Professional Documents

Culture Documents

Opticom Rack Mount Fiber Enclosures: Assembly View

Uploaded by

Mehdi SHOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Opticom Rack Mount Fiber Enclosures: Assembly View

Uploaded by

Mehdi SHCopyright:

Available Formats

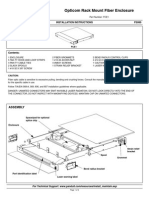

Opticom Rack Mount Fiber Enclosures

Part Numbers: FRME1U, FRME2U

© Panduit Corp. 2011 INSTALLATION INSTRUCTIONS FS002D

FRME1U FRME2U

Contents - (#) indicates FRME2U quantity

1 - ENCLOSURE 1 - STRAIN RELIEF BRACKET 4 - CABLE TIES, PLT2S-M0

2 - MOUNTING BRACKETS 2 (4) - BEND RADIUS CONTROL CLIPS 1 - CAUTION LABEL

4 - #10-32 x 5/16" SCREWS 2 (4) - NYLATCH PLUNGERS 1 - LASER WARNING LABEL

4 - #12-24 x 1/2" SCREWS 2 (4) - NYLATCH GROMMETS

4 - M6 x 1 SCREWS 2 (3) - ADHESIVE BACKED MOUNTS

1 - #10-32 x 3/8" SCREW 3 - ADHESIVE BEVEL ENTRY CLIPS

3 - #10-32 HEX NUTS 2 - SLACK SPOOLS

1 (2) - CABLE ENTRY GROMMET(S) 2 (3) -TAK-TYS, 6" pcs.

WARNING: UNMATED CONNECTORS MAY EMIT INVISIBLE LASER RADIATION. DO NOT LOOK DIRECTLY INTO THE END OF THE

CONNECTOR. DO NOT INSPECT WITH MAGNIFYING DEVICES. MAINTAIN CAP ON UNMATED CONNECTORS.

CAUTION:

Fiber optic cable is sensitive to excessive pulling, bending and crushing forces. Consult the manufacturer’s cable specification sheet for

the specific cable in use.

Follow TIA/EIA-568A, 569, 606, and 607 installation guidelines where applicable.

Care should be taken when opening and closing fully loaded drawer in order to protect fiber components.

ASSEMBLY VIEW showing Fiber Adapter Panels (FAPs) - sold separately.

Cover

Bend Radius Slack Spools

Control Clips

Trunk or Interconnect

Cable Entry Grommet

FAPs

(sold separately)

Strain Relief

Mounting Bracket

Brackets

Enclosure

Front Door Assembly Enclosure Sliding

(shown in open position) Drawer

NyLatch Plungers

Note: Front and rear doors and Grommets

are not interchangeable

Figure 1

For Technical Support: www.panduit.com/resources/install_maintain.asp

Page 1 of 8

© Panduit Corp. 2011 INSTALLATION INSTRUCTIONS FS002D

Preparation and Rack Mounting

Determine where the cable will enter the

enclosure. Carefully remove the knock-out so as

not to damage the surrounding sheet metal. DO

NOT install the grommet at this stage. Grommet

will be installed after the enclosure is mounted to

the rack.

Figure 2

Figure 2

Orientation for 19" rack

mounting Determine the proper orientation for the mounting

brackets according to rack size being used.

Install mounting bracket to the enclosure using (2)

(2) #10-32 x 5/16" screws

#10-32 x 5/16" screws. Repeat for other side.

Orientation for 23" rack

mounting

Figure 3A

Use (2) #12-24 x 1/2" Place enclosure mounting brackets at desired

screws on each side position on the rack. Mount the enclosure to the

rack using (4) #12-24 x 1/2" screws.

Use (4) M6 x 1 screws if mounting to a metric rack.

Figure 3B

Enclosure is accessible from the rear for mounting of

slack spools, Fiber Optic Splice Modules (FOSMs)

and other equipment.

(Rear View)

Figure 3C

For Technical Support: www.panduit.com/resources/install_maintain.asp

Page 2 of 8

© Panduit Corp. 2011 INSTALLATION INSTRUCTIONS FS002D

Grommet Cutting Diagram

After the enclosure is mounted to the rack,

determine the size of the innerduct (if any) that

will be used to bring the cable into the enclosure.

Prepare grommet according to the proper cutting

Cut out the small Cut the straight diagram to the left.

circle for 1" dia. lines for smaller

innerduct bundle sizes

Cut out the small Cut out the large circle Cut the straight lines

circle for 1-1/4" dia. for 1-1/2" dia. when not using any

innerduct innerduct innerduct

Figure 4A

Grommet

Figure 4B

#10-32 x 3/8" Screw Strain Relief

Bracket

Install the strain relief bracket near where the

cable will enter the enclosure. Secure with

#10-32 x 3/8" screw and #10-32 hex nut.

#10-32

Hex Nut

(cover not shown for clarity) Figure 5

For Technical Support: www.panduit.com/resources/install_maintain.asp

Page 3 of 8

© Panduit Corp. 2011 INSTALLATION INSTRUCTIONS FS002D

Field Termination or Pre-Terminated Trunk Installation

FAPs (3) capacity for FRME1U

(6) capacity for FRME2U

Slack Spools

Slack Spools may be mounted with adhesive

backing only or securing with #10-32 hex nuts.

Punch a hole through the adhesive backing and

place slack spools over #10-32 studs on the

tray. Secure with #10-32 hex nuts. Note spool

orientation.

Position FAPs between upright flanges as

shown. Once mounted, fully seat NyLatches to

secure.

Fully extend tray to ensure proper amount of

slack is used.

Tray shown fully extended

(cables omitted for clarity)

Note orientation of spools

(cover not shown)

Figure 6A

For Technical Support: www.panduit.com/resources/install_maintain.asp

Page 4 of 8

© Panduit Corp. 2011 INSTALLATION INSTRUCTIONS FS002D

Tak-Ty the cables utilizing Grommet

slots in enclosure

Route fiber through cable entry grommet as

shown. Use enough cable length to ensure

one complete loop of individual fibers around

“A” slack spools. Leave enough jacketed slack so

Fixed Tak-Ty when the drawer is fully extended the cables

Sub-unit are not put under tension. DO NOT use so

tubes Cable length much slack that the drawer cannot be returned

between to its home position. (See Figure 6C)

point “A” and

Free floating point “B” is Use Tak-Tys to secure fiber cords at the cable

Tak-Ty approx. 31" entry location and other points as shown.

[.787m]

Adhesive

Backed

Mount with

Tak-Ty Cable Jacket Adhesive Backed

Mount with Tak-Ty

“B” Individual

Individual

Fiber Break Fiber

out point

(See detail)

1.0"

Fiber Break out Detail

Be sure adhesive backed mount is positioned

to secure the jacketed trunk cable. DO NOT

secure individual 900µm buffered fibers

Drawer in extended position

(cover not shown)

Figure 6B

Drawer in home position

(cover not shown)

Figure 6C

For Technical Support: www.panduit.com/resources/install_maintain.asp

Page 5 of 8

© Panduit Corp. 2011 INSTALLATION INSTRUCTIONS FS002D

Fiber Optic Splice Module (FOSM) Installation - sold separately

FOSM (3) capacity for FRME1U

(6) capacity for FRME2U

Place first FOSM over #10-32 studs on sliding

tray and secure with #10-32 hex nuts.

Remaining FOSMs are stacked on top of each

other and snap in place.

Position FAPs between upright flanges as

shown. Once mounted, fully seat NyLatches to

secure.

FAPs (3) capacity for FRME1U

(6) capacity for FRME2U

Figure 7A

Tak-Ty the cables utilizing

slots in enclosure Grommet

“A”

Route fiber through cable entry grommet as

Fixed Tak-Ty

Sub-unit shown. Use enough cable length to ensure one

tubes complete loop of individual fibers around FOSM

slack spools.

Cable length Route 900µm buffered fiber from the trunk

between point cable and splice to pigtail per instructions in

“A” and point FS001*, “FOSM Opticom Fiber Optic Splice

“B” is approx Module Installation Instructions.”

Free floating 32.5" [.825m]

Tak-Ty Leave enough jacketed slack so when the

drawer is fully extended the cables are not put

“B” under tension. DO NOT use so much slack that

the drawer cannot be returned to its home

position. (See Figure 7C)

Use Tak-Tys to secure fiber cords at the cable

entry location and other points as shown.

Individual fiber

break out point

Drawer in extended position

(cover not shown) Figure 7B

* Denotes revision letter.

For Technical Support: www.panduit.com/resources/install_maintain.asp

Page 6 of 8

© Panduit Corp. 2011 INSTALLATION INSTRUCTIONS FS002D

Drawer in home position

(cover not shown)

Figure 7C

Bend Radius Control Clip Installation

Install plunger into grommet, but do not fully

seat. Slide bend radius control clip over the

Sliding Tray

sliding tray flange as shown.

Flange

Push grommet/plunger through bend radius

control clip and sliding tray flange holes. Fully

Bend Radius seat plunger into grommet to secure.

Control Clip Plunger

Repeat for other side.

Bend radius control clips must be installed to

retain the front door.

Grommet

Figure 8A

For Technical Support: www.panduit.com/resources/install_maintain.asp

Page 7 of 8

© Panduit Corp. 2011 INSTALLATION INSTRUCTIONS FS002D

Patch Cord Installation

Install patch cords into FAPs routing through

bend radius control clips and maintaining

proper patch cord bend radius.

Figure 9

Door Attachment

Install the front door as follows. Install the

rear door in a similar manner.

Pin

Position the door so that it rests on top of the

Inner hinge and up against the inner and outer

Tab tabs.

Hinge

Outer Tab Bend the bottom of the right side of the door

until the pin drops into the hinge. Repeat for

the left side.

Ben

d

Figure 10

The final door position should be on the

outside of the inner tabs.

If the door is installed properly it will open and

Inner Tabs close freely.

Attach Laser Warning Label and Caution

Label where they are clearly visible.

Figure 11

For Instructions in Local Languages E-mail:

and Technical Support: techsupport@panduit.com

www.panduit.com/resources/install_maintain.asp Phone:

www.panduit.com 866-405-6654

Page 8 of 8

You might also like

- ZXP 1 Series PDFDocument270 pagesZXP 1 Series PDFOle BoleNo ratings yet

- Jackscrew Backshell Installation Instructions: 190-00313-11 October, 2017 Revision EDocument24 pagesJackscrew Backshell Installation Instructions: 190-00313-11 October, 2017 Revision EAlex AnishchykNo ratings yet

- Mylk - Mylk (386) LayoutDocument6 pagesMylk - Mylk (386) Layoutmini998No ratings yet

- Opticom Rack Mount Fiber Enclosures: Assembly ViewDocument8 pagesOpticom Rack Mount Fiber Enclosures: Assembly ViewmrdcshoesNo ratings yet

- Combinacion Diales MecanicosDocument5 pagesCombinacion Diales MecanicosHo MeGaNo ratings yet

- Assembly Instructions: Folding MarkersDocument6 pagesAssembly Instructions: Folding MarkersPetrNo ratings yet

- 2007 HD TouringDocument68 pages2007 HD TouringRod SturgeonNo ratings yet

- Verj FinalDocument19 pagesVerj FinalMohammed SalamNo ratings yet

- AssuredSAN Rackmount Bracket Kit Installation 83-00004524-13-01-CDocument2 pagesAssuredSAN Rackmount Bracket Kit Installation 83-00004524-13-01-CKilly BlameNo ratings yet

- Basic Louver Installation, Operation & Maintenance InstructionsDocument5 pagesBasic Louver Installation, Operation & Maintenance InstructionsJane RoNo ratings yet

- JC-364-TSKS IOM EN Final HiRes NoCropsDocument12 pagesJC-364-TSKS IOM EN Final HiRes NoCropsFabio StuiNo ratings yet

- Accessories 220222003Document5 pagesAccessories 220222003magedsouryNo ratings yet

- 06-427 Cheetah Xi and CyberCat 50 Enclosure InstallationDocument2 pages06-427 Cheetah Xi and CyberCat 50 Enclosure InstallationMarcos Vinicius Salvador TeixeiraNo ratings yet

- Mini Scierie MontageDocument4 pagesMini Scierie Montagen_bernardNo ratings yet

- Iom TSKSDocument12 pagesIom TSKSTakbir2011No ratings yet

- Corning Industrial Connector Housing - Standard Recommended Procedure 003-597-QSGDocument4 pagesCorning Industrial Connector Housing - Standard Recommended Procedure 003-597-QSGmarkNo ratings yet

- DometicDualOutboardKit SKI 4445104029 AMER 2023-03-20Document3 pagesDometicDualOutboardKit SKI 4445104029 AMER 2023-03-20Léo fait du skateNo ratings yet

- Accessories: 1.1 Weld Lens AssemblyDocument6 pagesAccessories: 1.1 Weld Lens AssemblyLuis Fernando Flores CarrilloNo ratings yet

- Opticom Rack Mount Fiber Enclosure: Installation Instructions FS060Document4 pagesOpticom Rack Mount Fiber Enclosure: Installation Instructions FS060Dario Campos AlcantaraNo ratings yet

- WBB Weatherproof Back Box Accessory: 3825 Ohio Avenue, St. Charles, Illinois 60174 1-800-SENSOR2, FAX: 630-377-6495Document1 pageWBB Weatherproof Back Box Accessory: 3825 Ohio Avenue, St. Charles, Illinois 60174 1-800-SENSOR2, FAX: 630-377-6495Carlos YepezNo ratings yet

- 120G Wired Remote ManualDocument42 pages120G Wired Remote ManualHaytahNo ratings yet

- TJ Full Cage Kit Install: Parts ListDocument7 pagesTJ Full Cage Kit Install: Parts ListMark BarberaNo ratings yet

- Accessories HiDocument5 pagesAccessories Hiherve.rozecNo ratings yet

- Raymariner ManualDocument8 pagesRaymariner ManualMarcel SchumannNo ratings yet

- V LogoDocument3 pagesV LogoAdrián CasarrubiasNo ratings yet

- Vario Installation ManualDocument6 pagesVario Installation ManualQuintinNo ratings yet

- Kinetix K5300 FeedbackConnector 2198-In023 - En-PDocument4 pagesKinetix K5300 FeedbackConnector 2198-In023 - En-Pgianluca.fencoNo ratings yet

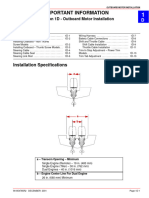

- Important Information: Section 1D - Outboard Motor InstallationDocument13 pagesImportant Information: Section 1D - Outboard Motor InstallationDr. Centelha Mecânica NaúticaNo ratings yet

- Optional Parts: 4-3. External Electronic Expansion Valve Kit For Indoor Unit CZ-P56SVK2, CZ-P160SVK2 (For R410A)Document3 pagesOptional Parts: 4-3. External Electronic Expansion Valve Kit For Indoor Unit CZ-P56SVK2, CZ-P160SVK2 (For R410A)Priesilia PresleyNo ratings yet

- 01-05 Unpacking A SwitchDocument11 pages01-05 Unpacking A SwitchRicardoCastroNo ratings yet

- VEC-1862 Instruction Manual Six-Meter Yagi AntennaDocument9 pagesVEC-1862 Instruction Manual Six-Meter Yagi AntennaJuan Ignacio Isla CortesNo ratings yet

- WEG Molded Case Circuit Breakers UBW225Document12 pagesWEG Molded Case Circuit Breakers UBW225Hélio SousaNo ratings yet

- Raystar 125 - 81247 - 3Document8 pagesRaystar 125 - 81247 - 3CARDONNo ratings yet

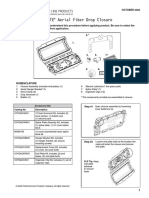

- Coyote Aerial Fiber Drop Closure: OCTOBER 2006Document4 pagesCoyote Aerial Fiber Drop Closure: OCTOBER 2006kjnjk uijhNo ratings yet

- Bottom Patch Lock Installation InstructionsDocument4 pagesBottom Patch Lock Installation InstructionsMangihot Lumban BatuNo ratings yet

- Timer IntermaticDocument2 pagesTimer Intermaticcle.contruccionNo ratings yet

- Rosemount 3051 Pressure Transmitter 3051cf Series Flow Meter en 73992Document52 pagesRosemount 3051 Pressure Transmitter 3051cf Series Flow Meter en 73992Kader BenNo ratings yet

- Installation Instructions: NZ Au GB IeDocument12 pagesInstallation Instructions: NZ Au GB IeR SNo ratings yet

- OPTEX HX40 ManualDocument12 pagesOPTEX HX40 Manualjoseluise68No ratings yet

- Crimping Die Assemblies 58492-1 and 58493 - 1Document3 pagesCrimping Die Assemblies 58492-1 and 58493 - 1zavabossNo ratings yet

- A26451800v01 (V16 - 02)Document4 pagesA26451800v01 (V16 - 02)Petyo GeorgievNo ratings yet

- TRAF-12-BAL SESTFt 02eDocument21 pagesTRAF-12-BAL SESTFt 02eJAIMENo ratings yet

- Terminating Head 58247 - 1 For MTA - 156 Receptacle Connectors Using Discrete WireDocument5 pagesTerminating Head 58247 - 1 For MTA - 156 Receptacle Connectors Using Discrete WiremaorNo ratings yet

- 8 ZXSDR R8862A Quick Installation Guide - R1.0 - CH - ENDocument30 pages8 ZXSDR R8862A Quick Installation Guide - R1.0 - CH - ENAndrie Purna FNo ratings yet

- BOSCH DS9370 Manual de Usuario InglésDocument8 pagesBOSCH DS9370 Manual de Usuario Inglésjulian vargasNo ratings yet

- RS-WMB, RD-WMB: Room DisplayDocument8 pagesRS-WMB, RD-WMB: Room DisplayAnonymous XYAPaxjbYNo ratings yet

- Eng SS 408-8623 CDocument4 pagesEng SS 408-8623 CKlaus Ø. NielsenNo ratings yet

- VDO Gauge - VL Hourmeter 12 - 24Document2 pagesVDO Gauge - VL Hourmeter 12 - 24HanNo ratings yet

- 25 K VInstall GuideDocument23 pages25 K VInstall GuideMarcelo ConchaNo ratings yet

- Snow Cab Kit: Installing The Snow Cab Frame On The SnowthrowerDocument4 pagesSnow Cab Kit: Installing The Snow Cab Frame On The SnowthrowerBJ DixNo ratings yet

- YellowGate Instruction Manual 5.2020Document16 pagesYellowGate Instruction Manual 5.2020TihonNo ratings yet

- Rep Rep Raf1051 5142000 - Vin7 D490248Document4 pagesRep Rep Raf1051 5142000 - Vin7 D490248jamesNo ratings yet

- Standby Battery Rack Assembly Instructions: Applies To All RDC Series RacksDocument8 pagesStandby Battery Rack Assembly Instructions: Applies To All RDC Series RacksYongki Adi Pratama PutraNo ratings yet

- Installation & Maintenance Information IF 1721: ApplicationDocument12 pagesInstallation & Maintenance Information IF 1721: ApplicationAndres VillacisNo ratings yet

- WheelHorse Bagger Manual For B Series and LT Series Tractors 810307R1Document8 pagesWheelHorse Bagger Manual For B Series and LT Series Tractors 810307R1Kevins Small Engine and Tractor ServiceNo ratings yet

- Proprietary Information: Downloaded From Manuals Search EngineDocument8 pagesProprietary Information: Downloaded From Manuals Search EngineManimaran MaranNo ratings yet

- Installation Instructions For General Duty Safety Switches Directives D'installation Pour Interrupteurs de Sécurité UniverselsDocument6 pagesInstallation Instructions For General Duty Safety Switches Directives D'installation Pour Interrupteurs de Sécurité UniverselscarteauNo ratings yet

- Tractor Umbrella Assembly Instructions and Replacement Parts ListDocument1 pageTractor Umbrella Assembly Instructions and Replacement Parts ListBobNo ratings yet

- TNC ConectorDocument2 pagesTNC ConectorLong ComtechNo ratings yet

- Kubota VC5030 RTVX900 - X1120D Wiper Kit (172 Degree) Rev. - , 6 PagesDocument7 pagesKubota VC5030 RTVX900 - X1120D Wiper Kit (172 Degree) Rev. - , 6 PagesmartinNo ratings yet

- VINTA Assembly Instruction (Single Polarity)Document3 pagesVINTA Assembly Instruction (Single Polarity)Liam BinghamNo ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- Plan of The Interview For The Participants of The Third Round: Physics and Physical SciencesDocument1 pagePlan of The Interview For The Participants of The Third Round: Physics and Physical SciencesMehdi SHNo ratings yet

- Potential Scientific Supervisors: Physical Sciences: Full Name University Field of Study Link To PortfolioDocument15 pagesPotential Scientific Supervisors: Physical Sciences: Full Name University Field of Study Link To PortfolioMehdi SHNo ratings yet

- Feroyd MousaVaYektaParastiDocument72 pagesFeroyd MousaVaYektaParastiMehdi SHNo ratings yet

- Program: Physical Sciences: EchanicsDocument5 pagesProgram: Physical Sciences: EchanicsMehdi SHNo ratings yet

- Fiber Optic Cable Storage and Respool Guide: ScopeDocument6 pagesFiber Optic Cable Storage and Respool Guide: ScopeMehdi SHNo ratings yet

- Mid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFDocument12 pagesMid-Span Access of Loose-Tube Ribbon Fiber Optic Cable PDFMehdi SHNo ratings yet

- Launch Cables PDFDocument17 pagesLaunch Cables PDFMehdi SHNo ratings yet

- Ch-1-Introduction To ComputersDocument15 pagesCh-1-Introduction To Computersanand_gudnavarNo ratings yet

- Muhammad Khalid: Cell: 03228620826, 03349087573 Tel: 0923631318Document1 pageMuhammad Khalid: Cell: 03228620826, 03349087573 Tel: 0923631318Abdourahmane BaNo ratings yet

- Audio/Video Multi-Channel Receiver: This Manual Is Applicable To The Following Model (S) and Type (S)Document15 pagesAudio/Video Multi-Channel Receiver: This Manual Is Applicable To The Following Model (S) and Type (S)Baris YaziciNo ratings yet

- Cdrom Drive OffsetsDocument74 pagesCdrom Drive OffsetsJuerrt5No ratings yet

- Emona Fotex Sample Labmanual Ver1 1 PDFDocument76 pagesEmona Fotex Sample Labmanual Ver1 1 PDFANGEL MORENONo ratings yet

- MLX90316 Datasheet Melexis PDFDocument48 pagesMLX90316 Datasheet Melexis PDFHussain Amir AliNo ratings yet

- Atmega 32 Musical FuntainDocument7 pagesAtmega 32 Musical FuntainPrashant KumarNo ratings yet

- Diac and Triac ExperimentsDocument10 pagesDiac and Triac ExperimentsAbhishekNo ratings yet

- Open Source Lora Wifi Gateway: OverviewDocument3 pagesOpen Source Lora Wifi Gateway: OverviewilyesNo ratings yet

- One PN Junction 2. Two PN Junctions 3. Three PN Junctions 4. Four PN JunctionsDocument17 pagesOne PN Junction 2. Two PN Junctions 3. Three PN Junctions 4. Four PN JunctionsPiyush sharmaNo ratings yet

- GE Active HarmonicDocument6 pagesGE Active HarmonicOliver HermosaNo ratings yet

- MS-AA71, AP2011 IT-CE Test Report-1000810Document135 pagesMS-AA71, AP2011 IT-CE Test Report-1000810wilmer ramosNo ratings yet

- VLSI Design: Dr. K. Srinivasa RaoDocument39 pagesVLSI Design: Dr. K. Srinivasa Raoshen shahNo ratings yet

- SMX 0602 0100 G4K User Installation Guide PDFDocument300 pagesSMX 0602 0100 G4K User Installation Guide PDFEligius MartinezNo ratings yet

- Gate-Solved-Question-Papers-For-Electronics & Communication Engineering PDFDocument112 pagesGate-Solved-Question-Papers-For-Electronics & Communication Engineering PDFRoshan SoniNo ratings yet

- WeidCat11 - Circuit-SurgeProtection 2016 - v3Document190 pagesWeidCat11 - Circuit-SurgeProtection 2016 - v3Roger MantillaNo ratings yet

- A Reference Design For Weigh Scales PDFDocument6 pagesA Reference Design For Weigh Scales PDFAntoni1968No ratings yet

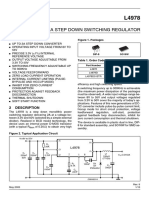

- Datasheet L4978D REGULADOR 16 PINESDocument13 pagesDatasheet L4978D REGULADOR 16 PINESpabloNo ratings yet

- A 6 TestverslagenDocument6 pagesA 6 TestverslagenAnonymous vQewJPfVXaNo ratings yet

- Single Phase Half Bridge InverterDocument29 pagesSingle Phase Half Bridge InverterGnanaseharan Arunachalam100% (1)

- Trellis Coded ModulationDocument29 pagesTrellis Coded ModulationYashwardhan SinghNo ratings yet

- M 136Document6 pagesM 136vinoth kumarNo ratings yet

- 3GPP TS 36.321: Technical SpecificationDocument47 pages3GPP TS 36.321: Technical Specificationshyam_utdNo ratings yet

- Sharp 25ub1 - 25uf1Document11 pagesSharp 25ub1 - 25uf1winda rinaNo ratings yet

- Ais Seatex 100Document113 pagesAis Seatex 100Parul MehtaNo ratings yet

- Manual DAP-2360Document3 pagesManual DAP-2360Jaime García GarcíaNo ratings yet

- MBE ReportDocument25 pagesMBE ReportasreemadhuriNo ratings yet