Professional Documents

Culture Documents

Inspection Procedure Material

Uploaded by

Zharel AhmadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Procedure Material

Uploaded by

Zharel AhmadCopyright:

Available Formats

Logo

Inspection Procedure

http://quality-management.magt.biz Saturday, October 11, 2014

Justification Project Details

Project Name EKO ENERGY ESTATE PROJECT

This Procedure is Of the lengthiness of the process.

written because: Contract Number -

Of the complexity of the process.

Client Satellite Oil & Gas International Limited - SOGIL

The process is routine, but it's essential that

Client’s representative Norman Nadera

everyone strictly follows the rules.

Main Contractor Cobel Construction Services Nigeria Ltd. - CCS

The process demands consistency.

Project Address Victoria Island – Lagos Nigeria

The process involves documentation.

The process involves significant change.

The process has serious consequences if done

wrong.

Purpose and Scope

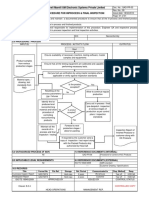

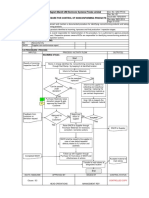

Start

The purpose of this inspection procedure is to ensure that:

- Only approved materials conforming to the specifications are

used for permanent works.

- Materials are fit for use and free of damages.

- Material documentation meets requirements.

Thus reworks and it’s impacts shall be minimized, non-conformities shall Receive

be avoided and finally client satisfaction shall be achieved or exceeded.

documentation

Input(s)

Common inputs to inspections are: Review

- Applicable Standards (BS etc., usually reflected in drawings and

material approvals), documentation

- Contractual Specifications,

- Approved Drawings,

- Method Statements,

- Material and other approvals,

- Formal instructions,

- …

Receive Material

Output(s)

Outputs of inspections are:

- Records,

- Recommendations and updates,

- …

Inspect Check

Inspection Process

- Receive material documentation,

- Review material documentation,

- Receive material,

- Inspect material for damages and specifications, Verify

- Verify compliance with applicable specifications and

requirements,

- Check quantities,

- Accept, Repair/Replace

- Update register and logs,

- …

Responsibilities

- The QC manager or his designee receives and reviews the Accept

various documents such as certificates, datasheets etc.

- The logistic staffs receive the material,

- The QC staffs inspect the material,

- The QC manager or his designee verifies adherence to

specifications,

- The logistic staffs check quantities,

- The client representative or his designee accepts the material, Register End

- The QC manager and the Log. manager or their respective

designees update register and logs.

- …

Author:

Marc Arnecke, PMP

You might also like

- PEIPL-SOP-01 For Incoming Material Insp.Document1 pagePEIPL-SOP-01 For Incoming Material Insp.Balkishan DyavanapellyNo ratings yet

- Control of Records ProcedureDocument1 pageControl of Records ProcedureZharel AhmadNo ratings yet

- Quality Record Procedure Rev-JDocument4 pagesQuality Record Procedure Rev-JherminNo ratings yet

- ESCL-SOP-018, Inspection and Test Procedure For Egba Split-ClampsDocument6 pagesESCL-SOP-018, Inspection and Test Procedure For Egba Split-ClampsadiqualityconsultNo ratings yet

- MAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1Document9 pagesMAI 07 - Control of Insp Measuring and Testing Equipment - DJ - v1IT Support - FernanNo ratings yet

- QG-QSP-08 Procedure For Control of Non-Conformance Product.Document5 pagesQG-QSP-08 Procedure For Control of Non-Conformance Product.omprakash yadavNo ratings yet

- QP Nonconforming Product Sample 2014Document2 pagesQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Control of Monitoring & Measuring DevicesDocument10 pagesControl of Monitoring & Measuring DevicesRamesh mudunuriNo ratings yet

- 8.5.2 Identification and TraceabilityDocument5 pages8.5.2 Identification and Traceabilitymedtaher missaoui0% (1)

- COMP-OPP-02 Procedure For Control and Validation of Service ProvisionDocument6 pagesCOMP-OPP-02 Procedure For Control and Validation of Service ProvisionISODCC DSPINo ratings yet

- NCR Procedure Rev. 0Document8 pagesNCR Procedure Rev. 0Ganjar Dreadlocks NugrahaNo ratings yet

- Quality Requirements For Subcontractor: Project ProcedureDocument15 pagesQuality Requirements For Subcontractor: Project ProcedureDindo QuintanNo ratings yet

- MRB NONCONFORMING MATERIALDocument10 pagesMRB NONCONFORMING MATERIALLilian RobertsonNo ratings yet

- Non-Conformance Control ProcedureDocument12 pagesNon-Conformance Control Proceduremomin100% (1)

- Appendix 2 Intersted Party ListDocument18 pagesAppendix 2 Intersted Party ListIndustrial RecruiterNo ratings yet

- QMS Inspection ProcedureDocument5 pagesQMS Inspection ProcedureReyhan MfNo ratings yet

- VECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0Document10 pagesVECO-QM-PRO-0001 Project Quality Audit Procedure, Rev. 0hymerchmidtNo ratings yet

- 04 Control of Calibrated EquipmentDocument8 pages04 Control of Calibrated EquipmentRina AnitaNo ratings yet

- 1-Quality Control PlanDocument3 pages1-Quality Control PlanVeysel KoçNo ratings yet

- QSV 2 Product Release Procedure EN 01Document6 pagesQSV 2 Product Release Procedure EN 01prashanthNo ratings yet

- Control of Documents ProcedureDocument1 pageControl of Documents ProcedureZharel AhmadNo ratings yet

- Procedure - Control of RecordsDocument4 pagesProcedure - Control of RecordsMarjorie Dulay DumolNo ratings yet

- Quality Process Map Shows Customer Requirements and Management SystemsDocument1 pageQuality Process Map Shows Customer Requirements and Management SystemsDaniel PradityaNo ratings yet

- ISO 9001 Quality Management SystemDocument5 pagesISO 9001 Quality Management SystemRodel B. AradaNo ratings yet

- PUR-PM-06 Initial Flow Control For PCS SupplierDocument4 pagesPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarNo ratings yet

- NCR Trend Analysis for Barzan Onshore ProjectDocument15 pagesNCR Trend Analysis for Barzan Onshore ProjectrmdarisaNo ratings yet

- Quality ControlDocument51 pagesQuality ControlOprisor CostinNo ratings yet

- Happy Forgings EMS PerformanceDocument3 pagesHappy Forgings EMS Performancemool raj100% (1)

- QP-QA-05-Control of Non-Conforming ProductDocument2 pagesQP-QA-05-Control of Non-Conforming ProductDebkanta DasNo ratings yet

- Internal Quality Audit ProcedureDocument2 pagesInternal Quality Audit ProceduremahendraNo ratings yet

- CS P12 Drawing Control ProcedureDocument4 pagesCS P12 Drawing Control Procedurerichard nagilusNo ratings yet

- Contract Review RecordDocument1 pageContract Review RecordXionNo ratings yet

- Project Name: Report No.: Raised To: Raised By: Package: Area/Location Raised DateDocument2 pagesProject Name: Report No.: Raised To: Raised By: Package: Area/Location Raised DateDinesh Badhe100% (1)

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- Vendor Qualification ProcDocument3 pagesVendor Qualification ProcSa Ra100% (1)

- Quality Manual: M. Barbisotti & Sons LTDDocument20 pagesQuality Manual: M. Barbisotti & Sons LTDengsam777100% (1)

- Quality Assurance Audit ChecklistDocument14 pagesQuality Assurance Audit Checklistnha nguyenNo ratings yet

- IAC Corrective Action ReportDocument2 pagesIAC Corrective Action Reportsvanand500No ratings yet

- ASMI-OSHMS-PR-14 - Control of Documents and Record Retention ProcedureDocument10 pagesASMI-OSHMS-PR-14 - Control of Documents and Record Retention ProcedureJHUPEL ABARIALNo ratings yet

- E9. Non-Conformity Report NCRDocument2 pagesE9. Non-Conformity Report NCRPeter IyereNo ratings yet

- PRC0502Document5 pagesPRC0502John Thompson100% (2)

- ISO-Control of Non Conforming ProductsDocument3 pagesISO-Control of Non Conforming Productsnoufal27100% (2)

- PQP Flow ChartDocument1 pagePQP Flow ChartFIRMANSYAHNo ratings yet

- ISO 9001 Quality Manual-WOLSTDocument29 pagesISO 9001 Quality Manual-WOLSTSergioNo ratings yet

- Quality System Procedure: Corrective Action 1.0 PurposeDocument4 pagesQuality System Procedure: Corrective Action 1.0 PurposeNaveenkumar RNo ratings yet

- Control of Monitoring and Measuring EquipmentDocument3 pagesControl of Monitoring and Measuring EquipmentLinda Setya WatiNo ratings yet

- Employee Training RecordDocument19 pagesEmployee Training Recordklinik utama Bali Puri MedikaNo ratings yet

- 15 (QSP-QA - 07) Process & Product AuditDocument3 pages15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- Issued Action Item Category Root Cause Resp. Target Action Taken Status Record of EffectivenessDocument4 pagesIssued Action Item Category Root Cause Resp. Target Action Taken Status Record of EffectivenessBharathNo ratings yet

- QAD Procedure - Control of Non-Conforming Products P1Document1 pageQAD Procedure - Control of Non-Conforming Products P1sumanNo ratings yet

- E-M00006-00-Q-QCP-100 Rev.0 - IFU Project Quality PlanDocument26 pagesE-M00006-00-Q-QCP-100 Rev.0 - IFU Project Quality Planmahesh100% (1)

- Sampling System Inspection Process Flow Chart 1Document1 pageSampling System Inspection Process Flow Chart 1sakshi patilNo ratings yet

- 9001 Audit Checklist - Quality Planning and DesignDocument14 pages9001 Audit Checklist - Quality Planning and DesignAmer RahmahNo ratings yet

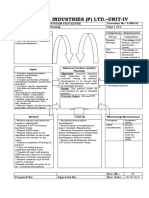

- Chopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureDocument5 pagesChopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureShankar ChowdhuryNo ratings yet

- Non Conformity Process Flow ChartDocument1 pageNon Conformity Process Flow ChartHermenegildo ChissicoNo ratings yet

- 1635 - 03 Control of Non Conforming Products Rev. 01Document5 pages1635 - 03 Control of Non Conforming Products Rev. 01Senthilkumar NarayananNo ratings yet

- TMT Procedure - Analysis of Data & Continuous Improvement P2Document1 pageTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNo ratings yet

- Lab Testing Services Audit ReportDocument8 pagesLab Testing Services Audit ReportMeghna SharmaNo ratings yet

- Internal QMS Audit Schedule: - Audit Area Department Auditor Auditee Audit Date RemaksDocument3 pagesInternal QMS Audit Schedule: - Audit Area Department Auditor Auditee Audit Date RemaksBihanChathurangaNo ratings yet

- Logo Workmanship InspectionDocument1 pageLogo Workmanship InspectionaezacsNo ratings yet

- 57 151202 1229142914 Architects Certification by Ar Joseph TanDocument35 pages57 151202 1229142914 Architects Certification by Ar Joseph TanNg JialinNo ratings yet

- Facilities ManagementDocument6 pagesFacilities ManagementZharel AhmadNo ratings yet

- Room Data Sheet TemplateDocument6 pagesRoom Data Sheet TemplateTong Yen ChinNo ratings yet

- Corrective Action ProcedureDocument1 pageCorrective Action ProcedureZharel AhmadNo ratings yet

- Internal Audits ProcedureDocument1 pageInternal Audits ProcedureZharel AhmadNo ratings yet

- @entrusty Letter of IntentDocument5 pages@entrusty Letter of Intentola789No ratings yet

- Non Conformance ProcedureDocument1 pageNon Conformance ProcedureZharel AhmadNo ratings yet

- Logo Workmanship InspectionDocument1 pageLogo Workmanship InspectionaezacsNo ratings yet

- Construction Management and AdministrationDocument9 pagesConstruction Management and AdministrationZharel AhmadNo ratings yet

- Preventive Action ProcedureDocument1 pagePreventive Action ProcedureZharel AhmadNo ratings yet

- CIPAA Syarikat Bina Darul AmanDocument48 pagesCIPAA Syarikat Bina Darul AmanZharel AhmadNo ratings yet

- PRePERTY DEViLOPMENT MANeGEMENT STRATEGYDocument10 pagesPRePERTY DEViLOPMENT MANeGEMENT STRATEGYZharel AhmadNo ratings yet

- BIM Key ContractualDocument4 pagesBIM Key ContractualZharel AhmadNo ratings yet

- Control of Documents ProcedureDocument1 pageControl of Documents ProcedureZharel AhmadNo ratings yet

- Facilities Management TopicsDocument6 pagesFacilities Management Topicsaezacs100% (2)

- Request For Information: Building Information Modelling (BIM) Implementation Project For PR1MADocument32 pagesRequest For Information: Building Information Modelling (BIM) Implementation Project For PR1MAZharel AhmadNo ratings yet

- Langkawi Discovery Park development timelineDocument1 pageLangkawi Discovery Park development timelineZharel AhmadNo ratings yet

- Langkawi Discovery Park development timelineDocument1 pageLangkawi Discovery Park development timelineZharel AhmadNo ratings yet

- Langkawi Discovery Park development timelineDocument1 pageLangkawi Discovery Park development timelineZharel AhmadNo ratings yet

- Development Management MonitorDocument9 pagesDevelopment Management MonitorZharel AhmadNo ratings yet

- Rubbish Treatment PlantDocument7 pagesRubbish Treatment PlantZharel AhmadNo ratings yet

- LDP Development Management MonitorDocument8 pagesLDP Development Management MonitorZharel AhmadNo ratings yet

- Facilities ManagementDocument6 pagesFacilities ManagementZharel AhmadNo ratings yet

- Sine Slab Calculations: Grade 40 Concrete With Additive 10mm Wire Frame 2 Lab. 60 Moulds Per Day Office OverheadDocument6 pagesSine Slab Calculations: Grade 40 Concrete With Additive 10mm Wire Frame 2 Lab. 60 Moulds Per Day Office OverheadZharel AhmadNo ratings yet

- FRH-MAST - Proposed Business ModelDocument6 pagesFRH-MAST - Proposed Business ModelZharel AhmadNo ratings yet

- CV Curriculum VitaeDocument5 pagesCV Curriculum VitaeZharel AhmadNo ratings yet

- Sec - Prop Pilot Project - 3Document31 pagesSec - Prop Pilot Project - 3Zharel AhmadNo ratings yet

- HBP17Document14 pagesHBP17Zharel AhmadNo ratings yet

- MKUCHAJR_PROPOSAL[1]Document9 pagesMKUCHAJR_PROPOSAL[1]innocentmkuchajrNo ratings yet

- Improving OBS Pharma's Performance and ImageDocument2 pagesImproving OBS Pharma's Performance and ImageFaiXan TariqNo ratings yet

- Business Environment Analysis of Shoppers Stop: Presented byDocument20 pagesBusiness Environment Analysis of Shoppers Stop: Presented byJannatNo ratings yet

- Question 1, 2, 3, 4Document7 pagesQuestion 1, 2, 3, 4Sreelakshmi KPNo ratings yet

- S4 HANA Business Partner TrainingDocument42 pagesS4 HANA Business Partner Trainingchaitanya100% (5)

- The influence of airline service quality on passenger satisfaction and loyalty in UgandaDocument14 pagesThe influence of airline service quality on passenger satisfaction and loyalty in UgandachrysobergiNo ratings yet

- Mktg1294 Asn02 Nguyenlethuyduyen s3891453 03Document25 pagesMktg1294 Asn02 Nguyenlethuyduyen s3891453 03Duyen NguyenNo ratings yet

- Vat Indirect Taxes in Africa 2023Document297 pagesVat Indirect Taxes in Africa 2023Olusola OgunyemiNo ratings yet

- Impact of SAS No. 94 On Computer Audit TechniquesDocument5 pagesImpact of SAS No. 94 On Computer Audit TechniquesJerome B. AgliamNo ratings yet

- EssayDocument12 pagesEssayNhãPhươngNo ratings yet

- Joint Venture ADV CH1Document8 pagesJoint Venture ADV CH1Tilahun GirmaNo ratings yet

- Perhitungan Kriteria Investasi: Net Present Value (NPV)Document12 pagesPerhitungan Kriteria Investasi: Net Present Value (NPV)Nurul FitrianaNo ratings yet

- 2022 Techwear GuideDocument42 pages2022 Techwear GuideCeline LowNo ratings yet

- Using Familiar Words SL - AnswerDocument5 pagesUsing Familiar Words SL - Answerashek mahmoodNo ratings yet

- Advertising & IMC Research TypesDocument40 pagesAdvertising & IMC Research TypesMaria Zakir100% (2)

- TEKsystems DeLL PartnershipDocument2 pagesTEKsystems DeLL PartnershipK L Narayana ReddyNo ratings yet

- Astrology Setup GuideLinesDocument15 pagesAstrology Setup GuideLinesVipul JujarNo ratings yet

- Agile TerminologyDocument2 pagesAgile TerminologySiva KumarNo ratings yet

- Accounting Information SystemDocument6 pagesAccounting Information SystemSamia Shahid100% (1)

- Module 06 - Policy and Procedure ManualDocument6 pagesModule 06 - Policy and Procedure ManualBea Reen BurgosNo ratings yet

- Use The Figure Below To Answer The Following QuestionsDocument5 pagesUse The Figure Below To Answer The Following QuestionsSlock TruNo ratings yet

- Cement Distribution Proposal for Addis AbabaDocument21 pagesCement Distribution Proposal for Addis AbabaTesfaye Degefa100% (5)

- Introduction To Business EconomicsDocument14 pagesIntroduction To Business EconomicsMujahid AmjidNo ratings yet

- RM 1Document260 pagesRM 1Thanasekaran TharumanNo ratings yet

- Assignment of MBA-1 Past QuestionDocument2 pagesAssignment of MBA-1 Past QuestionAshirbad NayakNo ratings yet

- Baldwin CompanyDocument4 pagesBaldwin CompanyShubham TetuNo ratings yet

- Problems On Contract CostingDocument11 pagesProblems On Contract CostingRoguewolfx VFX50% (2)

- SCM Lecture 3Document2 pagesSCM Lecture 3rishabh choudhryNo ratings yet

- Cost of Capital Optimization ModelingDocument71 pagesCost of Capital Optimization ModelingAhmed Mostafa ElmowafyNo ratings yet

- Application For Shifting Branch - Sharekhan LTD & SBPFSL - FinalDocument1 pageApplication For Shifting Branch - Sharekhan LTD & SBPFSL - Finalchethan0% (1)

![MKUCHAJR_PROPOSAL[1]](https://imgv2-2-f.scribdassets.com/img/document/722839407/149x198/8f31ac4be2/1713081319?v=1)