Professional Documents

Culture Documents

Method Statement For Hydro Test

Uploaded by

Sandeep kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Hydro Test

Uploaded by

Sandeep kumarCopyright:

Available Formats

METHOD STATEMENT FORM

1. Method Statement Particulars

Project: WFGD UNCHAHAR MS No. KGFPL/MS/27

Revision: 00 Date: Company: KGFPL

2. Work Activity

HYDRO STATIC TEST IN PIPE WORK

Activity Description:

Prior to the start of the hydro static pressure testing all other works on the system shall have been snagged by construction team and

disengaged and signed off by the quality department.

All open flanged, valve or screwed ends will be blanked off.

The fill point will be installed at the lowest point of the system, and a valve vent at the highest point of the system to be tested.

The vent will be piped to a drain point.

Pressure gauges with valid calibration certificates/stickers will be fitted adjacent to the pressure pump.

Pipework will be filled with water sufficiently in advance of the test to allow it to come to room temperature so that any sweating can

evaporate.

When the systems sufficiently filled the vent valve will be opened and allowed to run freely for a period of 5 minutes to ensure all the air is

out of the system, at that point the valve will be closed.

When the system is full and vented the test rig will be linked to the system and the pressure increased to the required system test pressure,

as required by the specification 1.5 the operating pressure.

When the test pressure is reached the valve at the fill point will be closed for a period of 15 minutes to stabilize the system, the gauges will

be checked to see if any pressure loss has occurred due to the stabilization, if so the test rig will be applied to bring the system test

pressure back up to the specification requirements.

Upon re pressurization the test rig shall than be dismantled from the system.

Care will be taken at this point to record the ambient room temperature of the start and finish time of the test. The duration of the test will

be 24 hours and temperatures should be recorded frequently.

A visual inspection of joints will take place during the test period to check for leaks, if any leakage found the test will be aborted. After the

leakage is rectified, the above procedure will be repeated for a re test to take place.

On satisfactory completion of the test, witnessed by the client, the pressure will be released through the vent pipe. The system then shall

be drained. Pressure testing report shall be prepared and signed by the client or any other concerned party.

Summary of the main hazards and associated control measures (include Environmental and Quality Procedures):

1. Site Clearance & Work Permit: PTW to be issued by Permit issuer and receiver after ensuring control measures are in place. No high-risk activity

will be started without any gaps from control measures. Workmen to be aware about the hazards and related control measures are in place

before start of activity.

2. Vehicle Movement: - Farana, Trailer movement should be in close supervision. Experienced banks man ensures the movement of vehicles.

3. Lifting Tools-Tackles: Ensure all tools & Tackles must be certified & TPI/ colour coding is necessary

4. Hot work: Ensure skilled crew for the job. Area will be defined. Welding Machine connection will be taken through RCCB. Using of fire protection

sheets providing fire extinguisher nearby during hot works.

5. PPEs: Safety helmets, safety shoes, fluorescent jacket & hand gloves shall always be ensured.

6. Housekeeping: -- Good housekeeping must be done before start and end of the day.

7. Working at adverse weather --. No work should be carried in strong wind, heavy rain and heavy hot and humid weathers.

8. Illumination --. Proper lighting arrangement to be provided at dark time.

9. Supervision --Close supervision should be provided by well experienced Engineer & Supervisor.

10. Impact of job to surrounding work area: Access / Road blockage to be taken care.

11. Scaffolding can collapse: Scaffolding should be built by competent scaffolder. After completion of scaffolding it should be inspected by competent

scaffolding inspector. After completion of scaffolding Green tag should be displayed. Workmen are allowed only on Green tag scaffolding.

12. Workmen can fall from scaffolding: Proper railing should be provided in working platform. Workmen should anchor their harness with rigid

structure. Workmen should not work standing on hand rail.

13. Electrical Safety: Male/Female Socket (IP-67) to be used and no cable joint should be there. Inspection to be done for the power tools before

using at site.

Commencement of Activity: Duration of Activity: 30 days

METHOD STATEMENT FORM

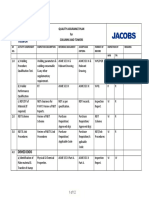

3. Responsible Engineer/Supervisor(s) Present At Work Place

4. Subcontractor(S) - Where Applicable including Responsible Engineer/Supervisor

5. Plant and Equipment Requiring Certification

6. Special Precautions and Checklist

1. Barricade the area before work started.

2. Experienced and competent workmen shall be deployed on the machine.

3. Proper communication shall be ensured among all the persons involved.

4. Workmen should work on complete scaffolding with green tag (as per GE standard).

5. Ensure full body harness and fall arrester for height work

6. Check all lifting tools & tackles like chain blocks physically and do TPI and calibrated by competent persons as per

BOCW act/ rules. Use only colour coded and tagged tools.

7. Never use defective tools & tackles. Ensure no overload condition.

8. Ensure PPE’s for all workmen. TBT shall be done before work on daily basis describing the details of the job

activities

7. Specific risk assessment or other special procedure required (If applicable list below)

1. Tool box training & POWRA along with Job safety analysis to be done before commencing the activity.

2. Trained operator shall be engaged.

3. Scaffolding should be check prior use.

4. Drinking water must be available at site.

5. Work in adverse weather condition (Rain / Storm / High Wind / Hot / Humidity / Cold): -

No work will be carried out in rainy & stormy condition. Enough drinking water available at site & instruction will

be given to personal to intake adequate drinking water in regular interval in case of Hot & Humidity condition.

6. Threat Contingency Plan

During any external threat from local people at site no argument will be done if necessary immediately work to be

stopped.

7. Emergency and first aid arrangements.

A- First aid box available at site office.

B -Emergency number displayed at site office

C -Emergency vehicle (Ambulance V/c No - ) available at site.

D. In case of an emergency, workmen will be rescued with the help of rescue kit.

METHOD STATEMENT FORM

8. Review Details:

Prepared By:

Sign: Date:

Reviewed By: Contractor EHS

Debashisha sahu Sign: Date:

ASUTOSH SHUKLA

Reviewed By: (GEPSIPL

ENGINNER)

Sign: Date:

Reviewed by: (GEPSIPL EHS

ENGINNER /MANAGER)

Sign: Date:

Approved By:

Mr. Shailesh Vashistha Sign: Date:

You might also like

- Procedure For DYE PENETRANT TestingDocument10 pagesProcedure For DYE PENETRANT TestingKarrar Talib100% (1)

- Hydrotest QI304-sampleDocument3 pagesHydrotest QI304-sampleHanuman Rao100% (1)

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (HVAC) - Sandvik G BlockParasNo ratings yet

- Concrete Casting Preparation For PourDocument4 pagesConcrete Casting Preparation For PourJedNo ratings yet

- PPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFDocument14 pagesPPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- WP 11 Corrosion Protection Tape CoatingDocument3 pagesWP 11 Corrosion Protection Tape CoatingKarthikNo ratings yet

- Pipeline TestingDocument4 pagesPipeline Testingveljko2008100% (1)

- Valve Hydro Test Status For AramcoDocument3 pagesValve Hydro Test Status For AramcousmanNo ratings yet

- Inspection, Flushing & Testing of Piping-21Document6 pagesInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaNo ratings yet

- Method Statement For For Cable Tray and Conduit Installation With Risk AssesmentDocument9 pagesMethod Statement For For Cable Tray and Conduit Installation With Risk Assesmentobasiigwe8499No ratings yet

- Method Statement Installation of Air Handling UntDocument6 pagesMethod Statement Installation of Air Handling UntkouarNo ratings yet

- EN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete ConstructionDocument33 pagesEN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete Construction章宇No ratings yet

- Gas Pipeline and Gas Metering and Regulating Station ProjectDocument18 pagesGas Pipeline and Gas Metering and Regulating Station ProjectAnonymous 7vljJzH100% (1)

- Pgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Document6 pagesPgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Manuel DizonNo ratings yet

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- Method Statement - Pouring Foundations-TemplateDocument13 pagesMethod Statement - Pouring Foundations-TemplateUğur BilenNo ratings yet

- Inspection Test Plan for Storage Tank & Piping System (ITPDocument6 pagesInspection Test Plan for Storage Tank & Piping System (ITPAhmad MohammadNo ratings yet

- Method Statement Form - HDPE PN10,16 PipeDocument22 pagesMethod Statement Form - HDPE PN10,16 PipeSmith SuwanNo ratings yet

- Vessel Final BoxDocument14 pagesVessel Final Boxmanoj thakkarNo ratings yet

- 22.MS For HydrotestDocument9 pages22.MS For HydrotestASHWANINo ratings yet

- 7560-Hydro Test - Sequence 1Document9 pages7560-Hydro Test - Sequence 1Bala MuruganNo ratings yet

- HVAC Duct Installation ProcedureDocument17 pagesHVAC Duct Installation ProcedureResearcher100% (1)

- QIPDocument9 pagesQIPzahid_497No ratings yet

- Installer's Guide For Condensing Units: 2TTB0 & 2TTB2Document8 pagesInstaller's Guide For Condensing Units: 2TTB0 & 2TTB2jimbodunkyNo ratings yet

- Afi SC03 QRBN Ci 00233Document1 pageAfi SC03 QRBN Ci 00233حسن كاظم ريسان B-4No ratings yet

- Transformer Installation MethodDocument12 pagesTransformer Installation MethodAmmar Alkindy100% (1)

- Ok-Hydraulic Oil Flushing at Terminal AreaDocument4 pagesOk-Hydraulic Oil Flushing at Terminal AreaEric TingNo ratings yet

- Procedure For Hydro Testing: Pressure TestDocument5 pagesProcedure For Hydro Testing: Pressure TestDevang ShahNo ratings yet

- 5F. Pressure Transmitter (Electronic Type) CalibratorDocument6 pages5F. Pressure Transmitter (Electronic Type) CalibratorIsaalexNo ratings yet

- Clean Pipes with Cardboard Bursting and Air BlowingDocument3 pagesClean Pipes with Cardboard Bursting and Air BlowingParthiban Karuna100% (1)

- Inspection & Test Plan For Control Valve: Project: PP Pe Pilot PlantDocument3 pagesInspection & Test Plan For Control Valve: Project: PP Pe Pilot PlantzsmithNo ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- Method Statement For Pipe Hydrostatic TestingDocument2 pagesMethod Statement For Pipe Hydrostatic TestingSandhyaRamakrishna100% (1)

- FR 002 Pressure Testing Inspection ChecklistDocument6 pagesFR 002 Pressure Testing Inspection Checklistum er100% (1)

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- Internal Painting Method StatementDocument8 pagesInternal Painting Method StatementMonali VarpeNo ratings yet

- Itp PWHTDocument1 pageItp PWHTTridib DeyNo ratings yet

- MS of Hydrotest Procedure SSDP Rev CDocument39 pagesMS of Hydrotest Procedure SSDP Rev CRachel FloresNo ratings yet

- Gas Pipe Fitting InstallationDocument2 pagesGas Pipe Fitting InstallationMcLester Love ElinaNo ratings yet

- Method Statement For LV Cables & Wires InstallationDocument6 pagesMethod Statement For LV Cables & Wires InstallationUmaira ZainalNo ratings yet

- Mechanical WIP ChecklistsDocument20 pagesMechanical WIP ChecklistsJovani G. BallonNo ratings yet

- Hindustan Petroleum Standard Piping Inspection Test PlanDocument6 pagesHindustan Petroleum Standard Piping Inspection Test Planمحمد أزها نو الدينNo ratings yet

- Safe concreting methodsDocument11 pagesSafe concreting methodsJustin Ranjit100% (1)

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- General Civil Work Method Statement For RoadsDocument3 pagesGeneral Civil Work Method Statement For RoadsKaram MoatasemNo ratings yet

- Wartsila India Ltd Boiler Hydro Test ProcedureDocument2 pagesWartsila India Ltd Boiler Hydro Test ProcedureKarthi KeyanNo ratings yet

- Maintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsDocument21 pagesMaintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsFranklin L SilvaNo ratings yet

- The Pressure Testing of DI CI and PVC Pipe - Upload - 27!10!16Document4 pagesThe Pressure Testing of DI CI and PVC Pipe - Upload - 27!10!16Rushan Lakdimuthu100% (1)

- ER288-Rebar Test PlanDocument4 pagesER288-Rebar Test PlanalfieNo ratings yet

- Submersible Pump Installation Check List: 1. Motor InspectionDocument2 pagesSubmersible Pump Installation Check List: 1. Motor Inspectiongrover2010No ratings yet

- Construction Mos For Underground Piping: Vietnam Japan Gas Joint Stock CompanyDocument18 pagesConstruction Mos For Underground Piping: Vietnam Japan Gas Joint Stock CompanyLai HuynhNo ratings yet

- Qa QCDocument10 pagesQa QCBrain Dee Tech LtdNo ratings yet

- Daily construction logDocument3 pagesDaily construction logJeri HeathNo ratings yet

- Quality Control Inspection Checklist: Gamuda BerhadDocument2 pagesQuality Control Inspection Checklist: Gamuda BerhadSyerifaizal Hj. MustaphaNo ratings yet

- 1-Manual Horizontal Stand CTS670 ST7H PDFDocument121 pages1-Manual Horizontal Stand CTS670 ST7H PDFManikandaprabhu ManickamNo ratings yet

- Hydrostatic Test ReportsDocument3 pagesHydrostatic Test ReportsHanuman RaoNo ratings yet

- SCOPE OF WORK For Cooling Tower Sump CLEANINGDocument10 pagesSCOPE OF WORK For Cooling Tower Sump CLEANINGAbhinav PradhanNo ratings yet

- Oil Retrieval Method StatementDocument3 pagesOil Retrieval Method StatementSagar SharmaNo ratings yet

- Method Statement - HVAC Duct Leakage Testing ProcedureDocument7 pagesMethod Statement - HVAC Duct Leakage Testing ProcedureSyed TouqeerNo ratings yet

- Safe Work Method For Hydro TestDocument1 pageSafe Work Method For Hydro TestEswar RaoNo ratings yet

- Code of Practice On Environmental Health (COPEH) 1998Document24 pagesCode of Practice On Environmental Health (COPEH) 1998Trang NgoNo ratings yet

- Safety PrecautionDocument1 pageSafety PrecautionSJ Chua100% (1)

- John Deere 300GLC - T357633X19 Maintenance PlannerDocument2 pagesJohn Deere 300GLC - T357633X19 Maintenance PlannerGeorge PlishkoNo ratings yet

- 16CS3123-Java Programming Course File-AutonomousDocument122 pages16CS3123-Java Programming Course File-AutonomousSyed WilayathNo ratings yet

- George Salvan Architectural Utilities 2 Electrical and Mechanical Equipment PDFDocument434 pagesGeorge Salvan Architectural Utilities 2 Electrical and Mechanical Equipment PDFclainNo ratings yet

- Welding ReportDocument15 pagesWelding ReportSamNo ratings yet

- Testing of Rubber Gaskets For Use As Elastomeric Seals For Joints in Potable Water Pipework and Pipeline - CleanedDocument5 pagesTesting of Rubber Gaskets For Use As Elastomeric Seals For Joints in Potable Water Pipework and Pipeline - CleanedKok WaiNo ratings yet

- Kodak X-Omat Multiloader 300 Film Feeder - User ManualDocument10 pagesKodak X-Omat Multiloader 300 Film Feeder - User ManualNikolay PenevNo ratings yet

- Waller Park Preview 2021Document7 pagesWaller Park Preview 2021Jason DelgadoNo ratings yet

- Teaching Guide 2Document172 pagesTeaching Guide 2Floura Sparks100% (1)

- C&I Engineering Field Cabinet SpecificationDocument6 pagesC&I Engineering Field Cabinet Specificationishu vohraNo ratings yet

- Melab1 Exp3Document11 pagesMelab1 Exp3John Ferben Sallena DepnagNo ratings yet

- 2SK2663Document1 page2SK2663hectorsevillaNo ratings yet

- Modified o and G Slides 2Document21 pagesModified o and G Slides 2Salam FaithNo ratings yet

- QUOTATION For ARIS 05 12 23Document5 pagesQUOTATION For ARIS 05 12 23Kasarachi AmadiNo ratings yet

- Training Manual-Piping: Piping Study Underground PipingDocument30 pagesTraining Manual-Piping: Piping Study Underground Pipingrams789100% (2)

- Commodore 64 Assembly Language Programming PDFDocument243 pagesCommodore 64 Assembly Language Programming PDFbandihoot100% (1)

- Boq PDFDocument12 pagesBoq PDFChandeshwor Shah0% (1)

- Chemistry PSPM 1 2008/2009Document3 pagesChemistry PSPM 1 2008/2009Viknish Arumugam50% (2)

- Using Impact LX With ReaperDocument8 pagesUsing Impact LX With Reaper算踏空100% (1)

- Safety Director EHS SH&E in Philadelphia PA Resume Dale JohnsonDocument2 pagesSafety Director EHS SH&E in Philadelphia PA Resume Dale JohnsonDale JohnsonNo ratings yet

- P16NF06FP STMicroelectronicsDocument9 pagesP16NF06FP STMicroelectronicsSoniaNo ratings yet

- Name of Work: Estimation For Proposed Construction of Tara Ramesh, Tangali, Kadur Taluk, Chikkamagalur DistrictDocument25 pagesName of Work: Estimation For Proposed Construction of Tara Ramesh, Tangali, Kadur Taluk, Chikkamagalur DistrictDEEPIKANo ratings yet

- ASTM D747 Overview PDFDocument41 pagesASTM D747 Overview PDFtangogll11No ratings yet

- Troubleshooting guide for car audio amplifierDocument2 pagesTroubleshooting guide for car audio amplifierDanny Garcia LopezNo ratings yet

- CSS Selector Cheat SheetDocument3 pagesCSS Selector Cheat SheetRodrigo-5553974No ratings yet

- SmarAct Vacuum Options V3bDocument8 pagesSmarAct Vacuum Options V3bnayakr1127No ratings yet

- Active Apprentices by Trade and by GenderDocument3 pagesActive Apprentices by Trade and by GenderThe Hamilton SpectatorNo ratings yet

- Component-Based Development Ben Fairfax Thursday 21st September 2006Document65 pagesComponent-Based Development Ben Fairfax Thursday 21st September 2006sdimi51No ratings yet

- PMAS-Arid Agriculture University RawalpindiDocument3 pagesPMAS-Arid Agriculture University RawalpindiAli AzanNo ratings yet