Professional Documents

Culture Documents

Tna Confectionery Brochure (EN)

Uploaded by

Bindu PanickerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tna Confectionery Brochure (EN)

Uploaded by

Bindu PanickerCopyright:

Available Formats

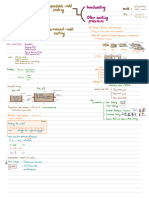

confectionery

metal detection

verification

packaging

case packing

distribution

processing

processing

weighing

coating

controls & integration processing coating distribution weighing & packaging

electrical design installation commissioning SCADA cooling technology oil powder horizontal motion vibratory motion belt conveyors weighing vertical form fill & seal packaging

HMI & network system remote control elevation conveyors metal detection verification

confection connection cool candy un-sticky situation sugar rush Variety packs

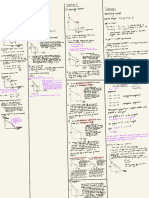

Simplify processes and maximise your productivity with our world Cool candies and other confections up to 10 times faster with Utilise innovative oil systems to enhance your product, line efficiency Get sugary confectionery from one station to the next in a continuous Get the shortest vertical product transfer from the scale to the

class range of electrical control systems and integration solutions patented cooling technology that uses hundreds of impingement and profitability. flow for increased production volume. pack using tna’s benchmark, performance packaging systems for

designed to handle any size confectionery production line. cooling jets. confectionery products.

• Incorporate advanced spray gun technology to apply minimal oil • Combine horizontal and vibratory motion technology for the

• Connect all systems in your production line to your Enterprise • Boost production volume capabilities using less time to cool as releasing agent in your confectionery moulds ultimate production line efficiency • Weigh and package confectionery products at speeds up to

Resource Planning systems such as SAP and operate all controls products and reduce your cost-per-piece 300 bags per minute with minimal breakage, loss of toppings

• Ensure the quality of your candies, gummies and other • Incorporate rigidised metal to minimise surface contact and

from a central location or loss of coatings

• Control temperatures of jellies and other gummy candies confections with precise oil application that won’t alter your prevent sticky products from backing up

• Get a 360° view with full production visibility through to prevent product wastage and wear on equipment from products flavour, texture or appearance • Maximise performance with the fastest product changeover

• Prevent residue and flavour build-up with non-stick coated trays

customised management reporting; including interfaces, sugary build-up times in the industry guaranteed with rapid former unload, dual

• Apply decorative and flavour enhancing ingredients using our

dashboards and reports specific to your production system • Create the perfect mix of candies and other confectioneries with spindle auto-splice film changes, one-touch GUI system

• Use less conveyor space to reduce the total footprint of your flexible quik-coat™ system

state-of-the-art blending systems programme change and quick-clean design

• Run at full speed thanks to seamless integration of parts and confectionery production line

technology, even if your line is comprised of dissimilar equipment • Ensure the highest level of sustainability with the world’s

“Customised designs smallest footprint and highest speeds in the confectionery

industry using 20% less energy than competitor systems

help optimise the use

“tna’s turnkey of existing space “Keep your products

solutions and project within your facility” in line with regional

management services safety regulations

give you an on-time, using tna’s patented

on-budget, high- metal detection and

quality installation verification solutions”

that’s stress-free

from start to finish”

es support

sal

r service projec

me tm

to

us

an

-market c

age

ment

ter

CONFECTIONERY

af

my-tna 360°

customer care

c t t e sti n g

programme

tr ai ni n

du

g

ro

p

tna is your single source supplier

for processing and packaging solutions

o rt al

np

tec

confectioneries are a sweet business that bring a variety of ni m

io

at

h

ca y -t

delicious opportunities no matter where you are in the world. l s e r vic e n a infor m

for over 30 years, tna and its family of brands has helped food

manufacturers capitalise on this industry that’s booming in gummies,

hard candies, chocolates and more. With more than 14,000

installations in over 120 countries, tna’s complete line of solutions

brings simplicity, flexibility and performance to candy-making

production lines everywhere – and can do the same for you!

to make the most of your opportunities, it’s more important

than ever to partner with a supplier who can offer innovative and

modular solutions to meet today’s consumer demands including:

• Producing premium candies as an affordable indulgence

• Including more natural ingredients for healthier

confectionery options

• Capturing the attention of all age groups with new and

innovative flavours

as your partner, tna offers complete, turnkey solutions from a

single, global source that also gives you the power and control to

boost production with:

• Improved line efficiency with integrated product controls and

scada reporting

• Advanced distribution technology that prevents sticky

situations and keeps production moving

• Increased weighing and packaging speeds with precision accuracy

• Reduced energy footprint for improved sustainability when

heating and cooling

tna’s fAMIly ContACt us AnywheRe, AnytIMe: tnasolutIons.CoM

• Minimised downtime to maximise the potential of your

of brands

tna is a leading global supplier of integrated food packaging and processing solutions with over

production line 14,000 systems installed across more than 120 countries. The company provides a comprehensive

range of products including materials handling, processing, coating, distribution, seasoning,

all of this in addition to our my-tna 360° customer care

weighing, packaging, cooling, freezing, metal detection and verification solutions. tna also

programme that’s available to you 24 / 7.

offers a variety of production line controls integration & SCADA reporting options, project

Find start-to-finish solutions for your confectionery line management and training. tna’s unique combination of innovative technologies, extensive

or just about any food application project management experience and 24 /7 global support ensures customers achieve faster,

more reliable and flexible food products at the lowest cost of ownership.

controls integration & scada | materials handling | processing |

freezing & cooling | coating | distribution | seasoning |

weighing | packaging | metal detection | verification |

project management | training | Cooling the Globe: Printed on recycled paper

confectionery_solutions_en_v1_7-2015

You might also like

- Tna Nuts and Legumes Brochure (EN)Document3 pagesTna Nuts and Legumes Brochure (EN)Bindu PanickerNo ratings yet

- Tna Cereals Brochure (EN)Document3 pagesTna Cereals Brochure (EN)Bindu PanickerNo ratings yet

- Tna French Fries Brochure (EN)Document3 pagesTna French Fries Brochure (EN)Bindu PanickerNo ratings yet

- Tna Baked Snacks Brochure (EN)Document3 pagesTna Baked Snacks Brochure (EN)Bindu PanickerNo ratings yet

- Tna Training Brochure (EN)Document3 pagesTna Training Brochure (EN)Bindu PanickerNo ratings yet

- Mindmap For Global Logistics Integration Ism EyefreightDocument1 pageMindmap For Global Logistics Integration Ism EyefreightEdison Reus SilveiraNo ratings yet

- Supply Chain Mindmapping: Enabling Operational Transparency in a VUCA WorldDocument1 pageSupply Chain Mindmapping: Enabling Operational Transparency in a VUCA WorldobNo ratings yet

- AbstractDocument3 pagesAbstractCivil BasundharaNo ratings yet

- The Communications Rainbow - MasterDocument1 pageThe Communications Rainbow - MastersavioursofpopNo ratings yet

- KEI Product CatalogueDocument31 pagesKEI Product CataloguesatheeskrsnaNo ratings yet

- Checklist of Candidates ExcelDocument5 pagesChecklist of Candidates Excelmmrahman93No ratings yet

- Nla News-Page24681426Document1 pageNla News-Page24681426James ScottNo ratings yet

- สรุป CastingDocument1 pageสรุป CastingTranrissNo ratings yet

- Future of XaasDocument42 pagesFuture of XaasDavid GalipeauNo ratings yet

- KEI Product CatalogueDocument31 pagesKEI Product CatalogueBhushan GuptaNo ratings yet

- Program-29 11 2019-Web3Document4 pagesProgram-29 11 2019-Web3Dejan VujičićNo ratings yet

- Agile Product RoadmapDocument1 pageAgile Product RoadmapVitória SlompoNo ratings yet

- Subway® Catering™ Subway® Catering™ Subway® Catering™ & DrinksDocument2 pagesSubway® Catering™ Subway® Catering™ Subway® Catering™ & DrinksNoufal AsifNo ratings yet

- Built Env 223Document4 pagesBuilt Env 223abeerah2234No ratings yet

- Examples of Applicable Steels For Typical Products: Cproperties of Die MaterialsDocument1 pageExamples of Applicable Steels For Typical Products: Cproperties of Die MaterialsErnestoFloresNo ratings yet

- The Abington Journal 04-13-2011Document28 pagesThe Abington Journal 04-13-2011The Times Leader100% (1)

- 72498-Payroll ERD PDFDocument1 page72498-Payroll ERD PDFjeffrey_m_suttonNo ratings yet

- 21MB0001 ModelDocument1 page21MB0001 ModelPhreetzi ÜnseenNo ratings yet

- Trading Income Tax BasicsDocument15 pagesTrading Income Tax BasicsJalees Ul HassanNo ratings yet

- Formulir Upload Persyaratan Seminar (Respons) PDFDocument4 pagesFormulir Upload Persyaratan Seminar (Respons) PDFRauzatun NusyuraNo ratings yet

- Mounting metal profiles on windowsDocument1 pageMounting metal profiles on windowsLabinot MorinaNo ratings yet

- rc0913_AlliedDocument4 pagesrc0913_AlliedsymonpatenNo ratings yet

- Cruise Ship Interiors 2023 - Sales PlanDocument1 pageCruise Ship Interiors 2023 - Sales Planpetrasb.amgNo ratings yet

- 4 Ethics - Monet CoDocument4 pages4 Ethics - Monet Cosbracca1No ratings yet

- Form Pendaftaran KKN TA 2021-2022 (Responses) - 2Document21 pagesForm Pendaftaran KKN TA 2021-2022 (Responses) - 2keropsesNo ratings yet

- 10% 15% 15% 50% 10% 100% Dd/mm/yyyy Yes/No 20% 50% 5% 10% 15% 100% Dd/mm/yyyy DaysDocument3 pages10% 15% 15% 50% 10% 100% Dd/mm/yyyy Yes/No 20% 50% 5% 10% 15% 100% Dd/mm/yyyy DaysBassem Ben FrajNo ratings yet

- Smartocto User Needs 2 PosterDocument1 pageSmartocto User Needs 2 PostergraceyangxiaoNo ratings yet

- Pot ADocument1 pagePot ATaufiQ WidodoNo ratings yet

- Pot ADocument1 pagePot ATaufiQ WidodoNo ratings yet

- Income Tax Fundamentals 2015 Whittenburg 33rd Edition Solutions ManualDocument6 pagesIncome Tax Fundamentals 2015 Whittenburg 33rd Edition Solutions Manualbrianbradyogztekbndm100% (45)

- Status and Order ChangeDocument1 pageStatus and Order ChangeSAUTOTNo ratings yet

- List of Numeric Codes For Railway Companies (RICS Code)Document8 pagesList of Numeric Codes For Railway Companies (RICS Code)Md. Shiraz JinnathNo ratings yet

- Merino Lam India 2023Document118 pagesMerino Lam India 2023Sourish MitraNo ratings yet

- Education Quality Improvement Program - EQUIP List of Tas To Be Sustained 2018Document1 pageEducation Quality Improvement Program - EQUIP List of Tas To Be Sustained 2018Sayed WafiullahNo ratings yet

- Technical Note: Connection Between An Omnipcx 4400 and A Pms On Ahl LinkDocument8 pagesTechnical Note: Connection Between An Omnipcx 4400 and A Pms On Ahl LinkMehdi GuetariNo ratings yet

- Technical Note: Connection Between An Omnipcx 4400 and A Pms On Ahl LinkDocument8 pagesTechnical Note: Connection Between An Omnipcx 4400 and A Pms On Ahl LinkMehdi GuetariNo ratings yet

- Balluff WP Traceability in ManufacturingDocument9 pagesBalluff WP Traceability in ManufacturingsaberbourasNo ratings yet

- Pronostico PeriodontalDocument25 pagesPronostico PeriodontalRodrigo RojasNo ratings yet

- Example QLASSIC Poster For BSR506 IIDocument1 pageExample QLASSIC Poster For BSR506 II2022495962No ratings yet

- Dubai BIM RoadmapDocument1 pageDubai BIM RoadmapZÄkãrîãêÊlJêmLîNo ratings yet

- Jingsun Solar Panel 570WDocument1 pageJingsun Solar Panel 570WalzenasekarpNo ratings yet

- Questions From Tutorials 1-4Document1 pageQuestions From Tutorials 1-4izziemartinez2001No ratings yet

- Screened Backshell Product FinderDocument1 pageScreened Backshell Product Finderpaula09No ratings yet

- BSP1702 NotesDocument7 pagesBSP1702 NotesliyangwongNo ratings yet

- T+U Tea PackagingDocument135 pagesT+U Tea PackagingDylan RobertsNo ratings yet

- Mva Pus85 PDFDocument1 pageMva Pus85 PDFmireNo ratings yet

- Small Résumé StatsDocument8 pagesSmall Résumé StatscameratalorenzoNo ratings yet

- IB113 The Law of Contract Student Handout 2022Document5 pagesIB113 The Law of Contract Student Handout 2022Sarah StevenNo ratings yet

- The steelmaking processDocument1 pageThe steelmaking processsmithNo ratings yet

- As Built: O U S EDocument1 pageAs Built: O U S EEdson HuertaNo ratings yet

- Paper MakingDocument1 pagePaper MakingBurak KucukkelesNo ratings yet

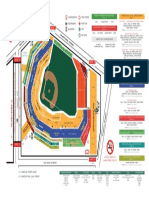

- Fenway Concessions MapDocument1 pageFenway Concessions MapCarlos Hernandez0% (1)

- Solid Surface: BenchtopsDocument7 pagesSolid Surface: BenchtopsSirvan HomaNo ratings yet

- Fidasinergiasia Fidasinergiasia Fidaasia: We Can Grow With Together From Nothing To SomethingDocument28 pagesFidasinergiasia Fidasinergiasia Fidaasia: We Can Grow With Together From Nothing To SomethingHanni AlrasyidNo ratings yet

- Absen Kelas 12 by Aisyah SalwaDocument4 pagesAbsen Kelas 12 by Aisyah SalwaMulki AhmadNo ratings yet

- TOP 100 Funniest WWW OnelinersDocument6 pagesTOP 100 Funniest WWW Onelinerssauravpal53No ratings yet

- The Maudsley Model of FTDocument8 pagesThe Maudsley Model of FTCandela SánchezNo ratings yet

- Y and Y For Schools: Answer KEY With ANS WER KEYDocument11 pagesY and Y For Schools: Answer KEY With ANS WER KEYJuan Martin ZafraNo ratings yet

- The Priest Who Refused To Bow Before The WindDocument56 pagesThe Priest Who Refused To Bow Before The WindKata MlekNo ratings yet

- APV Mixing and Blending Technology 5000 01 01 2009 GB PDFDocument12 pagesAPV Mixing and Blending Technology 5000 01 01 2009 GB PDFGilles DakouriNo ratings yet

- 7.7.21 - The Disobedient Baby BirdDocument11 pages7.7.21 - The Disobedient Baby BirdAarti ThakkarNo ratings yet

- Eng GR IiiDocument104 pagesEng GR Iiicharan213No ratings yet

- Area 1: Health, Nutrition and SafetyDocument23 pagesArea 1: Health, Nutrition and SafetyJoyz SarezNo ratings yet

- Egg DietDocument9 pagesEgg DietAaref DukhanNo ratings yet

- Guía 3 - Mayo - InglesDocument5 pagesGuía 3 - Mayo - InglesCarmen JeldresNo ratings yet

- Project Feasibility Study - Business Plan. - Haqiqa Investment Consultant in EthiopiaDocument1 pageProject Feasibility Study - Business Plan. - Haqiqa Investment Consultant in EthiopiaSuleman100% (2)

- Germans & Hungarians: 1828 Land Census, Vol. 14Document209 pagesGermans & Hungarians: 1828 Land Census, Vol. 14jetsetwilly100% (1)

- Manual of Methods OF Analysis of Foods: Cereal and Cereal ProductsDocument56 pagesManual of Methods OF Analysis of Foods: Cereal and Cereal Productsashwani0% (1)

- Cat 3 Presentstion: Satyam Kumar: 21scse1010304 Saurav Kumar: 21scse1010677 Saubhagya Pandey: 21scse1011260Document9 pagesCat 3 Presentstion: Satyam Kumar: 21scse1010304 Saurav Kumar: 21scse1010677 Saubhagya Pandey: 21scse1011260SATYAM KUMAR 21SCSE1010304No ratings yet

- 49 Shira Barak The Taste of Northern India 2014Document115 pages49 Shira Barak The Taste of Northern India 2014Miroslav ĐokićNo ratings yet

- Cream PuffsDocument1 pageCream PuffsLBakerNo ratings yet

- Filipino Spaghetti Recipe - Pinch of YumDocument41 pagesFilipino Spaghetti Recipe - Pinch of YumericNo ratings yet

- OrderDocument10 pagesOrderbsudhareddyNo ratings yet

- Ges 107Document140 pagesGes 107Oyedijo Debby100% (2)

- HomeopathyDocument109 pagesHomeopathyRashedul IslamNo ratings yet

- Biology 2021 Activity - Niches - WorksheetDocument1 pageBiology 2021 Activity - Niches - WorksheetAdrianna MooreNo ratings yet

- Rademaker LaminatorDocument12 pagesRademaker LaminatorVuong NguyenNo ratings yet

- Lesson 124Document6 pagesLesson 124Yu AkmaNo ratings yet

- Case Study of a 4-Year-Old Boy's DevelopmentDocument25 pagesCase Study of a 4-Year-Old Boy's DevelopmentAnia JuanNo ratings yet

- Present, Past, Future Tense Review QuizDocument2 pagesPresent, Past, Future Tense Review QuizJess Silves0% (1)

- SITHCCC019 Student Assessment TasksDocument23 pagesSITHCCC019 Student Assessment TasksShiney FernandoNo ratings yet

- Boost Nutritious Food Production with Diverse Agro-Ecological PracticesDocument118 pagesBoost Nutritious Food Production with Diverse Agro-Ecological PracticesVijay KumarNo ratings yet

- Soft Dough Bread RecipeDocument58 pagesSoft Dough Bread RecipeAdhithya SaiNo ratings yet