Professional Documents

Culture Documents

Masterprotect 1813: Amine-Cured, Pitch Free Epoxy

Uploaded by

Gavriel NgOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masterprotect 1813: Amine-Cured, Pitch Free Epoxy

Uploaded by

Gavriel NgCopyright:

Available Formats

MasterProtect® 1813

Amine-cured, pitch free epoxy

DESCRIPTION LIMITATIONS

A solvent-free, chemical resistant non- Do not use in water immersion over 60°C

carcinogenic coating. In appearance, Epoxies lose gloss, discolour and will chalk in

MasterProtect 1813 is smooth and glossy. direct sunlight exposure.

TYPICAL APPLICATIONS SURFACE AND SUBSTRATE

MasterProtect 1813 is used to provide a heavy PREPARATION

duty protective, waterproof, and flexible coating.

Widely used in the application for exterior, below GENERAL

grade, back filling and between slab application.

Surfaces must be clean and dry. Use suitable

methods to remove dirt, dust, oil an all other

ADVANTAGES forms of contamination that could interfere with

Good chemical resistance the adhesion of the coating.

Excellent abrasion resistance

High build coating CONTENT

Easy application: brush, roller, spray Concrete should be sound and sufficiently dry to

Economical accept MasterProtect 1813. Preferably having

Non-carcinogenic and non-toxic less than 5% surface moisture. Mechanically

Seamless finish surface profiling is the method of surface

Eco-friendly coating preparation. Mechanically profile the surface to

Excellent corrosion protection CSP3 as described by the International

Concrete Repair Institute. Voids and pinholes

PACKAGING AND COLORS must be repaired.

MasterProtect 1813 is supplied in 27 kg (18 L)

units and available in Black. STEEL

Prepare to SSPC-SP6. Surface profile 50-75

SOLIDS CONTENT micron.

By Volume: 100%

PLACING / APPLICATION

THEORETICAL COVERAGE RATE MasterProtect 1813 may be applied by airless

225 g/m² – 300 g/m² (150 μ – 200 μ DFT) spray, brush or roller. Please refer to our latest

Method Statement for detailed application

instructions.

DRY TEMPERATURE RESISTANCE

A loss of gloss and discolouration may be CLEANING

observed above 80°C.

Use a suitable thinner (Xylene / MEK / Acetone)

in case of spillage, absorb and dispose of in

accordance with local applicable regulations.

MasterProtect® 1813

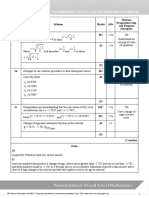

PERFORMANCE DATA*

Physical Characteristics

Appearance Black resinous thixotrope

Mixed Density (kg/L) ASTM D1475 ~ 1.5

Application Temperature

10°C 25°C 40°C

Pot-life - ASTM D 2471 3.5 h 60 min 40 min

Tack-free time - ASTM C 679 7h 5h 2h

Touch-free time 13 h 9h 5h

Bond strength (7 days) ASTM D4541 @ 1.90 MPa (Concrete failure)

150 μm DFT over concrete

Water permeability BS EN 12390 Part 8: Nil

2000 @ 5 bar pressure

Abrasion Test (CS17 wheel / 1000g /

33 milligrams

1000 cycle) at 7 days ASTM D 4060

Test reports & additional documentation are available upon request.

WATCHPOINTS appropriate respirators must be used by all

No additions or omissions are required and on application personnel. Treat splashes to eyes

no account should attempts be made to split and skin immediately. If accidentally ingested,

packs. Unsuitable in situations where foodstuffs seek immediate medical attention. Keep away

or potable water will be in contact with the from children and animals. Reseal containers

coating. after use.

QUALITY AND CARE

STORAGE AND SHELF LIFE

All products originating from Master Builders

Shelf life is 12 months when stored under cover,

Solutions Dubai, UAE facility are

out of direct sunlight and protected from

manufactured under a management system

extremes of temperature.

independently certified to conform to the

requirements of the quality, environmental and

HEALTH AND SAFETY occupational health & safety standards ISO

Read and follow all caution statements and on 9001, ISO 14001 and ISO 45001.

the MSDS for this product. Employ good

* Properties listed are based on laboratory controlled tests.

workmanlike safety precautions. Wear protective

clothing, gloves and eye protection. ® = Registered trademark of the MBCC Group in many countries.

When used as a tank lining or in enclosed areas

through air circulation must be used during and

after application until the application is cured. In

addition to ensuring proper ventilation,

MBS_CC-UAE/Pr_1813_11_09/v1/12_13/v2/09_19

The technical information and application advice given in this Master Builders Solutions publication are based on

STATEMENT OF the present state of our best scientific and practical knowledge. As the information herein is of a general nature, no

RESPONSIBILITY assumption can be made as to a product's suitability for a particular use or application and no warranty as to its

accuracy, reliability or completeness either expressed or implied is given other than those required by law. The user

is responsible for checking the suitability of products for their intended use.

Field service where provided does not constitute supervisory responsibility. Suggestions made by Master Builders

NOTE Solutions either orally or in writing may be followed, modified or rejected by the owner, engineer or contractor since

they, and not Master Builders Solutions, are responsible for carrying out procedures appropriate to a specific

application.

Master Builders Solutions

Construction Chemicals LLC

P.O. Box 37127, Dubai, UAE

Tel: +971 4 8090800

www.master-builders-solutions.com/en-ae

Disclaimer: the LRQA mark relates to

certified management system and not to the

product mentioned on this datasheet

You might also like

- Masterseal NP 472 (Brisk)Document2 pagesMasterseal NP 472 (Brisk)MumtazNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- 1 - Masterseal-M-262-TdsDocument2 pages1 - Masterseal-M-262-TdsPaul ManiquisNo ratings yet

- Masterseal TC 257 TdsDocument2 pagesMasterseal TC 257 TdsfirozembrayilNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- Masterflow 400 TdsDocument3 pagesMasterflow 400 TdsverNo ratings yet

- Masterprotect 1855 TdsDocument2 pagesMasterprotect 1855 TdsShahsoor Shah Majeed100% (1)

- Masterinject 1315 TdsDocument2 pagesMasterinject 1315 TdsMoatz HamedNo ratings yet

- Basf Masterprotect 1815 TdsDocument3 pagesBasf Masterprotect 1815 TdsEngTamer100% (1)

- Basf Masterprotect 2020Document2 pagesBasf Masterprotect 2020SHAIK ASIMUDDIN100% (1)

- Bond New Concrete to Old with EPDocument2 pagesBond New Concrete to Old with EPHtun ZarniNo ratings yet

- Masterseal 588: Description Packaging and ColorsDocument2 pagesMasterseal 588: Description Packaging and ColorsmariaNo ratings yet

- Cement Properties and CharacteristicsDocument2 pagesCement Properties and CharacteristicsAnonymous XVEucVMsENo ratings yet

- Mbrace Laminate LM, MM, HM TDSDocument3 pagesMbrace Laminate LM, MM, HM TDSDoug WeirNo ratings yet

- Masterbrace Adh 2200 TdsDocument2 pagesMasterbrace Adh 2200 TdsarchahmedassafNo ratings yet

- Masterprotect P 1801: Phenol Novolac Epoxy Amine Cured PrimerDocument2 pagesMasterprotect P 1801: Phenol Novolac Epoxy Amine Cured PrimerAli KayaNo ratings yet

- Basf Masterprotect P 659Document2 pagesBasf Masterprotect P 659Hassan Ahmed SyedNo ratings yet

- Webercote Protect PE - 0Document2 pagesWebercote Protect PE - 0Mohammed Tabraiz HussainNo ratings yet

- Polypoxy EC: Epoxy Based Cementitious Repair SystemDocument2 pagesPolypoxy EC: Epoxy Based Cementitious Repair SystemAlexi ALfred H. TagoNo ratings yet

- Polyprime PS: Primer For Porous JointsDocument2 pagesPolyprime PS: Primer For Porous JointsaahtagoNo ratings yet

- Ps 700Document2 pagesPs 700Maurício LopesNo ratings yet

- Mastertop P 651 TdsDocument2 pagesMastertop P 651 Tdsmuhammednaar32No ratings yet

- Masterprotect 190 TdsDocument3 pagesMasterprotect 190 Tdsjonte kimondioNo ratings yet

- Masterprotect 1814 TdsDocument3 pagesMasterprotect 1814 TdsfirozembrayilNo ratings yet

- ResiGard TAS 2022-08-18 06 - 13 - 14Document3 pagesResiGard TAS 2022-08-18 06 - 13 - 14Sridhar RajajiNo ratings yet

- Masterseal TC 242: Description Typical PropertiesDocument2 pagesMasterseal TC 242: Description Typical PropertiesGavriel NgNo ratings yet

- Masterseal TC 254 - TdsDocument2 pagesMasterseal TC 254 - TdsHanyNo ratings yet

- l2) Steelshield1200 3041Document2 pagesl2) Steelshield1200 3041Syed FaridNo ratings yet

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerNo ratings yet

- Masterseal NP 472 TdsDocument2 pagesMasterseal NP 472 TdsŠhehabAlŠhǻrnobiNo ratings yet

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerNo ratings yet

- Hyperdesmo®-Ady 610 - enDocument3 pagesHyperdesmo®-Ady 610 - enMajd M. KhalilNo ratings yet

- 15 - TDS - Concresive ERLDocument3 pages15 - TDS - Concresive ERLAlexi ALfred H. TagoNo ratings yet

- Basf Masterbrace Adh 2200 Tds 301963Document2 pagesBasf Masterbrace Adh 2200 Tds 301963Mohamed Abo-Zaid100% (1)

- Mea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaDocument2 pagesMea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaMuhammad hussainNo ratings yet

- Basf Masterinject 1315 TdsDocument2 pagesBasf Masterinject 1315 TdsDragu SorinNo ratings yet

- BASF MasterSeal NP 472Document2 pagesBASF MasterSeal NP 472HJNo ratings yet

- k3) Luxatherm5600 7954Document2 pagesk3) Luxatherm5600 7954Syed FaridNo ratings yet

- Flexseal PU440 TDSDocument2 pagesFlexseal PU440 TDSkumaraguruNo ratings yet

- 113 DR Fixit FastflexDocument3 pages113 DR Fixit FastflexSasi KumarNo ratings yet

- Dr. Fixit Newcoat Ezee - Waterproof CoatingDocument2 pagesDr. Fixit Newcoat Ezee - Waterproof CoatingJuneNo ratings yet

- Basf Masterprotect 1812 Tds PDFDocument2 pagesBasf Masterprotect 1812 Tds PDFHassan Ahmed Syed0% (1)

- Basf Masterprotect 1812 TdsDocument2 pagesBasf Masterprotect 1812 Tdssamer8saifNo ratings yet

- Masterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingSHAIK ASIMUDDINNo ratings yet

- DC 688 Technical Data SheetDocument3 pagesDC 688 Technical Data SheetHoang ThiNo ratings yet

- DYMAX Ga-103Document0 pagesDYMAX Ga-103Giosue GiacoppoNo ratings yet

- Polycoat Rbe FR: Rubberized Bitumen EmulsionDocument2 pagesPolycoat Rbe FR: Rubberized Bitumen EmulsionAbidNo ratings yet

- Epilux 155 SFDocument2 pagesEpilux 155 SFMohamed NasifNo ratings yet

- Hyperdesmo: (Classic Version) Polyurethane Liquid Membrane For Waterproofing & Protection, Easy ApplicationDocument4 pagesHyperdesmo: (Classic Version) Polyurethane Liquid Membrane For Waterproofing & Protection, Easy ApplicationGİZEM DEMİRNo ratings yet

- Radiant Barrier Coating: For Energy Conservation and Light ReflectionDocument2 pagesRadiant Barrier Coating: For Energy Conservation and Light ReflectionEsaNo ratings yet

- High Build Epoxy Anti-Corrosive Primer SpecsDocument2 pagesHigh Build Epoxy Anti-Corrosive Primer SpecsMuthuKumar100% (1)

- Hyperdesmo Polyurea 2K HCDocument3 pagesHyperdesmo Polyurea 2K HCmeena nachiyarNo ratings yet

- Dermaprimer: Product DescriptionDocument2 pagesDermaprimer: Product DescriptionSaud NawabNo ratings yet

- Slow Setting Bitumen Emulsion: Product Data SheetDocument2 pagesSlow Setting Bitumen Emulsion: Product Data Sheetmijanur rahmanNo ratings yet

- DR - Fixit Cipoxy 16DDocument3 pagesDR - Fixit Cipoxy 16DKiran KumarNo ratings yet

- Technical Data: P/S 870 Class A Corrosion Inhibitive SealantDocument2 pagesTechnical Data: P/S 870 Class A Corrosion Inhibitive SealantKentNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- 14 - TDS - Concresive 2020Document2 pages14 - TDS - Concresive 2020aahtagoNo ratings yet

- Qualipur 552 E TDSDocument2 pagesQualipur 552 E TDSjohnNo ratings yet

- Wa-624145 0002 0000Document1 pageWa-624145 0002 0000Gavriel NgNo ratings yet

- TF Draft Comments 2Document1 pageTF Draft Comments 2Gavriel NgNo ratings yet

- TF Draft Comments 4Document1 pageTF Draft Comments 4Gavriel NgNo ratings yet

- TF Draft Comments 3Document1 pageTF Draft Comments 3Gavriel NgNo ratings yet

- TF Draft Comments 1Document1 pageTF Draft Comments 1Gavriel NgNo ratings yet

- Master Emaco P210Document2 pagesMaster Emaco P210Gavriel NgNo ratings yet

- Wa-624145 0003 0000Document1 pageWa-624145 0003 0000Gavriel NgNo ratings yet

- Draft CommentsDocument6 pagesDraft CommentsGavriel NgNo ratings yet

- Wa-624145 0001 0000Document1 pageWa-624145 0001 0000Gavriel NgNo ratings yet

- Basf Masterseal NP 473u TdsDocument3 pagesBasf Masterseal NP 473u TdsAaaNo ratings yet

- Nitobond ArDocument46 pagesNitobond ArGavriel NgNo ratings yet

- Polygrout NS: Non-Shrink Free Flow Cementitious GroutDocument2 pagesPolygrout NS: Non-Shrink Free Flow Cementitious GroutGavriel NgNo ratings yet

- Sika Grout - 114 SaDocument3 pagesSika Grout - 114 SaGavriel NgNo ratings yet

- Masterflow 559: Versatile High Strength, Non Shrink Cementitious Construction GroutDocument3 pagesMasterflow 559: Versatile High Strength, Non Shrink Cementitious Construction GroutGavriel NgNo ratings yet

- 2.) MasterSeal NP 472 (BASF)Document2 pages2.) MasterSeal NP 472 (BASF)Gavriel NgNo ratings yet

- Constructive solutions for non-shrink cement groutDocument69 pagesConstructive solutions for non-shrink cement groutGavriel NgNo ratings yet

- Polyseal PS GG: 2 Part Gun Grade Polysulphide Joint SealantDocument4 pagesPolyseal PS GG: 2 Part Gun Grade Polysulphide Joint SealantGavriel NgNo ratings yet

- Nitoproof 10Document37 pagesNitoproof 10Gavriel NgNo ratings yet

- Nitoseal MS60Document62 pagesNitoseal MS60Gavriel NgNo ratings yet

- Nitocote PU AliphaticDocument28 pagesNitocote PU AliphaticGavriel NgNo ratings yet

- Masterseal TC 242: Description Typical PropertiesDocument2 pagesMasterseal TC 242: Description Typical PropertiesGavriel NgNo ratings yet

- Nitoproof PU AromaticDocument22 pagesNitoproof PU AromaticGavriel NgNo ratings yet

- MasterSeal 610Document2 pagesMasterSeal 610Gavriel NgNo ratings yet

- Inertol Poxitar: 2 Component, Heavy Duty, Coal Tar Based Epoxy Coating For Steel and ConcreteDocument4 pagesInertol Poxitar: 2 Component, Heavy Duty, Coal Tar Based Epoxy Coating For Steel and ConcreteGavriel NgNo ratings yet

- Waterproof acrylic cement coating protects concreteDocument2 pagesWaterproof acrylic cement coating protects concreteFourier MakambioNo ratings yet

- Nitocote ET402: Constructive SolutionsDocument3 pagesNitocote ET402: Constructive SolutionsGavriel Ng100% (1)

- MasterProtect 300Document3 pagesMasterProtect 300Gavriel NgNo ratings yet

- MasterSeal 550Document3 pagesMasterSeal 550Gavriel NgNo ratings yet

- Nitocote CM210Document91 pagesNitocote CM210Gavriel NgNo ratings yet

- CHEM 1211K Lab Fall 2020: Submission GuideDocument3 pagesCHEM 1211K Lab Fall 2020: Submission GuideParker Santo DomingoNo ratings yet

- Mark Scheme: Q Scheme Marks Aos Pearson Progression Step and Progress Descriptor 1A M1Document7 pagesMark Scheme: Q Scheme Marks Aos Pearson Progression Step and Progress Descriptor 1A M1Arthur LongwardNo ratings yet

- REVISED SYLLABUS Assessment of Learning 1Document7 pagesREVISED SYLLABUS Assessment of Learning 1FLORIFE CABANGON100% (1)

- Plant Floor Safety: Summer EditionDocument72 pagesPlant Floor Safety: Summer EditionStefanos DiamantisNo ratings yet

- Brian Leggett (Ed) 2006 Rhetorical-Approach-To-PersuasionDocument9 pagesBrian Leggett (Ed) 2006 Rhetorical-Approach-To-PersuasionM MoralesNo ratings yet

- Pioneers of Modern Architecture: Maseana ProjectDocument86 pagesPioneers of Modern Architecture: Maseana ProjectEriNo ratings yet

- International Case StudyDocument14 pagesInternational Case StudyPriyanka Khadka100% (1)

- Ecotourism EssayDocument2 pagesEcotourism EssayKarenNo ratings yet

- University of DelhiDocument4 pagesUniversity of DelhiNamasteNo ratings yet

- Joints, Bones & Healthy SkeletonsDocument2 pagesJoints, Bones & Healthy Skeletonsسكمي نعمة الكرمهNo ratings yet

- WEG Pump Genius 50059602 Brochure enDocument20 pagesWEG Pump Genius 50059602 Brochure enGabriel AraújoNo ratings yet

- Value Based MalaysiaDocument14 pagesValue Based MalaysiaabduNo ratings yet

- ANZ Aboriginal history, culture, and demographicsDocument13 pagesANZ Aboriginal history, culture, and demographicsЛада ПоселянинаNo ratings yet

- Inovasi Kurikulum Berdasarkan Komponen Kurikulum Strategi Dan Evaluasi Oleh: Sri MaryatiDocument16 pagesInovasi Kurikulum Berdasarkan Komponen Kurikulum Strategi Dan Evaluasi Oleh: Sri MaryatiFitroh NailulNo ratings yet

- Auveco HNI 490Document1 pageAuveco HNI 490BillNo ratings yet

- KNH 413 - Case Study 14Document17 pagesKNH 413 - Case Study 14api-301118772No ratings yet

- Mathematics Reference Books: No. Name Author PublisherDocument1 pageMathematics Reference Books: No. Name Author PublisherDelicateDogNo ratings yet

- Special MantrasDocument5 pagesSpecial Mantrasvenkataramanneralla100% (2)

- Amx4+ Renewal PartsDocument132 pagesAmx4+ Renewal Partsluilorna27No ratings yet

- CS-D Series: Protuner Software User ManualDocument33 pagesCS-D Series: Protuner Software User ManualRudy TorrezNo ratings yet

- Watching TV ads or internet ads? Pros, cons and preferencesDocument5 pagesWatching TV ads or internet ads? Pros, cons and preferencesJiaqi LiNo ratings yet

- Marketing Management Case Study AssignmentDocument19 pagesMarketing Management Case Study AssignmentSZANo ratings yet

- Herbal Mandis of UttarakhandDocument3 pagesHerbal Mandis of UttarakhandRavi VarmaNo ratings yet

- MTEX Plot Pole Figures and Inverse Pole FiguresDocument9 pagesMTEX Plot Pole Figures and Inverse Pole FiguresIniyan Thiruselvam Navaladi KarthikeyanNo ratings yet

- BS en 12457-2 - 2002Document30 pagesBS en 12457-2 - 2002Helio C. Souza33% (3)

- Ded Moroz Minitheme by SlidesgoDocument41 pagesDed Moroz Minitheme by SlidesgoTazkia AuditaNo ratings yet

- Java Mini ProjectDocument12 pagesJava Mini ProjectShridhar PatilNo ratings yet

- What is GMO - A guide to genetically modified organismsDocument14 pagesWhat is GMO - A guide to genetically modified organismsCristie Ann GuiamNo ratings yet

- Grade 10 Biology Week 8 Lesson 2 Worksheet 1 and SolutionsDocument4 pagesGrade 10 Biology Week 8 Lesson 2 Worksheet 1 and SolutionsAva HoNo ratings yet

- Probability Spinner WorksheetDocument2 pagesProbability Spinner WorksheetSara ShaiboonNo ratings yet