Professional Documents

Culture Documents

Epicyclic Gearbox Vibration PDF

Uploaded by

Hüseyin SuzukOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Epicyclic Gearbox Vibration PDF

Uploaded by

Hüseyin SuzukCopyright:

Available Formats

HUMS2003 CD-ROM

ANALYSIS OF EPICYCLIC GEARBOX VIBRATION

David Forrester

Air Vehicles Division, DSTO

David Blunt

Air Vehicles Division, DSTO

ABSTRACT

Many aircraft transmissions use epicyclic gear trains, particularly helicopter main rotor gearboxes and

propeller reduction gearboxes. As these gears form a non-redundant critical part of the drive to the main rotor,

or propeller, it is important to have advanced techniques and tools to assess the condition of these

components. One such tool is vibration analysis. However, epicyclic gear train vibrations are difficult to

analyse. Not only are there multiple planet gears producing similar vibrations, but there are multiple and

time-varying vibration transmission paths from the gear mesh points to any vibration transducer mounted on

the gearbox housing. These factors combine to reduce the sensitivity of conventional fault detection algorithms

when they are applied to epicyclic gears. This paper outlines the DSTO-developed techniques for analysing

epicyclic gear train vibration, based on an algorithm for separating the meshing vibrations from each planet.

The results of applying these techniques to seeded fault tests, using DSTO vibration data, are shown to

significantly improve the detection of localised gear faults.

INTRODUCTION In this paper, an alternative method for performing signal

averaging for epicyclic gearbox components is presented which

Synchronous signal averaging has proved to be the most useful overcomes these problems. A mathematical derivation of the

vibration analysis tool for detecting faults in gears. However, method is provided which shows that the averaging can be

there has been a problem in the past in applying the technique to performed with no loss of information by proportionally dividing

epicyclic gearboxes. An epicyclic gearbox has a number of planet the vibration data amongst the individual gear meshes. Practical

gears which all mesh with the sun and ring gears. The problems examples are presented which show that the method has far

encountered when attempting to perform a signal average for superior performance than conventional signal averaging.

components within an epicyclic gearbox are twofold. Firstly, there

are multiple tooth contacts, with each planet being simultaneously The techniques presented here are the subject of Australian Patent

in mesh with both the sun and ring gears, and secondly, the axis 40638/95 [3], United States Patent 6,298,725 [4], and United States

of the planets move with respect to both the sun and ring gears. Provisional Patent [5].

An earlier method of performing selective signal averaging on EPICYCLIC GEARBOX VIBRATION

epicyclic gearboxes was developed and tested at the Defence

Science and Technology Organisation (DSTO) [1,2], and proved Epicyclic gearboxes are typically used in applications requiring a

successful in detecting faults on individual planet gears. However, large reduction in speed (greater than three to one) at high loads,

this method was tedious to implement, required an excessively such as the final reduction in the main rotor gearbox of a

long time to perform even a small number of averages and helicopter. A typical epicyclic reduction gearbox has three or more

required the selective slicing up of the time signal which proved planet gears each meshing with a sun and ring gear, as shown in

to introduce discontinuities in the signal average. Figure 1. Drive is provided via the sun gear, the ring gear is

Copyright Commonwealth of Australia 2003

HUMS 2003 Conference 510 - 1

HUMS2003 CD-ROM

stationary and the axes of the planet gears are connected to a mounted on the ring gear of an epicyclic gear train will be the sum

carrier which rotates in relation to both the sun gear and the ring of the individual planet gear vibrations multiplied by the planet

gear. The planet carrier provides the output of the epicyclic gear pass modulations,

train. P

Vibration

x (t ) =

∑α

p =1

p (t )v p (t ) (4)

transducer

where αp(t) is the amplitude modulation due to planet p, and vp(t)

is the tooth meshing vibration for planet p.

The amplitude modulation function αp(t) (planet pass modulation)

will have the same form for all planets, differing only by a time

delay, and will repeat with the planet carrier rotation period 1/fc

∞

∑

p 2πmp

α p (t ) = a t + = A(m ) cos 2πmf c t + (5)

f c P P

m= 0

where a(t) is the planet pass modulation function and A(m) is its

Fourier Transform. Equation (4) can be rewritten in terms of the

common planet pass modulation function giving

Figure 1: Typical epicyclic gear train. P

Tooth meshing frequencies and relative rotations

x(t ) =

∑

p =1

a t +

p

v p (t ) .

f c P

(6)

Where fc , fp and fs are the rotational frequencies of the planet

carrier, planet and sun gear respectively, and there are Nr, Np and PLANET SEPARATION TECHNIQUE

Ns teeth on the ring, planet and sun gears respectively, the

meshing frequency of the epicyclic fm is given by: An alternate method of extracting representative signal averages

( )

f m = Nr fc = N p f p + fc = N s ( f s − f c ) (1) for each planet is to incorporate a selective (continuous) time filter

into the signal averaging process. The time filter proportionally

divides the overall vibration signal into the estimated

The relative frequencies f p + fc of the planet to the carrier and fs - fc

of the sun to the carrier are: contributions from each planet.

(

f p + fc = f m N p = fc Nr N p ) (2)

For each planet signal average, the time window, b(t), is centred at

f s − f c = f m N s = f c (N r N s ) (3) the point at which the planet is adjacent to the transducer. Signal

averaging of the filtered vibration signal is performed with a

Planet pass modulation period equal to the relative planet rotation, 1/(fp+fc), giving, where

N is the number of averages,

N −1

∑

The only place in which it is normally feasible to locate a

z p (t ) =

1 p l l

transducer to monitor the vibration of an epicyclic gear train is on b t + + x t + (7)

the outside of the ring gear. This gives rise to planet pass N f P f + f f + f

l =0

c p c p c

modulation due to the relative motion of the planet gears to the

transducer location.

With careful selection of the time window characteristics and the

As each planet approaches the location of the transducer, an signal averaging parameters, the separation can be performed

increase in the amplitude of the vibration will be seen, reaching a with minimum ‘leakage’ of vibration from other planets, no loss of

peak when the planet is adjacent to the transducer then reducing vibration data, and no distortion of the signal average.

as the planet passes and moves away from the transducer. For an

epicyclic gear train with P planets, this will occur P times per Properties and restrictions

revolution of the planet carrier, resulting in an apparent

It is shown in Appendix A that where:

amplitude modulation of the signal at frequency Pfc.

a) the separation time window is real valued, even and

Expected epicyclic gear train vibration signal periodic with the planet carrier rotation, 1/fc,

b) the signal averaging is performed over the relative

The expected planet gear vibration signal recorded at a transducer planet rotation period, 1/(fp+fc), and the number of

510 - 2 HUMS 2003 Conference

HUMS2003 CD-ROM

averages is an integer multiple of the number of teeth on SUN GEAR TECHNIQUE

the ring gear, Nr, and

c) the time window, b(t), is a Fourier series with less than P The sun gear technique computes ‘separated’ averages of the sun

terms, gear vibration ‘seen’ through each planet, which are then phase

the time filtered signal average for planet p (7) reduces to shifted so that the beginning of each average starts with the same

P sun gear tooth in mesh with each planet, and recombined

z p (t ) =

∑k =1

v k (t )c ( p − k ) . (8)

(averaged) to produce a modified sun gear average.

Ideally, with complete separation of the vibration from each

The separation function, c(n), is defined by both the applied time planet, the technique produces a modified average that represents

window, b(t), and the planet pass modulation function, a(t), the average meshing behaviour of the sun gear seen through a

P −1 single typical, or average, planet. In contrast, a conventional sun

c(n ) =

1

B(0 )A(0) +

2

∑m =0

2πmn

B(m)A(m) cos

P

(9) gear average represents the average meshing behaviour of the sun

gear seen through all the planets simultaneously (with the

accompanying summation and cancellation of certain vibration

where the applied time window is components).

P −1

b(t ) =

∑m =0

B (m ) cos(2πmf c t ) . (10) The procedure for computing the modified sun gear average is:

a) Compute the separated sun gear averages. This is the

same as computing the separated planet gear averages,

except that the averaging period is that of the sun gear

Note that the summation of the time filtered signal averages is instead of the planet gear. The same separation window

equal to the sum of the mean planet vibration signals multiplied function is used (i.e., the window function is still based

by a constant on the planet-carrier position).

P P P P

∑ z p (t ) = ∑ ∑

vk (t ) ∑ v (t ) .

c( p − k ) = PB (0 )A(0 )

b) Phase shift the separated sun gear averages so that the

k mesh points align. For example, in a three planet gear

p =1 k =1 p =1 k =1 train, Planet 2 must be shifted +120°, and Planet 3 must

That is, the separation process is performed using all of the be shifted -120° (or +240°) to align both with Planet 1, as

available vibration data. shown in Figure 2. Note that the sun gear meshes with

the planets in the reverse order that they pass the

Separation window functions transducer on the ring gear.

c) Combine (average) the aligned averages.

If the planet pass modulation was known exactly, complete

separation could be made by setting the time window coefficients, The theoretical development for this is shown in Appendix A.

B(0) = 1/A(0) and B(m≠0) = 2/A(m), giving c(0) = P and c(n≠0) = 0.

However, this is rarely practical in operational gearboxes.

+120° Vibration

transducer

Two separation windows which have been found to perform well

are a cosine window raised to the power of P-1 [3], 1

b(t ) = (1 + cos (2πf c t ))P −1 , (11)

which is a tapered function with maximum value when the planet

is adjacent to the transducer and a value of zero when the planet is

furthest from the transducer, and a window with B(0) = ½ and 2 -120°

B(m ≠0) = 1,

P −1

b(t ) =

1

2

+

∑ m =1

cos (2πmf c t ) , (12)

3

which relies upon the planet pass modulation itself to provide the

separation. That is, where the time window in (12) is used, the

separation function, c(n), becomes

P −1 Figure 2: Phase shifts for separated sun gear averages.

c(n ) =

∑m =0

2πmn

A(m ) cos

P

.

HUMS 2003 Conference 510 - 3

HUMS2003 CD-ROM

IMPLEMENTATION signal enhancement [6] on the separated signal averages for the

faulty planet using: (a) the planet separation technique with the

Angle domain time window defined in (11), and (b) the conventional signal

averaging technique. For this example, the analysis time is 75

In the preceding description of the technique, it is assumed that seconds (10 x 32 revolutions of the planet carrier). The kurtosis of

the speed of the epicyclic gearbox is constant. In practice, even for the residual signal is used as a measure of local variation in the

a nominally constant speed machine, this is not always the case. tooth meshing behaviour. The kurtosis is defined as the fourth

To allow for speed fluctuations all analysis is done in the 'angle' statistical moment normalised by the square of the variance. The

domain rather than the time domain; this simply involves the residual signal is obtained by removing all the known regular

substitution of a angular reference for the time based variable, t. frequency components such as the mesh harmonics. A kurtosis

value greater than 4.5 is considered to be a clear indication of a

In practice, the conversion from the time domain to the angle local defect and a value below 3.5 indicates a ‘good’ gear.

domain is done by synchronising the vibration signal sampling

with an angular reference on one of the shafts of the gearbox. The

synchronisation can be done either using phase-locked frequency

multipliers or by digital re-sampling [4, 5].

Planet carrier positional reference

For the calculation of the time windowed signal averages (7) a

planet carrier positional reference is required to set the starting

time (t = 0) to a point at which one of the planets (p = P) is

adjacent to the transducer. The positional reference can be

obtained either by using a shaft encoder/tacho on the planet

carrier (usually the output of the gearbox) or by software

synchronisation to the planet pass modulation signal.

In the case where a carrier positional reference is not directly

available, the planet carrier position can be estimated by Figure 3: Three-planet epicyclic gearbox.

examining the ‘planet pass modulation.’ This involves performing

a signal average of planet carrier (ring gear) vibration. As each 0.10

planet passes the transducer location the vibration level increases,

giving an amplitude modulation of the vibration signal.

Demodulation of the ring gear signal average about the gear mesh

Acceleration (g)

vibration [8] is used to determine the modulation peaks as each

planet gear passes the transducer location. The point with the

maximum amplitude in the demodulated signal average is

selected as the zero point for the planet carrier positional

reference.

-0.10

EXAMPLES 0 360

Rotation (degrees)

(a) Planet separation technique – Planet Gear 2 (Kurtosis = 5.9)

The following examples are from a recorded vibration signal of

0.10

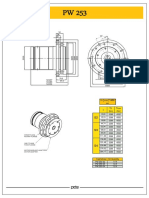

the epicyclic gearbox shown in Figure 3 with three planet gears

each having 32 teeth, a sun gear with 28 teeth, and a ring gear

with 95 teeth.

Acceleration (g)

Planet Gear

A small fault was implanted on one of the planet gears [2].

Approximately 0.05 mm was ground from the face of one of the

teeth to form a narrow flat surface at the pitch line. The gearbox

was reassembled so that when under load the damaged tooth face -0.10

0 360

meshed with the ring gear. Rotation (degrees)

(b) Conventional signal averaging technique (Kurtosis = 3.1)

Figure 4 shows the results obtained by performing a residual Figure 4: Planet gear fault.

510 - 4 HUMS 2003 Conference

HUMS2003 CD-ROM

The planet separation technique gives a kurtosis of 5.9, clearly averaging technique only gives a kurtosis of 4.9. It is also possible

indicating the presence of the fault. Over the same analysis period to see that the impacts of the fault with each of the planet gears

the conventional signal averaging technique (kurtosis=3.1) gives are distributed at intervals of 120° in the conventional average, but

no indication of the fault. they are aligned in the modified sun gear average, as shown in the

figure.

Sun Gear

CONCLUSION

A small fault was implanted on the sun gear [2]. Approximately

0.05 mm was ground from the face of one of the teeth to form a Techniques for analysing the individual planet and sun gear

narrow flat surface at the pitch line. The gearbox was reassembled vibration signatures in a epicyclic gearbox have been developed. It

so that when under load the damaged tooth face meshed with the has been shown that these techniques significantly improve the

planet gears. detection (by up to 90% using the residual kurtosis method) of a

single tooth fault in a planet or sun gear, and consequently have

Figure 5 shows the results obtained by performing a residual considerable advantages over conventional synchronous signal

signal enhancement [6] on the signal averages for the faulty sun averaging for condition monitoring of aircraft transmission

gear using: (a) the sun gear technique with the time window systems incorporating epicyclic gear trains.

defined in (11), and (b) the conventional signal averaging

technique. For this example, the analysis time is also 75 seconds REFERENCES

(10 x 32 revolutions of the planet carrier).

[1] Howard, I.M., “An Investigation of Vibration Signal

0.40 Averaging of Individual Components in an Epicyclic

1, 2, 3 Gearbox”, Propulsion Report 185, Department of Defence,

Aeronautical Research Laboratory, March 1991.

[2] McFadden, P.D. and Howard, I.M., “The Detection of Seeded

Acceleration (g)

Faults in an Epicyclic Gearbox by Signal Averaging of the

Vibration”, Propulsion Report 183, Department of Defence,

Aeronautical Research Laboratory, October 1990.

[3] Forrester, B.D., “Method and Apparatus for Performing

Selective Signal Averaging”, Australian Patent 672166

(40638/95).

-0.40

0 360 [4] Forrester, B.D., “A Method for the Separation of Epicyclic

Rotation (degrees)

Planet Gear Vibration Signatures”, United States Patent

(a) Sun gear technique (Kurtosis = 7.9)

6,298,725, October 2001.

0.40 3

[5] Blunt, D.M., “Synchronous Averaging of Epicyclic Sun Gear

1 Vibration”, United States Provisional Patent Application, 24

2

January 2003.

Acceleration (g)

[6] Forrester, B.D., “Advanced Vibration Analysis Techniques for

Fault Detection and Diagnosis in Geared Transmission

Systems”, PhD Thesis, Swinburne University of Technology,

February 1996.

[7] McFadden, P.D., “A Model for the Extraction of Periodic

Waveforms by Time Domain Averaging”, Aero Propulsion

-0.40

0 360

Technical Memorandum 435, Department of Defence,

Rotation (degrees) Aeronautical Research Laboratory, March 1986.

(b) Conventional signal averaging technique (Kurtosis = 4.9) [8] McFadden, P.D., “Examination of a Technique for the Early

Figure 5: Sun gear fault. Detection of Failure in Gears by Signal Processing of the Time

Domain Average of the Meshing Vibration”, Mechanical

The sun gear technique gives a kurtosis of 7.9, very clearly Systems and Signal Processing, Vol. 1(2), pp. 173-183, 1987.

indicating the presence of the fault, while the conventional

APPENDIX A: Theoretical Development

Planet Separation

Assuming that all vibration which is not synchronous with the relative planet rotation will tend toward zero with the signal averaging

HUMS 2003 Conference 510 - 5

HUMS2003 CD-ROM

process [6, 7], the time filtered signal average (7) using the time window, b(t), taken over N periods of the relative planet rotation, 1/(fp+fc),

can be expressed as

N −1

z p (t ) = ∑ b t +

1 p l x t + l

+

N l =0 f c P f p + f c f p + f c

N −1

lN p

P lN p

∑ b t + ∑

1 p k l

= + v k t +

a t + + (A.1)

f p + f c

N

l =0 fc P fc N r k =1

f c P fc N r

P

1 N −1 lN p lN p

∑

vk (t ) ∑

p k

= b t + + a t + +

k =1 N l =0 f c P f c N r f c P f c N r

where vk (t ) is the mean vibration for planet k, which repeats with period, 1/(fp+fc), and a(t) is the planet pass modulation (5).

Condition a): b(t) is real valued, even and periodic in 1/fc

Under the condition that b(t) is real valued, even and periodic in 1/fc,

∞

b(t ) = ∑ B(m)cos(2πmf t )

m =0

c

, (A.2)

and the time filtered signal average becomes

P

z p (t ) = ∑ v (t )Ψ( p, k , t )

k =1

k (A.3)

where

∞ ∞ N −1 cos (

2π (m + n ) f c t +

2π ( mp + nk )

+

2πl ( m + n )N p

)+

Ψ ( p, k , t ) = ∑∑ B(m )A(n ) ∑

P Nr

( )

1

m= 0 n = 0

2N

l = 0 cos 2π (m − n ) f c t +

2π ( mp − nk )

+

2πl (m − n ) N p

P Nr

( cos 2π (m + n ) f t +

c

2π ( mp

P

+ nk )

cos ) (

2πl ( m + n ) N p

Nr

) −

∞ ∞ (

N −1 sin 2π (m + n ) f t +

2π (mp + nk )

sin ) (

2πl (m + n ) N p

)+

∑∑ B(m )A(n ) ∑

c P Nr

=

( )

1 (A.4)

m = 0 n =0

2N

(

l = 0 cos 2π (m − n ) f c t +

2π (mp − nk )

P

cos )

2πl ( m − n ) N p

Nr

−

(

sin 2π (m − n ) f c t +

2π ( mp − nk )

P

sin ) (

2πl (m − n )N p

Nr

)

Condition b): the number of averages is an integer multiple of Nr

If the number of averages, N, is an integer multiple of the number of teeth on the ring gear, Nr, then, since

∑ cos ( ) = 1, n = −m

iN r −1

1 2πl ( m + n ) N p

Nr

iN r l =0

, (A.5)

∑ sin ( ) = 0, n ≠ −m

iN r −1

1 2πl ( m + n )N p

Nr

iN r l =0

we have

∑[ ( )+ B(m)A(m) cos( )]

1 ∞ 2πm ( p − k ) 2πm ( p − k )

Ψ ( p, k , t ) = B (m) A(− m ) cos P P

2 m=0

(A.6)

1

( )

∞

= B(0 ) A(0 ) +

2

B (m ) A(m ) cos ∑ 2πm ( p − k )

P .

m=0

510 - 6 HUMS 2003 Conference

HUMS2003 CD-ROM

Condition c): b(t) is a Fourier series with less than P terms

The summation in m is a discrete Fourier series with period P, and, to avoid aliasing, the number of terms in the series needs to be limited

to less than P. This is done by setting the limitation that the time window function, b(t), be a Fourier series of less than P terms,

P −1

b(t ) = ∑ B(m)cos(2πmf t )

m =0

c (A.7)

and the time filtered signal average over iNr averages with period, 1/(fp+fc ), becomes

P

z p (t ) = ∑ v (t )c( p − k )

k =1

k (A.8)

where

1 2πmn

P −1

c(n ) =

2

B(0)A(0) +

m= 0

∑

B(m)A(m) cos .

P

(A.9)

Sun Gear Technique

A similar result can be found for the separated sun gear averages by substituting relative sun rotation, 1/(fs-fc), instead of 1/(fp+fc), into

(A.1) giving the separated sun gear average for planet p, as

P

z s , p (t ) = ∑ v (t )c( p − k )

k =1

s, k (A.10)

where v s,k (t ) is the mean vibration of the sun gear with planet k, and c(n) is the same as (A.9).

The modified sun gear average, z ms (t ) , is then

P P

2πp

z ms (t ) = ∑∑ v s ,k t− c( p − k ) (A.11)

p =1 k =1 P

. gear averages so that the beginning of each average starts with the same sun gear tooth

where the delay, 2πp/P, aligns the separated sun

in mesh with each planet.

If the sun gear vibration with each planet is identical, it repeats with a period of 2πp/P, i.e.,

2πp

v s ,k (t ) = v s t + (A.12)

P

,

where vs is the meshing vibration of the sun gear with a planet. Substituting (A.12) into (A.11) gives

P P

z ms (t ) = v s (t ) ∑∑ c( p − k )

p =1 k =1 (A.13)

= PB (0 )A(0 )v s (t ).

and the modified sun gear average would thus represent, to within a constant, the average vibration of the sun gear with a single planet.

However, since the sun gear vibration will, in practice, not be identical with each planet, the modified average will only tend to average-

out the differences between the meshing behaviour with each planet. Nevertheless, because the separated averages will be aligned at the

same sun gear tooth, any localised sun gear defect will always appear at the same angular position, and thus be reinforced. This should

lead to an improved ability to detect the fault compared to an ordinary sun gear average, where the influence of the defect will be more

distributed.

HUMS 2003 Conference 510 - 7

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- GB40003Document3 pagesGB40003Hüseyin SuzukNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mech-RBD 13.0 AgendaDocument2 pagesMech-RBD 13.0 AgendaHüseyin SuzukNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- FNC 100h Series Encoder PDF 11787Document1 pageFNC 100h Series Encoder PDF 11787Hüseyin SuzukNo ratings yet

- Oimce0202 0622Document44 pagesOimce0202 0622Hüseyin SuzukNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Oiece0302 1122Document52 pagesOiece0302 1122Hüseyin SuzukNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Oidex0104 1114Document50 pagesOidex0104 1114Hüseyin SuzukNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Oivce0300 1222Document34 pagesOivce0300 1222Hüseyin SuzukNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- PW PDS Planet Reduktor Vinc KatalogDocument6 pagesPW PDS Planet Reduktor Vinc KatalogHüseyin SuzukNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Oitce0200 1222Document48 pagesOitce0200 1222Hüseyin SuzukNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- PC - Conveyors - 2015 - 01 - EN - PRINT Intl - YATIK (D3RST82XO)Document12 pagesPC - Conveyors - 2015 - 01 - EN - PRINT Intl - YATIK (D3RST82XO)Hüseyin SuzukNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Alpha - VDHp050-specDocument1 pageAlpha - VDHp050-specHüseyin SuzukNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- SF t603035gbDocument7 pagesSF t603035gbHüseyin SuzukNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Ignition Hazard Assessment For Gear UnitDocument2 pagesIgnition Hazard Assessment For Gear UnitHüseyin SuzukNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Shear Comparison ACI & EURODocument24 pagesShear Comparison ACI & EUROSangamesh BachaneNo ratings yet

- Lab Report 8Document14 pagesLab Report 8api-355836337No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Financial Time Series Forecasting Using Independent Component Analysis and Support Vector RegressionDocument11 pagesFinancial Time Series Forecasting Using Independent Component Analysis and Support Vector Regressionsarte00No ratings yet

- Datastructuresinc++ - Kanetkar PDFDocument116 pagesDatastructuresinc++ - Kanetkar PDFking_hhhNo ratings yet

- Software MeasurementDocument38 pagesSoftware MeasurementBilal BaberNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- ANOVA HomeworkDocument7 pagesANOVA HomeworkRobert Michael CorpusNo ratings yet

- Finite Element Analysis Answers by Mr. B. Guruprasad: Asst. Professor, MechanicalDocument146 pagesFinite Element Analysis Answers by Mr. B. Guruprasad: Asst. Professor, Mechanicalvishwajeet patilNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- RR210402 Signals - SystemsDocument8 pagesRR210402 Signals - SystemsThanikonda Reddy SreedharNo ratings yet

- DownloadfileDocument89 pagesDownloadfilePhani KumarNo ratings yet

- Graphing Calculator by Mathlab: User ManualDocument119 pagesGraphing Calculator by Mathlab: User ManualddNo ratings yet

- Friedman Laws of Nature and Causal NecessityDocument23 pagesFriedman Laws of Nature and Causal NecessityOscar Eduardo Ocampo OrtizNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 8509-Production & Operations ManagementDocument6 pages8509-Production & Operations ManagementHassan Malik100% (1)

- 9700 s12 GTDocument2 pages9700 s12 GTBilal AyubNo ratings yet

- Effect of Stacking Sequence On Notch Strength in LaminatesDocument10 pagesEffect of Stacking Sequence On Notch Strength in Laminatesசெல்வ குமார்No ratings yet

- C 89297 2698020354106393136Document7 pagesC 89297 2698020354106393136mystery26No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Waves UnitDocument97 pagesWaves Unitir123No ratings yet

- MECHANICAL DESIGN ENGINEERING - Geometrical Dimensioning and Tolerancing - What Is The CYLINDRICITY Tolerance?Document7 pagesMECHANICAL DESIGN ENGINEERING - Geometrical Dimensioning and Tolerancing - What Is The CYLINDRICITY Tolerance?Sathya DharanNo ratings yet

- Summative-TEst Q1 4th m91011Document1 pageSummative-TEst Q1 4th m91011Sharmaine MedianeroNo ratings yet

- Question Words 1 PDFDocument1 pageQuestion Words 1 PDFErwin N CasinoNo ratings yet

- Vol Prism 1Document2 pagesVol Prism 1Moneyball7No ratings yet

- Research Methods, 9Th Edition: Theresa L. White and Donald H. McburneyDocument145 pagesResearch Methods, 9Th Edition: Theresa L. White and Donald H. McburneyKassandra MartinezNo ratings yet

- Pymor: Model Order Reduction With PythonDocument43 pagesPymor: Model Order Reduction With PythonbrkyNo ratings yet

- Variable Speed Drives Altivar Machine ATV320: Catalog MarchDocument48 pagesVariable Speed Drives Altivar Machine ATV320: Catalog MarchDoug SantosNo ratings yet

- Events Union and IntersectionDocument21 pagesEvents Union and IntersectionTed JustinNo ratings yet

- Trigonometry Nichod by Abhas Saini All Imp Results and QuestionsDocument59 pagesTrigonometry Nichod by Abhas Saini All Imp Results and QuestionsAyush megha SinghNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mcdougal LittellDocument358 pagesMcdougal LittellvenkateshNo ratings yet

- Te Mech Academic Book PDFDocument123 pagesTe Mech Academic Book PDFPravinAutadeNo ratings yet

- CNN-Based Projected Gradient Descent For Consistent CT Image ReconstructionDocument14 pagesCNN-Based Projected Gradient Descent For Consistent CT Image ReconstructionJose Angel Duarte MartinezNo ratings yet

- 0 Book PDFDocument488 pages0 Book PDFGeorgeStefanescuNo ratings yet

- Deep Physical Neural Networks Trained With Backpropagation. Nature 2022, P L McmohanDocument11 pagesDeep Physical Neural Networks Trained With Backpropagation. Nature 2022, P L McmohanmahadimasnadNo ratings yet