Professional Documents

Culture Documents

University of Engineering & Technology, Taxila Department of Industrial Engineering

Uploaded by

HassanZameer0 ratings0% found this document useful (0 votes)

13 views2 pagesOriginal Title

MFCA Course Contents

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views2 pagesUniversity of Engineering & Technology, Taxila Department of Industrial Engineering

Uploaded by

HassanZameerCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

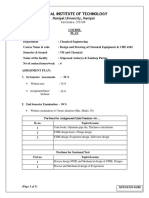

UNIVERSITY OF ENGINEERING & TECHNOLOGY, TAXILA

DEPARTMENT OF INDUSTRIAL ENGINEERING

Course Title: Metal Forming and Cutting Analysis Hours: 3,1

th

Semester: Fall 2018 (BSc Industrial Engineering) 7 Semester

Course distribution:

Week Course Contents Activity Tasks

1 Mechanical Properties of metal: An overview PBL Problem Sheet

2 Cutting Conditions and Machining methods PBL Problem Sheet

3 Orthogonal Machining and Chip formation analysis PBL Problem Sheet

4 Force model in cutting and Merchant’s Equation PBL Problem Sheet

5 Review Period and Problem Solving

6 Tool life and Cutting tool technology PBL Problem Sheet

7 Grinding process and abrasives PBL Problem Sheet

8 Conventional Vs Automated Machining Complex

Engineering Report

9 Economics of Machining

Problem

Review Period/Mid Term Exam

10 Presentation of Complex Engineering Problem Communicate PPT

11 Design for Manufacturing I Open Ended Lab In Lab

12 Design for Manufacturing II Open Ended Lab In Lab

13 NC codes for operations PBL Problem Sheet

14 Forging and Extrusion Analysis PBL Problem Sheet

15 Rolling & Drawing/ Deep Drawing Analysis PBL Problem Sheet

16 Casting Analysis Open Ended Lab In Lab

Review and Problem Solving

Marks distribution:

Mid Term Examination 30

Home works/Assignments 08

Quiz 12

Final Exam 50

Total marks 100

Text book:

-- Introduction to Manufacturing Processes, M. P. Groover, Wiley 2012

--Manufacturing Processes for Engineering Materials, Serope Kalpakjian, Steven R Schmid, fifth

edition, Pearson 2007

-- Principles of Metal manufacturing by Beddoes B

Course Teacher Chairman, Industrial Engg. Dept.

Prof. Dr. Mirza Jahanzaib

UNIVERSITY OF ENGINEERING & TECHNOLOGY, TAXILA

DEPARTMENT OF INDUSTRIAL ENGINEERING

Course Title: Metal Forming and Cutting Analysis Lab Hours: 1

Semester: Fall 2018 (BSc Industrial Engineering)

List of experiments:

Week List of experiments PLOs Learning levels Learning levels

(Psychomotor) (Affective)

Testing of hardness of metals: Al, Br, P2

1

Cu, etc

2 Cutting: threading, taper turning on lath P3

To check the effect of rake angle on chip P2

3

formation

To perform CNC Turning and step P2, P3

4 turning by using G and M codes d A1, A2

programming

5 Analysis of tool and measuring tool life P2

Comparing cutting and finishing with P2, P3

6

grinding and lathe

Comparing cutting time, cutting using P2, P3

7

lathe and NC machine

8 Review Period/Mid Term Exam

10 Open Ended lab P3

11 Open ended lab P3

12 To analyse open and closed die forging P2, P3

13 To analyse the extrusion process at P2, P3

d A1, A2

different die angles

14 To analyse the rolling and rerolling of P2, P3

sheet metal

15 To analyse the flow, sprue and gating P2, P3

systems in sand casting process

16 Review

You might also like

- Machine Screws: DIN 965 & ISO 7045 TorxDocument1 pageMachine Screws: DIN 965 & ISO 7045 TorxDerekNo ratings yet

- RMK Group A4 PPT MT-I (UNIT-I)Document82 pagesRMK Group A4 PPT MT-I (UNIT-I)Rajmchz100% (1)

- Cost Reduction of Brass Faucet Using Laser WeldingDocument14 pagesCost Reduction of Brass Faucet Using Laser Weldingumair saifullahNo ratings yet

- Untitled 1Document3 pagesUntitled 1AmanNo ratings yet

- Automotive Manufacturing Processes and TechnologiesDocument3 pagesAutomotive Manufacturing Processes and Technologiesvikas raiNo ratings yet

- MEF 112 Course HandoutDocument4 pagesMEF 112 Course HandoutAR7 StudioNo ratings yet

- Complete ReportDocument61 pagesComplete ReportMr KoolNo ratings yet

- R PT Instruction PlanDocument6 pagesR PT Instruction PlanVipin KumarNo ratings yet

- ME-220 Manufacturing Processes I Lab Workbook October 2022Document64 pagesME-220 Manufacturing Processes I Lab Workbook October 2022Aayan Ahmed KhanNo ratings yet

- Gujarat Technological University: Semester - V Subject Name: Manufacturing Technology-IIDocument3 pagesGujarat Technological University: Semester - V Subject Name: Manufacturing Technology-IITemp WorkNo ratings yet

- ME F219 - Course Handout - 2022-23Document3 pagesME F219 - Course Handout - 2022-23YERRAMILLI SRIVATSAVNo ratings yet

- Workshop ManualDocument85 pagesWorkshop Manualpavithrapappu88No ratings yet

- Lesson Plan: Veer Surendra Sai University of TechnologyDocument2 pagesLesson Plan: Veer Surendra Sai University of Technologysanthi saranyaNo ratings yet

- SSD Industrial Training Report Raigarh ChhattisgarhDocument23 pagesSSD Industrial Training Report Raigarh ChhattisgarhAviNo ratings yet

- Final M.E. Production EnggDocument18 pagesFinal M.E. Production EnggsatishNo ratings yet

- Design and Drawing COURSE PLAN 2017 FinalDocument5 pagesDesign and Drawing COURSE PLAN 2017 FinalqeftfgNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document4 pagesGujarat Technological University: W.E.F. AY 2018-19Divyeshkumar MorabiyaNo ratings yet

- Gujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyDocument3 pagesGujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyPratik VishwakarmaNo ratings yet

- Gujarat Technological University: Semester - V Subject Name: Manufacturing TechnologyDocument3 pagesGujarat Technological University: Semester - V Subject Name: Manufacturing TechnologystarboyNo ratings yet

- SYLL Proses Manu Updated Feb 2023Document4 pagesSYLL Proses Manu Updated Feb 2023Ilham AyuningNo ratings yet

- Process Equipment DesignDocument2 pagesProcess Equipment DesignAkshay UdayNo ratings yet

- E 87 PDFDocument69 pagesE 87 PDFVarun GuptaNo ratings yet

- De ZG663 Course Handout - Concurrent EnggDocument6 pagesDe ZG663 Course Handout - Concurrent Engglokesh prakashNo ratings yet

- 686 Electromedical Technology 2nd SemDocument24 pages686 Electromedical Technology 2nd Semmaymonamou 2001No ratings yet

- Course OverviewDocument14 pagesCourse OverviewVinayaka G PNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityDev IndustriesNo ratings yet

- Course ObjectivesDocument4 pagesCourse ObjectivesHOD TD GITNo ratings yet

- Diploma - VIII Fabrication Engg SyllabusDocument52 pagesDiploma - VIII Fabrication Engg Syllabusprashant4455No ratings yet

- Course ObjectivesDocument5 pagesCourse Objectives75Ujwal TDNo ratings yet

- BE Syllabus of Mumbai Uni3Document10 pagesBE Syllabus of Mumbai Uni3Rajendra B PawarNo ratings yet

- Course Outline MD ProjectDocument3 pagesCourse Outline MD ProjectEshet ShumetNo ratings yet

- Near Karna Petrol Pump, Modasa-383315, Gujarat, IndiaDocument60 pagesNear Karna Petrol Pump, Modasa-383315, Gujarat, IndiaHardik SolankiNo ratings yet

- Metal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyDocument4 pagesMetal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyFikadu EshetuNo ratings yet

- Introduction To The CourseDocument23 pagesIntroduction To The Coursemosab1234056No ratings yet

- Manufacturing ProcessDocument3 pagesManufacturing ProcessSatyam PatelNo ratings yet

- Course Handout (BMP)Document4 pagesCourse Handout (BMP)058-Somyajit RayNo ratings yet

- Course File FormatDocument18 pagesCourse File FormatUzair BukhariNo ratings yet

- Metal Forming Process 2 2 0 3 Prerequisite: - Course ObjectiveDocument3 pagesMetal Forming Process 2 2 0 3 Prerequisite: - Course ObjectiveB. selvababuNo ratings yet

- We 7102Document3 pagesWe 7102linsonNo ratings yet

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringDocument49 pagesRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringAbhi SharmaNo ratings yet

- Manufacturing Tech SyllDocument4 pagesManufacturing Tech SyllJagjit SinghNo ratings yet

- Karthik BN Technical Seminar PresentationDocument18 pagesKarthik BN Technical Seminar PresentationKIRAN TG 1SI19CS063No ratings yet

- Basic Civil Engineering Study Guide: CE 101 MathematicsDocument11 pagesBasic Civil Engineering Study Guide: CE 101 MathematicsMurali TharanNo ratings yet

- ME119 Schedule Course Contents Policies PDFDocument7 pagesME119 Schedule Course Contents Policies PDFPriyanshu MeshramNo ratings yet

- Rac AbstractDocument9 pagesRac AbstractRaja AdityaNo ratings yet

- Me 8392 - Manufacturing Technology: 14. Course OutcomesDocument6 pagesMe 8392 - Manufacturing Technology: 14. Course OutcomesERKATHIRNo ratings yet

- RTM Nagpur University Syllabus (Theory)Document5 pagesRTM Nagpur University Syllabus (Theory)Milind KshirsagarNo ratings yet

- Process Equipment Design: A Comprehensive GuideDocument3 pagesProcess Equipment Design: A Comprehensive GuideHardik SonvaneNo ratings yet

- Manufacturing Technology SyllabusDocument4 pagesManufacturing Technology Syllabushrana287No ratings yet

- Production TechniquesDocument2 pagesProduction TechniquesVELUGUBANTLA AALAPNo ratings yet

- Course ObjectivesDocument4 pagesCourse ObjectivesHOD TD GITNo ratings yet

- Kallam Haranadhareddy Institute of Technology ECE Workshop SyllabusDocument3 pagesKallam Haranadhareddy Institute of Technology ECE Workshop SyllabusmuraliNo ratings yet

- ME8491 Engineering Metallurgy COURSE PLANDocument4 pagesME8491 Engineering Metallurgy COURSE PLANKarthick NNo ratings yet

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909Document3 pagesGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909ShahinNo ratings yet

- AMT SyllabusDocument5 pagesAMT SyllabuschupchapNo ratings yet

- Experimental Investigation of Microdrilling Operation of Printed Circuit BoardDocument37 pagesExperimental Investigation of Microdrilling Operation of Printed Circuit BoardSUMANTH n vNo ratings yet

- Tool and Fixture Design For UsersDocument15 pagesTool and Fixture Design For UsersRahul KatnaNo ratings yet

- Optimization of Process Parameters in SheetDocument24 pagesOptimization of Process Parameters in SheetThiru MoorthyNo ratings yet

- Subject: Manufacturing Technology-Ilab: A. IntroductionDocument2 pagesSubject: Manufacturing Technology-Ilab: A. IntroductionIndrajeet SinghNo ratings yet

- Experimental Investigation For Erosion Rate of Aluminium Pipe Due To Flow of Nanofluids at Different Operating ConditionsDocument22 pagesExperimental Investigation For Erosion Rate of Aluminium Pipe Due To Flow of Nanofluids at Different Operating Conditionsganesh gundNo ratings yet

- Workshop Practice Project: Laptop Stands: Industrial Engineering Department University of Engineering and TechnologyDocument5 pagesWorkshop Practice Project: Laptop Stands: Industrial Engineering Department University of Engineering and TechnologyHassanZameerNo ratings yet

- Invasion of ArabsDocument3 pagesInvasion of ArabsWaleed Butt100% (1)

- BSC Eight Semester (Spring 2019) Examination in Industrial EngineeringDocument3 pagesBSC Eight Semester (Spring 2019) Examination in Industrial EngineeringHassanZameerNo ratings yet

- Title of BSC Final Year Project: (Binding Page)Document15 pagesTitle of BSC Final Year Project: (Binding Page)umerNo ratings yet

- Invasion of ArabsDocument3 pagesInvasion of ArabsWaleed Butt100% (1)

- Algorithm For UnconstrainedDocument30 pagesAlgorithm For UnconstrainedHassanZameerNo ratings yet

- BSC Eight Semester (Spring 2019) Examination in Industrial EngineeringDocument3 pagesBSC Eight Semester (Spring 2019) Examination in Industrial EngineeringHassanZameerNo ratings yet

- C++ Functions Introduction LabDocument12 pagesC++ Functions Introduction LabHassanZameerNo ratings yet

- BSC Eight Semester (Spring 2019) Examination in Industrial EngineeringDocument3 pagesBSC Eight Semester (Spring 2019) Examination in Industrial EngineeringHassanZameerNo ratings yet

- Dues Notice September 2020 PDFDocument3 pagesDues Notice September 2020 PDFHassanZameerNo ratings yet

- Non Conventional MachiningDocument15 pagesNon Conventional MachiningHassanZameerNo ratings yet

- Job Shop Scheduling Algorithms & HeuristicsDocument4 pagesJob Shop Scheduling Algorithms & HeuristicsHassanZameerNo ratings yet

- Application Form For HEC Projects (SR No1-6)Document1 pageApplication Form For HEC Projects (SR No1-6)HassanZameerNo ratings yet

- UET Taxila announces BSc Industrial Engineering second semester results Spring 2018Document3 pagesUET Taxila announces BSc Industrial Engineering second semester results Spring 2018HassanZameerNo ratings yet

- Lecture04 RichardsonDocument21 pagesLecture04 RichardsonMuhammed MohsinNo ratings yet

- Richardson Extrapolation NotesDocument7 pagesRichardson Extrapolation NotesHassanZameerNo ratings yet

- N2reopen PDFDocument4 pagesN2reopen PDFHassanZameerNo ratings yet

- New Doc 2019-11-14 19.34.11 PDFDocument3 pagesNew Doc 2019-11-14 19.34.11 PDFHassanZameerNo ratings yet

- Linear Programming A Modern Integrated AnalysisDocument11 pagesLinear Programming A Modern Integrated AnalysisHassanZameerNo ratings yet

- Interst Free Halmets PDFDocument2 pagesInterst Free Halmets PDFWJAHAT HASSANNo ratings yet

- 12V Air Cooler Power Up by Old PC Power Supply PDFDocument5 pages12V Air Cooler Power Up by Old PC Power Supply PDFHassanZameerNo ratings yet

- Objective of The ClassDocument4 pagesObjective of The ClassHassanZameerNo ratings yet

- 1 - Din 13-20 e - 0Document8 pages1 - Din 13-20 e - 0Joaquin Alvarez100% (1)

- SKF 2017 Lock NutsDocument31 pagesSKF 2017 Lock Nutswilliams vasquezNo ratings yet

- ISO 724 - Metric ThreadsDocument12 pagesISO 724 - Metric ThreadsIvan TurudićNo ratings yet

- GSK980TD Turning Machine CNC System User Manual (English Version)Document408 pagesGSK980TD Turning Machine CNC System User Manual (English Version)Yadai CastilloNo ratings yet

- BKH Ball Valve For Gas Steel: Available Sizes ConnectionsDocument3 pagesBKH Ball Valve For Gas Steel: Available Sizes ConnectionstadilakshmikiranNo ratings yet

- SolidCAM 2015 Turning and Mill Turn Training CourseDocument282 pagesSolidCAM 2015 Turning and Mill Turn Training Coursehaclongdaica1987100% (2)

- MTM Irfan Amin PDFDocument68 pagesMTM Irfan Amin PDFIrfan AminNo ratings yet

- Laboratory Manual MEC224 Mechanical Engineering WorkshopDocument30 pagesLaboratory Manual MEC224 Mechanical Engineering WorkshopSunil SharmaNo ratings yet

- Hanro Tools Incorporation Delhi IndiaDocument10 pagesHanro Tools Incorporation Delhi IndiaHanro Tools IncorporationNo ratings yet

- DIN 961 Hexagon Head Screws with Fine Pitch ThreadDocument3 pagesDIN 961 Hexagon Head Screws with Fine Pitch ThreadRolffoTelloNo ratings yet

- TC Thread Measuring FormulasDocument1 pageTC Thread Measuring FormulasVikas PatilNo ratings yet

- Machine LatheDocument4 pagesMachine LatheKirubel MulugetaNo ratings yet

- 5 - 4 - Spare Part List PCR2 - 29.03.2012-1.1Document38 pages5 - 4 - Spare Part List PCR2 - 29.03.2012-1.1AlvaroNo ratings yet

- Lineas HidraulicasDocument5 pagesLineas HidraulicasJesus BombasNo ratings yet

- CH Warman Shaft Lifting Nut Product BulletinDocument2 pagesCH Warman Shaft Lifting Nut Product BulletinRANAIVOARIMANANANo ratings yet

- Nud BSPP BookDocument28 pagesNud BSPP BookdekgaleNo ratings yet

- Precision components manufacturer excelling for over 40 yearsDocument17 pagesPrecision components manufacturer excelling for over 40 yearsNaveen PradeepanNo ratings yet

- Timex Group Precision Engineering Limited (TGPEL)Document24 pagesTimex Group Precision Engineering Limited (TGPEL)sanjeevbatra0% (1)

- Winchester Model 61Document23 pagesWinchester Model 61Herbert Menendez HuezoNo ratings yet

- GAGESDocument156 pagesGAGESUNIISCRIBDNo ratings yet

- Makita 1050D Spare PartsDocument3 pagesMakita 1050D Spare PartsNunoNo ratings yet

- Sae Adapters CatalogueDocument230 pagesSae Adapters CataloguehaggNo ratings yet

- Thread Methos PDFDocument5 pagesThread Methos PDFBharat PrajapatiNo ratings yet

- Price List - MM - Dated 20-04-2021Document1 pagePrice List - MM - Dated 20-04-2021mshNo ratings yet

- NTF (Vendedor)Document11 pagesNTF (Vendedor)SICAAM QUERETARONo ratings yet

- Asme B18.6.1 1997Document12 pagesAsme B18.6.1 1997Jesse ChenNo ratings yet

- TS-E 24mm f/3.5 L lens parts catalogDocument8 pagesTS-E 24mm f/3.5 L lens parts catalogWeijia MaNo ratings yet

- Nordberg 105 S N 34380Document33 pagesNordberg 105 S N 34380Gilberto Garnica MurilloNo ratings yet

- Documentatie Tehnica Tocator ST200Document3 pagesDocumentatie Tehnica Tocator ST200Ionuț CojocariuNo ratings yet