Professional Documents

Culture Documents

Screened Backshell Product Finder

Uploaded by

paula09Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Screened Backshell Product Finder

Uploaded by

paula09Copyright:

Available Formats

Screened Backshell Product Finder Click to view product on polamco.

com

Interconnect Solutions Worldwide

Additional

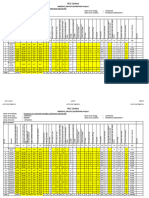

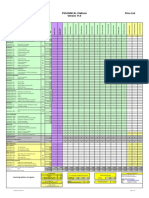

Cable Derived 38999 SERIES

Screen Termination Strain Relief Components

Sealing

Required

HE308 Standard

Anti-Decoupling

SERIES VERSION

Spin Coupling

Compression

VG Approved

I II III & IV

Cable Clamp

Boot Option

Heat Shrink

Reworkable

Low Profile

or Multiple

Individual

Grommet

Tool-free

Screens

Tie Post

Straight

STANDARD SERIES STANDARD VERSIONS

Screen

Overall

Band

CLICK TO VIEW

Boot

ARE HIGHLIGHTED ARE HIGHLIGHTED

45°

90°

BT BT - Band Termination • • • •

• Screen termination by stainless steel band

• Sealing and strain relief by heat shrink boot

• Standard range - many sizes available

• • • • BT (CE) - Die Cast Swept Elbow • •

from stock BT (LP-EB) - Low Profile EB Weld • • •

MB BT (SS) - Stainless Steel • • • •

• Designed specifically for micro band,

backshell is 5mm shorter than • • • • BT (NB) - Nickel Aluminium Bronze • • • •

equivalent BT backshell

• Sealing and strain relief by heat shrink boot

XBT - Composite • • •

DB XBT (-F) - Composite •

• Double band platform for optimum

• • • • •

termination of two distinct overall screens

• Sealing and strain relief by heat

BT (AD) - Anti-Decoupling • • • • •

shrink boot

BT (3C) - Cobra Head • • •

88

• Screen termination by standard

stainless steel band

MB - Micro Band Termination • • • •

• Strain relief by screw-on cable • • • • • • •

clamp “can”

DB - Double Band Termination * * *

BAND

• “Can” provides protection of screen

termination area 88 - Band-In-A-Can • • • •

89 88 (L25) - Micro Band-In-A-Can • • •

• Double band platform for optimum

termination of two distinct overall screens

• Strain relief by screw-on cable clamp “can”

• • • • 88 (3C) - Cobra Head • •

• “Can” provides protection of screen

termination area 89 - Double Band-In-A-Can • • • •

VG PVG1AH1 - Band Termination • • •

• Backshells in accordance with

VG95319-1011 • • • •

• Sealing and strain relief by heat shrink boot

PVG1BH3 - Band Termination (90°) • • •

• Optional conduit insert for VG-style conduit

PVG1GH1 - Band Termination • • •

AP

• Screen termination by standard stainless

steel band

PVG1HH3 - Band Termination (90°) • • •

• European preferred style, without band

• • • •

retention lip

PVG1Z - VG Conduit Adaptor Insert • • *

• Sealing and strain relief by heat shrink boot

PVG1DH1 - Low Profile / Step-Up Entry • • • •

DS

• Individual and overall screen termination AP - Band Termination • • • •

• Indivdual screens terminated inside the • • • • •

backshell, close to the connector in order

to minimise cross-talk

DS - Internal & External Band Termination • •

DS (T3) - Style 2 • •

*Please contact our sales team for further information

Additional

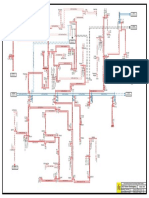

Cable Derived 38999 SERIES

Screen Termination Strain Relief Components

Sealing

Required

HE308 Standard

Anti-Decoupling

SERIES VERSION

Spin Coupling

Compression

VG Approved

I II III & IV

Cable Clamp

Boot Option

Heat Shrink

Reworkable

Low Profile

or Multiple

Individual

Grommet

Tool-free

Screens

Tie Post

Straight

STANDARD SERIES STANDARD VERSIONS

Screen

Overall

Band

CLICK TO VIEW

Boot

ARE HIGHLIGHTED ARE HIGHLIGHTED

45°

90°

91 91 - Spring Termination • • • •

SPRING

• Tool-free screen termination by stainless

steel constant-force spring

• Sealing and strain relief by heat shrink boot

• • • • • 91 (CE) - Die Cast Swept Elbow • •

• Standard range - many sizes available

from stock 91 (LP-EB) - Low Profile EB Weld • • •

60

BRAID TRAP MEMORY RING

• Low-profile screen termination by heat-

91 (SS) - Stainless Steel • • • •

shrink memory metal ring

• • •

• Pre-terminated screenbraid sock

version available

91 (NB) - Nickel Aluminium Bronze • • • •

• Sealing and strain relief by heat shrink boot X91 - Composite • • •

95 91 (3C) - Cobra Head • • •

• Tool-free 360° screen termination by

“barrel thread” braid trap system • • • • •

• Sealing and strain relief by heat shrink boot

91 - 440 Profile • • • •

• Cable clamp version also available

60 - Memory Ring Termination • • • •

70

BRAID TAIL

• Pre-terminated screenbraid sock

• High-reliability low-profile magna-form

60 (SS) - Stainless Steel • • • •

• • • • •

ring termination

• Sealing and strain relief by heat

60 (NB) - Nickel Aluminium Bronze • • • •

shrink boot

60 (T6) - Pre-Terminated Braid Tail • • • •

KMA*

• 360° termination of multiple individual screens

• Mesh tape bundle sytem creates

60 (3C) - Cobra Head • • •

• • • • • •

windowless EMI barrier even without 95 - Braid Trap Termination • • • •

MESH TAPE

overall screenbraid

• Sealing and strain relief by heat shrink boot

95 (SS) - Stainless Steel • • • •

KMCC*

• 360° termination of multiple individual screens 95 (NB) - Nickel Aluminium Bronze • • • •

• Mesh tape bundle sytem creates

windowless EMI barrier even without • • • • • 95 (3C) - Cobra Head • • •

overall screenbraid

• Strain relief by cable clamp: Tool-free

assembly and re-work

70 - Braid Tail Backshell • • • •

* MANUFACTURED UNDER LICENCE ‘AGUSTAWESTLAND HELICOPTERS UK PATENT 2239358’ 70 (SS) - Stainless Steel • • • •

70 (NB) - Nickel Aluminium Bronze • • • •

KMA - Mesh Tape Termination • • • •

KMA (D) - Double Slot version • • • •

KMCC - Mesh Tape Cable Clamp • • • •

Additional

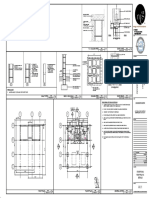

Cable Derived 38999 SERIES

Screen Termination Strain Relief Components

Sealing

Required

HE308 Standard

Anti-Decoupling

SERIES VERSION

Spin Coupling

Compression

VG Approved

I II III & IV

Cable Clamp

Boot Option

Heat Shrink

Reworkable

Low Profile

or Multiple

Individual

Grommet

Tool-free

Screens

Tie Post

Straight

STANDARD SERIES STANDARD VERSIONS

Screen

Overall

Band

CLICK TO VIEW

Boot

ARE HIGHLIGHTED ARE HIGHLIGHTED

45°

90°

308 308 - Dual Cone Termination • • • •

• Screen termination using two

overlapping cones

• Sealing and strain relief by

• • • • • 308 (NB) - Nickel Aluminium Bronze • • • •

heat shrink boot 318 - Triple Cone Termination • •

318 PVG1CH1 - Cone Termination • • •

• Individual and overall screen termination

using three overlapping cones • • • • • •

• Similar space envelope to 308 series PVG1FH1 - Cone Termination • • • •

• Sealing and strain relief by heat

shrink boot 64 - Cone Clamp Termination • • • •

VG

• Backshells in accordance with

64 (SS) - Stainless Steel • • • •

VG95319-1011 • • • • •

• Screen termination using cone-shaped

nut

64 (NB) - Nickel Aluminium Bronze • • • •

• Sealing and strain relief by heat shrink boot 64 - Step-Up / Step-Down version • • • •

64

• Individual screen termination using

castellated cone

64 (SS) - Step-Up / Step-Down version • • • •

• • • • •

• Sealing and strain relief by heat

shrink boot

64 (NB) - Step-Up / Step-Down version • • • •

CONE

• Cable clamp version also available

35 - Cone Clamp Cable Sealing Backshell • • • •

35

• Screen termination using two cones

• IP68 cable sealing grommet housed in

35 (NE) - Non-Environmental • • • •

separate chamber to cones

• • • • •

• Strain relief by cable clamp: Tool-free

36 - Cone Clamp Cable Sealing Backshell • • • •

assembly and re-work

36

36 (NE) - Non-Environmental • • • •

• Two or three cone option for individual

plus optional overall screen termination

39 - Cone Clamp Cable Sealing Backshell • • • •

• IP68 cable sealing grommet housed in • • • • • •

separate chamber to cones

• Strain relief by cable clamp: Tool-free

39 (NE) - Non-Environmental • • • •

assembly and re-work CS64 - Cone Clamp Cable Sealing Backshell • • • •

39

• Screen termination using single cone TAK - Heat Shrink Backshell Kit • • • •

• IP68 cable sealing grommet housed in

• • • • •

separate chamber to cone

• Strain relief by cable clamp: Tool-free

TAK (SS) - Stainless Steel • • • •

assembly and re-work

TAK (NB) - Nickel Aluminium Bronze • • • •

CS64

• Individual screen termination using

castellated cone

• IP68 cable sealing grommet housed • • • • •

in separate chamber to cone

• Strain relief by cable clamp: Tool-

free assembly and re-work

TAK

• Screened backshell with pre-installed

TAK

heatshrink boot

• Quick and easy installation

• • •

• High-reliability magna-form screen

termination

Non-Screened Backshell Product Finder Click to view product on polamco.com

Additional

Cable Derived 38999 SERIES

Screen Termination Strain Relief Components

Sealing

Required

HE308 Standard

Anti-Decoupling

SERIES VERSION

Spin Coupling

Compression

VG Approved

I II III & IV

Cable Clamp

Boot Option

Heat Shrink

Reworkable

Low Profile

or Multiple

Individual

Grommet

Tool-free

Screens

Tie Post

Straight

STANDARD SERIES STANDARD VERSIONS

Screen

Overall

Band

CLICK TO VIEW

Boot

ARE HIGHLIGHTED ARE HIGHLIGHTED

45°

90°

96 96 - Cable Clamp Backshell • • • •

• Lightweight open-frame cable clamp •

• Machined from solid for maximum 96 (SS) - Stainless Steel • • • •

strength and reliability

96 (NB) - Nickel Aluminium Bronze • • • •

77 96 (AD) - Anti-Decoupling • • • •

• Entry sizes to match cable bundle diameter •

STRAIN RELIEF

• Extended can offers protection to rear

of connector 77 - Cable Clamp, Optional Entry Size • • • •

37

37 - Cable Sealing Backshell • • • •

• IP68 cable sealing grommet

• Strain relief by cable clamp: Tool-free

• • 86 - Tie Post Backshell • • • •

assembly and re-work

86 (ET) - Earth Tag Option • • • •

86

• Lightweight strain-relief

97 - Heat Shrink Boot Backshell • • • •

• •

• Machined from solid for maximum

strength and reliability

97 (SS) - Stainless Steel • • • •

97

97 (NB) - Nickel Aluminium Bronze • • • •

• Profile specifically designed for optimum

performance with heatshrink boot • •

97 (ET) - Earth Tag Option • • • •

• Standard range - many sizes available

from stock 76 - Low Profile Heat Shrink Boot Backshell • • •

HEAT SHRINK BOOT

PVG1EH1 - Heat Shrink Boot Backshell • • • *

76 • •

• Low profile form for heatshrink boot 98 - E Nut Backshell • • •

Metric / Unified / PG / NPT Adaptor • • • •

VG Metric / Unified / PG / NPT Fixed Adaptor •

• Backshells in accordance with • •

VG95319-1011

• Sealing and strain relief by heat shrink boot DC - Extender / Angle Adaptor • • • •

DC (-F) - Fixed Extender Adaptor •

COMPRESSION NUT

98

GROMMET

• Provides protection and compression of the

connector grommet *Please contact our sales team for further information

THREAD ADAPTORS

• Backshell providing standard Metric, Imperial,

THREAD ADAPTORS

PG or NPT thread for a variety of applications

& EXTENDERS

EXTENDERS/

ANGLE ADAPTORS

• Extends connector rear

• Used in conjunction with any screened or

non-screened backshell

• Straight or angled versions

You might also like

- Pipe Ring Product Selector: Light-Duty Galvanized Pipe RingsDocument1 pagePipe Ring Product Selector: Light-Duty Galvanized Pipe RingsReem Ahmed KhalilNo ratings yet

- Thermacor Preinsulated PipesDocument6 pagesThermacor Preinsulated PipesBernard SolisNo ratings yet

- S027-TYPICAL WATER PROOFING DETAILSDocument1 pageS027-TYPICAL WATER PROOFING DETAILSWNo ratings yet

- SI 5NB0A 001 00 Eng - v1 - m56577569830747488Document1 pageSI 5NB0A 001 00 Eng - v1 - m56577569830747488brassoyNo ratings yet

- Masterpact NT RETURN Masterpact NW RETURN NS1600b... 3200 RETURN NS630b... 1600 RETURN NSX100... 250 RETURN NSX400... 630 54444Document1 pageMasterpact NT RETURN Masterpact NW RETURN NS1600b... 3200 RETURN NS630b... 1600 RETURN NSX100... 250 RETURN NSX400... 630 54444Anas BasarahNo ratings yet

- A321 Ata23Document1 pageA321 Ata23kpilNo ratings yet

- Maintenance Training: Speech CommunicationDocument2 pagesMaintenance Training: Speech CommunicationAnonymous QRVqOsa5No ratings yet

- Navistar Manual de Taller DT466 Amp I530eDocument1 pageNavistar Manual de Taller DT466 Amp I530eAnonymous 7t2BOJb100% (2)

- Villa Ocampo: A Resistencia CommunityDocument1 pageVilla Ocampo: A Resistencia CommunityjuampicNo ratings yet

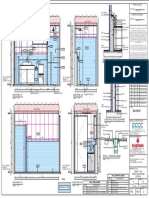

- 1802 A 424-1 F Toilet Elevation-Type 05Document1 page1802 A 424-1 F Toilet Elevation-Type 05nanieNo ratings yet

- A904 -PARKING DETAILSDocument1 pageA904 -PARKING DETAILSØwięs MØhãmmedNo ratings yet

- TH360B TH560B - CAT - Hydr System.Document2 pagesTH360B TH560B - CAT - Hydr System.Zeck33% (3)

- NEMA and IEC standard motor dimensionsDocument2 pagesNEMA and IEC standard motor dimensionsVijay Raghavan0% (1)

- RCC Slab Bridge Reconstruction 1X8.0 at 14+495-GADDocument1 pageRCC Slab Bridge Reconstruction 1X8.0 at 14+495-GADShivam SharmaNo ratings yet

- Maa Manasa Pole ShedulesDocument69 pagesMaa Manasa Pole Shedulesmuralipower1986No ratings yet

- SLD SumbagtengDocument1 pageSLD SumbagtengUlil AlbabNo ratings yet

- MGP0634X: Product Data SheetDocument1 pageMGP0634X: Product Data Sheetmoussa jameelNo ratings yet

- Notice The Complete Requirements For Procuring The Product Described Herein Shall Consist of This Document and The Latest Issue of As85049Document3 pagesNotice The Complete Requirements For Procuring The Product Described Herein Shall Consist of This Document and The Latest Issue of As85049daNo ratings yet

- 1802 A 423-1 G Toilet Elevation-Type 04Document1 page1802 A 423-1 G Toilet Elevation-Type 04nanieNo ratings yet

- Sectional Details Window - Sirsa School-Working DetailDocument1 pageSectional Details Window - Sirsa School-Working DetailAKB CONSULTANTSNo ratings yet

- D7H Series II Tractor Electrical SystemDocument2 pagesD7H Series II Tractor Electrical SystemAnonymous KOtSfT6q100% (1)

- Ada-Canyon Counties, IdahoDocument1 pageAda-Canyon Counties, IdahoIgor SemenovNo ratings yet

- HSP Skeleton ManualDocument2 pagesHSP Skeleton ManualturbojoNo ratings yet

- HFD01044.02.0101 schema hydraulique complet full spec LS G4Document1 pageHFD01044.02.0101 schema hydraulique complet full spec LS G4aldeirtrabalho001No ratings yet

- Frame Nema Iec Motores w22 Weg CompressDocument1 pageFrame Nema Iec Motores w22 Weg CompressRogelio FloresNo ratings yet

- Nc0-Ep-710-2303 (A) - Diesel Pump Controller: 46b 6b 26b 88n 85n 87n J6Document4 pagesNc0-Ep-710-2303 (A) - Diesel Pump Controller: 46b 6b 26b 88n 85n 87n J6KechaouNo ratings yet

- Turnigy D2830-11 1000kV - Ecalc - PropcalcDocument2 pagesTurnigy D2830-11 1000kV - Ecalc - PropcalcdurrohNo ratings yet

- Cable Sizing Calculation (1)Document125 pagesCable Sizing Calculation (1)crazy devilNo ratings yet

- ERAC DATASHEET WW en-GBDocument1 pageERAC DATASHEET WW en-GBJavier LópezNo ratings yet

- 2010 CENSUS MAP OF COLBERT COUNTY ALDocument1 page2010 CENSUS MAP OF COLBERT COUNTY ALIgor SemenovNo ratings yet

- Invisio-Corner Window ExampleDocument1 pageInvisio-Corner Window ExampleRimon GawandeNo ratings yet

- P20c30ug01prw Aecg Civugsdwg 34801 1 (A)Document1 pageP20c30ug01prw Aecg Civugsdwg 34801 1 (A)kaizen.hameshaNo ratings yet

- fda225a3bc8662db188cc33c8c14fa1d939bb2f58cb69bc1a538e0fb0485a8c7_optimDocument3 pagesfda225a3bc8662db188cc33c8c14fa1d939bb2f58cb69bc1a538e0fb0485a8c7_optimmartin.ca2117No ratings yet

- gnss-sp-26.790 - Model - PDF GenDocument1 pagegnss-sp-26.790 - Model - PDF GenviswanathNo ratings yet

- South Tse Tank Addc Electrical Drawing Approval (1) ..Document1 pageSouth Tse Tank Addc Electrical Drawing Approval (1) ..Swami NathanNo ratings yet

- HAI-0-POE-EL-PLA-LP-001-Lightning Protection LayoutDocument1 pageHAI-0-POE-EL-PLA-LP-001-Lightning Protection LayoutAgung FitrillaNo ratings yet

- Ec3-02 Catv - CCTV Single Line DiagramDocument1 pageEc3-02 Catv - CCTV Single Line DiagramSEDFREY DELA CRUZNo ratings yet

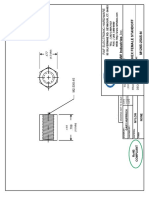

- Elemento-Termico-B11.5 3 G000103137Document1 pageElemento-Termico-B11.5 3 G000103137Enrique Espinosa SilvaNo ratings yet

- 17 NDocument1 page17 NSumeet MohantyNo ratings yet

- LayoutDocument1 pageLayoutBán ZoltánNo ratings yet

- 28 A. Station Auxiliary Board - Rev-01Document131 pages28 A. Station Auxiliary Board - Rev-01kha nguyenNo ratings yet

- Frame Connection To Steel Substrate Through Buck D: Roof Plan UpperDocument1 pageFrame Connection To Steel Substrate Through Buck D: Roof Plan UpperArturo Antolin Chávez ApeñaNo ratings yet

- 20 Gie 001 - M 1 2Document1 page20 Gie 001 - M 1 2fouad belalNo ratings yet

- Kone 1-4Document133 pagesKone 1-4José luis CasimiroNo ratings yet

- BPW BERGISCHE ACHSEN MAINTENANCE INSTRUCTIONSDocument1 pageBPW BERGISCHE ACHSEN MAINTENANCE INSTRUCTIONSsemu cNo ratings yet

- Abid CJV ConstructionDocument4 pagesAbid CJV ConstructionAliNo ratings yet

- Diamer Basha Dam Project: Borehole No. BDL-4 Upper Left Bank, Down Stream C-Axis, Central LineDocument4 pagesDiamer Basha Dam Project: Borehole No. BDL-4 Upper Left Bank, Down Stream C-Axis, Central LineAliNo ratings yet

- RA-159742 001 01 cabinet drawing and BOMDocument1 pageRA-159742 001 01 cabinet drawing and BOMsalman1111aNo ratings yet

- Ocoee Village Center - SF Park Pavilion (Drywall Estimate) - Counts Interior Corners, Doors, & Windows 5.29.23 @6.45AMDocument1 pageOcoee Village Center - SF Park Pavilion (Drywall Estimate) - Counts Interior Corners, Doors, & Windows 5.29.23 @6.45AMJames RecañaNo ratings yet

- 2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Conecuh County, AL: MILFORD 47500 Davis 18100Document1 page2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Conecuh County, AL: MILFORD 47500 Davis 18100Igor SemenovNo ratings yet

- 65K390PAD Aus M en QSPGDocument1 page65K390PAD Aus M en QSPGwiktor991No ratings yet

- Ship specs: length, breadth, draft, speedDocument2 pagesShip specs: length, breadth, draft, speedKyaw Win TunNo ratings yet

- Product data sheet for Rilux 6 W LED downlightDocument1 pageProduct data sheet for Rilux 6 W LED downlighta_orsikaNo ratings yet

- Siemens: PSS®SINCAL Platform Price ListDocument1 pageSiemens: PSS®SINCAL Platform Price ListJohnDoeNo ratings yet

- 22.5" & Above Wheel Diameter: 2021 Product Specification Guide - HEAVY DUTYDocument2 pages22.5" & Above Wheel Diameter: 2021 Product Specification Guide - HEAVY DUTYPSNo ratings yet

- Bobcat 320 WiringDocument1 pageBobcat 320 Wiringaa80% (5)

- 1802 A 422-1 G Toilet Elevation-Type 03Document1 page1802 A 422-1 G Toilet Elevation-Type 03nanieNo ratings yet

- 02-Door - Window Key PlanDocument1 page02-Door - Window Key PlanAmitNo ratings yet

- 1829726-Catalog Conectori Usb PDFDocument72 pages1829726-Catalog Conectori Usb PDFpaula09No ratings yet

- SSAS2.81 Magnetic PropertiesDocument2 pagesSSAS2.81 Magnetic Propertiesradule021No ratings yet

- ALAMEDocument4 pagesALAMEpaula09No ratings yet

- Features/Benefits Typical Applications: Specification ElectricalDocument2 pagesFeatures/Benefits Typical Applications: Specification Electricalpaula09No ratings yet

- Preturi - Magneti Din Pamanturi Rare - Neodim (NdFeB)Document7 pagesPreturi - Magneti Din Pamanturi Rare - Neodim (NdFeB)mmditaNo ratings yet

- Terminal Blocks: J - AccessoriesDocument24 pagesTerminal Blocks: J - Accessoriespaula09No ratings yet

- Distantier PDFDocument1 pageDistantier PDFpaula09No ratings yet

- MMPA Standard Specs for Permanent MagnetsDocument28 pagesMMPA Standard Specs for Permanent MagnetsWVP100% (1)

- CABLU MILITAR USB A-A - POLAMCO LTD-c4241 PDFDocument1 pageCABLU MILITAR USB A-A - POLAMCO LTD-c4241 PDFpaula09No ratings yet

- Cored Solder Wires Cored Solder Wires For Aluminium: Alu-SolDocument4 pagesCored Solder Wires Cored Solder Wires For Aluminium: Alu-Solpaula09No ratings yet

- Angrenaje Conice 2 PDFDocument19 pagesAngrenaje Conice 2 PDFpaula09No ratings yet

- Catalogo EntrelecDocument562 pagesCatalogo EntrelecFreddy JaramilloNo ratings yet

- Zell Metal Engineering Plastic Stock Shapes 2019 PDFDocument100 pagesZell Metal Engineering Plastic Stock Shapes 2019 PDFpaula09No ratings yet

- Unique Range of Bearings For Extreme Use: Affordable Technical - Available - Ready To UseDocument12 pagesUnique Range of Bearings For Extreme Use: Affordable Technical - Available - Ready To Usepaula09No ratings yet

- DICHTOMATIK Design GuidelinesDocument17 pagesDICHTOMATIK Design Guidelinespaula09No ratings yet

- Standard CatalogueDocument75 pagesStandard Cataloguepaula09No ratings yet

- Self Clinch Metric 2011 Small PDFDocument34 pagesSelf Clinch Metric 2011 Small PDFpaula09No ratings yet

- Man FXM FKM MotorsDocument148 pagesMan FXM FKM Motorspaula09No ratings yet

- Product Catalogue: (Edition in English) (Made in Germany)Document132 pagesProduct Catalogue: (Edition in English) (Made in Germany)paula09No ratings yet

- Catalog Flupec o Ring PDFDocument91 pagesCatalog Flupec o Ring PDFSilviu BoeriuNo ratings yet

- 951 Series Connectors: DeutschDocument19 pages951 Series Connectors: Deutschpaula09No ratings yet

- Alu Sol PDFDocument4 pagesAlu Sol PDFpaula09No ratings yet

- Myonic Catalogue enDocument75 pagesMyonic Catalogue enpaula09No ratings yet

- Brochure Eng 1Document16 pagesBrochure Eng 1paula09No ratings yet

- Man FXM FKM MotorsDocument148 pagesMan FXM FKM Motorspaula09No ratings yet

- Specif Electromec Bariera EnglDocument2 pagesSpecif Electromec Bariera Englpaula09No ratings yet

- NI Tutorial 11564 enDocument9 pagesNI Tutorial 11564 enpaula09No ratings yet

- Die Casting Aluminum Selection Guide PDFDocument4 pagesDie Casting Aluminum Selection Guide PDFblue79blogNo ratings yet

- Swagelok Flexible Metal Hoses MS-01-180Document88 pagesSwagelok Flexible Metal Hoses MS-01-180paula09No ratings yet

- Iiit Kota SyllabusDocument77 pagesIiit Kota SyllabusKeshav Sharma100% (1)

- LSLVG 100Document343 pagesLSLVG 100Yohanes TriatmojoNo ratings yet

- Synchronizing and Synchronizing EquipmentDocument10 pagesSynchronizing and Synchronizing EquipmentLog in 2007No ratings yet

- Circuits II Lab SyllabusDocument8 pagesCircuits II Lab SyllabusJuan Glicerio C. ManlapazNo ratings yet

- Practical Guide To Electrical Grounding, 1st Edition, 1999-EricoDocument134 pagesPractical Guide To Electrical Grounding, 1st Edition, 1999-EricoFABIANO FREIRE DA SILVANo ratings yet

- Assembly and Service Manual for AC Control Unit KS 45Document21 pagesAssembly and Service Manual for AC Control Unit KS 45alcom100% (1)

- Gear Tooth Speed SensorsDocument3 pagesGear Tooth Speed SensorsKartik GvrNo ratings yet

- TLE-EIM ExamDocument4 pagesTLE-EIM ExamMark Dexter MejiaNo ratings yet

- How To Use The Nanovna For The NFC Reader Antenna Design: Rev. 1.0 - 21 April 2020 Application Note 605210 Company PublicDocument24 pagesHow To Use The Nanovna For The NFC Reader Antenna Design: Rev. 1.0 - 21 April 2020 Application Note 605210 Company PublicvishnurajNo ratings yet

- Datasheet 12000 BtuDocument2 pagesDatasheet 12000 BtuDavid QuintanaNo ratings yet

- Power Supply Inverter 715G2824-6-5 AocDocument2 pagesPower Supply Inverter 715G2824-6-5 AocViktor CymbalyukNo ratings yet

- QinetiQ certifies Japan Radio Co.'s ECDIS and Raster Chart Display SystemDocument4 pagesQinetiQ certifies Japan Radio Co.'s ECDIS and Raster Chart Display Systemcem100% (1)

- Chem 3052 CHAPTER 7 (Nuclear Magnetic Resonance Spectroscopy (NMR) )Document6 pagesChem 3052 CHAPTER 7 (Nuclear Magnetic Resonance Spectroscopy (NMR) )ashenafiNo ratings yet

- Aukey Wireless Audio Receiver User ManualDocument1 pageAukey Wireless Audio Receiver User ManualJavier FernándezNo ratings yet

- UEE Braking MCQDocument14 pagesUEE Braking MCQDeshbhsuhan SangaleNo ratings yet

- NCR Selfserv™: 22, 22E, 25, 26, 28, 31, 36 Atms Site Preparation RequirementsDocument32 pagesNCR Selfserv™: 22, 22E, 25, 26, 28, 31, 36 Atms Site Preparation Requirementsmss_vnr50% (2)

- P-42 - Tank Monitoring SystemDocument118 pagesP-42 - Tank Monitoring SystemCengiz İyiceNo ratings yet

- WAGO 852-1305enDocument6 pagesWAGO 852-1305enMESSIASNo ratings yet

- First For Professionals: Torque WrenchesDocument9 pagesFirst For Professionals: Torque WrenchesAnonymous as5qbwfeNo ratings yet

- List of IEC Standards - WikipediaDocument26 pagesList of IEC Standards - WikipediaEngr saqibNo ratings yet

- Aplicaciones Con Sensores InfineonDocument72 pagesAplicaciones Con Sensores InfineonTom GNo ratings yet

- Single-And Multiple-Stage Cascaded Vapor Compression Refrigeration For Electronics CoolingDocument97 pagesSingle-And Multiple-Stage Cascaded Vapor Compression Refrigeration For Electronics CoolingAnn Loching NebabNo ratings yet

- C-051-VP-070-BDGS-PRO-0013 Rev. A Acceptance Test Procedure FAT - SAT - Start-Up - Insp Ection CommentsDocument7 pagesC-051-VP-070-BDGS-PRO-0013 Rev. A Acceptance Test Procedure FAT - SAT - Start-Up - Insp Ection CommentsAH WINKELNo ratings yet

- Vlsi Design FlowDocument7 pagesVlsi Design FlowAster RevNo ratings yet

- Helix Electrical Package RevB 9-7-16Document95 pagesHelix Electrical Package RevB 9-7-16casual divertidoNo ratings yet

- 【英文版】Selling Points BrochureDocument10 pages【英文版】Selling Points BrochureDaymar GarciaNo ratings yet

- Placas de CelularesDocument5 pagesPlacas de Celulares2023manuelmedinaNo ratings yet

- Fixed Heat Detector IQ8Quad With Isolator: Part-No. 802171Document1 pageFixed Heat Detector IQ8Quad With Isolator: Part-No. 802171motaNo ratings yet

- SWIR Imaging White Paper: Introduction to Shortwave Infrared TechnologyDocument5 pagesSWIR Imaging White Paper: Introduction to Shortwave Infrared TechnologytaikiNo ratings yet

- Enc28j60 HDocument11 pagesEnc28j60 HandrewNetwork100% (1)