Professional Documents

Culture Documents

HC-300 Desiccant Dehumidifi Er: Reactivation Air Wet Air

Uploaded by

Robson FernandesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HC-300 Desiccant Dehumidifi Er: Reactivation Air Wet Air

Uploaded by

Robson FernandesCopyright:

Available Formats

HC - 300 HC - 300 Desiccant Dehumidifier

ADVANTAGES

• High efficiency humidity control

• Light, compact, durable and

corrosion resistant construction

• Easy inspection and maintenance

• Simple ductwork and humidistat

connections

HC-300

Desiccant Dehumidifier

Munters compact dehumidifier combines state-of-the-art desiccant technology in a self-contained unit to provide dependability and long

operating life for humidity control at virtually any temperature. The HC-300 is perfect for product drying, mold and mildew control,

corrosion protection, storage and condensation control, while providing an industry leading 1.7 lb water/kWh* moisture removal efficiency.

Process air: Flow rate of 150-300 SCFM. 9.7 lb/hr* moisture removal. Capable of

processing saturated, conditioned or outside air. Industry leading 1.7 lb water/kWh* Reactivation Air Wet Air

moisture removal efficiency.

Contact air seals: Separate process and reactivation air streams to minimize leakage

and improve performance.

Electrical controls: Simple automatic control system monitors and controls unit functions.

Automatic restart after power failure. Visual indicators and contacts for remote run and

fault status. Elapse time meter. Auto/Manual selection switch with humidistat connection Dry Air Process Air

kit and optional low voltage humidistat.

Drive Motor

Drive system: Continuous rotation, with simple drive belt arrangement and few

moving parts.

Patented HoneyCombe® rotor

Reactivation utility: Solid-state energy modulation of heater reduces energy design provides a vast surface

area for desiccant

consumption that optimizes desiccant media regeneration. Includes independent

reactivation fan and high temperature protection.

In the 1950’s Munters invented modern

Dehumidifier housing: Light and durable weld aluminum cabinet with hinged front industrial dehumidification when it introduced

access panel. Process and reactivation airflow insulation to reduce heat loss and the self-regenerating desiccant rotor, the heart

condensation risk. Blower motors and control isolated from air streams, and fan guards of the dehumidifier.

provided for safety. Volume control dampers for adjusting process and reactivation air Today, Munters offers rotors with multiple

desiccant formulations and is the acknowledged

streams. Compact size for minimal space requirements and easy installation.

expert in the integration of rotors into

*

75°F and 85 gpp entering air conditions using actual running power of reactivation heater. dehumidification systems and air handlers.

Munters Corporation, AirTech

Phone +1 800 843 5360 / E-mail dhinfo@munters.com / munters.com

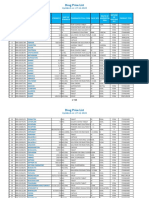

Model HC-300 Technical Specifications*

Front View Right Side View Process volume: 150-300 SCFM

REACTIVATION

AIR INLET

4.625"

Process E.S.P: 1.75" W.G.**

7" x 5.125" Max reactivation volume: 100 SCFM

Dehumidifier HC-300

PROCESS

AIR OUTLET Reactivation E.S.P: 1.25" W.G.**

7.438" O.D.

(DETACHABLE

24"

Max reactivation heater:

FAN GUARD)

REACTIVATION

FILTER ACCESS

14.875"

9.188"

HC-300 = 6kW@240/480V

Utilities: 208-240/1/60, 208-240/3/60,

14.375" 3"

TIME

METER

SELECTOR

PANEL REACTIVATION

460/3/60

Left Side View AIR OUTLET

Maximum FLA:

5.875" O.D.

ACCESS TO DESICCANT

WHEEL, WHEEL DRIVE

(DETACHABLE

FAN GUARD) HC-300 = 31A @ 240V/1/60Hz

ASSY., SEALS, ELECTRICAL

CONTROLS, PROCESS

PROCESS

AIR INLET

HC-300 = 19A @ 240V/3/60Hz

FILTERS, PROCESS AND

REACTIVATION BLOWERS

18.5" x 4.625"

HC-300 = 9.7A @ 460V/3/60Hz

Max dBA: 75 (three feet from dehumidifier

5.125"

5.188" except in path of airflows)

10.625"

22.5" Filters: Washable metal roughing filters

21.25" TYP

Options:

• Humidistat for on/off control

Model Max Length (in) Max Width (in) Max Height (in) Max Weight (lb) • Constant process blower

• Process inlet transitions for round duct

HC-300 30 23.5 24 115 • Precool module, water/glycol

**

Ducted application with fan guard removed

Suggested Specification Guide HC-300 Performance

Dehumidifier shall be of a type proven in satisfactory operation for a minimum of 10 years.

Dehumidifier shall be of the non-cycling sorption type with a single desiccant rotary structure.

The casing will be fabricated as a unitized body with welded aluminum construction for

maximum strength and durability. Suitable access panel shall allow access for inspection or

servicing without disconnecting ducting or electrical wiring. Airflow balancing dampers to

be furnished.

The rotary structure shall be a monolithic fabricated extended surface consisting of inert

silicates reinforced with uniform diameter glass fibers for maximum strength. The fabricated

structure shall be smooth and continuous in the direction of airflow without interruptions or

sandwich layers which restrict airflow or create a leakage path at joining surfaces. Desiccant shall

not channel, cake or fracture due to repeated temperature and moisture cycling. The materials of

construction shall be water washable, non-toxic and NFPA 255-ASTM E84 compliant.

Full face contact pressure seals shall be provided to separate the process and reactivation

air streams and eliminate detrimental leakage of air or moisture with static pressure Example:

differentials of up to 3" of water gauge. Process air in at 35% RH and 70˚F will hold

Dehumidifier shall be factory assembled; fully automatic, complete with HoneyCombe® space at 35% RH with a moisture load of

desiccant wheel, reactivation heaters, reactivation energy control system, roughing filters, 5.8 lb/hr. To find the temperature of process

industrial drive motor, fans, non-racheting desiccant drive unit, automatic controller and all outlet air (TPO) solve:

components’ auxiliaries. Reactivation energy modulation shall be stepless solid state TPO = .9 (3.6W + TPI) + 23 where

proportioning type. Dehumidifier shall be functionally tested at the manufacturer’s factory and TPI = temperature process inlet air °F

shipped complete with all components necessary to maintain normal operation. Example:

*Continual engineering and research for product improvement may result in design and specification changes. TPO = .9 (3.6 x 5.8 + 70) + 23

Consult factory for certified technical data. TPO = 105˚F

Australia Phone +61 2 8843 1588, dh.info@munters.com.au Austria Phone +43 1 6164298-0, luftentfeuchtung@munters.at Belgium Phone +32

1528 5611, info@muntersbelgium.be Brazil Phone +55 41 3317 5050, munters@com.br Canada Phone +1 905 858 5894, dhinfo@munters.com

China Phone +86 10 8041 8000, info@munters.com.cn Czech Republic Phone +420 544 211 434, info@munters-odvlhcovani.cz Denmark Phone

+45 4495 3355, info@munters.dk Finland Phone +358 20 776 8230, laitemyynti@ munters.fi France Phone +33 1 3411 5757, dh@munters.fr

Germany Phone +49 4087 96900, mgd@munters.de India Phone +91 20 668 18 900, info@munters.in Italy Phone +39 0183 52 11, marketing@

munters.it Japan Phone +81 3 5970 0021,mkk@munters.co.jp Korea Phone +82 2761 8701, munters@munters.co.kr Mexico Phone +52 722 270

40 49, munters@munters.com.mx Netherlands Phone +31 172 433231, vochtbeheersing@munters.nl Poland Phone +48 58305 3517, dh@munters.pl

Singapore Phone +65 6744 6828, info@munters.com.sg South Africa Phone +27 11 997 2000, info@munters.co.za Spain Phone +34 91 640 09 Munters Corporation

02, marketing@munters.es Sweden Phone +46 8 626 63 00, avfuktning@munters.se Switzerland Phone +41 52 343 8886, info.dh@munters.ch

Thailand Phone +66 2642 2670, info@munters.co.th Turkey Phone +90 216 548 1444, info@muntersform.com UAE +971 4887 6462, middle.east@

Tel: (800) 843-5360 E-mail: dhinfo@munters.com

munters.com United Kingdom Phone +44 1480 432243, info@munters.co.uk USA Phone+1 978 241 1100, dhinfo@munters.com Vietnam Phone +84 8 www.munters.com

8256 838, vietnam@muntersasia.com

PG0041 06/19

You might also like

- 2020 HL BrochureDocument12 pages2020 HL Brochurearkadi oikhman100% (1)

- Chillers CatalogueDocument42 pagesChillers CatalogueAlaa FaiqNo ratings yet

- Elgi EG 90 160kW 50Hz D I PDFDocument8 pagesElgi EG 90 160kW 50Hz D I PDFMAZENNo ratings yet

- HCD9000Document2 pagesHCD9000Walter naspiranNo ratings yet

- TRINITY Rotary Screw CompressorsDocument4 pagesTRINITY Rotary Screw CompressorsIngeniería AplicacionesNo ratings yet

- Ds MDC 10000 DD (Rotor 400mm) - enSCR - КопияDocument6 pagesDs MDC 10000 DD (Rotor 400mm) - enSCR - КопияMourad AhmadNo ratings yet

- Munters HCD Series: Modular Desiccant DehumidifiersDocument3 pagesMunters HCD Series: Modular Desiccant DehumidifiersIsabel MtzNo ratings yet

- 9837 2-3-12 91005 577E Adsorption Dryers Classical SystemDocument8 pages9837 2-3-12 91005 577E Adsorption Dryers Classical SystemLeonardo Tommy DacuNo ratings yet

- Small UP6 5-15HP BrochureDocument12 pagesSmall UP6 5-15HP BrochureMartin DavilaNo ratings yet

- ChicagoPneumatic CPX 21-5040 ENDocument2 pagesChicagoPneumatic CPX 21-5040 ENJorge ValenciaNo ratings yet

- UP5-11-37kW Fixed Speed Compressor BrochureDocument12 pagesUP5-11-37kW Fixed Speed Compressor BrochureMizan SarkarNo ratings yet

- Ingersoll Rand Rotary Screw Air Compressors 15 To 50 HP Brochure JECDocument11 pagesIngersoll Rand Rotary Screw Air Compressors 15 To 50 HP Brochure JECMardeni OliveiraNo ratings yet

- Mark MSM Mini 22-55 LeafletDocument6 pagesMark MSM Mini 22-55 LeafletzuzinoleksandrNo ratings yet

- Turboair Cooled 2000brochureDocument6 pagesTurboair Cooled 2000brochurechriss vzzNo ratings yet

- 30XA0252-1502 30XQ0330-1500: Aquaforce Liquid ChillerDocument32 pages30XA0252-1502 30XQ0330-1500: Aquaforce Liquid Chillermithilesh5103No ratings yet

- Atlas Copco piston compressor guideDocument2 pagesAtlas Copco piston compressor guideSerban Aurel CosminNo ratings yet

- COMPRESORES INDUS RECIPRODocument8 pagesCOMPRESORES INDUS RECIPROVictor Hugo Rodriguez CelyNo ratings yet

- DRE - English enDocument8 pagesDRE - English envijaykmjNo ratings yet

- CSM 3 - 4 - 5,5 - 7,5 HP: Otary Crew OmpressorDocument6 pagesCSM 3 - 4 - 5,5 - 7,5 HP: Otary Crew OmpressorVolodymуr VorobetsNo ratings yet

- 11 2020 Deitech EngDocument8 pages11 2020 Deitech EngJesus BouzonNo ratings yet

- Air-Cooled Liquid Chiller with Heat PumpDocument17 pagesAir-Cooled Liquid Chiller with Heat PumpMariano PeressuttiNo ratings yet

- HCD4500Document2 pagesHCD4500Walter naspiranNo ratings yet

- Improve Generator Protection with Continuous Hydrogen DryingDocument4 pagesImprove Generator Protection with Continuous Hydrogen DryingarisNo ratings yet

- PubliciteDocument12 pagesPubliciteHugues DescharmesNo ratings yet

- Parker&Domnick Hunter MIDIplus Isıtıcısız Basınçlı Hava KurutucularıDocument4 pagesParker&Domnick Hunter MIDIplus Isıtıcısız Basınçlı Hava Kurutucularımaxigas120No ratings yet

- Heatless Desiccant Dryers Bochure A4Document8 pagesHeatless Desiccant Dryers Bochure A4rodonganjaya22No ratings yet

- A-E-500 SIRC V-Series Compressed Air Solution 160415Document6 pagesA-E-500 SIRC V-Series Compressed Air Solution 160415Sigit WidagdoNo ratings yet

- USAIRTOWER AirtowerSeries 07-2019!46!37027Document8 pagesUSAIRTOWER AirtowerSeries 07-2019!46!37027vkees1987No ratings yet

- TR5010 1Document2 pagesTR5010 1Yellow FalconNo ratings yet

- Advanced Desiccant Dehumidifier for Precise Microclimate ControlDocument4 pagesAdvanced Desiccant Dehumidifier for Precise Microclimate ControlMourad AhmadNo ratings yet

- Turbair Blower (Type RT)Document2 pagesTurbair Blower (Type RT)Amir AbbaszadehNo ratings yet

- WCVS0905Document4 pagesWCVS0905Quynh NguyenNo ratings yet

- 38-Character for Screw Compressor DocumentDocument11 pages38-Character for Screw Compressor DocumentPaulo CezarNo ratings yet

- Airt Product Mx2 30 En1Document2 pagesAirt Product Mx2 30 En1Anonymous yPWi8p3KkANo ratings yet

- SC Ims10.sc01.00 Ultraceco - SC - Bro - enDocument4 pagesSC Ims10.sc01.00 Ultraceco - SC - Bro - enHEINER_PNo ratings yet

- OP2-Trane Odyssey PDFDocument4 pagesOP2-Trane Odyssey PDFletrunghaNo ratings yet

- Air-Cooled Liquid Chillers With Integrated Hydronic Module: AquasnapDocument12 pagesAir-Cooled Liquid Chillers With Integrated Hydronic Module: AquasnapDanieleNo ratings yet

- crd-szaritokDocument4 pagescrd-szaritoknarimanNo ratings yet

- Ductable Air-Cooled Liquid Chillers and Heat Pumps (30RBY/30RQYDocument32 pagesDuctable Air-Cooled Liquid Chillers and Heat Pumps (30RBY/30RQYBulat IııNo ratings yet

- EG Series Screw Air Compressors: Life Source of IndustriesDocument8 pagesEG Series Screw Air Compressors: Life Source of Industriespadhu_pNo ratings yet

- Airdryers: HamrinDocument30 pagesAirdryers: HamrinGuillermoNo ratings yet

- Hydrovane. Compresor A Paletas.Document24 pagesHydrovane. Compresor A Paletas.Juan M Flores MNo ratings yet

- ZAnder K-MT PDFDocument6 pagesZAnder K-MT PDFAirpowerService100% (1)

- Pure Performance: Dehumidification and Drying For Industrial and Commercial ApplicationsDocument24 pagesPure Performance: Dehumidification and Drying For Industrial and Commercial ApplicationsipraoNo ratings yet

- Tool AC-CATDocument19 pagesTool AC-CATnur rohmanNo ratings yet

- Girbau ST Series SecadorasDocument8 pagesGirbau ST Series Secadorasmairimsp20030% (1)

- Linha L e LSRDocument8 pagesLinha L e LSRaplicacao.evolucaoNo ratings yet

- Industrial Segment Wisair Leaflet en 6999010321 Tcm1495-3571071Document12 pagesIndustrial Segment Wisair Leaflet en 6999010321 Tcm1495-3571071David GarciaNo ratings yet

- TW HeatlssDocument12 pagesTW Heatlssherysyam1980No ratings yet

- Irits 0323 Euen Heated Heatless Desiccant DryersDocument8 pagesIrits 0323 Euen Heated Heatless Desiccant DryersGibran Al HudaNo ratings yet

- ASCENDANT Health Care Brochure - SEMCO 2016-02Document16 pagesASCENDANT Health Care Brochure - SEMCO 2016-02JorgeNo ratings yet

- Rotary Screw Compressors KW 5,5 7,5 11 15 18,5 22 30 Bar 8 10 13 15 MODULODocument8 pagesRotary Screw Compressors KW 5,5 7,5 11 15 18,5 22 30 Bar 8 10 13 15 MODULOHema RedaNo ratings yet

- Air-Cooled Liquid Chillers High Outdoor Temperature Version: Nominal Cooling Capacity 270-1700 KWDocument36 pagesAir-Cooled Liquid Chillers High Outdoor Temperature Version: Nominal Cooling Capacity 270-1700 KWAsad IqbalNo ratings yet

- Pneudri Maxi & MaxiplusDocument8 pagesPneudri Maxi & Maxiplusantonio timboNo ratings yet

- Manual ChillersDocument35 pagesManual ChillersMauricio BarrazaNo ratings yet

- DX300LCA: Crawler ExcavatorDocument20 pagesDX300LCA: Crawler ExcavatorDhany SiregarNo ratings yet

- AB Series - Oil Free Compressors-15Document1 pageAB Series - Oil Free Compressors-15Ismail AliNo ratings yet

- Chiller - CarrierDocument27 pagesChiller - CarrierJose Francisco Varela CruzNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Eddie Kramer Vocal Channel GuideDocument14 pagesEddie Kramer Vocal Channel GuideRobson FernandesNo ratings yet

- Eddie Kramer Vocal Channel GuideDocument14 pagesEddie Kramer Vocal Channel GuideRobson FernandesNo ratings yet

- Cena Mesa Inicial 2Document5 pagesCena Mesa Inicial 2Robson FernandesNo ratings yet

- What Is Live Music Production and Design BerkleeDocument5 pagesWhat Is Live Music Production and Design BerkleeRobson FernandesNo ratings yet

- Cena Mesa Inicial 1Document5 pagesCena Mesa Inicial 1Robson FernandesNo ratings yet

- JSDEWES d7.0259Document13 pagesJSDEWES d7.0259Robson FernandesNo ratings yet

- Cena Mesa Inicial 4Document5 pagesCena Mesa Inicial 4Robson FernandesNo ratings yet

- Cena Mesa Inicial 3Document5 pagesCena Mesa Inicial 3Robson FernandesNo ratings yet

- Optimization of Ice Thermal Storage System Design For Hvac SystemsDocument5 pagesOptimization of Ice Thermal Storage System Design For Hvac SystemsRobson FernandesNo ratings yet

- Radioreadyguide PDFDocument17 pagesRadioreadyguide PDFJulio C. Ortiz MesiasNo ratings yet

- 03-30017-01-En - RP-C Specification SheetDocument18 pages03-30017-01-En - RP-C Specification SheetEmir HarismiNo ratings yet

- Optimization of Ice Thermal Storage System Design For Hvac SystemsDocument5 pagesOptimization of Ice Thermal Storage System Design For Hvac SystemsRobson FernandesNo ratings yet

- Easy Smart Configuration Utility - UGDocument91 pagesEasy Smart Configuration Utility - UGRobson FernandesNo ratings yet

- Radioreadyguide PDFDocument17 pagesRadioreadyguide PDFJulio C. Ortiz MesiasNo ratings yet

- MultiRack Setup GuideDocument23 pagesMultiRack Setup GuideNomas Para MamarNo ratings yet

- Other Kits: Performing The ModDocument15 pagesOther Kits: Performing The ModRobson Fernandes100% (1)

- "Twin Reverb-Amp Ab763" Layout: Fender ModelDocument1 page"Twin Reverb-Amp Ab763" Layout: Fender ModelRobson FernandesNo ratings yet

- Magellan 3200vsiDocument4 pagesMagellan 3200vsiRobson FernandesNo ratings yet

- HRC Application 1.6 - Hotel Room Solution - PA-00712Document4 pagesHRC Application 1.6 - Hotel Room Solution - PA-00712Robson FernandesNo ratings yet

- Shure LX2 Wireless Handheld Transmitter Service Manual UpdateDocument45 pagesShure LX2 Wireless Handheld Transmitter Service Manual UpdateRobson FernandesNo ratings yet

- Acti 9 Itl - A9c30212Document2 pagesActi 9 Itl - A9c30212Robson FernandesNo ratings yet

- LTD Presets PDFDocument41 pagesLTD Presets PDFRobson FernandesNo ratings yet

- Front and Rear Panel Diagram of Amplifier ManualDocument42 pagesFront and Rear Panel Diagram of Amplifier ManualRobson FernandesNo ratings yet

- TCNovaSystem Sysex1 20.1Document19 pagesTCNovaSystem Sysex1 20.1Robson FernandesNo ratings yet

- Regulated SMPS data sheetDocument5 pagesRegulated SMPS data sheetRobson FernandesNo ratings yet

- Elliott Sound Products projeto layout Viagem Mental componentesDocument3 pagesElliott Sound Products projeto layout Viagem Mental componentesRobson FernandesNo ratings yet

- Derspiegel - Playful DuetDocument1 pageDerspiegel - Playful DuetgwapongkabayoNo ratings yet

- Echo Base Build PDF Updated 051810Document10 pagesEcho Base Build PDF Updated 051810Cadavre ExquisNo ratings yet

- Jwrhythmcopy ManualDocument2 pagesJwrhythmcopy ManualRobson FernandesNo ratings yet

- Syllabus of Modules FOR THE Electrician Domestic (ELE701)Document6 pagesSyllabus of Modules FOR THE Electrician Domestic (ELE701)udi969100% (1)

- Subsea Cable Floats: Rising To Your Undersea ChallengesDocument1 pageSubsea Cable Floats: Rising To Your Undersea ChallengesMAURICIO DE LOS SANTOS HERNANDEZNo ratings yet

- RMLNLU Moot Court Competition (Funding & Reimbursement) Policy, 2019.Document4 pagesRMLNLU Moot Court Competition (Funding & Reimbursement) Policy, 2019.Aakash ChauhanNo ratings yet

- Physical Properties of Groups 1, 17 and 18 ElementsDocument5 pagesPhysical Properties of Groups 1, 17 and 18 ElementslenovosubaNo ratings yet

- Amidoxime Vanadium U Da Çekiyor SıkıntısıDocument7 pagesAmidoxime Vanadium U Da Çekiyor SıkıntısıMelike AltayNo ratings yet

- Hospital Acquired Infections-IIDocument52 pagesHospital Acquired Infections-IIFATHIMA ANo ratings yet

- Periodontal DiseaseDocument4 pagesPeriodontal Diseasemojako_badboysNo ratings yet

- Libyan cuisine: Bazin, asida and moreDocument3 pagesLibyan cuisine: Bazin, asida and moreAndy Atehortua CiroNo ratings yet

- Principle of Economics Consolidated Assignements-2 - 10th February 22Document27 pagesPrinciple of Economics Consolidated Assignements-2 - 10th February 22Mani Bhushan SinghNo ratings yet

- Install Panel WallDocument10 pagesInstall Panel WallLuis PalaciosNo ratings yet

- A Review of Empathy Education in NursingDocument11 pagesA Review of Empathy Education in Nursinglora ardyaNo ratings yet

- S35MC Engine Layout and Load DiagramsDocument17 pagesS35MC Engine Layout and Load DiagramsMuhammad AlfaniNo ratings yet

- DAYCENT Model Overview, Testing and Application To AgroecosystemsDocument28 pagesDAYCENT Model Overview, Testing and Application To AgroecosystemsJunoNo ratings yet

- Chapter 18Document10 pagesChapter 18nehallakdawalaNo ratings yet

- Diesel Engine Operation and DiagDocument76 pagesDiesel Engine Operation and DiagHafiezul Hassan100% (3)

- Boq For Ifad Pump Project (Solar System With Drip & Microsprinkler Water Distribution)Document4 pagesBoq For Ifad Pump Project (Solar System With Drip & Microsprinkler Water Distribution)Mr. 420No ratings yet

- SpamDocument2 pagesSpamAshutosh SinghNo ratings yet

- Nichita Stanescu - The Poet of Loneliness and LossDocument28 pagesNichita Stanescu - The Poet of Loneliness and LossEmanuelaCiocanNo ratings yet

- Include The Following in Your RTI ApplicationDocument4 pagesInclude The Following in Your RTI ApplicationRam LoharNo ratings yet

- RP F107 PDFDocument45 pagesRP F107 PDFPriyam KmNo ratings yet

- The Morning Calm Korea Weekly - Oct. 14, 2005Document26 pagesThe Morning Calm Korea Weekly - Oct. 14, 2005Morning Calm Weekly NewspaperNo ratings yet

- CaraKumpul - Soal PAS Bahasa Inggris Kls 12Document7 pagesCaraKumpul - Soal PAS Bahasa Inggris Kls 12akusayanklenaNo ratings yet

- Lifting Plan ProcedureDocument4 pagesLifting Plan ProcedureNath YauNo ratings yet

- Airworthiness Directives Record ControlDocument4 pagesAirworthiness Directives Record ControlJuan builesNo ratings yet

- Hedging FuturesDocument39 pagesHedging Futuresapi-3833893100% (1)

- Me, Myself, and My Dream CareerDocument12 pagesMe, Myself, and My Dream CareerJed CameronNo ratings yet

- PPR - LISTS - Registered Medicine Price List - 20221127 BahrainDocument318 pagesPPR - LISTS - Registered Medicine Price List - 20221127 BahrainvdvedNo ratings yet

- ActinobacillosisDocument16 pagesActinobacillosisMd Shamim AhasanNo ratings yet

- The Pediatric Mandible I. A Primer On Growth and DevelopmentDocument10 pagesThe Pediatric Mandible I. A Primer On Growth and DevelopmentJulián David Ríos ZuluagaNo ratings yet

- Manual de Reparacion TXV75Document16 pagesManual de Reparacion TXV75Ovh MaquinariasNo ratings yet