Professional Documents

Culture Documents

Track-Type Tractor: Net Power (1,900 RPM)

Uploaded by

Anas MaksoudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Track-Type Tractor: Net Power (1,900 RPM)

Uploaded by

Anas MaksoudCopyright:

Available Formats

D8T

TRACK-TYPE TRACTOR

Net Power (1,900 rpm)

ISO 9249/SAE J1349 264 kW (354 hp)

ISO 9249/SAE J1349 (DIN) (359 hp)

Operating Weight

Standard 39 750 kg (87,600 lb)

LGP 37 750 kg (83,200 lb)

Cat® C15 ACERT™ Engine meets U.S. EPA Tier 4 Final/EU Stage IV/Korea Tier 4 Final emission standards

with an aftertreatment system that is designed to be transparent to the operator.

PUSHING YOUR PROFITS FORWARD

The new Cat® D8T is designed for performance and efficiency to give you a faster return on your

equipment investment:

+ MORE POWER AND PRODUCTIVITY WITHOUT USING MORE FUEL

+ UNPRECEDENTED EASE OF OPERATION

+ CHOICE OF FACTORY INTEGRATED TECHNOLOGY OPTIONS TO SUIT YOUR BUSINESS

THE NEW THE CAT D8T is the right choice

when your business demands a

CAT D8T ® step up in performance. A new

Caterpillar designed, fully automatic

4-speed transmission is at the heart

of performance improvements that

take you to a whole new level of

productivity and efficiency.

PRODUCTIVITY THAT PAYS

2 D8T TRACK-TYPE TRACTOR

MOVE MORE,

DON’T BURN MORE. MOVE UP TO 18% MORE MATERIAL

MOVE UP TO 18% MORE MATERIAL PER HOUR.*

PER HOUR

Fully automatic transmission, added power and steering performance

THAT’S ALMOST LIKE HAVING AN

EXTRA MACHINE ON THE JOB! team up for a new level of productivity. Larger blade capacity gets the

job done in fewer passes.

MONDAY

BURN ZERO ADDITIONAL FUEL

TUESDAY

Move more material without burning more fuel in most applications.

Use up to 11% less fuel in lighter applications.

WEDNESDAY

MOVE MORE. SPEND LESS.

THURSDAY GRADE Technologies help you work more precisely for faster results,

less rework. New blade and undercarriage options help you take on

the harshest conditions at a lower overall cost.

FRIDAY

8-HOUR WORK DAY × 18% EFFICIENCY IMPROVEMENT =

AN EXTRA 1.44

AN EXTRA 1.44 HOURS WORTH OF WORK COMPLETED EACH DAY Comparisons to previous D8T model.

1.44 HOURS/DAY × 5 DAYS A WEEK = AN ADDITIONAL 7.2 HOURS

OF WORK USING ABOUT THE SAME AMOUNT OF FUEL

*COMPARED TO PREVIOUS MODEL

D8T TRACK-TYPE TRACTOR 3

FULLY AUTOMATIC

New Caterpillar designed, fully automatic 4-speed

transmission continuously adjusts for maximum

performance and efficiency – no need for operator

to upshift/downshift. FEWER PASSES

Largest Semi-Universal (SU) blade in the

size class gives you 19% more capacity.

Increase blade payload by up to 25%,

especially in hard ground or rock, with

optional Performance Cutting Edges.

MORE POWER TO WORK

Take advantage of up to 13% more drawbar

horsepower to the ground. Auto shift works up

CLASS-LEADING STEERING

and down the entire working range, so power

Move material more easily while turning with and fuel consumption are optimized throughout

10% more steering torque. Automatic transmission, the dozing cycle.

differential steering and dedicated steering and

implement pumps combine to provide best-in-class

steering performance under load.

4 D8T TRACK-TYPE TRACTOR

These days, you need every edge

you can get to win the bid and get

TECHNOLOGY CHOICES

the job done on time and on spec.

Caterpillar offers you a choice of HELP YOU

STAY AHEAD

technology options to help you

stay in front of the competition.

GRADE FOR DOZERS

Cat Connect GRADE technologies help operators of varying experience levels hit target grade faster and more accurately.

Finish jobs in fewer passes, and with less operator effort, saving you time and helping you increase profit.

D8T TRACK-TYPE TRACTOR 5

BETTER

GRADES

LESS EFFORT

FIRST PASS TO FINISH GRADE SIMPLE: NO GPS NEEDED

Optional Cat GRADE with 3D automates blade Cat GRADE with Slope Assist™ automatically maintains blade position

movements in fine grading and production dozing without a GPS signal. Ideal for jobs like building pads, creating

applications. Reduces operator inputs by as much simple design plans on-the-go, or working where GPS is unavailable.

as 80%. Antennas mounted on top of the cab eliminate (Single Tilt only.)

blade masts and cables. Decreases the need for

grade checkers and staking for greater safety

and lower labor costs.

READY WHEN YOU ARE

With Attachment Ready Option (ARO), your dozer comes from

the factory ready for simple installation of an aftermarket grade

control system.

HELPING HANDS

Automate repetitive tasks to help reduce operator fatigue.

Auto Blade Assist lets you preset AutoCarry automates blade lift Automatic Ripper Control with new

blade pitch positions for the load, for more consistent blade loads. rip-to-depth feature that automatically

carry and spread portions of Helps reduce track slip. Works adjusts engine speed and ripper

the cycle. seamlessly with GRADE with 3D. depth to reduce track slip.

6 D8T TRACK-TYPE TRACTOR

CAT LINK TECHNOLOGY

TAKES THE GUESSWORK OUT OF MANAGING YOUR EQUIPMENT

CAT LINK telematics technology helps take the complexity out of managing your job sites – by gathering data generated by your

equipment, materials, and people – and serving it up to you in customizable formats.

CAT PRODUCT LINK™

Product Link™ collects data automatically and accurately

from your assets – any type and any brand. Information such as

location, hours, fuel usage, productivity, idle time, maintenance

alerts, diagnostic codes, and machine health can be viewed

online through web and mobile applications.

VISIONLINK®

Access information anytime, anywhere with VisionLink® – and use

it to make informed decisions that boost productivity, lower costs,

simplify maintenance, and improve safety and security on your

job site. With different subscription level options, your Cat dealer

can help you configure exactly what you need to connect your

fleet and manage your business, without paying for extras you

don’t want. Subscriptions are available with cellular or satellite

reporting or both.

COMMAND FOR DOZING

When dozers work in hazardous mining and earthmoving

applications, remote control dozing option helps improve safety

and efficiency. Operator controls the machine using a line-of-sight

console or a remote operator station. Deep integration with

machine systems enables smooth, precise control for maximum

efficiency and productivity.

D8T TRACK-TYPE TRACTOR 7

TOUGH ON THE JOB

EASY ON OPERATORS

MORE PRODUCTIVITY CONTROL

LESS EFFORT CLOSE AT HAND

Get optimal performance and fuel efficiency with less operator All speed and turning input is packaged in a single hand control

effort. Just set the desired ground speed and the transmission for easy operation. A detented thumbwheel puts on-the-fly

optimizes the dozer based on the demands of the job. No need ground speed changes at your fingertips – one bump for small

for operator to upshift/downshift. increments, roll all the way forward/back for large increments.

SMOOTH RIDE

An added gear between first and second and seamless lock-up

clutch engagement ensure smooth shifting.

8 D8T TRACK-TYPE TRACTOR

BIGGER

PAYLOAD

FASTER PAYDAY

MORE CAPACITY. FEWER PASSES. BETTER BALANCE.

Largest Semi-Universal blade in the size class, now offering 19% BETTER PERFORMANCE.

more capacity so you make fewer passes. Or choose Universal,

Tag-link design mounts blade closer to the machine for stability,

Angle or Specialty blades to best suit your applications.

balance, blade penetration and maneuverability. Optional Dual

Tilt positions the blade forward for better penetration, then tilts

back for carrying capacity and load control.

DURABILITY OUT FRONT

Blades are made from high tensile strength steel, with strong

box-section design, heavy moldboard construction and

hardened bolt-on cutting edges/end bits.

LOAD FASTER IN HARD GROUND

Patented Performance Cutting Edges for Semi-Universal blades load faster and increase blade payload by

up to 25%.* Designed for better penetration in hard/frozen ground and moderate rock, ripping may even be

reduced in some situations.

+ DIGS DEEPER TO AID BLADE CONTROL, LOAD RETENTION, TRACTION. REDUCES TRACK SLIP.

+ EQUAL WEAR LIFE/LIFE CYCLE COST* – NO MID-LIFE EDGE FLIP OR END BIT REPLACEMENT REQUIRED, REDUCING

MAINTENANCE TIME. BUILT-IN WEAR INDICATORS, EASY TO INSTALL, INTERCHANGEABLE WITH TRADITIONAL EDGES.

+ VERSATILITY – ON-PLANE CUTTING SYSTEM ALLOWS FINISH GRADING.

*Compared to standard cutting edges.

D8T TRACK-TYPE TRACTOR 9

ON TRACK TO LOWER COSTS

ELEVATE YOUR PERFORMANCE

ELEVATED SPROCKET HEAVY DUTY MORE WEAR LIFE

Caterpillar exclusive elevated sprocket DURABILITY New, optional Heavy Duty Extended Life

gives you an added edge in machine Undercarriage – Cat HDXL with DuraLink™

Standard Heavy Duty undercarriage with

balance, durability and service – features heavier bushings for up to 25%

the exclusive Cat Positive Pin Retention

ease. Reduces shock loads to drive more wear life, especially in high abrasion

system is well-suited to aggressive work

train components. Fully suspended conditions. Patented crowned DuraLink

like land clearing, side-slopes, or working

undercarriage provides more ground is hardened for longer life and reduced

in rocky or uneven terrain.

contact in tough terrain. scalloping, which improves ride after

50% link wear.

Comparisons to Positive Pin Retention undercarriage.

10 D8T TRACK-TYPE TRACTOR

WHEN

UPTIME

COUNTS

MAINTENANCE MADE EASY

Spend more time on the job and less time and money

on maintenance.

SAVE TIME, SAVE MONEY RUN CLEANER

Grouped service points and ground level service center for more High quality cartridge fuel filters are purpose-built to help keep

convenient regular maintenance. your fuel system clean and extend injector life. An integrated

drain valve makes service easier, and the non-metallic design

helps reduce waste.

LONGER SERVICE INTERVAL LOWER LIFETIME COST

Larger one-piece oil pan doubles engine oil service interval to Major structures and components are built to be rebuilt,

500 hours, saving you time and parts cost. providing lower lifetime operating costs.

MORE TIME SAVERS

Added features to save time and maintenance expense.

Programmable automatic reversing Optional Powered Bottom Guards Electronic fluid level verification

fan clears debris from the radiator reduce downtime for maintenance at startup for coolant, power train

package. Now standard to give you and enhance safety. Simply remove and engine oil means you can save

more value. bolts and use remote switch to open time, as well as reduce trips up

from the center for quick clean-out, and down from the cab to inspect

or from one side for full access. compartments.

D8T TRACK-TYPE TRACTOR 11

GREATER VISIBILITY EASY ON AND OFF

A rear vision camera and cylinder mounted Convenient steps, handles and guardrail help you get on

mirrors are available to enhance visibility and off the tractor with greater ease. Access lighting can

around the machine. be turned on from a ground level switch.

OPERATOR PROTECTION SAFETY REMINDER

Standard Operator Presence detection system allows Seat belt indicator reminds the operator to buckle

the machine to idle when the operator is not seated, up with a light/alarm, and registers a fault code

but locks out the power train and front implements through Product Link if the operator fails to fasten

to avoid unintentional movement. the seat belt.

12 D8T TRACK-TYPE TRACTOR

WASTE

HANDLER

PURPOSE-BUILT FOR PERFORMANCE

Build or close cells, push trash or spread cover – the D8T WH is

designed and built from the frame up to take on the challenges

of landfill work.

GUARD AGAINST DEBRIS CUSTOMIZED COMPONENTS

Specialized guarding, striker bars and seals help protect against Insulated Clean Emissions Module and thermal shields provide

impact and airborne debris. Bottom and Final Drive guarding the highest level of protection. Specialized air handling features

helps prevent damage from wrapping debris. help deliver cleaner air to the machine and to the cab.

MAKE SHORT WORK OF CLEANOUT READY TO WORK

Faster cleanout and enhanced safety with optional Powered Landfill blades and center-hole track shoes help optimize your

Bottom Guards. High debris cooling system with automatic waste handler for the job. Lights are mounted up and away from

reversing fan. main debris area for protection, while still shining plenty of light

on the work area.

D8T STOCKPILE ARRANGEMENT

Specialized guarding and seals help protect the machine from damage and debris build-up. Specialized track

shoes and woodchip and coal blades help optimize your machine.

+ HIGH DEBRIS COOLING SYSTEM WITH AUTOMATIC REVERSING FAN FOR EASY CLEANOUT.

+ THERMAL PROTECTION WITH INSULATED CLEAN EMISSIONS MODULE AND SHIELDS.

+ SCREENED PRECLEANER AND ROOF-MOUNTED FILTER HELP PROTECT AGAINST DUST AND DEBRIS.

D8T TRACK-TYPE TRACTOR 13

TECHNICAL SPECIFICATIONS

See cat.com for complete specifications.

ENGINE AIR CONDITIONING SYSTEM

Engine Model Cat C15 ACERT The air conditioning system on this machine contains the fluorinated

Emissions Tier 4 Final/Stage IV/ greenhouse gas refrigerant R134a (Global Warming Potential = 1430).

Korea Tier 4 Final The system contains 2.5 kg of refrigerant which has a CO2 equivalent

Net Power (Rated) – 1,900 rpm of 3.575 metric tonnes.

ISO 9249/SAE J1349 264 kW 354 hp OPERATING WEIGHT

ISO 9249/SAE J1349 (DIN) 359 hp Standard (single shank ripper) 39 750 kg 87,600 lb

Engine Power (Maximum) – 1,600 rpm LGP (drawbar) 37 750 kg 83,200 lb

ISO 14396 294 kW 394 hp Waste Handler 39 650 kg 87,400 lb

ISO 14396 (DIN) 400 hp LGP Waste Handler 41 850 kg 92,300 lb

Displacement 15.2 L 928 in³

• All nonroad Tier 4 Final, Stage IV, and Korea Tier 4 Final diesel engines are TRANSMISSION

required to use only Ultra Low Sulfur Diesel (ULSD) with 15 ppm (mg/kg) 1 Forward 3.5 km/h 2.2 mph

of sulfur or less, or up to B20 biodiesel blended with ULSD. B20 should 1.5 Forward 4.8 km/h 3.0 mph

meet ASTM D7467 specification (biodiesel blend stock should meet 2 Forward 6.6 km/h 4.1 mph

Cat biodiesel spec, ASTM D6751 or EN 14214). Cat DEO-ULS™ or oils that

3 Forward 11.3 km/h 7.0 mph

meet the Cat ECF-3, API CJ-4, and ACEA E9 specification are required.

Consult your OMM for further machine specific fuel recommendations. 1.5 Reverse 4.8 km/h 3.0 mph

• Diesel Exhaust Fluid (DEF) used in Cat Selective Catalytic Reduction 2.0 Reverse 6.4 km/h 4.0 mph

(SCR) systems must meet the requirements outlined in the International 2.5 Reverse 8.7 km/h 5.4 mph

Organization for Standardization (ISO) standard 22241. 3.0 Reverse 11.8 km/h 7.3 mph

Drawbar Pull

SERVICE REFILL CAPACITIES

1 Forward 659.2 kN 148,200 lbf

Fuel Tank 627 L 165 gal

1.5 Forward 490.8 kN 110,350 lbf

Diesel Exhaust Fluid Tank 24 L 6.3 gal

2 Forward 366.1 kN 82,300 lbf

Cooling System 86 L 22.7 gal

3 Forward 205.8 kN 46,250 lbf

Engine Crankcase* 38 L 10 gal

Power Train 155 L 41 gal

Final Drives (each) 12.5 L 3.3 gal

Roller Frames (each) 65 L 17.2 gal

Pivot Shaft Compartment 40 L 10.6 gal

Hydraulic Tank 75 L 19.8 gal

*With oil filter.

WIDTH

D8T BLADE CAPACITY OVER ENDBITS HEIGHT

Semi-Universal (SU)* 10.3 m³ | 13.4 yd³ 4042 mm | 13.3 ft 1747 mm | 5.7 ft

SU with Performance Cutting Edges 10.3 m³ | 13.4 yd³ 3962 mm | 13.0 ft 1747 mm | 5.7 ft

Universal with Rock Guard, Wear Plate 11.8 m³ | 15.4 yd³ 4265 mm | 14.0 ft 2012 mm | 6.6 ft

Angle Blade 5.2 m³ | 6.8 yd³ 5043 mm | 16.5 ft 1177 mm | 3.9 ft

LGP SU Landfill 22.2 m³ | 29.0 yd³ 4543 mm | 14.9 ft 2454 mm | 8.0 ft

*Also with rock guard/wear plate or push plate.

• Additional blades available. Please consult your Cat dealer for details.

DIMENSIONS STANDARD NON-SUSPENDED LGP

Width of Tractor (without trunnions/standard shoe width) 2693 mm | 106.0 in 2693 mm | 106.0 in 3302 mm | 130.0 in

Machine Height to ROPS** (to top of railing) 3566 mm | 140.4 in 3575 mm | 140.7 in 3566 mm | 140.4 in

Length of Track on Ground 3206 mm | 126.2 in 3258 mm | 128.3 in 3206 mm | 126.2 in

Length of Basic Tractor (tag link trunnion to tip of rear grouser)* 4647 mm | 183.0 in 4647 mm | 183.0 in 4647 mm | 183.0 in

Ground Pressure 89.6 kPa | 13.0 psi 89.6 kPa | 13.0 psi 53.3 kPa | 7.7 psi

Ground Clearance 613 mm | 24.1 in 606 mm | 23.8 in 613 mm | 24.1 in

*Add the following measurements for attachments: Ripper (single shank) 1519 mm/59.8 in; Ripper (multi-shank) 1613 mm/63.5 in; Drawbar 406 mm/16.0 in;

SU Blade 1844 mm/72.6 in; U Blade 2241 mm/88.2 in; A Blade (not angled) 2027 mm/79.8 in; A Blade (angled 25 degrees) 3068 mm/120.8 in.

**When Cat GRADE Control 3D antennas are installed, overall machine height increases by approximately 82 mm/3.2 in.

14 D8T TRACK-TYPE TRACTOR

STANDARD & OPTIONAL EQUIPMENT

Standard and optional equipment may vary. Consult your Cat dealer for details.

POWER TRAIN STANDARD OPTIONAL UNDERCARRIAGE STANDARD OPTIONAL

Cat C15 ACERT diesel engine, electronic Gauge arrangements – Standard or LGP

unit injection

Positive Pin Retention (PPR) undercarriage

Engine mounted aftertreatment to meet

610 mm (24 in) PPR moderate service shoes*

Tier 4 Final/Stage IV/Korea Tier 4 Final

emission standards Heavy Duty, Extended Life (HDXL)

undercarriage

Brakes, Extreme Service

*For optional track shoe offerings, please refer to chart in

Drains, ecology, power train

Technical Specifications brochure on cat.com.

Engine, thermal shield

HYDRAULICS STANDARD OPTIONAL

Fan, suction, auto reversing

Four planet, double-reduction planetary Hydraulics, electronically controlled,

final drives load-sensing

Full autoshift Hydraulics, independent steering

and work tool pumps

High performance single plane

cooling system ELECTRICAL STANDARD OPTIONAL

Oil change system, high speed Converter, 24V to 12V

Radiator, 6.35 fins per inch, debris Ground level service center with hour meter

Torque divider with lock-up clutch Lights – premium light package

Transmission, electronically-controlled Lights – six-light package

powershift

PUSH ARMS STANDARD OPTIONAL

CAT CONNECT TECHNOLOGY STANDARD OPTIONAL

Single tilt

Attachment Ready Option (ARO)

Dual tilt

AutoCarry/AutoRip, single tilt or dual tilt

Cat GRADE with 3D GUARDS STANDARD OPTIONAL

Cat GRADE with Slope Assist Hinged bottom guards

Cat Slope Indicate Powered bottom guards

COMMAND for Dozing Ready Guard, fan debris

Product Link – Cellular or Dual Mode Guard, fast fuel

Guard, fuel tank

OPERATOR ENVIRONMENT STANDARD OPTIONAL

Rear screen

Access/egress lighting with shutdown timer

Sweeps group

Armrests, adjustable

Radio, AM/FM, Bluetooth® REAR ATTACHMENTS STANDARD OPTIONAL

ROPS mounted air conditioner Ripper

Seat, cloth, air-suspension Counterweight, rear

Seat, cloth, heated or heated/ventilated Drawbar, rigid

Touchscreen operator interface Winch

Visibility arrangement – mirrors

or single camera

Not all features are available in all regions. Please check with your local Cat dealer for specific offering availability in your area.

For additional information, refer to the Technical Specifications brochure available at www.cat.com or your Cat dealer.

D8T TRACK-TYPE TRACTOR 15

For more complete information on Cat products, dealer services and industry solutions, visit us on the web at www.cat.com AEXQ2367

Build Number: 21A

© 2018 Caterpillar. All Rights Reserved. (Aus-NZ, Eur,

N Am, Korea)

VisionLink is a trademark of Trimble Navigation Limited, registered in the United States and in other countries.

Materials and specifications are subject to change without notice. Featured machines in photos may include additional

equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, BUILT FOR IT, their respective logos, “Caterpillar Yellow,” the “Power Edge” trade dress as well as

corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

www.cat.com www.caterpillar.com

You might also like

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Track-Type Tractor: Net Power (2,200 RPM)Document16 pagesTrack-Type Tractor: Net Power (2,200 RPM)xaicunifierakNo ratings yet

- Track-Type Tractor: 197 KW (265 HP) 268 MHP 29 776 KG (65,644 LB)Document16 pagesTrack-Type Tractor: 197 KW (265 HP) 268 MHP 29 776 KG (65,644 LB)seniölene kimisevecemNo ratings yet

- Track-Type Tractor: Engine WeightsDocument16 pagesTrack-Type Tractor: Engine WeightseddyfredyNo ratings yet

- Track-Type Tractor: Net Power (1,700 RPM)Document16 pagesTrack-Type Tractor: Net Power (1,700 RPM)Agung ArdhanaNo ratings yet

- Track-Type Tractor: Engine WeightDocument20 pagesTrack-Type Tractor: Engine WeightFIGUEIRAS & LOUREIRO,Lda Sociedade de construçõesNo ratings yet

- Cat D1Document16 pagesCat D1Mohammad Fikri Aditya RamadhanNo ratings yet

- Track-Type Tractor: Engine Engine (Continued)Document24 pagesTrack-Type Tractor: Engine Engine (Continued)eddyfredy100% (1)

- Track-Type Tractor: Engine Engine (Continued)Document24 pagesTrack-Type Tractor: Engine Engine (Continued)Anas MaksoudNo ratings yet

- Wheel ExcavatorDocument24 pagesWheel ExcavatorForomaquinasNo ratings yet

- Wheel ExcavatorDocument24 pagesWheel ExcavatorForomaquinas100% (1)

- Wheel Loader: Engine Maximum Power Operating WeightDocument16 pagesWheel Loader: Engine Maximum Power Operating WeightBitbitterNo ratings yet

- Track-Type Tractor: Engine Engine (Continued)Document20 pagesTrack-Type Tractor: Engine Engine (Continued)Jose Luis Garcia BlancoNo ratings yet

- CM20200806 Eccff 7f5a8Document8 pagesCM20200806 Eccff 7f5a8Maulana IqbalNo ratings yet

- 1421493914cat M315DDocument24 pages1421493914cat M315DSoban ReddyNo ratings yet

- Caterpillar M313DDocument24 pagesCaterpillar M313DForomaquinas100% (1)

- Cat 982 BrochureDocument16 pagesCat 982 BrochureAMNo ratings yet

- CAT SpecalogDocument36 pagesCAT SpecalogBen GottmanNo ratings yet

- AEXQ2463 00 - Next Gen - D6 XE Key Features English 1Document4 pagesAEXQ2463 00 - Next Gen - D6 XE Key Features English 1Christopher Jesus Reàtegui OlivaresNo ratings yet

- Caterpillar 390F L Hydraulic Excavator (2017)Document36 pagesCaterpillar 390F L Hydraulic Excavator (2017)Alexis Bustios100% (1)

- D6T EspecificacionesDocument24 pagesD6T EspecificacionesDaniel BazánNo ratings yet

- Cat 390 SpecDocument36 pagesCat 390 SpecblawrenceNo ratings yet

- Cat D6T SpecsDocument24 pagesCat D6T Specsmogahed rashidNo ratings yet

- M318DDocument32 pagesM318DJulio Cesar Jauregui ApazaNo ratings yet

- CM20200806 Eccff 7f5a8Document4 pagesCM20200806 Eccff 7f5a8Yoyoo SusantoNo ratings yet

- Wheeled Excavator: Engine Weights Bucket Specifications Working RangesDocument32 pagesWheeled Excavator: Engine Weights Bucket Specifications Working RangesSEBASTIAN SUAREZNo ratings yet

- Cragadora 966 GIIDocument16 pagesCragadora 966 GIIelizaldetelmoNo ratings yet

- Guia 432 e CaterpillarDocument20 pagesGuia 432 e CaterpillarMaxNo ratings yet

- Wheel Loader Aggregate Handler: Reliability Ease of OperationDocument8 pagesWheel Loader Aggregate Handler: Reliability Ease of Operationعباس محمدNo ratings yet

- Cat 980L: Wheel LoaderDocument2 pagesCat 980L: Wheel LoaderEstrella AnguianoNo ratings yet

- Hydraulic Excavator: Engine DriveDocument36 pagesHydraulic Excavator: Engine DriveKishawn FoxNo ratings yet

- 938 K PDFDocument36 pages938 K PDFJuanNo ratings yet

- Cat 32606Document2 pagesCat 32606axon-techNo ratings yet

- Caterpillar d8tDocument38 pagesCaterpillar d8tRogelio Augusto Rodriguez SanchezNo ratings yet

- 329F Aehq7270-00Document36 pages329F Aehq7270-00kiddrix gamerNo ratings yet

- Excavadora M316DDocument36 pagesExcavadora M316DFelipe HernándezNo ratings yet

- Brochure 291 1000000460Document32 pagesBrochure 291 1000000460don cargaNo ratings yet

- Folder 924KDocument4 pagesFolder 924KDelgado FelipeNo ratings yet

- 938g PDFDocument24 pages938g PDFLuis Fernando Vasquez Ramos100% (1)

- 326F Aehq7271-00Document36 pages326F Aehq7271-00kiddrix gamerNo ratings yet

- Small Specalog For Cat D3 Track-Type TractorDocument4 pagesSmall Specalog For Cat D3 Track-Type Tractorlaptop.bmsNo ratings yet

- 330D Texr0431Document24 pages330D Texr0431suwarjitechnic100% (1)

- Excavator 470glc G Series Dkax470gDocument20 pagesExcavator 470glc G Series Dkax470gNelson Andrade VelasquezNo ratings yet

- 794 AC R2900G: Underground LoaderDocument24 pages794 AC R2900G: Underground Loaderdiego.sud25No ratings yet

- 212cat mh3022Document36 pages212cat mh3022CatalinNo ratings yet

- Heel Oader: SpecificationsDocument4 pagesHeel Oader: Specificationstohid 23No ratings yet

- 432e Hehb3125Document24 pages432e Hehb3125Maklin LimaNo ratings yet

- Cargador 966 Nex GenDocument16 pagesCargador 966 Nex GenmiguelNo ratings yet

- Raymond End Rider Model 8410 Sell SheetDocument2 pagesRaymond End Rider Model 8410 Sell Sheettimmybuds23No ratings yet

- Heel Oader: SpecificationsDocument4 pagesHeel Oader: SpecificationsM ElnagarNo ratings yet

- Dozer D375A 8 Brochure English EN-D375A-8BR01-0722-V12Document20 pagesDozer D375A 8 Brochure English EN-D375A-8BR01-0722-V12marionabil998No ratings yet

- D85-18 WH PDFDocument20 pagesD85-18 WH PDFSBNo ratings yet

- 430E/ 430E IT: Backhoe LoaderDocument32 pages430E/ 430E IT: Backhoe Loadercameron_froeseNo ratings yet

- Specalogue PDFDocument24 pagesSpecalogue PDFEhabNo ratings yet

- Retro Excavadora - 430E-430EITDocument32 pagesRetro Excavadora - 430E-430EITAndrés lyricsNo ratings yet

- d6n BulldozerDocument24 pagesd6n BulldozerElías Cesar AcuñaNo ratings yet

- IT14GDocument20 pagesIT14GBilal VURALNo ratings yet

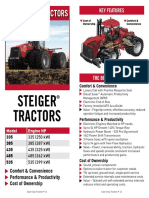

- Steiger TractorsDocument3 pagesSteiger Tractorsahmed0% (1)

- 323-07 2022 - BrochureDocument16 pages323-07 2022 - BrochureDuyNo ratings yet

- Hydraulic Excavator: Engine Power Operating Weight - North America Operating Weight - Europe/Australia and New ZealandDocument16 pagesHydraulic Excavator: Engine Power Operating Weight - North America Operating Weight - Europe/Australia and New Zealandnemi90No ratings yet

- Advanced Ignition Systems: Technical Possibilities and LimitationsDocument11 pagesAdvanced Ignition Systems: Technical Possibilities and LimitationsAnas MaksoudNo ratings yet

- Automobile Driver Fingerprinting: Miro Enev, Alex Takakuwa, Karl Koscher, and Tadayoshi KohnoDocument17 pagesAutomobile Driver Fingerprinting: Miro Enev, Alex Takakuwa, Karl Koscher, and Tadayoshi KohnoAnas MaksoudNo ratings yet

- 2018E-Challenger Charger-Drive Modes OM SU-1stDocument81 pages2018E-Challenger Charger-Drive Modes OM SU-1stAnas MaksoudNo ratings yet

- U.S. EPA Tier 4 Final Engine: Crawler DDocument20 pagesU.S. EPA Tier 4 Final Engine: Crawler DAnas MaksoudNo ratings yet

- Track-Type Tractor: Engine Engine (Continued)Document24 pagesTrack-Type Tractor: Engine Engine (Continued)Anas MaksoudNo ratings yet

- Dozer: Operating Weight Engine PowerDocument20 pagesDozer: Operating Weight Engine PowerAnas Maksoud100% (1)

- Volvo c90Document3 pagesVolvo c90Anas MaksoudNo ratings yet

- Research Contract: Reservoir Safety Advice: Rev 01 May 2006 Job Number 0022203/ 206Document11 pagesResearch Contract: Reservoir Safety Advice: Rev 01 May 2006 Job Number 0022203/ 206박래건No ratings yet

- TM Current RatingsDocument6 pagesTM Current RatingsGopi NathNo ratings yet

- SSR 2012 PDFDocument550 pagesSSR 2012 PDFArshad Hussain100% (1)

- Road Accidents in India: Dinesh MOHANDocument5 pagesRoad Accidents in India: Dinesh MOHANsom_dsNo ratings yet

- PMDG 777 Tutorial 1Document128 pagesPMDG 777 Tutorial 1gigipresh100% (1)

- SERVICE MANUAL. Permobil C500. Power WheelchairDocument68 pagesSERVICE MANUAL. Permobil C500. Power Wheelchairwilson de jesus mirandaNo ratings yet

- Discover EasytronicDocument77 pagesDiscover EasytronicMohamed Mohamed100% (3)

- 8N Hydraulic Lift - How To Repair Economically: by Tim DaleyDocument32 pages8N Hydraulic Lift - How To Repair Economically: by Tim DaleyJeffrey FarmerNo ratings yet

- Internal Combustion Engines: Turbo ChargersDocument15 pagesInternal Combustion Engines: Turbo ChargersMuhammad SaqibNo ratings yet

- L136 Instalation Manual - 65.99893-8001CDocument91 pagesL136 Instalation Manual - 65.99893-8001Ccupid75100% (1)

- FinCon Business PlanDocument21 pagesFinCon Business PlanAden InsangNo ratings yet

- Codified Ordinance 4373 94Document297 pagesCodified Ordinance 4373 94bassarrabsNo ratings yet

- Captura de Droguri La Bordul Navei MSC GayaneDocument3 pagesCaptura de Droguri La Bordul Navei MSC Gayanemihai_mitza_2No ratings yet

- Importing With SAMSON Eco Hoppers: Dry Bulk MaterialsDocument3 pagesImporting With SAMSON Eco Hoppers: Dry Bulk MaterialsAtul HingnekarNo ratings yet

- Bar Chart of Oh Unit #3 BoilerDocument3 pagesBar Chart of Oh Unit #3 BoilerVikasShuklaNo ratings yet

- BIOBASE Deep Freezer BDF-40V268 '362 User Manual 202008Document18 pagesBIOBASE Deep Freezer BDF-40V268 '362 User Manual 202008Eliana Arroyo MedinaNo ratings yet

- Power Point Aerodrome Traffic CircuitDocument14 pagesPower Point Aerodrome Traffic Circuitweed cokeNo ratings yet

- Jotun Paints-Onboard Maintenance Manual-Rig KrathongDocument48 pagesJotun Paints-Onboard Maintenance Manual-Rig Krathongmehanson francisNo ratings yet

- Abb GisDocument106 pagesAbb GisttyNo ratings yet

- RT1120 - Parts (Rev - Set2009)Document223 pagesRT1120 - Parts (Rev - Set2009)frank0% (1)

- Safety Operator Training HD785-20120910Document21 pagesSafety Operator Training HD785-20120910mohan100% (2)

- Maglev PDFDocument56 pagesMaglev PDFOğulcan AtılkanNo ratings yet

- Qc-Sop-0 - Drilling of PoleDocument7 pagesQc-Sop-0 - Drilling of PoleAmeerHamzaWarraichNo ratings yet

- Inmovilizador Ford PDFDocument13 pagesInmovilizador Ford PDFluis antonio de jesudNo ratings yet

- Draft Awb - Leistung - Asunción PDFDocument1 pageDraft Awb - Leistung - Asunción PDFLu CasasNo ratings yet

- LTA - ANNUAL - REPORT - 2016-2017 SingaporeDocument49 pagesLTA - ANNUAL - REPORT - 2016-2017 SingaporeKirana PitalokaNo ratings yet

- Iq-Bsr-Bas: Express WorldwideDocument2 pagesIq-Bsr-Bas: Express WorldwideKhurram ShahzadNo ratings yet

- Onsigner Per-Kta Etkt - Ferrum AustralisDocument15 pagesOnsigner Per-Kta Etkt - Ferrum AustralisTB AhmedNo ratings yet

- Gp2 User Manual 2008 v10Document91 pagesGp2 User Manual 2008 v10octavioNo ratings yet

- 89257663-A793224-,b780938-,d203506-,e839440-,w116158-,ckd936514 - FM (4) (En)Document316 pages89257663-A793224-,b780938-,d203506-,e839440-,w116158-,ckd936514 - FM (4) (En)Игорь КрюковNo ratings yet