Professional Documents

Culture Documents

Ok-Hydraulic Oil Flushing at Terminal Area

Uploaded by

Eric TingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ok-Hydraulic Oil Flushing at Terminal Area

Uploaded by

Eric TingCopyright:

Available Formats

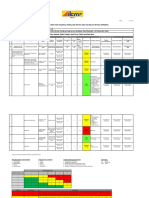

PETRONAS LNG COMPLEX

JOB HAZARD ANALYSIS

Serial Number: 0003377 Owner: PDD/4

Revision Number 1 Date Created: 27/01/2017 10:58

Job Title MDR PROJECT – HYDRAULIC OIL FLUSHING AT MODULE 5 AREA

Status Approved

Area MLNG DUA

Author Michael Ling

Job Hazard Analysis Members

No Name Department Status Date Time

1 Lau Ho Kung Project Delivery Department Reviewed 30/01/2017 23:42

2 Sukiman Bin Hamdin Health, Safety & Environment Reviewed 06/02/2017 12:49

3 Donney Mon Meng Chik Operations Department Reviewed 02/02/2017 02:15

Contractors

HYPERWAVE - LP CONSORTIUM

Worksheet

JOB HAZARD ANALYSIS WORKSHEET

No. Description of Job Potential Hazard/Risk Who/What Might Control Measure/Mitigation Action Party

Step be Harmed

1.0 Mobilization and MLNG JHA No: 2490 REFER TO

demobilization of MOBILIZATION AND DEMOBILIZATION OF MATERIAL, EQUIPMENT & PARTS USING FORKSLIFT,

material and LORRY, TRAILER, MOBILE CRANE & LORRY CRANE INCLUDING MANUAL HANDLING AT TERMINAL

equipment to site AREA

2.0 To operate flushing Defective equipment People · To ensure all the equipment Work Leader

unit powered by are inspected and approved by

generator set and AIN/45

laser particle · To pre-inspect the machines

counter. and equipment prior to use

· All defective equipment shall

be remove from site

Obstructing People · To station machine at proper Work Leader

emergency walkway designated location approved by

OPS Area

· Do not obstruct any

firefighting facilities

· To install hard barricade and put

up safety signage at work site

Static electricity People · To confirm machines to be Work Leader

installed with two earthing (min 25mm

sq)

Electric shock People · To comply with TIEC & Work Leader

PETI requirement

· To wear rubber coated hand glove

· To remove defective cable from site

· To stop work when raining

High pressure People · To confirm all relief valve and Work Leader

hydraulic oil release pressure gauge have been pop-tested

from flushing unit and calibrated

· To slowly open the valve

Trapped pressure People To completely depressurize the Work Leader

remaining pressure back to flushing

unit and confirmed by competent

personnel operating the flushing unit

·

Tripping People · To lay flexible hose and cable properly Work Leader

· To station equipment at

approved designated location

· To ensure emergency route

not blocked by equipment

3.0 Pressure test (220 High Pressure People · The area under the pressure Work Leader

barg) using flushing test vicinity area to be barricaded PMT

unit using red

/white barricade tape

· To post warning (Pressure test is

in progress) signboard

· Only authorized personnel can

enter pressure test area.

· To be fully supervised by

authorized person.

· Only authorized personnel to

carry out pressure test work

· Usage of high pressure certified

hoses and fittings

· Increase pressure gradually

High pressure Hose People · To use rated and high pressure Work Leader

Loose type of hose and connector (Swagelok)

· To install whip check on the hose

Over Pressure People · To ensure the flushing unit is Work Leader

installed with relief valve

· Use proper rating and

calibrated pressure gauge.

· Authorized personnel to monitor

the activity

4.0 Leak check during Leak Pressure People · No repair & modification work Work Leader

holding pressure Asset during holding pressure

· If leak detected, reduce pressure

gradually and repair can only

commence once the line is fully

depressurized

· Pressure test area to be monitored

and must not be left unattended.

· To use correct type high

pressure certified hose and fittings

Oil Leak Environme · To provide spill kit at site. · Work

nt · To carry out cleaning Leader

and housekeeping

· Oil contaminated cotton

rags or gloves to be disposed

as schedule waste

5.0 Mobilize Drums Oil spillage People · To ensure drums to be transported Work Leader

Environment in pallet

· To ensure spill kit at site.

Heavy drum People · To use pallet jack for transporting. Work Leader

· To practice proper lifting

posture. (Highlight during tool-box

talk on proper lifting technique).

· Barricade work area and

signage shall be posted.

Pinch point People · To use cotton/ semi-leather Work Leader

gloves when handling of waste oil

drum

· To be more vigilant and

establish good communication during

transfer

6.0 Draining / filling of Slippery floor from People · To ensure secondary drip pans Work Leader

hydraulic oil into drum spilled oil Environment and adequate absorbent are provided

/ tank at site.

· To ensure proper containment of

spent hydraulic oil and dispose it as

schedule waste as per MLNG

requirement.

· To ensure empty oil drums are free

from defect before handling and

transport to site.

· To standby spill kit at site

7.0 Housekeeping Slip, trip and fall People · To maintain good housekeeping at Work Leader

all times

Scheduled waste Environment · To ensure proper segregation Work Leader

of general waste and schedule

waste

· All schedule waste to be declared

and disposed as per MLNG regulation

and requirements

General Notes

1. Emergency contact number:

Duty Shift Superintendent Ext: - 6007/MLNG RADIO (Process 2 Channel)

Duty Shift Manager Ext.: - 6085

Industrial Clinic Ext.: - 3911 / 3933

PDD 4 / PMT: - 6393/ MLNG RADIO (MDR Channel)

MLNG OPS/12: - MLNG RADIO (MDR Channel)

Approval status

Prepared By Contractors

Name : Michael Ling HYPERWAVE - LP CONSORTIUM

Date : 27/01/2017 Time : 10:58

You might also like

- Electrical Insulation and Thermal Measurements For Motors and Drives AnDocument4 pagesElectrical Insulation and Thermal Measurements For Motors and Drives Anmu_ignoreNo ratings yet

- Radiographic Examination Procedure For Asme CodeDocument33 pagesRadiographic Examination Procedure For Asme CodeEdAlmNo ratings yet

- API-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFDocument3 pagesAPI-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFSailesh SharmaNo ratings yet

- Asme Guidance Notes: Prepared by TQ. Hoa - 9/2014Document1 pageAsme Guidance Notes: Prepared by TQ. Hoa - 9/2014Trịnh Quốc TuyếnNo ratings yet

- Minimum Practical Wall ThicknessDocument5 pagesMinimum Practical Wall ThicknessDiana CarolinaNo ratings yet

- How To Select Welding ElectrodesDocument6 pagesHow To Select Welding ElectrodesRobert DelafosseNo ratings yet

- MS-M2101 (S09) - HSSE-GP-003 ERP Rev 0Document32 pagesMS-M2101 (S09) - HSSE-GP-003 ERP Rev 0Lau Poung HieNo ratings yet

- JIT Supervisor Verifier Training v10Document51 pagesJIT Supervisor Verifier Training v10Farghud EismethNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- Material Conversion TableDocument1 pageMaterial Conversion TableravikumarangNo ratings yet

- Analysis of Motor - Pump Vibration - Kishore KaruppaswamyDocument8 pagesAnalysis of Motor - Pump Vibration - Kishore KaruppaswamyhafezasadNo ratings yet

- How To Write A Welding Procedure Specification (WPS)Document5 pagesHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoNo ratings yet

- Doc. No Revision No Revision DateDocument6 pagesDoc. No Revision No Revision DateShyam SinghNo ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- Technical Proposal Descaling Removal Pulai - A (2013 ASD)Document22 pagesTechnical Proposal Descaling Removal Pulai - A (2013 ASD)hash117No ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- GRE INS-009, Flange Bolting ProcedureDocument6 pagesGRE INS-009, Flange Bolting Proceduresyed jafar100% (1)

- Samson Globe Control ValveDocument12 pagesSamson Globe Control ValveShishir DwivediNo ratings yet

- Mset Engineering SDN BHD: Door End Closure Replacement MLNG (PL 291)Document3 pagesMset Engineering SDN BHD: Door End Closure Replacement MLNG (PL 291)BhisamS SallehNo ratings yet

- Welding Material Control ProcedureDocument12 pagesWelding Material Control ProcedureWalter RuedaNo ratings yet

- Doha North Sewerage Treatment & Associated WorksDocument67 pagesDoha North Sewerage Treatment & Associated WorksLito MendozaNo ratings yet

- HIRARC FORM 2023 - Tugasan Start Up and Shut Down OPPDocument4 pagesHIRARC FORM 2023 - Tugasan Start Up and Shut Down OPPMuhammad 'Aizat PaimanNo ratings yet

- 6 Contractor QC Resume Review ChecklistDocument1 page6 Contractor QC Resume Review ChecklistMudabbir HussainNo ratings yet

- EM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFDocument37 pagesEM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFdang2172014No ratings yet

- 15-Document Distribution RecordDocument1 page15-Document Distribution RecordNiraNo ratings yet

- Shoring ProcedureDocument7 pagesShoring Procedurechebok manNo ratings yet

- Method Statement For The Repair Works of HDPEDocument1 pageMethod Statement For The Repair Works of HDPEshameemNo ratings yet

- Method Statement For Hydro TestDocument3 pagesMethod Statement For Hydro TestSandeep kumar100% (1)

- Oil Pantriting ProcedureDocument5 pagesOil Pantriting ProcedureSERT-QA/QC- BUZNo ratings yet

- W14-661 (0 To 40 Bar) PDFDocument3 pagesW14-661 (0 To 40 Bar) PDFBalaji BobadeNo ratings yet

- Weld Repair ProcedureDocument51 pagesWeld Repair Proceduremohd as shahiddin jafriNo ratings yet

- Welding Procedure Specification (WPS)Document30 pagesWelding Procedure Specification (WPS)ganathaNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Document19 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNo ratings yet

- Radiation Safety Distance DiagramDocument3 pagesRadiation Safety Distance DiagramEswaranNo ratings yet

- Threaded JointsDocument9 pagesThreaded JointsEssKayNo ratings yet

- User'S Manual: MANUAL NO - GL240-UM-153Document150 pagesUser'S Manual: MANUAL NO - GL240-UM-153Ta100% (1)

- TADANO 80ton GR-800EX - Specification & Load Chart PDFDocument13 pagesTADANO 80ton GR-800EX - Specification & Load Chart PDFBruce Li0% (1)

- Asme 1325-18 (2007)Document1 pageAsme 1325-18 (2007)Matthew TaylorNo ratings yet

- QW 381Document1 pageQW 381Waqas WaqasNo ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- TSK Fully Automatic Batch Type CentrifugeDocument15 pagesTSK Fully Automatic Batch Type CentrifugeAfaaq HussainNo ratings yet

- Steel Material Table PDFDocument1 pageSteel Material Table PDFNathanNo ratings yet

- PP WP28Document15 pagesPP WP28mohd as shahiddin jafriNo ratings yet

- Scope: Method Statement For Welding ControlDocument6 pagesScope: Method Statement For Welding ControlSIBINNo ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- 0610.1 - Shell and Tube Heat ExchangersDocument30 pages0610.1 - Shell and Tube Heat Exchangersvenkatrangan2003No ratings yet

- TCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerDocument118 pagesTCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerNam NguyenNo ratings yet

- CS 5200 SC01 Ope PRC 253007 - A - C2Document78 pagesCS 5200 SC01 Ope PRC 253007 - A - C2chancele nguepdjopNo ratings yet

- Pulley 1Document4 pagesPulley 1Vijayakumar SamyNo ratings yet

- Snoop Leak Test LiquidDocument6 pagesSnoop Leak Test Liquidaldi_crisNo ratings yet

- EFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDocument2 pagesEFCO Maschinenbau India Private Limited: Job Card - Isolation ValveDebasis Pattnaik DebaNo ratings yet

- Vessel Final BoxDocument14 pagesVessel Final Boxmanoj thakkarNo ratings yet

- 4.2.1 HVA Adhesive Anchor: Anchoring SystemsDocument15 pages4.2.1 HVA Adhesive Anchor: Anchoring SystemsechavarriNo ratings yet

- Why Is "Cold Cutting" Superior To Plasma Cutting?Document9 pagesWhy Is "Cold Cutting" Superior To Plasma Cutting?ahmedNo ratings yet

- Sarawak Work Permit Process-Flow (6 & 12 Months) : No Time Frame 180 Working Days 3 Working DaysDocument1 pageSarawak Work Permit Process-Flow (6 & 12 Months) : No Time Frame 180 Working Days 3 Working DaysRamLooNo ratings yet

- Pressure Gauge Technical InformationsDocument4 pagesPressure Gauge Technical Informationssahayaraaj100% (1)

- Covered Electrodes For Stainless Steel: Avesta Electrodes Product ProgrammeDocument4 pagesCovered Electrodes For Stainless Steel: Avesta Electrodes Product Programmekamals55No ratings yet

- 4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andDocument3 pages4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andEric TingNo ratings yet

- Tie - in Mechanical Installation JHADocument7 pagesTie - in Mechanical Installation JHAmalik jahanNo ratings yet

- 4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andDocument3 pages4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andEric TingNo ratings yet

- 3059-CABLE TERMINATION, LOOP TEST, LEAK TEST, PRE-COMMISSIONING Mod 5Document10 pages3059-CABLE TERMINATION, LOOP TEST, LEAK TEST, PRE-COMMISSIONING Mod 5Eric TingNo ratings yet

- 01000910Document13 pages01000910minhthanhmosNo ratings yet

- 3922-MDR Project - Installation and Relocation Reposition of Lighting Fixture Including Testing at Module 5 PDFDocument3 pages3922-MDR Project - Installation and Relocation Reposition of Lighting Fixture Including Testing at Module 5 PDFEric TingNo ratings yet

- Petronas Technical Standards: Preparation of Process Flow Schemes and Process Engineering Flow SchemesDocument19 pagesPetronas Technical Standards: Preparation of Process Flow Schemes and Process Engineering Flow SchemesEric TingNo ratings yet

- 3059-CABLE TERMINATION, LOOP TEST, LEAK TEST, PRE-COMMISSIONING Mod 5Document10 pages3059-CABLE TERMINATION, LOOP TEST, LEAK TEST, PRE-COMMISSIONING Mod 5Eric TingNo ratings yet

- Ok-Venting & Charging of Nitrogen Accumulator at Terminal AreaDocument3 pagesOk-Venting & Charging of Nitrogen Accumulator at Terminal AreaEric TingNo ratings yet

- 3922-MDR Project - Installation and Relocation Reposition of Lighting Fixture Including Testing at Module 5Document3 pages3922-MDR Project - Installation and Relocation Reposition of Lighting Fixture Including Testing at Module 5Eric TingNo ratings yet

- Tech Spec Boiler Cleaningrev2Document21 pagesTech Spec Boiler Cleaningrev2Eric TingNo ratings yet

- Petronastechnicalstandards: Pipe SupportsDocument41 pagesPetronastechnicalstandards: Pipe SupportsEric TingNo ratings yet

- Tank Info PDFDocument8 pagesTank Info PDFEric TingNo ratings yet

- t1642164 B PDFDocument10 pagest1642164 B PDFEric TingNo ratings yet

- Iso 8501Document4 pagesIso 8501cisar0007100% (2)

- DOSH Shutdown RolesDocument4 pagesDOSH Shutdown RolesEric TingNo ratings yet

- M180-14 Civil and TanksDocument53 pagesM180-14 Civil and TanksEric TingNo ratings yet

- Api 610Document11 pagesApi 610prakasharmyNo ratings yet

- Petronastechnicalstandards: Pipe SupportsDocument41 pagesPetronastechnicalstandards: Pipe SupportsEric TingNo ratings yet

- Optimized BurnerDocument12 pagesOptimized BurnerprashantNo ratings yet

- Em Piping ClassDocument25 pagesEm Piping ClassEric TingNo ratings yet

- PDFDocument48 pagesPDFEric Ting100% (1)

- Corrosion EconomicsDocument9 pagesCorrosion EconomicsEmmanuel EkongNo ratings yet

- SP Coating and Wrapping of Line PipeDocument14 pagesSP Coating and Wrapping of Line PipeĐiệnBiênNhâm100% (1)

- Mesh To Micron ConverterDocument1 pageMesh To Micron ConverterAniket royNo ratings yet

- The Nature of Water: P - A - R - T - 1Document7 pagesThe Nature of Water: P - A - R - T - 1nemamohaNo ratings yet

- JHA Bolting Unbolting and Manual LiftingDocument4 pagesJHA Bolting Unbolting and Manual LiftingEric Ting100% (1)

- Optimized BurnerDocument12 pagesOptimized BurnerprashantNo ratings yet

- Optimized BurnerDocument12 pagesOptimized BurnerprashantNo ratings yet

- Fired Boilers: 2.1 Design PrinciplesDocument6 pagesFired Boilers: 2.1 Design PrinciplesEric TingNo ratings yet

- Corrosion EconomicsDocument9 pagesCorrosion EconomicsEmmanuel EkongNo ratings yet

- Artificial Intelligence in Power System OperationsDocument8 pagesArtificial Intelligence in Power System OperationsDummyofindiaIndiaNo ratings yet

- Alien Bestiary PDFDocument450 pagesAlien Bestiary PDFDũng Lê100% (13)

- Certified Vendors As of 6 17 22Document18 pagesCertified Vendors As of 6 17 22Harry ConnerNo ratings yet

- Arid Agriculture University, RawalpindiDocument4 pagesArid Agriculture University, RawalpindiIsHa KhAnNo ratings yet

- FreeBSD HandbookDocument26 pagesFreeBSD Handbookhembeck119No ratings yet

- Transfer Request 2022 - CBOA CHENNAIDocument5 pagesTransfer Request 2022 - CBOA CHENNAIVignesh NarayananNo ratings yet

- Vastra Grah .Pvt. LTD: In-House Manufacturing FacaltyDocument2 pagesVastra Grah .Pvt. LTD: In-House Manufacturing FacaltySaurabh JainNo ratings yet

- Dokumen - Tips Dm3220-Servicemanual PDFDocument62 pagesDokumen - Tips Dm3220-Servicemanual PDFwalidsayed1No ratings yet

- Children Literature Evaluation Form I Aint Gonna Paint No MoreDocument4 pagesChildren Literature Evaluation Form I Aint Gonna Paint No Moreapi-548506674No ratings yet

- James Bruce, One of Russian Tsar Peter The Great's Key Advisors (1669-1735)Document2 pagesJames Bruce, One of Russian Tsar Peter The Great's Key Advisors (1669-1735)Johanna Granville100% (1)

- Step Buying Process in LazadaDocument4 pagesStep Buying Process in LazadaAfifah FatihahNo ratings yet

- Reading Comprehension Pre TestDocument7 pagesReading Comprehension Pre TestMimimiyuhNo ratings yet

- Lesson Plan - Manner, Matter, and MethodDocument3 pagesLesson Plan - Manner, Matter, and MethodRIVALDO MALAWATNo ratings yet

- Trockel Flash Art 1987Document4 pagesTrockel Flash Art 1987cvg_geNo ratings yet

- Factors Affecting Pakistani English Language LearnersDocument19 pagesFactors Affecting Pakistani English Language LearnersSaima Bint e KarimNo ratings yet

- B737 AutothrottleDocument103 pagesB737 AutothrottleZaw100% (1)

- A Priori and A Posteriori Knowledge: A Priori Knowledge Is Knowledge That Is Known Independently of Experience (That IsDocument7 pagesA Priori and A Posteriori Knowledge: A Priori Knowledge Is Knowledge That Is Known Independently of Experience (That Ispiyush_maheshwari22No ratings yet

- Mark Scheme: Double Award Science BiologyDocument9 pagesMark Scheme: Double Award Science BiologyDaniel LoughreyNo ratings yet

- Eating Well: Snacks For 1-4 Year OldsDocument42 pagesEating Well: Snacks For 1-4 Year OldsAndreea AndreiNo ratings yet

- Cassius Resume CVLatestDocument3 pagesCassius Resume CVLatestCaszNo ratings yet

- Pricelist LV Siemens 2019 PDFDocument96 pagesPricelist LV Siemens 2019 PDFBerlianiNo ratings yet

- Marking Scheme According To AIDocument2 pagesMarking Scheme According To AIAbdul RehmanNo ratings yet

- Qatar OM PART C PDFDocument796 pagesQatar OM PART C PDFBobi Guau100% (3)

- Pengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Document11 pagesPengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Rezaa RezNo ratings yet

- Final Exam Tle Grade 8Document4 pagesFinal Exam Tle Grade 8John leo Claus67% (3)

- LNMIIT Course Information Form: A. B. C. D. E. FDocument2 pagesLNMIIT Course Information Form: A. B. C. D. E. FAayush JainNo ratings yet

- John Deere CaseDocument2 pagesJohn Deere CaseAldo ReynaNo ratings yet

- The Positive and Negative Impact of Inclusive LeadershipDocument9 pagesThe Positive and Negative Impact of Inclusive LeadershipAmbreen ZainebNo ratings yet

- ECON 211: Principles of Macroeconomics-901: Smhussain@vcu - EduDocument6 pagesECON 211: Principles of Macroeconomics-901: Smhussain@vcu - EdusshinnNo ratings yet