Professional Documents

Culture Documents

FF-Textiles

Uploaded by

Tony Martin0 ratings0% found this document useful (0 votes)

36 views1 pageGiw

Original Title

1466672291_FF-Textiles

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGiw

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

36 views1 pageFF-Textiles

Uploaded by

Tony MartinGiw

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

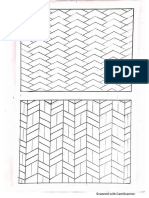

ROTRONIC HUMIDITY FUN FACTS

Humidity in Textile Manufacturing

Textiles in general Why the need

In the days when cave men to measure humidity?

ruled the world, people were dress- Controlling humidity in the tex-

ing with animal fur to protect them- tile industry is essential. Too dry or

selves from the elements. Today we an unbalanced environment will

are far beyond that point and a have the following negative effects

wide range of natural as well as on product quality and the produc-

synthetic fibers have widely tion process.

replaced animal fur.

The modern textile industry

grew out of the industrial revolu-

Static electricity

Dry materials create more fric-

tion in the 18th Century as mass

tion and are more prone to static

Fabric shrinkage

production of clothing became a

electricity. Higher humidity reduces Low humidity causes fabric

mainstream industry. To handle the

static problems and makes materi- shrinkage. Maintaining the appro-

huge demand for textiles, sophisti-

als more manageable enabling prite level of humidity permits

cated machines are now producing

more efficient production. greater reliability in cutting and fit-

impressive quantities. For example,

ting during garment creation. Strict

denim is being produced at a rate

of one square meter per minute. Moisture Regain control of humidity in the pro-

duction environment allows for

To ensure optimum perform- Moisture Regain is defined as tighter quality control where

ance of modern spinning, twisting the weight of water in a material dimensions are important, such as

or weaving machines, a consistent expressed as a percentage of the in the carpet industry.

environment must be created and oven dry weight.

maintained. Dry air causes lower regain and

That’s where humidity and tem- this contributes to poor quality and

Product weight

perature measurement plays an lower productivity. By humidifying Textile weights are determined

important role. the environment, the materials are at standard condition of 65% RH

kept at optimum regain and are less and 20°C (68°F). Maintaining humi-

prone to breakage, heating and dity will ensure accurate product

Facts & Figures friction effects. The materials handle weights, ensuring appropriate profits.

• China has the largest textile industry and feel better, have fewer imper-

directly followed by India. In 2010 fections and are more uniform. Dust

China`s textile industry exported 25 Humidification reduces fly and

billion USD worth of textiles. Yarn strength micro dust, providing a healthier

• The textile industry in India is experi- Yarns with low moisture con- and more comfortable working

encing annual growth rates of 9-10%. tent are weaker, thinner, more environment.

• China is the largest producer of cotton brittle and less elastic.

with 34 million bales each year.

• Australia produces about 25% of the Best humidity level for Spinning Twisting Winding Weaving

world wool production followed by Wool 50-85%rH 60-65%rH 55-60%rH 50-60%rH

China at 18% and United States at 17%. Cotton 35-65%rH 50-65%rH 55-65%rh 70-85%rH

Man made fibres 50-65%rH N/A 60-65%rH 60-70%rh

135 Engineers Road, Hauppauge, NY 11788

Tel. 631-427-3898 • Fax. 631-427-3902 • info@rotronic-usa.com

You might also like

- Sustainable Innovations in Textile Chemical ProcessesFrom EverandSustainable Innovations in Textile Chemical ProcessesNo ratings yet

- History of Smart Textiles: A Comprehensive Guide To E-TextilesFrom EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesNo ratings yet

- Why Humidify in The Textile IndustryDocument2 pagesWhy Humidify in The Textile IndustrySuresh Gadhwal100% (1)

- 10 5923 J Textile 20120105 02Document8 pages10 5923 J Textile 20120105 02Éder Cerqueira StefanonNo ratings yet

- Presentation, Advancements in TextilesDocument41 pagesPresentation, Advancements in TextilesAwais KhanNo ratings yet

- Fabric Manufacturing Process PDFDocument2 pagesFabric Manufacturing Process PDFMaciel75% (4)

- An Innovative Process of Producing Garments With Functional and Fashion Aspects TTDocument9 pagesAn Innovative Process of Producing Garments With Functional and Fashion Aspects TTMitesh ShahNo ratings yet

- Environmental Protection and Sustainability in The Textile IndustryDocument3 pagesEnvironmental Protection and Sustainability in The Textile IndustryCarlos Ernesto Aguilar LópezNo ratings yet

- Project Report On Non Woven Fabric Production Spun BondedDocument5 pagesProject Report On Non Woven Fabric Production Spun BondedEIRI Board of Consultants and PublishersNo ratings yet

- 10 Point Guide To Humidity Control in Textile Manufacturing en RT PDFDocument12 pages10 Point Guide To Humidity Control in Textile Manufacturing en RT PDFAman DeepNo ratings yet

- Yarn Conditioning PDFDocument2 pagesYarn Conditioning PDFMuhammad Qamar TusiefNo ratings yet

- Report On Garment Appreciation by Reversing The Manufacturing ProcessesDocument16 pagesReport On Garment Appreciation by Reversing The Manufacturing ProcessesADYA MANISHINo ratings yet

- Yarn ConditioningDocument2 pagesYarn ConditioningMiguel Morales ChNo ratings yet

- Airlaid & Spunlace NonwovenDocument5 pagesAirlaid & Spunlace NonwovenRonak JoshiNo ratings yet

- CostingDocument25 pagesCostingagga1111100% (1)

- Is21 Final ReviewerDocument4 pagesIs21 Final ReviewerChloe Andrea BuzonNo ratings yet

- FileDocument9 pagesFileeradu seidNo ratings yet

- Yarn ConditioningDocument4 pagesYarn ConditioningSatish KulkarniNo ratings yet

- Fabric Processing PDFDocument2 pagesFabric Processing PDFMarniNo ratings yet

- Overview of Non-Wovens Manufacturing: Learning ObjectivesDocument16 pagesOverview of Non-Wovens Manufacturing: Learning ObjectivesyonasNo ratings yet

- Sustainable ProductionDocument30 pagesSustainable ProductionAnkita RajNo ratings yet

- Textile Waste in IndiaDocument12 pagesTextile Waste in IndiaThe United IndianNo ratings yet

- The Importance of Humidity Control in Textile ProcessingDocument7 pagesThe Importance of Humidity Control in Textile ProcessingMahabbat HossainNo ratings yet

- Headers To Find ClipartDocument6 pagesHeaders To Find ClipartShiwangi NagoriNo ratings yet

- Project Report 1 Merged CompressedDocument39 pagesProject Report 1 Merged CompressedAnmol AgrawalNo ratings yet

- Clothing WasteDocument20 pagesClothing WasteVjan Christia RazonNo ratings yet

- Non WovenDocument16 pagesNon WovenMuhammad RizwanNo ratings yet

- Development and Characterisation of Nonwoven Fabrics For Apparel Applications 2165 8064 1000359Document7 pagesDevelopment and Characterisation of Nonwoven Fabrics For Apparel Applications 2165 8064 1000359Jorge Eduardo Ortega PalaciosNo ratings yet

- The Problem and Its BackgroundDocument10 pagesThe Problem and Its BackgroundJessica SaballeroNo ratings yet

- Nonwoven IndustryDocument6 pagesNonwoven IndustryGaurav SachanNo ratings yet

- Sustainable FashionDocument6 pagesSustainable FashionbreakbeatdocNo ratings yet

- Nonwovens Made of CottonDocument5 pagesNonwovens Made of CottonrejoramaNo ratings yet

- Upload TextilDocument2 pagesUpload TextilManoj MandavkarNo ratings yet

- Smart FabricsDocument10 pagesSmart FabricsShweta KhatriNo ratings yet

- Eco Friendly Garment Finishes The Need of Hour For FashionDocument12 pagesEco Friendly Garment Finishes The Need of Hour For FashionAntotexNo ratings yet

- Scrap It OutDocument5 pagesScrap It OutROHIT KUMAR SINGHNo ratings yet

- Productivity Improvement of Loom Shed by Optimizing Relative HumidityDocument6 pagesProductivity Improvement of Loom Shed by Optimizing Relative HumiditySatadeep Datta0% (1)

- Recent Developments in Processing of Textiles - Sayantika DebnathDocument2 pagesRecent Developments in Processing of Textiles - Sayantika DebnathRimsha EramNo ratings yet

- Project By-Prateek Shukla and Malay SinghDocument9 pagesProject By-Prateek Shukla and Malay SinghbanarashiNo ratings yet

- DebateDocument4 pagesDebatebpd.santosNo ratings yet

- Nano Technology Adds Value To Textile Finishing: Written By: V. ParthasarathiDocument5 pagesNano Technology Adds Value To Textile Finishing: Written By: V. ParthasarathiMythiliNo ratings yet

- Spectrum of Textile IndustryDocument59 pagesSpectrum of Textile IndustryShrikant Gadge0% (1)

- Dhileep FinalDocument20 pagesDhileep FinaljujuNo ratings yet

- Wet Laid ProcessDocument21 pagesWet Laid ProcessRıdvan Çıngar100% (1)

- Recycled Fibers An OverviewDocument6 pagesRecycled Fibers An OverviewAngie DevoreNo ratings yet

- Cotton Stickiness in The Spinning Process: Vignesh Dhanabalan (Senthil Kumar Iit)Document8 pagesCotton Stickiness in The Spinning Process: Vignesh Dhanabalan (Senthil Kumar Iit)vigneshdhanabalanNo ratings yet

- Journal of The Society of Dyers and ColouristsDocument6 pagesJournal of The Society of Dyers and ColouristsUjjwal JhaNo ratings yet

- Fast FashionDocument9 pagesFast Fashionrphase890No ratings yet

- Corn FiberDocument5 pagesCorn Fiberreenaagarwal2008100% (1)

- Advancementsin Textile FinishingDocument10 pagesAdvancementsin Textile Finishingstephanie chiamacaNo ratings yet

- Seminar On Fibers To Non Woven FabricsDocument18 pagesSeminar On Fibers To Non Woven FabricsIti DubeyNo ratings yet

- FinishingDocument3 pagesFinishingTom KattoorNo ratings yet

- Moisture Management of TextilesDocument8 pagesMoisture Management of TextilesMohammed Atiqul Hoque Chowdhury100% (1)

- Hvac Design of Textile IndustryDocument9 pagesHvac Design of Textile Industrymahboob100% (1)

- Project - FibreDocument2 pagesProject - FibreNithya PrakashNo ratings yet

- HE Need FOR Circular Fashion: Lesson OverviewDocument8 pagesHE Need FOR Circular Fashion: Lesson OverviewKatalin KarakóNo ratings yet

- Nonwoven FabricsDocument54 pagesNonwoven FabricsMd. Saidul IslamNo ratings yet

- Sustainable Innovations in Recycled TextilesFrom EverandSustainable Innovations in Recycled TextilesNo ratings yet

- The Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentFrom EverandThe Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentNo ratings yet

- FF-TextilesDocument1 pageFF-TextilesTony MartinNo ratings yet

- PhysiDocument1 pagePhysiTony MartinNo ratings yet

- Tony Martin (BFT - 20 - 1157) JuryDocument29 pagesTony Martin (BFT - 20 - 1157) JuryTony MartinNo ratings yet

- Eye TestDocument2 pagesEye TestTony MartinNo ratings yet

- Art Nouveau - The Peacock SkirtDocument1 pageArt Nouveau - The Peacock SkirtTony MartinNo ratings yet

- FF-TextilesDocument1 pageFF-TextilesTony MartinNo ratings yet

- Current Trends in Textiles For Technical PDFDocument9 pagesCurrent Trends in Textiles For Technical PDFTony MartinNo ratings yet

- Materials: Textile-Integrated Thermocouples For Temperature MeasurementDocument22 pagesMaterials: Textile-Integrated Thermocouples For Temperature MeasurementTony MartinNo ratings yet

- Sensors10 YongZhangDocument5 pagesSensors10 YongZhangTony MartinNo ratings yet

- ED Drawing 1Document3 pagesED Drawing 1Tony MartinNo ratings yet

- ED Drawing 3Document1 pageED Drawing 3Tony MartinNo ratings yet

- Jawad Ahmad Ob1Document4 pagesJawad Ahmad Ob1Jawad ahmadNo ratings yet

- Khadi PrintingDocument2 pagesKhadi PrintingTanushri VermaNo ratings yet

- Bs 534Document26 pagesBs 534Lucian Chitu75% (4)

- Textile Wastewater Treatment Using Advanced Oxidation Process (AOP)Document10 pagesTextile Wastewater Treatment Using Advanced Oxidation Process (AOP)Ekbal 6MNo ratings yet

- 7th Chemistry DLP Study Package FinalDocument101 pages7th Chemistry DLP Study Package FinalAdityaNo ratings yet

- What Is Art Crafts?Document16 pagesWhat Is Art Crafts?John DiestroNo ratings yet

- Optimization of Dyeing Condition and Its Dyeing On Palmyrah (Borassus Flabellifer) LeavesDocument6 pagesOptimization of Dyeing Condition and Its Dyeing On Palmyrah (Borassus Flabellifer) LeavesAnne CalyxNo ratings yet

- Spinning ProjectDocument21 pagesSpinning ProjectMLastTryNo ratings yet

- Textile CurriculumDocument37 pagesTextile CurriculumSabbir HossainNo ratings yet

- A Survey of Ethiopian Manufacturing SectorDocument86 pagesA Survey of Ethiopian Manufacturing SectorPeter MuigaiNo ratings yet

- Textil Abreviations and Fiber DefinitionDocument9 pagesTextil Abreviations and Fiber Definitionrikrdo1979No ratings yet

- Commodity CodesDocument55 pagesCommodity CodesjesuswithusNo ratings yet

- Furniture SitRep AdvDocument67 pagesFurniture SitRep AdvjorementillaNo ratings yet

- Gatron Annual Report 2016Document127 pagesGatron Annual Report 2016rohanNo ratings yet

- Cognex Deep Learning: Textile Inspection Industry OverviewDocument7 pagesCognex Deep Learning: Textile Inspection Industry OverviewPrabhuti ChauhanNo ratings yet

- Traditional Indian Costumes and Textiles: January 2004Document11 pagesTraditional Indian Costumes and Textiles: January 2004Vijay ZorroNo ratings yet

- HANDOUT Grade 8 Arts First QuarterDocument4 pagesHANDOUT Grade 8 Arts First QuarterJelai MatisNo ratings yet

- CVDocument3 pagesCVRumman TalukdarNo ratings yet

- An Insight Into Bag FiltersDocument35 pagesAn Insight Into Bag Filtersraja sharma100% (1)

- VOLVO-2009 Chemical - InfoDocument220 pagesVOLVO-2009 Chemical - InfowurtukukNo ratings yet

- AnakaputhurDocument3 pagesAnakaputhurAnusha AshokNo ratings yet

- HesseDocument56 pagesHesseERIC B. ACOSTANo ratings yet

- 1-Jabiru J170 Constructors Manual WEBDocument377 pages1-Jabiru J170 Constructors Manual WEBSaeid MirNo ratings yet

- Navdeep Singh SodhiDocument35 pagesNavdeep Singh SodhiAditi ChauhanNo ratings yet

- Testing BookletDocument8 pagesTesting BookletveselieNo ratings yet

- Cloth Points From Groz-BeckertDocument2 pagesCloth Points From Groz-BeckertFrancisco LobatonNo ratings yet

- Investment Opportunity in Manufacturing Industry PDFDocument34 pagesInvestment Opportunity in Manufacturing Industry PDFGashaw AlelignNo ratings yet

- Defects in Digital Printing FabricsBerger9 2010Document3 pagesDefects in Digital Printing FabricsBerger9 2010Rahul ChoudhuryNo ratings yet

- Lahore 8Document422 pagesLahore 8Farooq AzamNo ratings yet

- AFTAB IV ReportDocument14 pagesAFTAB IV Reportanjali jhudeleNo ratings yet