Professional Documents

Culture Documents

D-02 Model 7041 Flange Adapter - PN 10 PN 16

Uploaded by

Yovanny TelloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D-02 Model 7041 Flange Adapter - PN 10 PN 16

Uploaded by

Yovanny TelloCopyright:

Available Formats

7041 D-02

MODEL 7041 FLANGE ADAPTER- PN 10 / PN 16

The Model 7041 Flange Adapter allows for a direct connection of PN 10* and PN

16 flanges. The specially designed gasket enables the transition from a

grooved system to a flanged system or component with this single flange

adapter. The two-segment design provides an easy and fast installation. 2”

through 12” (50 mm – 300 mm) flange adapters are supplied hinged as a single

assembly, while 14” -24” (Model 7041N) are supplied with two separate

segments and a draw kit. All include an EPDM rubber gasket and plated track

bolts and nuts. Housing segments are supplied with our standard painted

finishes, i.e. orange or RAL3000 red. Optional finishes such as hot dipped zinc

galvanized and custom epoxy coatings are available.

* PN10: 2” - 6” (50 mm – 150 mm) only.

Always fasten the bolts to the required torque. Please refer to page 3.

For Fire Protection pressure rating, listing, and

approval information, refer to Data Sheet B-42 or

visit SHURJOINT website, www.shurjoint.com for

details or contact your SHURJOINT Representative.

Full warranty terms

can be found on

www.shurjoint.com

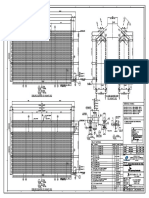

Model 7041 Flange Adapter - PN 10 / PN 16

Max.

Working Max. End

Nominal Pipe Pressure Load Dimensions Sealing Surface Bolts

Size O.D. (CWP)* (CWP) A B C D E No. Size Weight

in in PSI Lbs Lbs

mm mm mm mm mm mm

mm mm Bar kN Kgs

2 2.375 300 1000 5.1

165 125 22 60 78 4 M16

50 60.3 20 4.6 2.3

3.000 300 1590 5.7

76.1 mm 185 145 22 76 92 4 M16

76.1 20 7.3 2.6

3 3.500 300 2165 7.1

200 160 24 89 106 8 M16

80 88.9 20 9.9 3.2

4 4.500 300 3580 7.5

220 180 24 114 132 8 M16

100 114.3 20 16.4 3.4

5.500 300 5340 9.8

139.7 mm 250 210 25 140 159 8 M16

139.7 20 24.5 4.4

6.500 300 7460 11.3

165.1 mm 285 240 24 165 182 8 M20

165.1 20 34.2 5.1

6 6.625 300 7750 10.1

285 240 24 168 182 8 M20

150 168.3 20 35.6 4.6

8 8.625 300 13140 17.2

340 295 29 219 236 12 M20

200 219.1 20 60.3 7.8

10 10.750 300 20410 25.2

405 355 30 273 295 12 M24

250 273.0 20 93.6 11.4

12 12.750 300 28710 30.2

460 410 32 324 346 12 M24

300 323.9 20 131.8 13.7

Note: 2" - 6" flange drilling to PN 10 / PN 16 and 8" and above to PN 16.

* Working Pressure is based on roll grooved standard wall carbon steel pipe.

D-02-1/4 Rev.L 20160310

7041 D-02

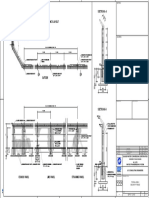

MODEL 7041N FLANGE ADAPTER - PN 16, 14" ~ 24"

14” ~ 24”: Supplied with a draw kit.

Model 7041N Flange Adapter - PN 16

Max.

Working Max. End

Nominal Pipe Pressure Load Dimensions Sealing Surface Bolts

Size O.D. (CWP)* (CWP) A B C D E No. Size Weight

in in PSI Lbs Lbs

mm mm mm mm mm mm

mm mm Bar kN Kgs

14 14.000 300 34620 48.7

520 470 36 356 383 16 M24

350 355.6 20 158.8 22.1

16 16.000 300 45220 59.7

580 525 38 406 431 16 M27

400 406.4 20 207.4 27.1

18 18.000 300 57230 71.6

640 585 40 457 486 20 M27

450 457.2 20 262.5 32.5

20 20.000 300 70650 103.4

715 650 43 508 537 20 M30

500 508.0 20 324.0 47.0

24 24.000 300 101740 160.6

840 770 48 610 635 20 M33

600 609.6 20 466.7 73.0

* Working Pressure is based on roll grooved standard wall carbon steel pipe.

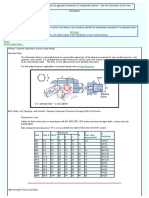

Important Notes:

1. The Model 7041 flange adapter requires a hard flat face for 4. When assembling a Model 7041 flange adapter against a

effective sealing. When the mating surface is not adequate butterfly valve or ball valve, make sure that the outside

as with the serrated faces of some valves or the rubber- diameter of the flange adapters do not interfere with the

faced wafer valves, a sandwich plate must be used. valve actuator or the mounting pad of the actuator.

5. Bolt tightening sequence: Like a regular flange joint, it is

important to make flange faces contact parallel. Tighten

nuts alternately in the sequence of diagonally opposite pairs

as shown below until the flange faces meet and make a

metal-to-metal contact.

2. The Model 7041 flange adapter has small triangular teeth

inside the key shoulder to prevent the pipe from rotating.

The teeth should be ground off when mating to a rubber-

lined flange.

3. The Models 7041 flange adapter shall not be used as

anchor points for tie-rods across non-restrained joints.

D-02-2/4 Rev.L 20160310

7041 D-02

Performance Data

The following tables show the maximum working pressures (CWP) of Shurjoint Model 7041 Flange Adapter PN 10 / PN 16 used on both

carbon steel and stainless steel pipes. Shurjoint ductile iron couplings can be used in conjunction with stainless steel pipe in non-corrosive

environment as the flow media does not come in direct contact with the coupling housings but rather only the gasket.

Model 7041 on Carbon Steel Pipe Model 7041 on Stainless Steel Pipe

Nom. Size Cut-Grooved Roll-Grooved Nom. Size Cut-Grooved Roll-Grooved

XS STD STD Sch. 10 Sch. 7 Sch. 80S Sch. 40S Sch. 40S Sch. 10S Sch. 5S

in / mm in / mm

PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar PSI / Bar

2 300 300 300 250 NR 2 300 300 275 275 175

50 20 20 20 17 50 20 20 19 19 12

2½ 300 300 300 250 NR 2½ 300 300 275 275 175

65 20 20 20 17 65 20 20 19 19 12

3 300 300 300 250 NR 3 300 300 275 275 175

80 20 20 20 17 80 20 20 19 19 12

4 300 300 300 250 NR 4 300 300 275 275 175

100 20 20 20 17 100 20 20 19 19 12

5 300 300 300 250 NR 5 300 300 275 200 175

125 20 20 20 17 125 20 20 19 14 12

6 300 300 300 250 NR 6 300 300 250 200 125

150 20 20 20 17 150 20 20 17 14 9

8 300 300 300 200 NR 8 300 300 200 NR

NR

200 20 20 20 14 200 20 20 14

10 300 300 300 200 NR 10 300 300 200 NR

250 20 20 20 14 250 20 20 14

NR

12 300 300 300 200 NR 12 300 300 200 NR

NR

300 20 20 20 14 300 20 20 14

Note: Hydrostatic shell test: 450 psi (30 Bar) per ANSI B16.5

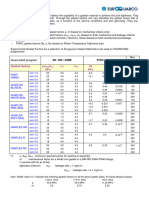

Required Bolt Torque

The table below provides the standard torque values for proper assembly of Shurjoint flange adapters. Use a torque

wrench so that all the nuts are tightened equally with a same torque value. Shurjoint flange adapters are sealed with elastic

(rubber) gaskets, which require much lower torques than those that utilize metallic gaskets.

Model 7041 Flange Adapter – PN 10 / PN 16

Nom. Size Bolt Required Torque

mm No Size (mm) Lbs-Ft Nm

50 4 M16 110 ~ 140 149 ~ 190

65 4 M16 110 ~ 140 149 ~ 190

80 8 M16 110 ~ 140 149 ~ 190

100 8 M16 110 ~ 140 149 ~ 190

125 8 M20 220 ~ 250 298 ~ 339

150 8 M20 220 ~ 250 298 ~ 339

200 12 M20 220 ~ 250 298 ~ 339

250 12 M24 320 ~ 400 434 ~ 542

300 12 M24 320 ~ 400 434 ~ 542

350 16 M24 320 ~ 400 434 ~ 542

400 16 M27 360 ~ 520 488 ~ 705

450 20 M27 360 ~ 520 488 ~ 705

500 20 M30 450 ~ 725 610 ~ 982

600 20 M33 620 ~ 1000 841 ~ 1356

D-02-3/4 Rev.L 20160310

7041 D-02

MATERIAL SPECIFICATIONS

• Housing: (Option) Grade “T” Nitrile (Color code: Orange stripe)

Ductile Iron to ASTM A536, Gr. 65-45-12 and or ASTM A395, Recommended for petroleum products, air with oil vapors,

Gr. 65-45-15, min. tensile strength 65,000 psi (448 MPa). vegetable and mineral oils within the specified

temperature range. Also good for water services under

+150 oF (+66 oC). Temperature range: -20 oF to +180 oF

• Surface Finish: (-29 oC to +82 oC).

Standard painted finishes in orange or RAL3000 red. Do not use for HOT WATER above +150 oF (+66 oC) or

Hot dip zinc galvanized (Option). HOT DRY AIR above +140 oF (+60 oC).

Epoxy coatings in RAL3000 red or other colors (Option)

Other options: Grade “O” - Fluoroelastomer.

• Rubber Gasket: Grade “L” - Silicone.

Grade “E” EPDM (Color code: Green stripe) Good for cold & For additional details contact Shurjoint.

hot water up to +230oF (+110oC). Also good for services for

water with acid, water with chlorine, deionized water, seawater

and waste water, dilute acids, oil-free air and many chemicals. • Standard Hex Bolts & Nuts:

Not recommended for petroleum oils, minerals oils, solvents Plated hex bolts conforming to ASTM A307 with hex nuts. (2

and aromatic hydrocarbons. nuts and bolts are supplied). Bolts and nuts for the flange

Maximum Temperature Range: -30oF (-34oC) to +230oF connection to be supplied by installer.

(+110oC)*.

*EPDM gaskets for water services are not recommended for • Draw Kit:

steam services unless couplings or components are accessible Screw Rod: Carbon Steel.

for frequent gasket replacement. Assembly holders: Ductile Iron.

Bolts & Nuts: Commercial.

General Notes:

Maximum Working Pressure (CWP) listed is the maximum cold water pressure for general piping services tested to ASTM F1476 and or AWWA C606

methods. Figures listed are based on roll- or cut-grooved standard wall carbon steel pipe. For other pipe schedules or pipe materials, contact

Shurjoint for additional information.

Max. End Load is calculated based on the maximum working pressure (CWP).

Listed and or Approved Pressures are pressure ratings for fire protection systems, tested and approved by various approval bodies. Please always

refer to the latest approval data posted on the Shurjoint website.

Field Joint Test: For one time only the system may be tested hydrostatically at 1½ times the maximum working pressure listed (AWWA C606 5.2.3).

Warning: Piping systems must always be depressurized and drained before attempting disassembly and or removal of any components.

The 10 Year Limited Warranty applies to manufacturing defects only and does not cover severe service/temperature applications or wear parts.

Shurjoint reserves the right to change specifications, designs and or standard without notice and without incurring any obligations.

Shurjoint product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise

measurements, please contact Shurjoint Technical Service. Shurjoint reserves the right to change or modify product design, construction,

specifications, or materials without prior notice and without incurring any obligations to make such changes and modifications on Shurjoint

products previously subsequently sold.

D-02-4/4 Rev.L 20160310

You might also like

- D-01 Model 7041 Flange Adapter-Ansi Class 125150Document4 pagesD-01 Model 7041 Flange Adapter-Ansi Class 125150Daniel SanNo ratings yet

- Kokamthan Pipe Culverts BBSDocument3 pagesKokamthan Pipe Culverts BBSSreekanth SattirajuNo ratings yet

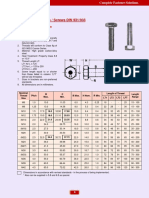

- Torque Details-Hex Bolt DIN 933Document2 pagesTorque Details-Hex Bolt DIN 933coolkaisy100% (2)

- Bar ScheduleDocument14 pagesBar ScheduleNuwan AththanayakaNo ratings yet

- Profile Europene DIN EN-10034 - 21.11.2023Document75 pagesProfile Europene DIN EN-10034 - 21.11.2023elenasandreiNo ratings yet

- B Davi-1Document8 pagesB Davi-1harisNo ratings yet

- Gasket FactorsDocument2 pagesGasket Factorsadamos.georgiosNo ratings yet

- Nyrgby & Nyfgby 0.6/1 (1.2) KV: SupremeDocument1 pageNyrgby & Nyfgby 0.6/1 (1.2) KV: SupremeFerdiNo ratings yet

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- Single Core Armoured LV CablesDocument1 pageSingle Core Armoured LV CablesPrashanth ShastryNo ratings yet

- Backing Rings Data PDFDocument1 pageBacking Rings Data PDFAbhijeet SahuNo ratings yet

- Iso 4162Document2 pagesIso 4162Guillermo TorresNo ratings yet

- Metric, Stud, Double End, DIN 939, Class 8.8, Plain: Page 1 of 2 REV-00 Date: September 11, 2018 M.STD - DE.939.8.8.PDocument2 pagesMetric, Stud, Double End, DIN 939, Class 8.8, Plain: Page 1 of 2 REV-00 Date: September 11, 2018 M.STD - DE.939.8.8.Pdinesh panchalNo ratings yet

- 2 3 4 Core Xlpe Swa LSF LV CablesDocument1 page2 3 4 Core Xlpe Swa LSF LV CablesPrashanth ShastryNo ratings yet

- J-30 MODEL SJ-300F RESILIENT SEATED BUTTERFLY VALVE - Rev.NDocument5 pagesJ-30 MODEL SJ-300F RESILIENT SEATED BUTTERFLY VALVE - Rev.NMichel De Souza CorreaNo ratings yet

- Product Range - Pipes - : Load and Service Years Can Be Seen atDocument4 pagesProduct Range - Pipes - : Load and Service Years Can Be Seen atConstantin CilibiuNo ratings yet

- Hex Jam Nut Metric (ISO 4035)Document1 pageHex Jam Nut Metric (ISO 4035)Abu IrfanNo ratings yet

- Cable 4 X 6mm2 Non-ArmouredDocument1 pageCable 4 X 6mm2 Non-Armouredjack.izzatiNo ratings yet

- Standard Bolt Tightening TorqueDocument2 pagesStandard Bolt Tightening TorqueARUNKANNANNo ratings yet

- Three Four Leg Chain SlingDocument5 pagesThree Four Leg Chain SlingchristopherNo ratings yet

- PBSD002 1 EN 0214 - ProductSheetDocument2 pagesPBSD002 1 EN 0214 - ProductSheetdenisNo ratings yet

- Wrench ClearancesDocument2 pagesWrench ClearancesRowan JoguilonNo ratings yet

- Electrical Calculation Sheet - EcsDocument47 pagesElectrical Calculation Sheet - EcsPradeesh Vijayan (v.prathi)No ratings yet

- BBBarBrochure - 2011 05 30 PDFDocument7 pagesBBBarBrochure - 2011 05 30 PDFKS LeeNo ratings yet

- Model 7041-A Flange-Ansi Class 125/150Document2 pagesModel 7041-A Flange-Ansi Class 125/150Zaira LorenaNo ratings yet

- Dimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFDocument8 pagesDimensions, Sizes and Specification of JIS B2220 Standard Steel Flanges PDFMohamad RifkiNo ratings yet

- Geomiq Air Bending ChartDocument2 pagesGeomiq Air Bending ChartStanley kNo ratings yet

- Geomiq Air Bending Chart PDFDocument2 pagesGeomiq Air Bending Chart PDFhrcozgNo ratings yet

- Wideflange PDFDocument4 pagesWideflange PDFandNo ratings yet

- Particle Size ConversionDocument2 pagesParticle Size ConversionsajimarsNo ratings yet

- Giddings & Lewis Zappendix ADocument9 pagesGiddings & Lewis Zappendix AAngel AdautaNo ratings yet

- JIS Flange STDDocument10 pagesJIS Flange STD何宗仁No ratings yet

- ROB - ComparisonDocument6 pagesROB - ComparisonvinoraamNo ratings yet

- Pressure Proced TestDocument2 pagesPressure Proced TestMabel GamaleriNo ratings yet

- High Tensile Bolts TechnicalDocument6 pagesHigh Tensile Bolts Technicalventhan_kalaiNo ratings yet

- Upvc PipesDocument1 pageUpvc PipesMuneer mahammadNo ratings yet

- British Steel European Ipe Sections DatasheetDocument3 pagesBritish Steel European Ipe Sections Datasheetreach_arindomNo ratings yet

- Bar ScheduleDocument2 pagesBar ScheduleNuwan AththanayakaNo ratings yet

- A Good Practice Guide For Flange Jointing of Polyethylene Pressure Pipes 1Document5 pagesA Good Practice Guide For Flange Jointing of Polyethylene Pressure Pipes 1Bimal DeyNo ratings yet

- Katalog AnkeraDocument20 pagesKatalog AnkeraBosko MiljevicNo ratings yet

- British Steel European Sections Product RangeDocument9 pagesBritish Steel European Sections Product Rangemdakhan679No ratings yet

- Jis b2220 Flange Standard Dimensions 5kDocument1 pageJis b2220 Flange Standard Dimensions 5kSatrio Sigit PurnomoNo ratings yet

- Standard Torque Values - Metric SystemDocument1 pageStandard Torque Values - Metric Systemnate anantathat100% (1)

- Metric DIN 558 Fully Threaded Hexagon Screws/BoltsDocument5 pagesMetric DIN 558 Fully Threaded Hexagon Screws/BoltsFirdaus KuswoyoNo ratings yet

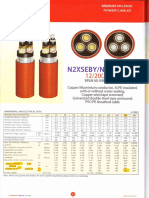

- MV Cable Current Carrying Capacity NA2XSEYBY SucacoDocument1 pageMV Cable Current Carrying Capacity NA2XSEYBY SucacoharisNo ratings yet

- 8-Titan Steel Coupler ProfileDocument33 pages8-Titan Steel Coupler ProfileMirza Shaizad BegNo ratings yet

- Equal Engineers and Consultants: Boq For Green Field Share Site DHK - G2988Document10 pagesEqual Engineers and Consultants: Boq For Green Field Share Site DHK - G2988JibonGhoshPritomNo ratings yet

- Standard Torque Values - Metric SystemDocument1 pageStandard Torque Values - Metric SystemproteccionesNo ratings yet

- Metric DIN 985 Low Profile Nylon Insert Hexagon Stop Lock NutsDocument4 pagesMetric DIN 985 Low Profile Nylon Insert Hexagon Stop Lock Nutsvikram jainNo ratings yet

- WSA 109 - 2011 Flange Gaskets Working SheetDocument1 pageWSA 109 - 2011 Flange Gaskets Working SheetAbit BronjaNo ratings yet

- Model 7170 Flange Adapter Ansi Class 125 / 150Document3 pagesModel 7170 Flange Adapter Ansi Class 125 / 150Saul AntayhuaNo ratings yet

- Dimensions of Metric Hex NutsDocument2 pagesDimensions of Metric Hex Nutsdidik sNo ratings yet

- Meteric Standard Bolt Tightening TorqueDocument2 pagesMeteric Standard Bolt Tightening TorquenixneonNo ratings yet

- Catalog Series RTC Aventics en 6912350Document150 pagesCatalog Series RTC Aventics en 6912350Omar Jasid LaraNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- Head ClearancesDocument2 pagesHead ClearancesMohan Rao0% (2)

- Grooved Fittings - ShurjointDocument7 pagesGrooved Fittings - ShurjointitskittylimNo ratings yet

- Slip On Flanges ANSI B16.5 300lbsDocument1 pageSlip On Flanges ANSI B16.5 300lbskannu19802550No ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- 0707 13 F 4200 Ultrasonic Flow Meter Manual 05 15Document52 pages0707 13 F 4200 Ultrasonic Flow Meter Manual 05 15Yovanny TelloNo ratings yet

- GBH Professional: OBJ - BUCH-2212-001.book Page 1 Thursday, March 19, 2015 11:53 AMDocument12 pagesGBH Professional: OBJ - BUCH-2212-001.book Page 1 Thursday, March 19, 2015 11:53 AMYovanny TelloNo ratings yet

- Handwriting A To M (Capitals) PDFDocument1 pageHandwriting A To M (Capitals) PDFYovanny TelloNo ratings yet

- AWWA C208 Fabricated Steel Pipe Fittings PDFDocument28 pagesAWWA C208 Fabricated Steel Pipe Fittings PDFYovanny TelloNo ratings yet

- AWWA C208 Fabricated Steel Pipe Fittings PDFDocument28 pagesAWWA C208 Fabricated Steel Pipe Fittings PDFYovanny TelloNo ratings yet

- Bolted, Sleeve-Type Couplings For Plain-End Pipe: AWWA StandardDocument32 pagesBolted, Sleeve-Type Couplings For Plain-End Pipe: AWWA StandardYovanny TelloNo ratings yet

- JNK Heaters Co., LTD.: Engineering & ConstructionDocument1 pageJNK Heaters Co., LTD.: Engineering & ConstructionYovanny TelloNo ratings yet

- AWWA C208 Fabricated Steel Pipe Fittings PDFDocument28 pagesAWWA C208 Fabricated Steel Pipe Fittings PDFYovanny TelloNo ratings yet

- Bolted, Sleeve-Type Couplings For Plain-End Pipe: AWWA StandardDocument32 pagesBolted, Sleeve-Type Couplings For Plain-End Pipe: AWWA StandardYovanny TelloNo ratings yet

- Awwa C206 PDFDocument20 pagesAwwa C206 PDFYovanny TelloNo ratings yet

- ME100 VD C H1 BA 013 R01 ModelDocument1 pageME100 VD C H1 BA 013 R01 ModelYovanny TelloNo ratings yet

- 16.11 Forged Fittings, Socket-Welding and ThreadedDocument27 pages16.11 Forged Fittings, Socket-Welding and ThreadedYovanny TelloNo ratings yet

- ME100 VD C H1 BA 011 R01 ModelDocument1 pageME100 VD C H1 BA 011 R01 ModelYovanny TelloNo ratings yet

- JNK Heaters Co., LTD.: Engineering & ConstructionDocument1 pageJNK Heaters Co., LTD.: Engineering & ConstructionYovanny TelloNo ratings yet

- Asme B31.4 (2002) PDFDocument125 pagesAsme B31.4 (2002) PDFYovanny TelloNo ratings yet

- 2010014-Me100-Vd-Allitem-fa-310 r3 (Inlet Silencer Drawing For F.d.fan)Document5 pages2010014-Me100-Vd-Allitem-fa-310 r3 (Inlet Silencer Drawing For F.d.fan)Yovanny Tello100% (1)

- Asme 30.16 InterpretacionDocument190 pagesAsme 30.16 InterpretacionYovanny TelloNo ratings yet

- Quiz Rce 309Document4 pagesQuiz Rce 309abhiNo ratings yet

- Prusa BOM.2Document3 pagesPrusa BOM.2Willow PrusaNo ratings yet

- ULTIMATE STRESS DESIGN Sample OnlyDocument2 pagesULTIMATE STRESS DESIGN Sample OnlyE SNo ratings yet

- Ficha Tecnica - DuraliteDocument2 pagesFicha Tecnica - DuraliteedocducNo ratings yet

- Materials Testing and Characterization TechniquesDocument1 pageMaterials Testing and Characterization TechniquesdsathiyaNo ratings yet

- Austentite Steel Thermal StabilizationDocument17 pagesAustentite Steel Thermal StabilizationArangamar KumaranNo ratings yet

- Neo-Dyn Series 132PDocument2 pagesNeo-Dyn Series 132PRicardo Cabrera OsinagaNo ratings yet

- Non Structural CrackDocument3 pagesNon Structural CrackAsyraf ZailudinNo ratings yet

- Appolo - Fire Detection SystemDocument63 pagesAppolo - Fire Detection SystemAvinash NathNo ratings yet

- TDS ASTM LM915 Eng 210923Document2 pagesTDS ASTM LM915 Eng 210923PrashaNo ratings yet

- SS 557 2010 Preview PDFDocument9 pagesSS 557 2010 Preview PDFdhruvNo ratings yet

- Application of Fluid Machinery: Piping Design and Pump SelectionDocument16 pagesApplication of Fluid Machinery: Piping Design and Pump SelectionLeslie CatindigNo ratings yet

- Arshad Siddiqui: HighlightsDocument3 pagesArshad Siddiqui: HighlightsMuhammad FaisalNo ratings yet

- ASTM A681-08 - Standard Specification For Tool Steels AlloyDocument14 pagesASTM A681-08 - Standard Specification For Tool Steels Alloyhand42100% (1)

- Section A PipeDocument18 pagesSection A PipeOsama sayedNo ratings yet

- Aggregate Impact ValueDocument4 pagesAggregate Impact ValuevinoNo ratings yet

- Radiantec Radiant Heat Design and Construction Manual PDFDocument16 pagesRadiantec Radiant Heat Design and Construction Manual PDFPhil KrahnNo ratings yet

- Detailed Estimate For Box CulvertDocument19 pagesDetailed Estimate For Box CulvertJohn Ricky Exequiel CalaraNo ratings yet

- Glass Ionomer CementsDocument10 pagesGlass Ionomer CementsYounes DiyaneNo ratings yet

- AAC Block Adhesive TDS NEWDocument2 pagesAAC Block Adhesive TDS NEWAakriti VermaNo ratings yet

- 3 1 3-01 08-Occ2-GbDocument2 pages3 1 3-01 08-Occ2-GbRa HulNo ratings yet

- A Review On Modular Construction For High-Rise Buildings: Building Structures-Arc 652Document6 pagesA Review On Modular Construction For High-Rise Buildings: Building Structures-Arc 652SUBHIKSHA D 1861738No ratings yet

- QCDD Fire Safety Standards Civil Defense CommentsDocument7 pagesQCDD Fire Safety Standards Civil Defense CommentsjaimonjoyNo ratings yet

- Flare KOD SizingDocument4 pagesFlare KOD SizingSaid Ahmed Salem100% (1)

- QP10-Q-612 Rev0 Typical SSD-1 Security FenceDocument1 pageQP10-Q-612 Rev0 Typical SSD-1 Security Fencenawajha0% (1)

- 17-Retaining Wall DesignDocument24 pages17-Retaining Wall DesignPuti Mayesti100% (6)

- Dme Fastrack - Cie 1 - Oct 2021Document2 pagesDme Fastrack - Cie 1 - Oct 2021FOODIE USNo ratings yet

- Datos Tecnicos RLNDocument7 pagesDatos Tecnicos RLNgustavoNo ratings yet

- Steel Metal Product Supplier Provider All Product Grade ListDocument20 pagesSteel Metal Product Supplier Provider All Product Grade ListPRAVINNo ratings yet

- Comparison Carrier vs. McQuayDocument2 pagesComparison Carrier vs. McQuayPradeep SukumaranNo ratings yet