Professional Documents

Culture Documents

Choke manifold HP test offline rig unit

Uploaded by

ayhamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Choke manifold HP test offline rig unit

Uploaded by

ayhamCopyright:

Available Formats

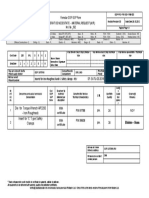

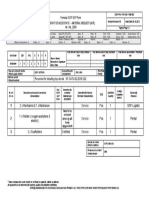

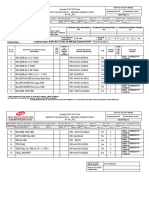

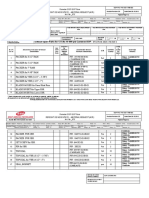

Choke manifold test offline with the rig HP testing unit

Preparation

- The Tool Pusher or the Night Pusher (PIC) must inspect and approve the installation before the test

procedure is started and operates all valves to ensure they are working properly.

- Cold work permit to be issued and JSA discussed with the parties involved in the testing job.

- Pre job meeting with the personnel involved. Barrier tape around the Choke manifold and close area

access, according with GSP Procedures Manual. For the first test of the manifold, which places the

entire manifold under test pressure, ensure that all personnel are removed to a safe area, preferably

behind a solid barrier. Ensure that all entrances to the test area are closed and under control. For

subsequent tests of the manifold, ensure that all personnel are in a safe area and that control of all

entrances to the test area is maintained.

REMARK: Through the cementing manifold we can connect the high pressure pump, instead

cementing pump.

- Fill up Choke Manifold with Sea Water.

When you have return through the poor boy to the flow line, stop the pump.

- Connect testing line (cementing line) to valve #3. Close valve #3 and test the valve and the test line.

-Always apply the pressure step by step.

Put back the choke manifold valves in drilling position

NB: The test pressure applied must not exceed the working pressure of the choke manifold and

valves.

Perform all testing of choke manifold equipment in accordance with specifications. The Company

Man’s signature provides final approval that a valid test of equipment was performed.

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- CHK3 Choke Manifold Test Rev 1Document1 pageCHK3 Choke Manifold Test Rev 1ayhamNo ratings yet

- Wellsite Pressure TestDocument5 pagesWellsite Pressure TestBambang PermanaNo ratings yet

- Chamber Test of BOPDocument7 pagesChamber Test of BOPadeelsn100% (2)

- Hydrostatic Pressure Testing Procedure1 PWLDocument6 pagesHydrostatic Pressure Testing Procedure1 PWLYavannaNo ratings yet

- Calibration and leak testing of Saudi Aramco instrumentation systemsDocument10 pagesCalibration and leak testing of Saudi Aramco instrumentation systemsNAVANEETHNo ratings yet

- Leak Test Procedure For SubDocument5 pagesLeak Test Procedure For Subpallav chatterjeeNo ratings yet

- Method of Statement Testing of PipeDocument5 pagesMethod of Statement Testing of PipevpamatyaNo ratings yet

- Method Statement For Hydrostatic Pressure Testing of Chilled Water PipeworkDocument3 pagesMethod Statement For Hydrostatic Pressure Testing of Chilled Water Pipeworkamg007100% (3)

- Valve MaintenanceDocument20 pagesValve MaintenanceSaka MpfmNo ratings yet

- P3-PTP-001 R0 Piping Pressure Test ProceduresDocument8 pagesP3-PTP-001 R0 Piping Pressure Test ProceduresHengNo ratings yet

- General Firefighting Wet Systems Method Statement For Testing & CommissioningDocument11 pagesGeneral Firefighting Wet Systems Method Statement For Testing & CommissioningAhmad Omar100% (3)

- Method Statement - HVAC Duct Leakage Testing ProcedureDocument7 pagesMethod Statement - HVAC Duct Leakage Testing ProcedureSyed TouqeerNo ratings yet

- LEAK TEST Method Statement Ponticelli & Total Petroleum.Document7 pagesLEAK TEST Method Statement Ponticelli & Total Petroleum.Fasola Lawal100% (4)

- 0051-1104 Method Statement Pneumatic TestingDocument9 pages0051-1104 Method Statement Pneumatic TestingHasif Mohammed67% (3)

- Procedure For Hydro Testing: Pressure TestDocument5 pagesProcedure For Hydro Testing: Pressure TestDevang ShahNo ratings yet

- MS (Hydrotest - Heat Exchanger)Document4 pagesMS (Hydrotest - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- Pressure Testing ProcedureDocument7 pagesPressure Testing ProcedureChristopher uche100% (1)

- Sprinkler System Testing-Commissioning Method StatementDocument2 pagesSprinkler System Testing-Commissioning Method StatementMehmet Durmaz67% (9)

- Hydrostatic Test ProcedureDocument2 pagesHydrostatic Test ProcedureAlan AtienzaNo ratings yet

- Tests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water LevelDocument6 pagesTests For Surface Wellheads and BOP Equipment Used in Operations On Land and Above Water Levelahmed121No ratings yet

- Pneumatic Test - Write UpDocument7 pagesPneumatic Test - Write UpDilip0% (1)

- 004 Annexure D Job Safety SAnalysis JSADocument3 pages004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- Piping Hydrotest Procedure GuideDocument3 pagesPiping Hydrotest Procedure GuideFrank100% (6)

- Pressure Testing Fire Water LineDocument9 pagesPressure Testing Fire Water Linesharif339No ratings yet

- Bop Pressure Testing Procedure: Romfor International LTDDocument6 pagesBop Pressure Testing Procedure: Romfor International LTDSergio Fabian VasicekNo ratings yet

- PRE-TEST TEMPORARY LINES BEFORE PRESSURIZATIONDocument2 pagesPRE-TEST TEMPORARY LINES BEFORE PRESSURIZATIONJorge GarciaNo ratings yet

- 4pipefitting Pressure Test 170129022549 PDFDocument13 pages4pipefitting Pressure Test 170129022549 PDFKamarul NizamNo ratings yet

- Pressure Test ProceduresDocument4 pagesPressure Test ProceduresApneryanus LepingNo ratings yet

- 10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)Document1 page10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)caovanthien10121992No ratings yet

- Chase Method Statement Dry Riser TestingDocument6 pagesChase Method Statement Dry Riser Testingarmagan55No ratings yet

- Testing & Commissioning of Pressurization UnitsDocument3 pagesTesting & Commissioning of Pressurization UnitsDong VanraNo ratings yet

- Method Statement For Hydro TestDocument3 pagesMethod Statement For Hydro TestSandeep kumar100% (1)

- Quality Procedure For Pressure Test (Hydro) : QCP-HP110Document9 pagesQuality Procedure For Pressure Test (Hydro) : QCP-HP110AAISATNo ratings yet

- MS (Pneumatic Test - Heat Exchanger)Document4 pagesMS (Pneumatic Test - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Document7 pagesINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- Hydrotest ProcedureDocument6 pagesHydrotest ProcedureIkhsan Hj SiratNo ratings yet

- Piping Hydrotest ProcedureDocument9 pagesPiping Hydrotest Procedurewendypost73100% (1)

- Construction Procedure For HydrotestingDocument7 pagesConstruction Procedure For HydrotestingEddie Tai100% (1)

- SOP For Pressure TestingDocument3 pagesSOP For Pressure TestingvictorNo ratings yet

- Testing and Commissioning Method Statement Procedure For Argonite SystemDocument2 pagesTesting and Commissioning Method Statement Procedure For Argonite SystemHumaid ShaikhNo ratings yet

- Safe Work Method For Hydro TestDocument1 pageSafe Work Method For Hydro TestEswar RaoNo ratings yet

- Generic Well Test ProgramDocument9 pagesGeneric Well Test Programinyene ekereNo ratings yet

- 0310-HPT Hydrostatic Pressure Test Procedure RADocument6 pages0310-HPT Hydrostatic Pressure Test Procedure RARamakrisnanMeenakshiSundaramRamaNo ratings yet

- What's The Min &max Range of Pressure Gauge For Hydro TestDocument4 pagesWhat's The Min &max Range of Pressure Gauge For Hydro TestdushyantNo ratings yet

- 08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Document12 pages08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Avak NishanNo ratings yet

- Pressure Testing of Pipelines: CR Asia GroupDocument7 pagesPressure Testing of Pipelines: CR Asia Groupvishal bailurNo ratings yet

- Method Statement For The Installation of TransformerDocument11 pagesMethod Statement For The Installation of TransformerShaikh Ahamed100% (1)

- Evaluating and Reducing The Risks of Pneumatic Proof-Pressure Testing in Metal Expansion JointsDocument3 pagesEvaluating and Reducing The Risks of Pneumatic Proof-Pressure Testing in Metal Expansion JointslishiqianNo ratings yet

- Test Unit Safety Valves - enDocument12 pagesTest Unit Safety Valves - enAndreas SetiadiNo ratings yet

- Slickline Operations Safety PracticesDocument4 pagesSlickline Operations Safety PracticesYermi ParabangNo ratings yet

- Guidelines For PSV Test Bench & PSV TestingDocument2 pagesGuidelines For PSV Test Bench & PSV Testinghaunted houseNo ratings yet

- Method Statement Form: Location of ActivityDocument2 pagesMethod Statement Form: Location of ActivitySikander GirgoukarNo ratings yet

- Pneumatic Testing ProcedureDocument4 pagesPneumatic Testing ProcedureEddie TaiNo ratings yet

- Drainnage Piping After InstallationDocument4 pagesDrainnage Piping After InstallationqaqcmepteamNo ratings yet

- Method of Statemnet For Testing Commissioning of Chilled Water PumpsDocument3 pagesMethod of Statemnet For Testing Commissioning of Chilled Water PumpsHasan V SNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Section 20 - Introduction To Rig Sizing ExerciseDocument13 pagesSection 20 - Introduction To Rig Sizing ExerciseayhamNo ratings yet

- Operating Instructions: User Manual No.: T4854-Z-Ma-001, Rev. 0 Equipment: Hydraracker X-Y 1 of 89Document89 pagesOperating Instructions: User Manual No.: T4854-Z-Ma-001, Rev. 0 Equipment: Hydraracker X-Y 1 of 89ayhamNo ratings yet

- Rotary Drilling RigsDocument58 pagesRotary Drilling Rigsmarageo100% (6)

- Cyber BaseDocument39 pagesCyber BaseayhamNo ratings yet

- Operating Instructions: User Manual No.: T4802-Z-MA-001, Rev. 0 Equipment: Top Drive 1 38Document38 pagesOperating Instructions: User Manual No.: T4802-Z-MA-001, Rev. 0 Equipment: Top Drive 1 38ayhamNo ratings yet

- BHA 04 Logging PDFDocument1 pageBHA 04 Logging PDFayhamNo ratings yet

- Section 25 - Wrap Up PDFDocument20 pagesSection 25 - Wrap Up PDFSohaib RashidNo ratings yet

- Operation Manual: Drawworks Control SystemDocument49 pagesOperation Manual: Drawworks Control Systemayham0% (1)

- GSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0562 - Inserts For Iron Roughneck and C - Safety Clamps - REVDocument1 pageGSP-SATURN-MR-205-2018-DRL-0562 - Inserts For Iron Roughneck and C - Safety Clamps - REVayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0564 - Valve Seat Puller For API 7 Valve Seat 4 Web StyleDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0564 - Valve Seat Puller For API 7 Valve Seat 4 Web StyleayhamNo ratings yet

- BbprocedureDocument3 pagesBbprocedureayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0562 - Inserts For Iron Roughneck and C - Safety ClampsDocument1 pageGSP-SATURN-MR-205-2018-DRL-0562 - Inserts For Iron Roughneck and C - Safety ClampsayhamNo ratings yet

- GSP-PRC-PRO-001-FRM-003 Form Material RequestDocument1 pageGSP-PRC-PRO-001-FRM-003 Form Material RequestayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0561 - Tubing Head To BOP Adaptors Spool & Ring GasketsDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0561 - Tubing Head To BOP Adaptors Spool & Ring GasketsayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0373 - Third Party Inspection For TDS 8S & Solid Control SystemDocument1 pageGSP-SATURN-MR-205-2018-DRL-0373 - Third Party Inspection For TDS 8S & Solid Control Systemayham100% (1)

- Gsp-Saturn-Mr-205-2018-Drl-0460 - Lifting CapsDocument1 pageGsp-Saturn-Mr-205-2018-Drl-0460 - Lifting CapsayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedayhamNo ratings yet

- Gsp-Saturn-Mr-205-2018-Drl-0375 - 13 .625 Cameron Bop Critical Spare PartsDocument2 pagesGsp-Saturn-Mr-205-2018-Drl-0375 - 13 .625 Cameron Bop Critical Spare PartsayhamNo ratings yet

- Demco Gate Valve PDFDocument56 pagesDemco Gate Valve PDFyacine3516100% (1)

- GSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedDocument2 pagesGSP-SATURN-MR-205-2018-DRL-0417 - BOLTS AND WASHERS TO REPAIR For 13 58 X 10k CAMERON BOP RevisedayhamNo ratings yet

- GSP-SATURN-MR-205-2018-DRL-0375 - 13 .625 CAMERON BOP CRITICAL SPARE PARTS - Revised 2Document2 pagesGSP-SATURN-MR-205-2018-DRL-0375 - 13 .625 CAMERON BOP CRITICAL SPARE PARTS - Revised 2ayhamNo ratings yet

- Gsp-Saturn-Mr-205-2018-Drl-0375 - 13 .625 Cameron Bop Critical Spare PartsDocument2 pagesGsp-Saturn-Mr-205-2018-Drl-0375 - 13 .625 Cameron Bop Critical Spare PartsayhamNo ratings yet

- Demco CatalogDocument50 pagesDemco CatalogEduardo100% (3)

- Drill Pipe Float Valve Catalog - WebDocument24 pagesDrill Pipe Float Valve Catalog - Webcaballero_tigreNo ratings yet