Professional Documents

Culture Documents

Su Tu Trang Full Field Development Phase 1 Project: Vendor Front Sheet

Uploaded by

Tuan buivietOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Su Tu Trang Full Field Development Phase 1 Project: Vendor Front Sheet

Uploaded by

Tuan buivietCopyright:

Available Formats

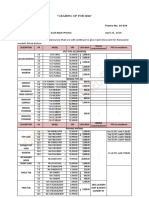

SU TU TRANG FULL FIELD

DEVELOPMENT PHASE 1 PROJECT

VENDOR FRONT SHEET

DOCUMENT TITLE

Catalogue Data

TOTAL NO. OF PAGES

10

(INCLUDING FRONTSHEET)

VENDOR'S ORDER NO.

G09

VENDOR'S OWN DOCUMENT NO REV. NO DATE VENDOR'S APPROVAL

G09

A 9.12.2015 TISH

Submitted For :

SU TU TRANG FULL FIELD

REVIEW APPROVAL

DEVELOPMENT - PHASE 1

INFO FINAL DOCS

PROJECT

REVIEW DOES NOT CONSTITUTE ACCEPTANCE OF

VENDOR

VELOCITY ENERGY PTE LTD

DESIGN DETAILS, CALCULATIONS, TEST METHODS OR

NAME:

MATERIALS DEVELOPED OR SELECTED BY VENDOR

NOR DOES IT RELIEVE VENDOR FROM FULL

COMPLIANCE WITH CONTRACTUAL OR OTHER

PACKAGE

FLEXIBLE HOSES AND

OBLIGATIONS.

CONNECTORS

DESCRIPTION:

1. ACCEPTED

PO/LOI NO: 071-2015/STTFFD-LOI

2. ACCEPTED, PROCEED WITH WORK AND

INCORPORATE COMMENTS AND RE-SUBMIT

TAG NOS./PO ITEM NOS:

SP-O809, SP-O810

3. NOT ACCEPTED.

REVISE AND RE-SUBMIT.

4. FOR INFORMATION ONLY.

SEQUENCE

DE PTSC CLJOC PACKAGE NO. VDRL CAT.

REV.

NO.

Name:

N.A.Trung

CLJOC PIPING:

Code 4

Date:

11-Dec-15 V.T.Thuc STFFD-P1-

17 Dec 2014 G09 0001 A

005008-1

Sign:

Thermoplastic Hoses

for Ultra High Pressure

Catalogue 4462 Global Edition

Intro

Thermoplastic Hoses for Ultra High Pressure

Why use Parker thermoplastic hoses?

Why use Parker thermoplastic hoses?

Parker thermoplastic hose is the right answer for many technical challenges. With

unique features and performance characteristics thermoplastic hose outrivals even

established alternatives. Whether the task requires extreme temperatures, pressures,

robustness or special custom designs, these hoses will not disappoint you.

See below the benefits offered by our complete hose range – also products featured

in other catalogs – shown in comparison to other standard hose types :

Temperature Range

••

Operating temperatures ranging from

-50°C up to +230°C

• Best choice for dynamic applications even

at very low temperatures

•

•

Full working pressure even at extreme

temperatures

Chemical Resistance

• Chemically inert, no interaction with the

media

• Resistant against virtually all acids and

alkalines

XIII

Intro

Thermoplastic Hoses for Ultra High Pressure

Why use Parker thermoplastic hoses?

Abrasion

••

Outer covers to withstand extreme wear

••

Superior resistance and extended service

life

UV / Ozone & Seawater Resistance

•

•

Build for harsh and exposed installations

• Environmental influences have minimal

effect on hose life

Compact OD

• Space saving due to very small diameters

• Optimized routing and design in constricted

installation spaces

• Prevent using overdimensioned hoses

XIV

Intro

Thermoplastic Hoses for Ultra High Pressure

Why use Parker thermoplastic hoses?

Small ID

• Only thermoplastic hoses allow small

IDs down to below 2mm

• Space saving

• Offers improved technical solutions in

constricted installation spaces

Low Weight

• Major weight savings

• Energy savings as less mass needs to be

moved

Non-Conductive

• Mandatory safety feature for applications

•

with high voltage and high frequency

• Electrically isolating according to SAE J51 7

XV

Intro

Thermoplastic Hoses for Ultra High Pressure

Why use Parker thermoplastic hoses?

Customization

••

Multiple colors

• Twin and multiple lines

•

•

Hose bundles

•

•

Customer specific designs

Preforming

Combining the advantages of bent metal

••

pipe with the flexibility of hose

• Reducing weight, noise and vibration

compared to bent metal pipe solutions

• Preformed hoses are maintaining their full

technical specifications

Cleanliness

• Less abrasion and contamination inside

the hose

••

Reduced residue build up

• Extended lifetime for filters, valves and

hydraulic systems

XVI

Intro

Thermoplastic Hoses for Ultra High Pressure

Why use Parker thermoplastic hoses?

Permeation Resistance

••

Low gas permeation

•

• Reduced ingression reduced risk of media

contamination

Long Length

• Up to 5,000 m and more continuous length

• Reduced scrap of bulk hose

• Easy winching and handling offer fast

deployment of long length

Highest Pressure

• Up to 4,000 bar working pressure

• Highest technical standards and production

controls assure safety

XVII

Intro

Thermoplastic Hoses for Ultra High Pressure

Why use Parker thermoplastic hoses?

Wide range of applications

• Standard hydraulics

• Hydraulic control

••

Industrial hydraulics e.g.

• Chemical injection

– alternative energies

• BOP Control

– machine tools

• Hydraulic lines on Subsea BOPs

– injection molding

• Hot lines from vessel or rig

• Mobile hydraulics e.g. to Subsea BOP

– material handling

• Hydrostatic testing

– construction

• Equipment maintenance

– agriculture

• Well equipment testing

• Automotive and truck industry

• Cementing operations

acc. to API 7K FSL 0

• Mini hydraulics

• Acidizing

• Lubrication

• General Fluid and Gas Injection

• Chemical industry

• Mud Circulation

• Process industry

• Jumpers

• Industrial gases

• Flying Leads

• Alternative fuels

• Electro/Hydraulic Workover

• Boats and yachts

• Pipeline Testing

• Pneumatics

• Life Science

• Media transfer

• Sewer Cleaning

• Water jetting

• Water blasting

• Water cutting

• Hydro testing

• Bolt tensioning

• Hydraulic jacking

• Rescue equipment

XVIII

Intro

Thermoplastic Hoses for Ultra High Pressure

Value added services

Value added services

Parker Polyflex and the Parker Sales Companies offer value

added services that compliment our production capabili-

ties and product portfolio. These services are in place to

meet the increasing customization and system criteria that

our customers expect from a world-class supplier.The value

added services detailed below are typical of the products and

secondary services that we provide to our customers. If you

have additional service needs that we have not detailed be-

low please contact us. We are happy to discuss all potential

solutions for your requirements.

ParkerStore™

At Parker Hannifin, we’re continually looking for ways

to deliver more products, more efficiently.

The Global ParkerStore™ network enables Parker

to provide:

• Prompt, efficient, professional in-store services

while you wait

• Expert local services and support

• A safe, friendly and convenient shopping

environment

• A greater range of parts options so you get

exactly what you’re looking for.

Customers trust ParkerStores to provide OEM and MRO custom-

ers with direct access to:

• Custom-made hydraulic hose assemblies and

complementary products to support their applications

and decrease their downtime

• Expert technical support

• Professional, personalized services, including

24/7/365 support

• The convenience, comfort and amenities of a local

service provider.

XIX

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- BMC 2250 ManualDocument120 pagesBMC 2250 ManualMuhammad Rifqi Anindito100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Audi A6 C5 - 1998 Schematy ElektryczneDocument52 pagesAudi A6 C5 - 1998 Schematy ElektryczneAdi- Laz100% (2)

- Yamaha YZF-R15 SM (English)Document338 pagesYamaha YZF-R15 SM (English)Willie82% (28)

- Blackbox Trislander Tutorial LIEO To LFKJDocument25 pagesBlackbox Trislander Tutorial LIEO To LFKJGraham WaterfieldNo ratings yet

- Catalogo de Pecas Manipulador Telescópico Caterpillar TL-642Document344 pagesCatalogo de Pecas Manipulador Telescópico Caterpillar TL-642angel richard silvestre suazo100% (2)

- MS 01 180 CatalogDocument93 pagesMS 01 180 CatalogTuan buivietNo ratings yet

- Coupling CatalogDocument84 pagesCoupling CatalogTuan buivietNo ratings yet

- BUL 4462 Product Overview Hose Bulletin UK MainDocument4 pagesBUL 4462 Product Overview Hose Bulletin UK MainTuan buivietNo ratings yet

- AGHO Catalogue Hydraulic Hose 18-06-2018 en Low-ResDocument31 pagesAGHO Catalogue Hydraulic Hose 18-06-2018 en Low-ResTuan buivietNo ratings yet

- 204-00 Suspension SystemDocument3 pages204-00 Suspension SystemFerhan SerdarogluNo ratings yet

- Promo No. 16-034 Revied Pansonic Cash Back PromoDocument3 pagesPromo No. 16-034 Revied Pansonic Cash Back PromoJezarie Delos ReyesNo ratings yet

- 6.1 Monologo Bus Driver - John Burns - SolDocument2 pages6.1 Monologo Bus Driver - John Burns - SolYazmin Vasquez BarreraNo ratings yet

- EH4500 BrakesDocument45 pagesEH4500 BrakesChester Dalitso MwanzaNo ratings yet

- Hyundai CRETA N Line - Product 2 Pager Final - UnlockedDocument3 pagesHyundai CRETA N Line - Product 2 Pager Final - Unlockedrishabhmahajan453No ratings yet

- 2 Reciprocating Compressor DesignsDocument31 pages2 Reciprocating Compressor DesignsEslam RedaNo ratings yet

- Earthmovers September 2021Document104 pagesEarthmovers September 2021Kunaphat ChNo ratings yet

- Electromechanical Parking Brake: TRW Automotive Aftermarket PEUGEOT 5008 (0A - , 0E - )Document3 pagesElectromechanical Parking Brake: TRW Automotive Aftermarket PEUGEOT 5008 (0A - , 0E - )dzadza2No ratings yet

- Operation & Maintenance Manual: Diesel Vehicle EngineDocument158 pagesOperation & Maintenance Manual: Diesel Vehicle Engineالمعز محمد عبد الرحمن100% (1)

- Energy Savings Opportunities in Control ValvesDocument2 pagesEnergy Savings Opportunities in Control Valveswerdna67No ratings yet

- Torre Sauter 4 PosiçõesDocument22 pagesTorre Sauter 4 PosiçõesPaulo Henrique ValérioNo ratings yet

- STIGA Spare Parts - shp60Document7 pagesSTIGA Spare Parts - shp60MiguelasNo ratings yet

- Head Lamp & Head Lamp Leveling Device (HLLD) Circuit: 5-78 Electrical Wiring DiagramsDocument4 pagesHead Lamp & Head Lamp Leveling Device (HLLD) Circuit: 5-78 Electrical Wiring DiagramsMen PanhaNo ratings yet

- 94 Integra Ac Belt ReplacementDocument2 pages94 Integra Ac Belt ReplacementRandy TurnerNo ratings yet

- JourneyDocument194 pagesJourneyjuan carlos garciaNo ratings yet

- 9321 18 ING 01 DOC 06 - B - B 4 - TowerMillDocument79 pages9321 18 ING 01 DOC 06 - B - B 4 - TowerMillDyajaira Huarcaya HilarionNo ratings yet

- 2019 Advance Alliance Autograph Owners ManualDocument178 pages2019 Advance Alliance Autograph Owners ManualJose Luis DelgadoNo ratings yet

- Hydraulic Diagram, With Option Components: Service InformationDocument2 pagesHydraulic Diagram, With Option Components: Service InformationSONNo ratings yet

- Offshore - Packaged Air Conditioning UnitDocument7 pagesOffshore - Packaged Air Conditioning UnitLovre PerkovićNo ratings yet

- 966 Fuel SystemDocument12 pages966 Fuel SystemWalid HouranNo ratings yet

- Howen AI MDVR Released 07 1Document12 pagesHowen AI MDVR Released 07 1Julio MuñozNo ratings yet

- Furniture AnnexDocument6 pagesFurniture AnnexAlaa HusseinNo ratings yet

- Dodge Charger 69 RT BlueDocument1 pageDodge Charger 69 RT BluekevinNo ratings yet

- Connecting The Suzi Between Truck and TrailerDocument1 pageConnecting The Suzi Between Truck and TrailerJustice TsaurayiNo ratings yet