Professional Documents

Culture Documents

Process Flow Charts For Fruits and Vegetables

Uploaded by

xinaw932090 ratings0% found this document useful (0 votes)

71 views13 pagesOriginal Title

note_3_Process_flow_charts_fruis_and_vegetables

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

71 views13 pagesProcess Flow Charts For Fruits and Vegetables

Uploaded by

xinaw93209Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

Process Flow Charts for Fruits and Vegetables

Process and material

Flow Chart for

Lemon Squash

Production

Process and material

Flow Chart for

Mango Drink

Production

Process and material

Flow Chart for

Mango Jam

Production

Process and material

Flow Chart for

Mango Pickle

Production

Process and material

Flow Chart for

Orange Squash

Production

Process and material

Flow Chart for Banana

Slice Production

by Osmotic Dehydration

Process and material

Flow Chart for

Sweetened Pineapple

Slice Production

Process and material

Flow Chart for

Puffed Potato

Production

Process and material

Flow Chart for

Tomato Sauce

Production

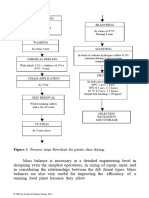

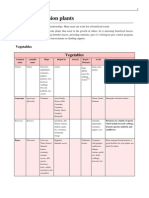

Tomato( 1 kg)

Process and material flow chart

for production of Tomato Sauce Cleaning, washing and evaporation

of surface moisture

from tomato concentrate

produced using Thin Film

Scraped Surface Evaporator Scalding

in boiling water for 3min

Spicemix, 0.0204 kg

Sugar, 0.047 kg Pulping Seed + Skin, (0.138 kg)

Juice, 0.862 kg ( 4 Bx)

Juice, 0.25 kg Juice, 0.612 kg

Spice extraction,

(i)First stage boiling Concentration

inopen pan for 20 min Water

by using thin film scraped surface vapour, 0.662 kg

(ii)Second stage

boiling after addition of

Tomato evaporator at 75 oC, 355 rpm

concentrate for 5 min concentrate,

0.136 kg (18 Bx)

Water vapour 0.123 kg.

, kg

Tomato sauce, 0.33

Process and material

Flow Chart for

Tomato Ketchup

Production

Process and material

Flow Chart for

Tomato Powder

Production using

Foam Mat Drying

You might also like

- Enjoy Cooking The Costco WayDocument256 pagesEnjoy Cooking The Costco Wayhwmaw100% (1)

- Martha Stewart Living - September 2016 PDFDocument132 pagesMartha Stewart Living - September 2016 PDFNinfea.net100% (4)

- Ugandan Social Worker Juggles Urban Tomato Farming Reaping BigDocument7 pagesUgandan Social Worker Juggles Urban Tomato Farming Reaping BigMasiko JamesNo ratings yet

- Soya BeanDocument13 pagesSoya Beansrimalathi100% (1)

- Saba BananaDocument50 pagesSaba BananaRichard Carizon0% (1)

- Food Processing Lab 1Document19 pagesFood Processing Lab 1Vanessa LimNo ratings yet

- Kolej Tingkatan 6 ChemiDocument23 pagesKolej Tingkatan 6 Chemi琳儿No ratings yet

- EXP 3 DesignDocument52 pagesEXP 3 DesignnasuhaNo ratings yet

- Pectin ExtractionDocument30 pagesPectin ExtractionRam ChaitanyaNo ratings yet

- Technical Dossier: Ready-To-Use Dosa Batter in Retail PacksDocument13 pagesTechnical Dossier: Ready-To-Use Dosa Batter in Retail PacksRajesh KumarNo ratings yet

- Notes On RTS BeveregesDocument5 pagesNotes On RTS BeveregesNirmal SharmaNo ratings yet

- Idli Pre Mix MakingDocument14 pagesIdli Pre Mix MakingSanjeev ChaudharyNo ratings yet

- Laporan Lks VcoDocument15 pagesLaporan Lks VcoCaalsa CacaNo ratings yet

- Exercise No. 1 DataDocument11 pagesExercise No. 1 DataCarol Manongsong EncarnadoNo ratings yet

- Internship Report On Dashen BreweryDocument27 pagesInternship Report On Dashen BreweryYng Dmb Broke Guy100% (2)

- Snack CrackersDocument46 pagesSnack CrackersJoana BentoNo ratings yet

- Appendix A Material Balance: 1691.31 KG/HR Banana Powder 1691.31 KG/HRDocument7 pagesAppendix A Material Balance: 1691.31 KG/HR Banana Powder 1691.31 KG/HRMarielle Eden Ulanday TamboleroNo ratings yet

- Patent Search WorksheetDocument4 pagesPatent Search WorksheetMary Lynn Dela PeñaNo ratings yet

- Media and Their CompositionDocument22 pagesMedia and Their Compositionالمركز الطبي الحديثNo ratings yet

- Mozzarella Cheese - Process Flow DiagramDocument1 pageMozzarella Cheese - Process Flow DiagramawaaanNo ratings yet

- Pengolahan Limbah Buangan Industri Tahu Dengan Menggunakan Bioreaktor Biakan Melekat Secara Anaerob-AerobDocument12 pagesPengolahan Limbah Buangan Industri Tahu Dengan Menggunakan Bioreaktor Biakan Melekat Secara Anaerob-AerobRizky AnjanaNo ratings yet

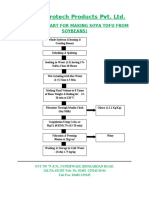

- Process Chart For Making Soya TofuDocument3 pagesProcess Chart For Making Soya TofuGAURI AGROTECHNo ratings yet

- Chapter 2.1 - Production of Tomato ProductsDocument49 pagesChapter 2.1 - Production of Tomato ProductsSyahirah FazialNo ratings yet

- Lecture 3 SugarDocument31 pagesLecture 3 Sugarmail3temuNo ratings yet

- Shaka R GanjDocument36 pagesShaka R Ganjhk168No ratings yet

- Utilization of Banana Peel For Bioethanol Production Using Baker's Yeast StarterDocument7 pagesUtilization of Banana Peel For Bioethanol Production Using Baker's Yeast StarterTsukishima KeiNo ratings yet

- Garmentswashing 140503100214 Phpapp01Document19 pagesGarmentswashing 140503100214 Phpapp01satexNo ratings yet

- Chapter 5 NewDocument17 pagesChapter 5 NewAnonymous sus3ugOxkwNo ratings yet

- Semester ProjectDocument21 pagesSemester ProjectTamr KasayeNo ratings yet

- Formula 1639 Red Clay Mask StickDocument1 pageFormula 1639 Red Clay Mask StickEricaDalcinNo ratings yet

- Article1380534996 - Taiwo Et Al PDFDocument3 pagesArticle1380534996 - Taiwo Et Al PDFLuxainne Tremont EchegarayNo ratings yet

- Vinegar and Wine Making PresentationDocument27 pagesVinegar and Wine Making PresentationKMNo ratings yet

- Coffee Pulping: Chapter - 21Document4 pagesCoffee Pulping: Chapter - 21Vivi VargasNo ratings yet

- FermentationDocument38 pagesFermentationhiteshtanwer13No ratings yet

- 0 0 1211812181211ManufacturingProcessDocument17 pages0 0 1211812181211ManufacturingProcessLUISNo ratings yet

- FST528 Lab ManualDocument31 pagesFST528 Lab ManualNurSyazaHani100% (2)

- Quis B.ing Pak JayusDocument3 pagesQuis B.ing Pak JayusNaila Aulia FatwaNo ratings yet

- Production of Vinegar From Coconut (Cocos Nucifera)Document66 pagesProduction of Vinegar From Coconut (Cocos Nucifera)Jagna LannaoNo ratings yet

- Potato Slices ProductionDocument29 pagesPotato Slices Productioneuchariauboh6No ratings yet

- Chapter - IV: Detection, Isolation A N D Characterization of The PathogenDocument40 pagesChapter - IV: Detection, Isolation A N D Characterization of The PathogenCarlos Alberto Ramirez GarciaNo ratings yet

- Technical Study Objectives: Gok, A Dumpling Wrapped With Taro Root Filled With Meat and Sweet TaroDocument18 pagesTechnical Study Objectives: Gok, A Dumpling Wrapped With Taro Root Filled With Meat and Sweet TaroDreaming DuckyyyNo ratings yet

- Magnesium Citrate Solution I. Objective: To Prepare Magnesium Citrate Solution II. MaterialsDocument2 pagesMagnesium Citrate Solution I. Objective: To Prepare Magnesium Citrate Solution II. Materialsسلطانة عبد اللهNo ratings yet

- finalpaperreporttoKRC Bukojuice PDFDocument11 pagesfinalpaperreporttoKRC Bukojuice PDFMira Thrina CapilitanNo ratings yet

- Muskan SoniDocument26 pagesMuskan Soni58 Komal SoniNo ratings yet

- SlideDocument13 pagesSlideAisarya DasNo ratings yet

- Chemestry PresentationDocument17 pagesChemestry PresentationFAGUN SONINo ratings yet

- E AnilDocument32 pagesE AnilShaik ShafiNo ratings yet

- Rutva PPT ProjectDocument31 pagesRutva PPT Projectrutvikchabhadiya111No ratings yet

- Bodebrown Mild AleDocument2 pagesBodebrown Mild Aleadriano70No ratings yet

- RESULTS Tinh B TDocument3 pagesRESULTS Tinh B THƯƠNG NGUYỄN LÊ NGỌCNo ratings yet

- Thermal Effects On Hydrothermal Biomass Liquefaction: # Humana Press Inc. 2008Document8 pagesThermal Effects On Hydrothermal Biomass Liquefaction: # Humana Press Inc. 2008Amal ..No ratings yet

- Analysis The Activities of Clean in Place (Cip) of Sauce Production in Producing WasteDocument12 pagesAnalysis The Activities of Clean in Place (Cip) of Sauce Production in Producing WasteNi IluhNo ratings yet

- Pumpkin Moringa SpreadDocument8 pagesPumpkin Moringa SpreadMary Lynn Dela PeñaNo ratings yet

- In GradientsDocument2 pagesIn GradientsrejamskNo ratings yet

- CoCo PorterDocument2 pagesCoCo PorterSilviu NistorNo ratings yet

- Project SampleDocument3 pagesProject SampleFranchiezca AoananNo ratings yet

- Project Profile On Soya Milk, Paneer & CurdDocument9 pagesProject Profile On Soya Milk, Paneer & CurdShashank ChauhanNo ratings yet

- Daily Report - TC CDP Level 1: SubjectDocument4 pagesDaily Report - TC CDP Level 1: SubjectMuhammad IsroNo ratings yet

- Flavor-Forward Fruit - Boiron-Baldor 31 January 2012Document12 pagesFlavor-Forward Fruit - Boiron-Baldor 31 January 2012mlaiskonis50% (2)

- Chataignier CC and Sodatan Auto C The Future of Chestnut PDFDocument21 pagesChataignier CC and Sodatan Auto C The Future of Chestnut PDFLacus Aurelia Aurita ThinkpositiflyNo ratings yet

- Mayonnaise PlantDocument19 pagesMayonnaise PlantVishal Salve100% (1)

- Sodium Benzoate TauqeerDocument17 pagesSodium Benzoate TauqeerSana AsifNo ratings yet

- Manual of Methods OF Analysis of Foods: Milk and Milk ProductsDocument197 pagesManual of Methods OF Analysis of Foods: Milk and Milk ProductsGajendra Singh Raghav100% (2)

- Name HereDocument1 pageName Heretisafe6813No ratings yet

- Dairy Products Production Flow ChartDocument14 pagesDairy Products Production Flow Chartxinaw93209No ratings yet

- Chapter 07 2SPPDocument37 pagesChapter 07 2SPPxinaw93209No ratings yet

- Name HereDocument1 pageName Heretisafe6813No ratings yet

- Name HereDocument1 pageName Heretisafe6813No ratings yet

- Morrison 1988Document18 pagesMorrison 1988Kristem KertzeifNo ratings yet

- 6 Week Shred Crock Pot RecipesDocument56 pages6 Week Shred Crock Pot Recipesk h100% (1)

- Pablo NerudaDocument4 pagesPablo Nerudarupal aroraNo ratings yet

- IELTS Essentials (2020) PDFDocument62 pagesIELTS Essentials (2020) PDFKhant Zaw Thant100% (1)

- KCSAP TIMPS - Tomato VC June2019Document131 pagesKCSAP TIMPS - Tomato VC June2019IdrisNo ratings yet

- Word Problems Problem Workbook PDFDocument22 pagesWord Problems Problem Workbook PDFBobToms100% (2)

- I. IntroductionDocument36 pagesI. IntroductionKatrina FamadorNo ratings yet

- E-CBEA TLE-G9 CookeryDocument5 pagesE-CBEA TLE-G9 CookeryRexie FriasNo ratings yet

- Kitchen Garden Lay OutDocument24 pagesKitchen Garden Lay OutDr.Eswara Reddy SiddareddyNo ratings yet

- Times Leader 05-19-2012Document58 pagesTimes Leader 05-19-2012The Times LeaderNo ratings yet

- A Couple of Spoonfuls Cookbook April 2019 - 2024-02-03T145744.143Document40 pagesA Couple of Spoonfuls Cookbook April 2019 - 2024-02-03T145744.143readreaz98No ratings yet

- Zat Pengatur Tumbuh (ZPT) or Growth Regulatory Substances. The Gibberellin IsDocument2 pagesZat Pengatur Tumbuh (ZPT) or Growth Regulatory Substances. The Gibberellin IsMochammad FebriantoNo ratings yet

- Case Study KishanDocument2 pagesCase Study KishanParas SavasiyaNo ratings yet

- What's Cookin' Good Lookin'Document20 pagesWhat's Cookin' Good Lookin'Stad IcsNo ratings yet

- HNF 103 Scientific PaperDocument5 pagesHNF 103 Scientific PaperMadeleineNo ratings yet

- 4A Dr. Y. Mori 160607 - Mebiol APO Presentation PDFDocument46 pages4A Dr. Y. Mori 160607 - Mebiol APO Presentation PDFDavaatseren NarmandakhNo ratings yet

- FNS20121000003 50900123 PDFDocument21 pagesFNS20121000003 50900123 PDFTalia SyanilaNo ratings yet

- Abhishek Dabur ReportDocument45 pagesAbhishek Dabur ReportAbhishek SinghNo ratings yet

- Vegetable QuestionDocument47 pagesVegetable QuestionSubs KatsNo ratings yet

- Benefits of Fruit and Vegetables For HealthDocument45 pagesBenefits of Fruit and Vegetables For HealthKafid BramNo ratings yet

- Ent203 Reading Assignment Reading Passage 1 1. San FranciscoDocument28 pagesEnt203 Reading Assignment Reading Passage 1 1. San FranciscoLe Ba Tam (K17 CT)No ratings yet

- Quest5 AB Unit1Document16 pagesQuest5 AB Unit1INGRID100% (1)

- Organic Tomato Production: A Project of The National Center For Appropriate TechnologyDocument24 pagesOrganic Tomato Production: A Project of The National Center For Appropriate TechnologyRebecca SheaNo ratings yet

- Companion PlantsDocument11 pagesCompanion PlantsAnica Molnar100% (1)

- List of Thesis Titles of PG StudentsDocument20 pagesList of Thesis Titles of PG Studentslakhi100% (7)

- 220 Fungicide Boosts Tomato Yield Blight UgandaDocument12 pages220 Fungicide Boosts Tomato Yield Blight UgandamaphikoNo ratings yet

- Catalogo Agrotextile EngDocument44 pagesCatalogo Agrotextile Engrolametrica100% (1)