Professional Documents

Culture Documents

Unit - Ii Forecasting, Capacity Anf Facility Design SYLLABUS: Demand Forecasting - Need, Types, Objectives and Steps. Overview of Qualitative and

Uploaded by

sabha5121021Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit - Ii Forecasting, Capacity Anf Facility Design SYLLABUS: Demand Forecasting - Need, Types, Objectives and Steps. Overview of Qualitative and

Uploaded by

sabha5121021Copyright:

Available Formats

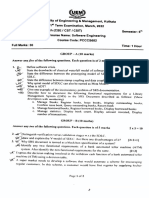

UNIT - II FORECASTING, CAPACITY ANF FACILITY DESIGN

SYLLABUS: Demand Forecasting – Need, Types, Objectives and Steps. Overview of Qualitative and

Quantitative methods, Capacity Planning – Long Rage, Types, Developing Capacity Alternatives,

Overview of Sales and Operations Planning. Overview of MRP, MRP II and ERP. Facility Location –

Theories, Steps in Selection, Location Models, Facility Layout – Principles, Types, Planning Tools and

Techniques

PART - A

S.NO QUESTIONS BT LEVEL COMPETENCE

1 Define capacity requirement planning. Level 1 Remembering

Compare mean absolute deviation (MAD) and mean

2 Level 2 Understanding

squared error (MSE).

How would you state the characteristics of Demand

3 Level 3 Applying

Forecasting?

4 What are the methods of Qualitative Forecasting? Level 4 Analysing

5 Can you elaborate on the reason why forecast is needed? Level 5 Evaluating

6 How could you define Capacity planning? Level 6 Creating

7 Define aggregate planning. Level 1 Remembering

8 State the factors affecting Capacity Planning. Level 2 Understanding

9 Differentiate between RCCP and CRP Level 3 Applying

10 Outline the Capacity Planning process. Level 4 Analysing

11 Define Material Requirement Planning. Level 5 Evaluating

12 What can you say about Bill of Materials? Level 6 Creating

13 How would you explain Enterprise Resource Planning? Level 1 Remembering

14 Identify the steps in Location Planning. Level 2 Understanding

15 Can you explain Cellular Manufacturing Level 3 Applying

16 What is your opinion on Product Layout? Level 4 Analysing

17 Define MRP II. Level 1 Remembering

18 Compare MRP I and MRP II. Level 2 Understanding

19 What are the inputs of MRP system? Level 1 Remembering

20 What is facility location? Level 1 Remembering

S.NO QUESTIONS BT LEVEL COMPETENCE

1 How would you show the evolution of MRP and ERP? Level 1 Remembering

2 What can you say about MRP II? Level 2 Understanding

a) How would you explain the types of capacity?

(6Marks)

b) Alpha company has the following sales pattern.

(7Marks)

3 Year 1 2 3 4 5 6 7 8 9 Level 3 Applying

Sales in Lakhs 6 8 11 23 29 34 40 45 56

Compute the sales forecast for the 10th Year

a) How would you use the different alternatives for

capacity development? (5Marks)

4 Level 4 Analysing

b) How would you classify the facility

layout?(8Marks)

A) Past data about the load on the stamping center are as

follows:

5 Level 5 Evaluating

a) Find the exponential smoothing forecast for the

month of December 2009. Take (a=0.33) (4Marks)

b) Compare your answer with five months moving

average forecast.(4Marks)

B) How would you classify the various types of demand

forecasting and explain in detail any two qualitative

and quantitative methods of demand forecasting?

(5Marks)

How would you describe the capacity requirement Level 6 Creating

6

planning? Explain with suitable example.

a) What factors should be considered when selecting the

appropriate capacity? How does the choice of capacity relate

to other decision in operation management and to other Level 1 Remembering

7 functional areas? (6Marks)

b) Can you assess the principles and techniques of facility

layout? (7Marks)

A company has to decide on the location of a new plant.

It has narrowed down the choice to 3 locations A,B and

C data in respect of which is furnished below:

Locations

Data A B

C (Rupees)

(Rupees) (Rupees)

Wages and Salaries 20000 20000 20000

Power and Water

Expenses 20000 30000 25000

Raw Materials and

Other Supplies 80000 75000 60000

8 Total Initial Level 2 Understanding

200000 300000 250000

investment

Distribution

50000 40000 60000

Expenses

Miscellaneous

Expenses 40000 25000 30000

Expected Sales Per

Year 225000 250000 225000

Use a suitable criterion and advise the company on

the best choice.

a) A steel plant has a design capacity of 50,000 tons of

steel per day, effective capacity of 40,000 tons of steel

per day an actual output of 36,000 tons of steel per

9 day. Compute the efficiency of the plant and its Level 3 Applying

utilization. (8Marks)

b) How would you explain the problems

in implementing ERP?(5Marks)

Give a detailed account on Material Requirement

10 Level 4 Analysing

Planning

State the factors which should be kept in mind while deciding

11 upon a suitable type of plant layout Level 1 Remembering

12 Discuss various types of Facility layout Level 2 Understanding

Explain the steps in Location Selection and Discuss the

13 Level 4 Analysing

factors affecting facility location.

14 Compare and contrast MRP I and MRP II Level 1 Remembering

PART - C

S.No Questions

A TV assemble unit has 5 work stations whose individual capacities per shift are given below.

1 The capacity of the assembly line is 350 TV’s per day of single shift. Calculate the system

capacity and system efficiency?

2 During which type of situations do you decide to improve or modify the existing layout?

You might also like

- BA5206-Operations Management PDFDocument17 pagesBA5206-Operations Management PDFSeyed BillalganiNo ratings yet

- BA7201 Operations ManagementDocument18 pagesBA7201 Operations ManagementkismuganNo ratings yet

- Unit - V Scheduling and Project Management SYLLABUS: Project Management - Scheduling Techniques, PERT and CPMDocument4 pagesUnit - V Scheduling and Project Management SYLLABUS: Project Management - Scheduling Techniques, PERT and CPMsabha5121021No ratings yet

- Operations Management - Nature, Importance and Historical DevelopmentDocument3 pagesOperations Management - Nature, Importance and Historical Developmentsabha5121021No ratings yet

- MG6863 - ENGINEERING ECONOMICS - Question BankDocument19 pagesMG6863 - ENGINEERING ECONOMICS - Question BankSRMBALAANo ratings yet

- Jeppiaar Nagar, Chennai – 600119 III Semester BA5029 –SERVICES OPERATIONS MANAGEMENT Question BankDocument12 pagesJeppiaar Nagar, Chennai – 600119 III Semester BA5029 –SERVICES OPERATIONS MANAGEMENT Question BankDr.Satish RadhakrishnanNo ratings yet

- MBAI204 - OM - Assignment No. 2 - 2020Document11 pagesMBAI204 - OM - Assignment No. 2 - 2020Ruchi AryaNo ratings yet

- Unit - Iv Materials ManagementDocument4 pagesUnit - Iv Materials Managementsabha5121021No ratings yet

- Department of Management Studies: Prepared byDocument15 pagesDepartment of Management Studies: Prepared byBavatharaniNo ratings yet

- Paper13 PDFDocument4 pagesPaper13 PDFMithilesh RamgolamNo ratings yet

- Ama 4305 Operation Research Assignment Sem Ii 20-21Document2 pagesAma 4305 Operation Research Assignment Sem Ii 20-21Meshack ShahNo ratings yet

- QP 8 PGDMM PGDSCM L 2 Years Dec 2019Document2 pagesQP 8 PGDMM PGDSCM L 2 Years Dec 2019Aman KumarNo ratings yet

- MBA205 Solved SMU AssignmentDocument4 pagesMBA205 Solved SMU AssignmentArvind KNo ratings yet

- Chhattisgarh Institute of Technology, Rajnandgaon Chhattisgarh Institute of Technology, RajnandgaonDocument3 pagesChhattisgarh Institute of Technology, Rajnandgaon Chhattisgarh Institute of Technology, RajnandgaonAkhilesh Kumar RajbharNo ratings yet

- Unit - II Cycle Test Part - A (10 2 20)Document1 pageUnit - II Cycle Test Part - A (10 2 20)Senthil Kumar GanesanNo ratings yet

- SRM Valliammai Engineering College: (An Autonomous Institution)Document16 pagesSRM Valliammai Engineering College: (An Autonomous Institution)Arun ArunNo ratings yet

- Question Paper Code:: Reg. No.Document20 pagesQuestion Paper Code:: Reg. No.Sarthak MittalNo ratings yet

- SYBMS Paper SEM IV MU 2017-18Document4 pagesSYBMS Paper SEM IV MU 2017-18Dannie D'souzaNo ratings yet

- Operations ManagementDocument7 pagesOperations ManagementPrabhamohanraj MohanrajNo ratings yet

- Integrated Professional Competence Course - Group Ii Mock Test Paper November-2010 Set - 1Document3 pagesIntegrated Professional Competence Course - Group Ii Mock Test Paper November-2010 Set - 1Amitcafe PlayNo ratings yet

- Unit - Iii - Design or Product, Process and Work Systems SYLLABUS: Product Design - Influencing Factors, Approaches, Legal, Ethical and EnvironmentalDocument3 pagesUnit - Iii - Design or Product, Process and Work Systems SYLLABUS: Product Design - Influencing Factors, Approaches, Legal, Ethical and Environmentalsabha5121021No ratings yet

- V Sem BCA QBDocument42 pagesV Sem BCA QBSathishaNo ratings yet

- Time: 3 Hours Max. Marks: 70Document2 pagesTime: 3 Hours Max. Marks: 70Saidinesh SurineniNo ratings yet

- HT TP: //qpa Pe R.W But .Ac .In: CS/B.Tech (CSE-NEW) /SEM-6/CS-604C/2013Document4 pagesHT TP: //qpa Pe R.W But .Ac .In: CS/B.Tech (CSE-NEW) /SEM-6/CS-604C/2013Kunal NandyNo ratings yet

- Salesforce QB - Internal FinalDocument6 pagesSalesforce QB - Internal Final20kd1a05c1No ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityJigarNo ratings yet

- Operations Management CourseDocument8 pagesOperations Management Courseelsonpaul100% (1)

- BCA 5th Sem Dec 2017Document7 pagesBCA 5th Sem Dec 2017lolol lololNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityHarsh GakhreNo ratings yet

- 1 Term Examination, March, 2022: Semester: 6thDocument4 pages1 Term Examination, March, 2022: Semester: 6thAnushree MondalNo ratings yet

- Se M1 QuesDocument1 pageSe M1 Quesanon_65439220No ratings yet

- Operation Management 2014 QuestionsDocument5 pagesOperation Management 2014 QuestionsAshutosh AgalNo ratings yet

- Answer ALL Questions Answer ALL Questions: PART-A (10 X 2 20 Marks)Document3 pagesAnswer ALL Questions Answer ALL Questions: PART-A (10 X 2 20 Marks)Nambi RajanNo ratings yet

- Industrial Engineering Question BankDocument4 pagesIndustrial Engineering Question BankAashishNo ratings yet

- CS/B.Tech (CSE-NEW) /SEM-6/CS-604C/2013: Name Roll No. Invigilator's SignatureDocument4 pagesCS/B.Tech (CSE-NEW) /SEM-6/CS-604C/2013: Name Roll No. Invigilator's SignatureBarnali GuptaNo ratings yet

- ERP Implementation at LacrimedicsDocument2 pagesERP Implementation at LacrimedicsDivya PunjabiNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document2 pagesQuestion Paper Code:: (10×2 20 Marks)Jeya Prakash100% (1)

- Ilovepdf MergedDocument11 pagesIlovepdf MergedAnanda KrishnanNo ratings yet

- 2023apr-dip-pm-newDocument6 pages2023apr-dip-pm-newcojena1466No ratings yet

- S. K. Patel Institute of Management and Computer Studies Production and Operations Management (CC 206) Mid Term ExaminationDocument2 pagesS. K. Patel Institute of Management and Computer Studies Production and Operations Management (CC 206) Mid Term ExaminationParnika JhaNo ratings yet

- Departmentof Mechanicalengineering Question Bank Viiisemester - Ie6605Productionplanning Andcontrol Question Bank U N I T I I N T R O D U C T IO NDocument12 pagesDepartmentof Mechanicalengineering Question Bank Viiisemester - Ie6605Productionplanning Andcontrol Question Bank U N I T I I N T R O D U C T IO NSanthanakumar MNo ratings yet

- DBMS Question BankDocument12 pagesDBMS Question BankKhushi PachauriNo ratings yet

- CAPM Notes TutorialsDocument3 pagesCAPM Notes TutorialsSameer AmjadNo ratings yet

- PPAC Supplementary Exams March/April 2012Document1 pagePPAC Supplementary Exams March/April 2012samarsekharreddyNo ratings yet

- Ipcc Paper1Document9 pagesIpcc Paper1chaitanya bharvadaNo ratings yet

- Ram PDFDocument8 pagesRam PDFParth GamiNo ratings yet

- Software EngineerDocument3 pagesSoftware EngineerSANATANI HINDU (BHARATIYA)No ratings yet

- QuestionsDocument2 pagesQuestionsChandra Shekar Reddy TummuriNo ratings yet

- Unit 3Document3 pagesUnit 3nalayiniNo ratings yet

- Jntuk 2 1 Mefa Nov 2017 Q PDocument5 pagesJntuk 2 1 Mefa Nov 2017 Q PsaiNo ratings yet

- Production planning and control techniques for mechanical engineeringDocument2 pagesProduction planning and control techniques for mechanical engineeringSadhasivam U. R. INo ratings yet

- Software Engineering Regulation – 2019Document14 pagesSoftware Engineering Regulation – 2019Karuna Karan KNo ratings yet

- PPC Model Exam Question PaperDocument2 pagesPPC Model Exam Question PapertharunNo ratings yet

- CACEP Question BankDocument8 pagesCACEP Question BankRajha RajeswaranNo ratings yet

- Bca 04 BAIT 03Document2 pagesBca 04 BAIT 03Jatin SinghNo ratings yet

- Angel charities IT module question bankDocument1 pageAngel charities IT module question bankImran JamadarNo ratings yet

- GTU Exam Questions on Engineering Economics and ManagementDocument18 pagesGTU Exam Questions on Engineering Economics and ManagementHrishikesh Bhavsar100% (1)

- Be Summer 2022Document2 pagesBe Summer 2022dbtrivedi4uNo ratings yet

- Bda Important QuestionsDocument4 pagesBda Important QuestionsVenkatesh Patnala SoniNo ratings yet

- Rewired: The McKinsey Guide to Outcompeting in the Age of Digital and AIFrom EverandRewired: The McKinsey Guide to Outcompeting in the Age of Digital and AIRating: 4.5 out of 5 stars4.5/5 (2)

- Unit - IDocument45 pagesUnit - Isabha5121021No ratings yet

- Data Analysis and Business ModellingDocument8 pagesData Analysis and Business Modellingsabha5121021No ratings yet

- Financial Management Goals and ObjectivesDocument114 pagesFinancial Management Goals and Objectivessabha5121021No ratings yet

- Unit - Iv Materials ManagementDocument4 pagesUnit - Iv Materials Managementsabha5121021No ratings yet

- Unit - Iii - Design or Product, Process and Work Systems SYLLABUS: Product Design - Influencing Factors, Approaches, Legal, Ethical and EnvironmentalDocument3 pagesUnit - Iii - Design or Product, Process and Work Systems SYLLABUS: Product Design - Influencing Factors, Approaches, Legal, Ethical and Environmentalsabha5121021No ratings yet

- Malicious Cryptography Cryptovirology and KleptographyDocument13 pagesMalicious Cryptography Cryptovirology and KleptographySpoe3400No ratings yet

- Quality Control Circle (QCC) Story 7 StepsDocument2 pagesQuality Control Circle (QCC) Story 7 StepspsureshpNo ratings yet

- Fact Finding TechniquesDocument11 pagesFact Finding TechniquesValrie Coley-Brown100% (1)

- Class 10 All MCQs Complete Book SmartDocument26 pagesClass 10 All MCQs Complete Book SmartHammad Ahmed KhanNo ratings yet

- Lesson Plan ApproximationsDocument1 pageLesson Plan ApproximationsJonathan Robinson100% (2)

- Sparking InnovationDocument8 pagesSparking InnovationGouri GargateNo ratings yet

- Delphi XE2 Foundations - Part 1 - Rolliston, ChrisDocument160 pagesDelphi XE2 Foundations - Part 1 - Rolliston, ChrisJoel Quezada100% (2)

- Electronic Remote Control: Operation ManualDocument30 pagesElectronic Remote Control: Operation ManualSurendran PattineyapanNo ratings yet

- HD One X S User Guide PDFDocument19 pagesHD One X S User Guide PDFprasad100% (1)

- Automatic Melting Point Determination: Simple, Efficient and Video-RecordedDocument12 pagesAutomatic Melting Point Determination: Simple, Efficient and Video-RecordedNdra PompomorinNo ratings yet

- Disaster Recovery Plan Check ListDocument5 pagesDisaster Recovery Plan Check ListRulingEmpror100% (5)

- Daewoo DVN-14F6N, DVN-20F6N Chassis CN-140 TV VCR PDFDocument142 pagesDaewoo DVN-14F6N, DVN-20F6N Chassis CN-140 TV VCR PDFplatonvhmNo ratings yet

- ADP Connection For PayForce Requirements20303Document2 pagesADP Connection For PayForce Requirements20303claokerNo ratings yet

- Serial Card and Series 2 SDocument3 pagesSerial Card and Series 2 Sscribd_thakur0% (1)

- Computer Network SlidesDocument24 pagesComputer Network SlidespsnvaratharajanNo ratings yet

- Pharmacokinetic Dosage Design and ModificationDocument7 pagesPharmacokinetic Dosage Design and ModificationJuan CarNo ratings yet

- CL Commands ViiDocument338 pagesCL Commands Viiapi-3800226No ratings yet

- Dr. Ambedkar FoundationDocument1 pageDr. Ambedkar Foundationteja tejaNo ratings yet

- Homework Assignment #1: Boost Converter SimulationDocument2 pagesHomework Assignment #1: Boost Converter Simulationsasa50% (18)

- PNB Project ReportDocument17 pagesPNB Project ReportNeha SareenNo ratings yet

- Grade XII - Orientation PPT 2022-23Document81 pagesGrade XII - Orientation PPT 2022-23BHAVISHA BHATIANo ratings yet

- CyberArk Training Course Content v1Document9 pagesCyberArk Training Course Content v1Mensis LatinsNo ratings yet

- Measuring Stradivari Violin "Cremonese" (1715) by 3D ModelingDocument5 pagesMeasuring Stradivari Violin "Cremonese" (1715) by 3D ModelingAdriano AngelicoNo ratings yet

- Extending HammerDB Autopilot at the Command LineDocument2 pagesExtending HammerDB Autopilot at the Command Lineabc6309982No ratings yet

- Hart Application GuideDocument189 pagesHart Application GuideRoy RamosNo ratings yet

- VB 6.0 TutorialsDocument19 pagesVB 6.0 TutorialsSantoshNo ratings yet

- Resume for Manoj MadduriDocument3 pagesResume for Manoj MadduriSita Ram RamisettyNo ratings yet

- Capacity Monitoring GuideDocument27 pagesCapacity Monitoring GuidePraveen DubeyNo ratings yet

- Direct Marketing: RFM AnalysisDocument32 pagesDirect Marketing: RFM AnalysisNeha MishraNo ratings yet