Professional Documents

Culture Documents

SOP For Pressure Testing

Uploaded by

victor0 ratings0% found this document useful (0 votes)

96 views3 pagesThis standard operating procedure outlines the steps for conducting gas pressure testing, including: preparing the testing apparatus, discussing hazards with the pressure tester, ensuring warning signs and barriers are in place during testing, pressurizing components, inspecting for leaks, and installing and removing the pressure testing cup. Communication between crew members is emphasized throughout to ensure safety.

Original Description:

Original Title

SOP for Pressure Testing

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis standard operating procedure outlines the steps for conducting gas pressure testing, including: preparing the testing apparatus, discussing hazards with the pressure tester, ensuring warning signs and barriers are in place during testing, pressurizing components, inspecting for leaks, and installing and removing the pressure testing cup. Communication between crew members is emphasized throughout to ensure safety.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

96 views3 pagesSOP For Pressure Testing

Uploaded by

victorThis standard operating procedure outlines the steps for conducting gas pressure testing, including: preparing the testing apparatus, discussing hazards with the pressure tester, ensuring warning signs and barriers are in place during testing, pressurizing components, inspecting for leaks, and installing and removing the pressure testing cup. Communication between crew members is emphasized throughout to ensure safety.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

STANDARD OPERATING PROCEDURES

TASK NO. : Gas Pressure Testing

SECTION :

APPLICABLE POSITIONS :

STANDARD : This must be communicated to all workers and should sign.

EQUIPMENT:

Gloves, goggles, cleaning supplies, testing apparatus, welding machines, respiratory apparatus.

PROCEDURE:

Prepare to conduct pressure test.

Discuss site-specific hazards with pressure tester.

While completing the pressure test, make sure that the “BOP closed” tag is used and hung on the hoisting

clutch.

The Driller must make sure that the pressure tester is aware of the hazards related to the catwalk and pipe

arm.

Rig in pressure tester’s line.

Make sure the pressure tester has his “High Pressure Line” sign in a clearly visible, high traffic location.

The Driller or assigned crew member must make sure that the pressure tester routes his line in a safe

location that does not interfere with upcoming rig activity.

Pressure up bop components.

The Driller must make sure of the following:

o That while the pressure tester is pumping up equipment, all workers remain clear of

all pressure testing equipment,

o that workers remain clear of the rig floor and cellar area during the pressure test, and

o that all rig hands know where the pressure tester’s line is located at all times during the pressure

test.

Inspect all lines under pressure.

The pressure tester must notify the Driller if there are any leaks.

When the Driller receives the “All Clear” signal from the pressure tester signifying that all the pressure has

been bled off, the Driller must direct the rig crew to hammer up any leaking unions.

When the rig is finished hammering up the unions, the Driller must clear the area and notify the pressure

tester that heis “Clear” to resume testing.

Ill pressure tester’s cup.

Prepared by: PAGE NO : 1

Approved by: DEPARTMENT:

Date :

Revision: Yes , No

STANDARD OPERATING PROCEDURES

The pressure testing cup must be installed at the rig floor.

Before picking up the tester’s cup, pick up a joint of drill pipe with the pipe arm and place the joint into the

derrick.

The Driller must work with the Motor hand to make up the drill pipe to the top drive and torque it up in

preparation for the pressure test.

Use the picker to raise the pressure testing cup up to the rig floor.

Use enough man power to put the cup on so the job is not difficult or awkward.

The Driller must make sure that the slips are set in the table and blind rams are closed. Place the cup into

the slips and make up the drill pipe up to the tester’s cup. Place the “BOP Closed “tag on the hoisting control.

The Driller must spin in the drill pipe into the pressure tester’s cup with the Floor hand holding the cup in

place.

If the cup is too long or heavy to handle manually, hoist it to the rig floor and put it in the Apache wrench so it

can be made up with the top drive.

6. Make up heavy or long pressure tester’s cup in Apache wrench.

Use a winch and pick-up nubbin if the pressure tester’s cup and or crossovers are too long or heavy.

When placing the cup assembly into the Apache wrench, have clear communication between the Motor hand

running the Apache jaws and the worker handling the cup.

The Motor hand must back the Apache wrench out of the way while the crew is attempting the spin the test

cup into the quill.

TIPS AND TRICKS:

All inspections must be properly carried out after the work has been done.

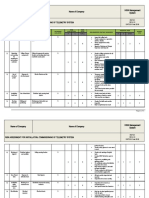

Communication of SOP

Name of Employee Employee Number Job Title Role in this SOP Signature

Prepared by: PAGE NO : 2

Approved by: DEPARTMENT:

Date :

Revision: Yes , No

STANDARD OPERATING PROCEDURES

Prepared by: PAGE NO : 3

Approved by: DEPARTMENT:

Date :

Revision: Yes , No

You might also like

- Wellsite Pressure TestDocument5 pagesWellsite Pressure TestBambang PermanaNo ratings yet

- SWMS Cherry PickerDocument15 pagesSWMS Cherry Pickervictor0% (1)

- Generic Well Test ProgramDocument9 pagesGeneric Well Test Programinyene ekereNo ratings yet

- Risk Assessment Leak SealingDocument5 pagesRisk Assessment Leak Sealingvictor100% (2)

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- Managing Risk in Information Systems Final ReviewDocument10 pagesManaging Risk in Information Systems Final ReviewhomenetworkNo ratings yet

- Accumulator Draw Down TestDocument8 pagesAccumulator Draw Down Testadeelsn100% (4)

- RISK ASSESSMENT FOR INSTALLATION OF Mechanical MaintenanceDocument11 pagesRISK ASSESSMENT FOR INSTALLATION OF Mechanical Maintenancevictor100% (1)

- Lifting and Rigging ProcedureDocument8 pagesLifting and Rigging ProcedureKluKlux Land100% (2)

- 02 Reset Pop Off ValveDocument5 pages02 Reset Pop Off ValveShussan PrinceNo ratings yet

- Confined Space Risk Assessment WHSFOR-009BDocument3 pagesConfined Space Risk Assessment WHSFOR-009BvictorNo ratings yet

- Hydrotest Procedure For Pressure VesselDocument7 pagesHydrotest Procedure For Pressure Vesselvijay vickyNo ratings yet

- 01 Pressure Gauge CalibrationDocument3 pages01 Pressure Gauge CalibrationSantosh Odiyar0% (1)

- Leak Test Procedure For SubDocument5 pagesLeak Test Procedure For Subpallav chatterjeeNo ratings yet

- 250 Amf LogicDocument10 pages250 Amf LogicChakravarthy Veeru0% (1)

- General Firefighting Wet Systems Method Statement For Testing & CommissioningDocument11 pagesGeneral Firefighting Wet Systems Method Statement For Testing & CommissioningAhmad Omar100% (3)

- Chamber Test of BOPDocument7 pagesChamber Test of BOPadeelsn100% (2)

- Risk Assessment For Installation of BalustradeDocument6 pagesRisk Assessment For Installation of Balustradevictor100% (1)

- HYDROTEST - JeevaDocument68 pagesHYDROTEST - JeevaJayaraman KamarajNo ratings yet

- Hydrostatic Pressure Testing Procedure1 PWLDocument6 pagesHydrostatic Pressure Testing Procedure1 PWLYavannaNo ratings yet

- Leak Test Procedure PDFDocument6 pagesLeak Test Procedure PDFanon_456282505100% (3)

- Leak Test Procedure InstrumentDocument10 pagesLeak Test Procedure InstrumentNAVANEETHNo ratings yet

- Risk Assessment For Installation of Telemetry SystemDocument5 pagesRisk Assessment For Installation of Telemetry SystemvictorNo ratings yet

- Hydrotest ProcedureDocument6 pagesHydrotest ProcedureIkhsan Hj SiratNo ratings yet

- SCSSVDocument8 pagesSCSSVSaqxank100% (4)

- Skid Mounted Test UnitDocument30 pagesSkid Mounted Test UnitSALIM ALI AFIFFNo ratings yet

- LD2 Drilling Practices & Lessons Learned - A.boubeniaDocument8 pagesLD2 Drilling Practices & Lessons Learned - A.boubeniaAli BoubeniaNo ratings yet

- Testing and Commissioning For Pressurization UnitDocument3 pagesTesting and Commissioning For Pressurization UnitDong VanraNo ratings yet

- SWP For Gas Detection System and TelemetryDocument3 pagesSWP For Gas Detection System and TelemetryvictorNo ratings yet

- Catamaran AnalysisDocument83 pagesCatamaran AnalysisbhukthaNo ratings yet

- Work Procedure For Pre-CommissioningDocument19 pagesWork Procedure For Pre-CommissioningTrustEmma100% (3)

- 11 5K 5K Annular BOPDocument4 pages11 5K 5K Annular BOPEdwin MP0% (1)

- Valve) - 2. End Fittings For ClosureDocument10 pagesValve) - 2. End Fittings For ClosureNaveen Vel100% (1)

- Sequence Identified Hazards Key Processes To Be Followed Precautions / PPE Required Planned Job Observations CommentsDocument3 pagesSequence Identified Hazards Key Processes To Be Followed Precautions / PPE Required Planned Job Observations CommentsvictorNo ratings yet

- Method Statement For Gas Detection System and Telemetry SystemDocument2 pagesMethod Statement For Gas Detection System and Telemetry SystemvictorNo ratings yet

- Daily Check ListDocument40 pagesDaily Check ListVamshi Krishna DaravathNo ratings yet

- Pressure Test BOP 03.95Document4 pagesPressure Test BOP 03.95Babi LakhdariNo ratings yet

- D2070-3TR10 Cessna 206 1977 1986Document200 pagesD2070-3TR10 Cessna 206 1977 1986Elmer Villegas100% (2)

- Engineering Internship Final Report: An Internship With Fortescue Metals Group LimitedDocument96 pagesEngineering Internship Final Report: An Internship With Fortescue Metals Group LimitedIbrahim NashidNo ratings yet

- Guidelines For PSV Test Bench & PSV TestingDocument2 pagesGuidelines For PSV Test Bench & PSV Testinghaunted houseNo ratings yet

- Well Control Drills and Exercises WIPER TRIPDocument3 pagesWell Control Drills and Exercises WIPER TRIPmanuelperdomotNo ratings yet

- MM RT Flex96c - WECS 9520 - Dynex - 2014 04Document730 pagesMM RT Flex96c - WECS 9520 - Dynex - 2014 04Luci LucianNo ratings yet

- Hydrotest Procedure For Pressure VesselDocument6 pagesHydrotest Procedure For Pressure VesselAbdul Kharis100% (1)

- APD - Positive Test, Negative Test and Displacement ProceduresDocument7 pagesAPD - Positive Test, Negative Test and Displacement ProceduresAntonio Hdez JmnzNo ratings yet

- 0983 03 Method Statement For Installation Testing of Fire Fighting PipesDocument3 pages0983 03 Method Statement For Installation Testing of Fire Fighting PipesAnkit KumarNo ratings yet

- Document No. Revision No. Date Compiled: Date of Next Review: SHE/PRO/4.4.6.30 1 September 2016 September 2017Document3 pagesDocument No. Revision No. Date Compiled: Date of Next Review: SHE/PRO/4.4.6.30 1 September 2016 September 2017victorNo ratings yet

- Kick Drill While Drilling - Pit Drills ProcedureDocument3 pagesKick Drill While Drilling - Pit Drills Proceduremontacer badreddine100% (1)

- Qdoc - Tips Volvo g930 Motor Grader Service Repair ManualpdfDocument16 pagesQdoc - Tips Volvo g930 Motor Grader Service Repair ManualpdfLarzon Rodriguez0% (1)

- SWMS ScaffoldingDocument9 pagesSWMS Scaffoldingvictor100% (2)

- 0983-03 Method Statement For Installation & Testing of Fire Fighting PipesDocument4 pages0983-03 Method Statement For Installation & Testing of Fire Fighting Pipeshasan_67648961650% (2)

- CIMP2.5.2 Manuel Reference ENG 2012-05-23Document130 pagesCIMP2.5.2 Manuel Reference ENG 2012-05-23emilperijocNo ratings yet

- Hydrotest and Pigging Procedure CNGDocument8 pagesHydrotest and Pigging Procedure CNGAlokNo ratings yet

- Leak Test Proce.-TankDocument7 pagesLeak Test Proce.-Tankpraveen 0064No ratings yet

- 10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)Document1 page10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)caovanthien10121992No ratings yet

- CHK3 Choke Manifold Test Rev 2Document1 pageCHK3 Choke Manifold Test Rev 2ayhamNo ratings yet

- Standard Operating Procedures: Prepared By: Approved By: Date: Department: Page NoDocument2 pagesStandard Operating Procedures: Prepared By: Approved By: Date: Department: Page NovictorNo ratings yet

- 6month (Idins) - Control Valve Function Test and Positioner CalibrationDocument3 pages6month (Idins) - Control Valve Function Test and Positioner CalibrationJAGDEV PANESARNo ratings yet

- Procedure Leak Test Dan VacuumDocument5 pagesProcedure Leak Test Dan VacuumwahyuNo ratings yet

- CHK3 Choke Manifold Test Rev 1Document1 pageCHK3 Choke Manifold Test Rev 1ayhamNo ratings yet

- Temporary Operating Procedure: PW Well Wash ProcedureDocument11 pagesTemporary Operating Procedure: PW Well Wash ProcedureStiflar SparksNo ratings yet

- MS (Hydrotest - Heat Exchanger)Document4 pagesMS (Hydrotest - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- IDC SOP #2 Pressure Test of The StandpipeDocument5 pagesIDC SOP #2 Pressure Test of The StandpipekareemNo ratings yet

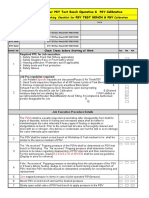

- SOP For Well Test REV 1.01 - ENIDocument4 pagesSOP For Well Test REV 1.01 - ENIibraheem alsarrajNo ratings yet

- Procedure To Pressure Test Choke ManifoldDocument1 pageProcedure To Pressure Test Choke ManifoldNnennaNo ratings yet

- 08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Document12 pages08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Avak NishanNo ratings yet

- Pressur Testing Check ListDocument1 pagePressur Testing Check Listnadir zedNo ratings yet

- SOP WI Pneumatic On-Off Valves - Calibrating Stroke CheckDocument1 pageSOP WI Pneumatic On-Off Valves - Calibrating Stroke CheckJarrodNo ratings yet

- 4.6 - LP - Gas - Meter - Calibration - TestingDocument5 pages4.6 - LP - Gas - Meter - Calibration - Testingابوالحروف العربي ابوالحروفNo ratings yet

- RWRG0056 - Range Shift Complaints - Fault Code 41: Pre-Authorized Warranty Repair Guideline RWRG0056Document2 pagesRWRG0056 - Range Shift Complaints - Fault Code 41: Pre-Authorized Warranty Repair Guideline RWRG0056Antonio TorresNo ratings yet

- Reprocessing Flexible Endoscopes Leak Testing For Karl Stor ScopesDocument1 pageReprocessing Flexible Endoscopes Leak Testing For Karl Stor ScopesEl ChelNo ratings yet

- SunnyDocument32 pagesSunnysunithadurgamNo ratings yet

- Eo Reactor Work Instruction RevDocument4 pagesEo Reactor Work Instruction Revvishal bailurNo ratings yet

- Sample IOM-SchlumbergerDocument10 pagesSample IOM-Schlumbergerbmanojkumar16No ratings yet

- Sop of k3 A B Off Gas Compressor Start Up After Maintenance.Document4 pagesSop of k3 A B Off Gas Compressor Start Up After Maintenance.00083583rfNo ratings yet

- Pressure Test ProceduresDocument4 pagesPressure Test ProceduresApneryanus LepingNo ratings yet

- Procedure If Shallow Gas Is EncounteredDocument5 pagesProcedure If Shallow Gas Is EncounteredTaufik HidayatNo ratings yet

- Experiment1 PressureDocument10 pagesExperiment1 PressureMuhammad AqibNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- XYZ Laboratory: Iso/Iec 17025 Quality ManualDocument13 pagesXYZ Laboratory: Iso/Iec 17025 Quality ManualvictorNo ratings yet

- F D A O R A: ORA Laboratory Manual Volume IDocument3 pagesF D A O R A: ORA Laboratory Manual Volume IvictorNo ratings yet

- Injury Statistics SheetDocument1 pageInjury Statistics SheetvictorNo ratings yet

- What Is The Purpose of This FormDocument2 pagesWhat Is The Purpose of This FormvictorNo ratings yet

- Observer's Report: Emergency Evacuation DrillDocument1 pageObserver's Report: Emergency Evacuation DrillvictorNo ratings yet

- Covid-19 Dashboard: Reporting SystemDocument5 pagesCovid-19 Dashboard: Reporting SystemvictorNo ratings yet

- Invoice For YoutubeDocument1 pageInvoice For YoutubevictorNo ratings yet

- Explosive RegDocument26 pagesExplosive RegvictorNo ratings yet

- Excel Tutorial How To Create Beautiful Analytics Dashboard Report in Microsoft ExcelDocument5 pagesExcel Tutorial How To Create Beautiful Analytics Dashboard Report in Microsoft ExcelvictorNo ratings yet

- 6.1.a 6.2.a 6.3.a 6.3.b 6.3.c: DOC-1 DOC-2Document23 pages6.1.a 6.2.a 6.3.a 6.3.b 6.3.c: DOC-1 DOC-2victorNo ratings yet

- Black and White CV in MS WORD Design CreditDocument2 pagesBlack and White CV in MS WORD Design CreditvictorNo ratings yet

- HSE Officer Action 2020Document9 pagesHSE Officer Action 2020victorNo ratings yet

- Invoice For YoutubeDocument1 pageInvoice For YoutubevictorNo ratings yet

- Jacob ScottDocument2 pagesJacob ScottvictorNo ratings yet

- 77 VLOOKUP by DateDocument1 page77 VLOOKUP by DatevictorNo ratings yet

- Audit Report: Company NameDocument2 pagesAudit Report: Company NamevictorNo ratings yet

- Standard Operating Procedures: Prepared By: Approved By: Date: Department: Page NoDocument2 pagesStandard Operating Procedures: Prepared By: Approved By: Date: Department: Page Novictor0% (1)

- Document No. Revision No. Date Compiled: Date of Next Review: SHE/PRO/4.4.6.30 1 September 2016 September 2017Document5 pagesDocument No. Revision No. Date Compiled: Date of Next Review: SHE/PRO/4.4.6.30 1 September 2016 September 2017victorNo ratings yet

- WSWP For Joint SealingDocument7 pagesWSWP For Joint SealingvictorNo ratings yet

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument42 pages@airbus: Component Maintenance Manual With Illustrated Part Listjoker hotNo ratings yet

- Muhammad Nabeel - ResumeDocument2 pagesMuhammad Nabeel - Resumeaurwah saleemNo ratings yet

- Timesheet Management SystemDocument2 pagesTimesheet Management Systemrahulsisodia9409No ratings yet

- Trinidad and Tobaggo Corruption Ballah ReportDocument132 pagesTrinidad and Tobaggo Corruption Ballah Reportsylodhi100% (1)

- TheBalance Letter 2060144Document3 pagesTheBalance Letter 2060144amirNo ratings yet

- Material SpecificationsDocument45 pagesMaterial SpecificationsJefferson Fontanilla GanadoNo ratings yet

- P2597 B04 PCB Assembly DrawingDocument1 pageP2597 B04 PCB Assembly DrawingAfortunatovNo ratings yet

- Assignment On MCDDocument8 pagesAssignment On MCDshamim hossainNo ratings yet

- Understanding Kalido Data ArchitectureDocument24 pagesUnderstanding Kalido Data Architectureshare_bodNo ratings yet

- Risk Sharing Partnership - Supply Chain Reilience - 2015Document7 pagesRisk Sharing Partnership - Supply Chain Reilience - 2015valdivijNo ratings yet

- Lecture # 4 PDFDocument41 pagesLecture # 4 PDFjunaid_256No ratings yet

- 1003 - Marius Popa PDFDocument13 pages1003 - Marius Popa PDFnnoumanNo ratings yet

- Recruitment Process in ACC CEMENTDocument83 pagesRecruitment Process in ACC CEMENTAmit PasiNo ratings yet

- Contact-Cooled Rotary Screw Air Compressors: R-Series 37-45 KW (50-60 HP) 50 HZDocument2 pagesContact-Cooled Rotary Screw Air Compressors: R-Series 37-45 KW (50-60 HP) 50 HZrodrigoNo ratings yet

- IJERI Vol1 N2 Fall 2009Document68 pagesIJERI Vol1 N2 Fall 2009Saeid MoslehpourNo ratings yet

- Sa-7918-1, Rev A, (850146), 12.16.2018Document2 pagesSa-7918-1, Rev A, (850146), 12.16.2018Rami ELLOUMINo ratings yet

- 1 2 1 A AircraftcontrolsurfaceDocument3 pages1 2 1 A Aircraftcontrolsurfaceapi-325611195No ratings yet

- Sustainable Solution Steering: Accelerator Example CollectionDocument175 pagesSustainable Solution Steering: Accelerator Example CollectionMartha Valentina Aguilar GonzalezNo ratings yet

- Supplier Development in Indian OrganizationsDocument13 pagesSupplier Development in Indian OrganizationsRashi TaggarNo ratings yet

- Process Simulation Using Delmia: Răcăşan Radu, GYÖRKE Gyöngyi Timea, Ghinea Rare Ş, POPIŞTER Florin, NEAMŢU Călin DanDocument10 pagesProcess Simulation Using Delmia: Răcăşan Radu, GYÖRKE Gyöngyi Timea, Ghinea Rare Ş, POPIŞTER Florin, NEAMŢU Călin DanproxxonNo ratings yet

- AMD FirePro PTC DataSheetDocument2 pagesAMD FirePro PTC DataSheetsebi270No ratings yet

- 4839 10 PDFDocument199 pages4839 10 PDFyan ming fokNo ratings yet