste-to-Energy Technologies in EnhancedDocument14 pagesBosmans Et Al. (2013) - The Crucial Role of Waste-to-Energy Technologies in EnhancedAnonymous Zsi5ODm2PYNo ratings yet

- A Review On Use of Metakaolin in Cement Mortar and Concrete: July 2014Document6 pagesA Review On Use of Metakaolin in Cement Mortar and Concrete: July 2014raviteja036No ratings yet

- Agro-Culture Liquid Fertilizers: A. General InformationDocument2 pagesAgro-Culture Liquid Fertilizers: A. General InformationAsterism TechPro RajasthanNo ratings yet

- SUSPENSIONDocument11 pagesSUSPENSIONAnoosha FarooquiNo ratings yet

- Chem 2 Chemistry in Your World 2nd Edition Hogg Solutions ManualDocument38 pagesChem 2 Chemistry in Your World 2nd Edition Hogg Solutions Manualgarrywolfelsjftl100% (14)