Professional Documents

Culture Documents

Operation and Maintenance: Model 873-400 Regulator

Uploaded by

ilham rusdyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation and Maintenance: Model 873-400 Regulator

Uploaded by

ilham rusdyCopyright:

Available Formats

drw 875-400 1/89, 980123, 990804,010619; 090519; 090805PS; 090910PS; 090917PS

OPERATION AND MAINTENANCE

MODEL 873-400 REGULATOR

The model 873 is a piston type hand loading OPERATION

regulator. It utilizes a balanced poppet design for high Outlet pressure is adjusted by knob 10 (refer to

flow and minimum effect of inlet pressure on outlet drawing) to the desired value as read on the outlet

pressure. The poppet assembly is contained in a gauge. When reducing the pressure the regulator

cartridge with internal filtration for easy in-field will self vent via the vent hole near the cap. This is

changing. The regulator is self venting but is normal. When reducing set pressure reduce

optionally available without the vent. pressure to below the new setting then increase

SPECIFICATIONS pressure to the new setting. If in-field adjustment is

• Maximum inlet pressure 6000 PSI (40 to be avoided, the knob 10 can be replaced by a

MPa) bolt and lock nut. A 3/8" by 24 thread per inch bolt

• Outlet pressure 0 to400 PSI with a minimum thread length if one inch is required.

• Flow coefficient (Cv ) 0.8

(equivalent to 0.23" orifice)

MAINTANENCE & REPAIR

• Rise of outlet pressure with

CAUTION As with any regulator or valve,

particulates or moisture can plug or freeze the

drop of inlet pressure 10 PSI/1000 PSI

internal filter or valve seat.This can occur when up-

• Materials - body and cap - aluminum

stream dryers are not changed or remain unused for

internals - brass,stainless,

long periods allowing corossion materials to

seals, - KEL-F, Viton

• Fittings 1/4" FNPT inlet

accumulate. In critical applications where it is

important not to lose flow, a larger particulate filter

1/2" FNPT outlet

should be used upstream. Also an orifice such as

• Size 3" dia x 6" lg

the Aqua model 796 should be used downstream.

This reduces the tendency to freeze when moisture

INSTALLATION is present. Consult factory for details. The user

Use a suitable pipe thread sealant such as teflon tape should establish time intervals for changing the

on inlet and outlet threads. Avoid over torquing pipe

valve cartridge, filter and upstream dryers based on

thread. Normal torque applied with a 6 or 8 inch long

wrench is ample. Use ample teflon tape - 3 or 4 turns, experience and service conditions. No

not 1 or 2 turns. The inlet is on the left when facing representation is made herein as to time intervals as

the adjusting knob with the two gage ports upward. each use is unique. Back-up systems should be

An optional panel mounting nut is available (part no. used in very critical applications since field

952). This nut permits mounting the regulator using a maintenance is hard to insure. The poppet

1.25" hole in a panel or plate. The regulator is NOT cartridge 895 is a factory assembled item and

shipped oxygen clean and should NOT be used for should be replaced if required and not

oxygen service as provided. Consult the factory for disassembled unless absolutely necessary. Spare

details on oxygen service. The 1/2" port is the outlet. cartridges are available at a nominal cost and should

The 1/4" port adjacent to the 1/2" port is the outlet be kept on hand if rapid repairs are required. IN ALL

gauge port. The other two 1/4" ports are the inlet and CASES THE UNIT CAN BE RETURNED TO THE

inlet gauge ports. Either of these ports can be used FACTORY IF APPLICABLE OR DEALER FOR

as the inlet. Connect the inlet to the source gas such REPAIR UNDER WARRANTY OR AT A NOMINAL

as a high pressure storage tank. The outlet is capable CHARGE. Maintenance or repairs should only be

of being adjusted from 0 to 400 PSI. AN OUTLET done by qualified personnel in a clean environment

GUAGE AND RELIEF VALVE SET NO HIGHER THAN by following the drawings and parts lists herein.

400 PSI SHOULD BE CONNECTED TO THE If leakage occurs through the regulator or out the

OUTLET. A 1/2" NPT SIZE RELIEF VALVE SHOULD regulator vent, allow the inlet and outlet pressure to

BE USED FOR FULL PROTECTION. IF THE INLET equalize by shutting off the inlet. If leakage

PRESSURE CAN EXCEED 6000 PSI A RELIEF continues after the inlet and outlet equalize the

VALVE SHOULD ALSO BE INSTALLED AT THE vent seat 5 or piston seal 14 are leaking. Replace

INLET TO PREVENT EXCEEDING 6000 PSI. these. If leakage stops when the inlet and outlet

pressure equalize the poppet cartridge item 1 is

leaking. Replace this.

AQUA ENVIRONMENT CO,. INC.

Aqua Environment Co. Inc. drw 875 pg 2 of 2

ASSEMBLY & DISASSEMBLY - h. Screw cap 3 and body 2 together. Hold

cap 3 downward so seat 5 does not fall out

MODEL 873-400 REGULATOR

during assembly. Torque to 10 to 20 ft lbs

using a strap wrench or by hand.

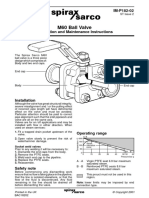

ITEM QTY PART NO. DESCRIPTION i. Install spring guide 8. then bearing

1 1 895 poppet assy plate 11, then bearing12, then second

2 1 893 body bearing plate 11, then spring 13, then

3 1 879 cap spring guide 6 into cap as shown. Use

4 1 744 piston ample Slick 50 EP grease or equivilant on

5 1 946-1 vent seat (vented) the bearings. Silicone spray can be used to

1 1035-1 seat- not vented coat these parts and act as a preservative.

6 1 849 spring guide j. Screw cap 7 onto cap 3. Hold cap 7

7 1 903 cap downward so parts stay in place during

8 2 410 spring guide (n0te 4) assembly. Torque to about 20 ft lbs.

9 1 378-2 adjusting screw k. Install adjusting screw 9 and knob 10 as

10 1 379-30 knob shown using Slick 50 or EP grease.

11 2 379-37 bearing plate

12 1 379-38 bearing 4. Two item 8 are required for full spring

13 1 379-5 spring travel

14 1 876-24 seal (2-122) Vit. 75 5. model 873-400NA denotes fixed

15 1 876-15 seal (2-010) Vit. 90 adjustment and uses a bolt and locking nut

16 1 876-16 seal (2-020) Vit. 90 instead of items 9 and 10.

17 1 876-27 seal (2-135) Vit. 90 6. model 873-400NV denotes non vented

18 1 944 piston hsg regulator.

19 1 945 stop ring

20 1or2 952 mount nut - optional

21 979-400 REPAIR KIT - includes

items 1,5,14,15,16,17 10

NOTES

9

1. Technical bulletin - 874

895 poppet cartridge assy - drw 896 8

2. Use Dow silicone grease 111 or

11

equivalent on seals and threads except seal 20

14. Pack this area with Cristo-lub MCG 121. 7 6

Use Slick 50 EP grease or equivalent on 12

5

bearings 11 and 12 and on threads between

13

items 7 and 9.

4

3. ASSEMBLY 14

a. Clean all parts and insure there are no 3

visible chips or particulates.

15

b. Inspect vent seat 5 under 10X 1

magnification at sealing edge. Wipe clean 18

as required. 19

c. Install cartridge 1 with seal 16 in

housing 2. Torque to 10 to 20 ft lbs. 2

17

d. Install seal 14 on piston 4. Pack heavily

16

with Cristo-lub MCG 121.

Outlet Inlet

e. Carefully slide piston 4 into hsg 18 as

shown.

f. Install seal 15 and vent seat 5 into piston

as shown.

g. Install seal 17 as shown.

Model 873-400

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 873 400 Regulator Operation and Maintenance ManualDocument2 pages873 400 Regulator Operation and Maintenance ManualHassan KhattabNo ratings yet

- ASC Air Starter ST700 SeriesDocument29 pagesASC Air Starter ST700 SeriesLeonid KolesnikovNo ratings yet

- Manual Arranque NeumaticoDocument52 pagesManual Arranque NeumaticoSabry Socarrás AarónNo ratings yet

- IR Turbine Power Starters TS700Document20 pagesIR Turbine Power Starters TS700andistwn99No ratings yet

- Stripper TOT 2.50 10M DS34 TechMan1146Document13 pagesStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaNo ratings yet

- Swing-Flex Check Valve: Operation, Maintenance and Installation ManualDocument8 pagesSwing-Flex Check Valve: Operation, Maintenance and Installation ManualAhmed ShawkyNo ratings yet

- 2, 5 Inch Side Door Stripper PDFDocument16 pages2, 5 Inch Side Door Stripper PDFOvRrj AhmedNo ratings yet

- Manual 1956 PN 09-1013 VF-61Document3 pagesManual 1956 PN 09-1013 VF-61fabiosparkNo ratings yet

- Service Guide: Armstrong Inverted Bucket Steam TrapsDocument36 pagesService Guide: Armstrong Inverted Bucket Steam Trapsaacp271165No ratings yet

- Operation & Maintenance of Plug Valves PDFDocument5 pagesOperation & Maintenance of Plug Valves PDFعزت عبد المنعمNo ratings yet

- XTV Trip ValvesDocument4 pagesXTV Trip ValvesBharath Nadimpalli50% (4)

- Hydraulic Stuffing Box Technical ManualDocument8 pagesHydraulic Stuffing Box Technical ManualsambhajiNo ratings yet

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDocument4 pagesAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangNo ratings yet

- ST900 Ed12Document28 pagesST900 Ed12moisesNo ratings yet

- 05-9040-269 ANGMC-6019-US Anderson Greenwood PDFDocument33 pages05-9040-269 ANGMC-6019-US Anderson Greenwood PDFDIONNY VELASQUEZNo ratings yet

- Peco Filter CaseDocument11 pagesPeco Filter CaseLuis MaureraNo ratings yet

- Normally Closed Solenoid Valves PDFDocument55 pagesNormally Closed Solenoid Valves PDFrahulNo ratings yet

- De Esfera0-Instalação e ManutençãoDocument2 pagesDe Esfera0-Instalação e ManutençãoHélder SilvaNo ratings yet

- Iom WKM 310FDocument4 pagesIom WKM 310FNasir NaqviNo ratings yet

- Manual Zetkama Fig.215 - 216Document8 pagesManual Zetkama Fig.215 - 216George_Wabag_2014No ratings yet

- Items 4-7 and 9-17)Document5 pagesItems 4-7 and 9-17)Haroldo VieiraNo ratings yet

- Installation and Operating Instructions: Hayward High-Performance PumpsDocument4 pagesInstallation and Operating Instructions: Hayward High-Performance Pumpsa siongNo ratings yet

- Instalacion y Mantenimiento FT FTI OKDocument4 pagesInstalacion y Mantenimiento FT FTI OKAura RamirezNo ratings yet

- Pressure Relief Valves Operating Instructions: Supplemental ProtectionDocument2 pagesPressure Relief Valves Operating Instructions: Supplemental ProtectionlorenzoNo ratings yet

- F110-14, F1110-14 Specification SheetDocument6 pagesF110-14, F1110-14 Specification SheetWattsNo ratings yet

- Es Acv M115F M1115FDocument4 pagesEs Acv M115F M1115FWattsNo ratings yet

- Technical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Document16 pagesTechnical Manual CT Bop 5.12 10K Es54 Single P/S M60es54-U543xl-Man-001Riski KurniawanNo ratings yet

- Tech 1183 Man StripperDocument19 pagesTech 1183 Man StripperDonna Gray100% (1)

- Jatco O9a TransmissionDocument2 pagesJatco O9a TransmissionDusko IvanNo ratings yet

- Instructions For TC083 PER-CAST VACUUM CASTING MACHINE PDFDocument5 pagesInstructions For TC083 PER-CAST VACUUM CASTING MACHINE PDFMarciaNo ratings yet

- Flow Safe - F84L - CatalogueDocument12 pagesFlow Safe - F84L - CataloguecookienutNo ratings yet

- Es Acv 1116FMDocument4 pagesEs Acv 1116FMWattsNo ratings yet

- Manual SSW10Document31 pagesManual SSW10Victor RodriguezNo ratings yet

- Ford C-4 Manual Valve Body Installation Instructions Reversed Pattern Manual (PRN123) #72010Document2 pagesFord C-4 Manual Valve Body Installation Instructions Reversed Pattern Manual (PRN123) #72010G Ramon SPNo ratings yet

- Kennedy Valve: Kennedy Valve Resilient Wedge Gate Valve Maintenance ManualDocument11 pagesKennedy Valve: Kennedy Valve Resilient Wedge Gate Valve Maintenance ManualttyNo ratings yet

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesNo ratings yet

- Instalacion Marcha NeumaticaDocument36 pagesInstalacion Marcha Neumaticaacere18No ratings yet

- 3.06 Quad BOP 10K EH PDFDocument28 pages3.06 Quad BOP 10K EH PDFOvRrj Ahmed0% (1)

- Condensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsDocument4 pagesCondensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsMarcial NuñezNo ratings yet

- Catálogo Anderson Greenwood 400sDocument32 pagesCatálogo Anderson Greenwood 400sDaniela BeltranNo ratings yet

- TEEL BRONZE ROTARY PUMP Manual & Parts ListDocument8 pagesTEEL BRONZE ROTARY PUMP Manual & Parts ListMoToBunnYNo ratings yet

- Apco Airvacuum Valves Avv Sales 601Document8 pagesApco Airvacuum Valves Avv Sales 601Jhony MedranoNo ratings yet

- Needle Valve Maintenance Instructions - Alco Valves PM-221Document5 pagesNeedle Valve Maintenance Instructions - Alco Valves PM-221AzaelNo ratings yet

- Gate Valve Installation InstructionsDocument20 pagesGate Valve Installation InstructionsRomi Kristanto100% (1)

- Installation and Maintenance Information: StartersDocument32 pagesInstallation and Maintenance Information: StartersRicardoAguilarHidalgoNo ratings yet

- Angle Type Blowdown ValveDocument7 pagesAngle Type Blowdown ValverikumohanNo ratings yet

- Series 767FR Specification SheetDocument4 pagesSeries 767FR Specification SheetFEBCONo ratings yet

- PositionerDocument13 pagesPositionerLeonidas PetrouNo ratings yet

- MODEL 5500 HYDRAULIC TUBING TONG OPERATIONS AND SERVICE MANUALDocument37 pagesMODEL 5500 HYDRAULIC TUBING TONG OPERATIONS AND SERVICE MANUALLucas Lewis0% (3)

- Series 919 Installation InstructionsDocument8 pagesSeries 919 Installation InstructionsWattsNo ratings yet

- 2B) Inlet Air Shut-Off ValveDocument2 pages2B) Inlet Air Shut-Off ValveMohamed HamedNo ratings yet

- !warning!: Installation and Operating ManualDocument9 pages!warning!: Installation and Operating Manualcreyesdear3978No ratings yet

- Detector de Temperatura 4103DDocument4 pagesDetector de Temperatura 4103Djose luis rattiaNo ratings yet

- Im 306Document10 pagesIm 306Iwan SetiawanNo ratings yet

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Document8 pagesVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliNo ratings yet

- Operating Manual for Self-Priming PumpDocument9 pagesOperating Manual for Self-Priming PumpANo ratings yet

- Ingersoll Rand SS815 Parts ManualDocument36 pagesIngersoll Rand SS815 Parts ManualSergei KurpishNo ratings yet

- Johnson Ultra Ballast Pump Installation Instructions PDFDocument5 pagesJohnson Ultra Ballast Pump Installation Instructions PDFRizal FalevyNo ratings yet