Professional Documents

Culture Documents

Effects of environmental factors on maxillofacial elastomers

Uploaded by

palliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effects of environmental factors on maxillofacial elastomers

Uploaded by

palliCopyright:

Available Formats

Effects of environmental factors on maxillofacial elastomers:

Part -Literature review

Carl J. Andres, DDS, FvISD,~ Steven P. Haug, DDS,b

Garbs A. Munoz, DDS, MSD,e and Guillermo Bernal, DDSd

Indiana University, School of Dentistry, Indianapolis, Ind.

Part I of a four-part report presents a comprehensive review of the literature

pertaining to physical property testing of materials for facial and somatoprosthe-

ses. The report was conducted in preparation for testing four current maxillofacial

elastomers: MDX 4-4210, Silastic 4-4515, Medical Adhesive type A, and Epithane-3,

and two recently introdu’ced materials: Silicone A-2186 and Silicone A-102.

(J PEOSTHET DENT 1992;68:327-30.)

T he search for an ideal material for prosthetic re- In 1969, Cantor et a1.12 stated that “advances in facial

habilitation of patients with disfigured or missing facial or prostheses have paralleled deveIopment of an art form-

body features has continued from the beginnings of re- there is no scientific basis or reproducible objective method

corded history. Earliest forms of facial prostheses were for evaluation of materials used.” They studied methods of

constructed of wood, ivory, waxes, and meta1s.l In 1945, predictably and objectively measuring color analysis, du-

Clarke2 described techniques for fabricating prostheses rability, and dimensional stability of three elastomers, thus

from latex rubber, glycerin-gelatin formulations, and elec- beginning the establishment of testing criteria for maxillo-

troplated metals. facial materials. Their efforts were expanded by Sweeney

Modern materials for external. prostheses include vinyl et a1.6 in 1972, whose objectives were “to develop a series

plastisols, poly(methy1 methacrylate), polyurethanes, la- of evaluations to measure properties needed and defined in

tex, and silicone polymers. Silicone elastomers were first scientific terms so that the weakest properties can be im-

used for external prostheses by Barnhart in 1960 and have proved in the future.” As a result of their research, a pro-

since become the material of choice because of their ehem- posal was made for a tentative table of specifications for

ical inertness, strength, durability, and ease of manipula- properties of maxillofacial elastomers. This study was the

tion. Bulbulian4 tabulated and rated the essential qualities first to measure aging of materials in an artificial weather-

of materials used for facial prostheses in 1945 and further ing environment.

elaborated on these ratings in 1946.j Subsequently, many In 1974, Lontz, Schweiger, and Burger13 used the tensile

authors6-1’ have reviewed the qualities of an ideal material modulus of maxillofacial materials to match the elastomers

for facial prostheses. Lewis et a1.8 classified three categories to various tissues of the body, such as aorta, tendon, and

of ideal properties of these materials: (1) processing char- muscle fibers.

acteristics that include low viscosity, extended working In 1975, Koran and CraigI pubiished the first of a series

time, capability of intrinsic and extrinsic coloration, low of research reports evaluating currently used maxillofacial

processing temperature, and ease of molding using reusable materials. They stated that “maxillofacial materials have

molds; (2) mechanical or performance characteristics such been neglected in research investigations of dental materi-

as high tensile strength, high percent elongation, elastic als. As a result of the limited market for these products,

modulus, high tear strength, sufficient hardness, dimen- manufacturers have only a nominal interest in their pro-

sional stability, proper surface tension, coefficient of fric- duction and marketing.” This study investigated the “dy-

tion, and resistance to chemicals and ultraviolet light; and namic” properties of selected silicone elastomers, plasti-

(3) patient accommodation properties that guarantee a cized polyvinyl chloride, and polyurethane, at tempera-

product that is nontoxic, nonallergenic, noncarcinogenic, tures ranging from -15’ to 37’ C, and added another

easily cleansable, lightweight, compatible with adhesives, dimension to the scientific evaluation of maxiliofacial ma-

and that has a reasonable cost. terials.

In 1976, Firtell, Donneau, and Anderson15 introduced

the concept of combining materials to achieve improved

Presented in part before the Annual Session of the Academy of properties by mixing conventional room temperature-vul-

Prosthodontics, Palm Springs, Calif. canized (RTV) silicone with RTV silicone foam to produce

“Associate Professor and Director, Graduate Prosthodontics. a lighter weight prosthesis. However, the strength of the

hAssistant Professor, Department of Prosthodontics.

“Associate Professor, Department of Prosthodontics. elastomer decreased along with the decreased weight.

dGraduate Student, Department of Prosthodontics. In 1978, Gonzales et a1.16z17 and Goldberg et aLI inde-

10/l/37924 pendently tested polyurethane elastomers with physical

THE JOURNAL OF PROSTHETIC DENTISTRY 327

ANDRES ET AL

properties that were modifiable by varying the amounts of 14.24% after 900 hours in the weatherometer. Polyure-

the components of the three-part system. The investigators thane had good dimensional stability before aging (0.36% ),

concluded that the physical properties could be altered by but disintegrated after 600 hours of aging in the weather-

modifying the ratio of components and that the physical ometer.

properties conformed to the table of specifications origi- Yu, Koran, and CraigZ3 proceeded to evaluate the phys-

nally proposed by Sweeney et al6 ical properties of PVC, polyurethane, three RTV silicones

In 1977, Moore et al9 conducted a survey of 75 compa- (Silastic 382, Silastic 399, and MDX 4-4210), and one HTV

nies and institutions known to be involved in polymer silicone (Silastic 4-4515; Dow Corning, Midland, Mich.)

chemistry in an attempt to uncover potential new materi- before and after accelerated aging. Ultimate tensile

als for facial prostheses. Less than half of those queried re- strength, percent elongation, shear strength, tear energy,

sponded, and only one company had products considered and Shore A hardness were measured. After 600 hours of

worthy of evaluation. Materials tested were MDX 4-4210 accelerated aging, the polyurethane elastomer was severely

elastomer (Dow Corning, Midland, Mich.), unmodified and degraded. The properties of the remaining materials were

thinned with 360 medical fluid, and Silastic 382 medical not greatly affected by 900 hours of accelerated aging. PVC

grade elastomer (Dow Corning). This study introduced the exhibited the largest change, with a decrease of 17% in

“‘O-ring” specimen for tensile stress-strain testing. Previ- shear strength. Silastic 4-4515 exhibited the best overall

ous testing had been conducted on specimens die cut from stability. When considering ease of manipulation and

sheets of polymer, which produced small nicks or flaws in processing, MDX 4-4210 was considered the best choice

the edges of the specimens, resulting in crack propagation among the products tested. Yu, Koran, and Craigz4 then

and premature specimen failure. The O-ring specimens did repeated the testing of MDX 4-4210 incorporating 11

not require the use of special clamps or end-bonded grips maxillofacial pigments. Their results indicated that addi-

that further complicated the testing process. Instead, the tion of pigments can vary physical and mechanical proper-

specimens were stretched between two freely rotating Tef- ties, but the changes observed were not large enough to

lon pulleys mounted on axles that inserted into the grips of compromise the clinical use of the material. The prepared

the tensile testing machine. samples showed little or no change in physical and me-

Craig et al.lg tested the color stability of nonpigmented chanical properties after 900 hours of accelerated aging in

polyvinyl chloride (PVC), polyurethane, and four silicone the weatberometer.

elastomers including MDX 4-4210 and MDX 4-4515 after In 1980, Wiensz5 compared accelerated aging in the

aging in a weatherometer. PVC tended to lighten in color weatherometer with outdoor aging in R.ochester, Minne-

after 100 hours. The polyurethane material was severely sota. Measurements of Shore A hardness, axial stiffness,

degraded after 300 hours. All silicone materials were color- elastic modulus, strain energy, and apparent tensile

stable, with MDX 4-4210 exhibiting the best overall prop- strength were made at 0,500,1000, and 1500 hours for ac-

erties. Koran et al.“* repeated the testing of MDX 4-4210 celerated aging and at 0,3,6,9, and 12 months for control

using 11 different maxillofacial pigments and measured and outdoor aging. Two polyurethane elastomers, Calthane

luminous reflectance, contrast ratio, dominant wavelength, and Epithane-3 (Dare Products, Inc., Butler, Wise.), were

and excitation purity. Very small changes were docu- tested along with one silicone elastomer, MDX 4-4210.

mented. They concluded that the data did not correspond Calthane specimens were severely affected by both aging

with the clinical observations of large color changes over methods. Epithane-3 specimens were disintegrated at 1500

time with the prostheses in use. Further studies were con- hours of accelerated aging. Minimal changes in dimension,

ducted on nonpigmented and pigmented materials by the color, and Shore A hardness were observed for MDX

same authorszl to determine resistance to external staining 4-4‘210. In general, accelerated weathering appeared to al-

with tea, lipstick, and disclosing solution. Materials tested ter the physical and mechanical properties sooner and with

included two RTV silicones, MDX 4-4210 and Silastic 382; greater magnitude than outdoor weathering. For some

one high temperature-vulcanized (HTV) silicone, 4-4515; properties, 1500 hours of accelerated weathering produced

and a PVC material. Tea produced the least color change; effects similar to those of 12 months of outdoor weathering

lipstick and disclosing solution produced the greatest in Rochester, Minn.

change. MDX 4-4210 was the most resistant to tea and dis- Lewis and CastleberrylO published a review of their ma-

closing solution, but showed. the greatest color change from terials research and tabulated processing characteristics

lipstick. PVC was the least resistant to staining, while all and performance characteristics of an “ideal material.”

silicones displayed good stain resistance. Craig, Koran, and Yu’r reviewed the development of max-

Yu and Korar? studied permanent deformation of four illofacial materials in the 70s concluding that based on ex-

silicone materials, PVC, and polyurethane before and after isting knowledge, RTV silicone polymers of the addition

accelerated aging. All silicones displayed excellent dimen- type (MDX 4-4210) offer optimum overall properties for

sional stability before and after aging, with permanent de- maxillofacial application.

formations ranging from 0.22 % to 0.26 % , PVC exhibited In 1982, Udagama and Drane26 introduced a new silicone

a permanent deformation of 13.80% before aging and elastomer-methyl triacetoxy silane cross-linked silicone

328 AUGUST 1992 VOLUME 68 NUMBER 2

PROPERTIES OF MAXILLOFACIAL ELASTOMERS: I

(Medical Adhesive type A, or Dow Corning A-891). No of MDX 4-4210 base material mixed with Medical Adhe-

physical property testing was reported. sive type A material in an attempt to produce a softer, more

In 1984, Abdelnnabi et alz7 compared a new material, pliable material. The technique was first applied by

polydimethyl siloxane, with M:DX 4-4210. Polydimethyl Udagama.34 Physical properties were tested before and af-

siloxane showed significant differences in tensile strength, ter accelerated aging. Hardness decreased proportionally

tensile modulus, tear resistance, hardness, and percent with the increase of MDX 4-4210. Tear strength was

elongation over MDX 4-4210 , but the authors concluded increased for the lowest ratio (80/20) and decreased pro-

that MDX 4-4210 remained the material of choice because portionally as MDX 4-4210 increased. Maximum elonga-

of ease of manipulation plus the ability to modify consis- tion nearly doubled from the 100 % type A to the 60140 and

tency by the addition of silicone fluid. 50/50 ratios.

Turner et a12* evaluated a new isophorone polyurethane In 1987, Udagama34 presented a technique for bonding

material, comparing properties elf a commercially available a thin, prefabricated polyurethane film to silicone pros-

polyurethane, Epithane-3, and MDX 4-4210 before and theses to increase tear resistance and adhesive compatibil-

after accelerated aging. Results indicated that the isopho- ity. Various lining materials were tested, including ethyl

rone polyurethane was superior in some respects to MDX methacrylate, polyvinyl buteral, methyl methacrylate, and

4-4210 . Epithane-3 polyurethane disintegrated after 700 polyvinyl acetate. Polyurethane was selected as the mate-

hours in the weatherometer. Color stability of this new rial of choice because of its transparency, high tear resis

material was reported in part II of their study.2g Four color tance, moldability, and compatibility with water base skin

systems were evaluated: artist’s oil pigments, dry earth adhesives.

pigments, kaolin modified with dry earth pigments, and This literature review indicates that materials presently

Daro skin pigments (produced for use with Epithane-3.) used for maxillofacial prosthetics are improved and ade-

Isophorone polyurethane with no color added served as the quate but not ideal. If a material has adequate strength and

control. Visual and spectophotometric observations re- durability, it frequently is too hard or lacking in process-

vealed no statistically significant differences for any of the ing characteristics. Attempts to modify materials to im-

color systems before or after aging. The Daro color system prove an undesirable characteristic have resulted in a de-

caused a decrease in tear strength after aging. crease of desirable properties. Therefore it appears the

Wolfaardt, Chandler, and Smith30 compared the physi- single “ideal” facial prosthetic material is not available.

cal properties of a new silicone material developed specif- Research trends toward development of a composite pros-

ically for facial prostheses by the Institute of Maxillofacial thesis constructed of two or more materials laminated and

Technology in London, England. The properties of the new bonded together, each having its own “ideal” characteris-

material, Cosmesil (Cosmedica, Uwist, Cardiff, Wales, tics, must continue.

U.K.), were compared with Silastic 382 and MDX 4-4210 This project was designed to evaluate physical properties

and with a third silicone elastomer marketed under the of maxillofacial materials currently in use, including MDX

trade name Silskin (Thackray, Leeds, England). Cosmesil 4-4210, Medical Adhesive type A material, Silastic 4-4515,

was designed to be processed with varying degrees of hard- Epithane-3, and two recently introduced materials, A-

ness and was tested in the hardest and softest consistencies. 2186 and A-102 (Factor II Products, Lakeside, Ariz.). The

The Cosmesil materials were superior to other materials in study was designed to produce baseline data for future devel-

all properties tested. opment of a composite or laminated facial prosthesis

Kouyoumdjian et al.sl evaluated mechanical properties technique.

of MDX 4-4210 before and after modification by the addi- Part I of this article has presented a review of the

tion of 360 medical fluid. Five percent, 10%) and 15% by literature pertinent to property testing of maxillofacial

weight were added to the base material. Tensile strength, materials. Part II will present the results of an interna-

ultimate elongation, tear resistance, and hardness were tional survey of prosthodontists and prosthetists soliciting

decreased in a linear fashion as the amount of additive was information relating to the material(s) of choice, advan-

increased. tages and disadvantages of the selected material(s),

Bell, Chalian, and Moore32 evaluated four experimental methods of coloring prostheses, and properties of an

RTV silicone elastomers, comparing their physical proper- “ideal” material. Part III will present the results of phys-

ties with those of an HTV silicone (Silastic 4-4515) and ical property testing of four current materials, Silastic

with previous similar test results of MDX 4-4210 and Si- 4-4210, Silastic 4-4515, Medical Adhesive type A material

lastic 4-4514. Tensile strength, tear strength, and percent [A891], and Epithane-3, and two recently introduced ma-

elongation of the new materials were superior to previous terials, A-2186 and A102. Properties tested include tensile

test results for MDX 4-4210 and 4-4514. The new materi- strength, percent elongation, tear strength, and Shore A

als were harder than previously tested materials. hardness.

In 1987, research turned to modification of existing ma- Parts III and IV will provide data indicating the effects

terials or fabrication of composite materials to achieve of seven environmental variables: passage of time, natural

more ideal properties. Farah et al. 33 tested various ratios weathering, two types of adhesives, two types of cleaning

THE JOURNAL OF PROSTHETIC DENTISTRY 329

solvents, and cosmetics (cold cream) on the materials 18. Goldberg AJ, Craig RG, Filisko FE. Polyurethane elastomers as max-

illofacial prosthetic materials. J Dent Res 197&57:563-g.

tested.

19. Craig RG, Koran A, Yu R, Spencer J. Color stability of elastomers for

Part IV will present the results of optical property test- maxillofacial appliances. J Dent Res 1978;57:866-71.

ing, including color change in nonpigmented materials and 20. Koran A, Yu R, Powers JM, Craig RG. Color stability of a pigmented

elastomer for maxillofacial appliances. J Dent Res 1979;58:1450-4.

optical density. 21. Koran A, Powers JM, Lepeak PJ, Craig RG. Stain resistance of maxil-

lofacial materials. J Dent Res 1979;58:1455-60.

REFERENCES 22. Yu R, Koran A. Dimensional stability of elastomers for maxillofacial

1. Phillips RW, Margetis PM, Urban JJ, Leonard F. Materials for the appliances. J Dent Res 1979;58:1908-9.

23. Yu R, Koran A, Craig RG. Physical properties of maxillofacial elas-

fabrication of maxillofacial prosthesis. In: Chalian VA, Drane JB,

tomers under conditions of accelerated aging. J Dent Res 1980;59:1041-7.

Standish SM, eds. Maxillofacial prosthetics: Multidisciplinary practice.

24. Yu R, Koran A, Craig RG. Physical properties of a pigmented silicone

Baltimore: The Williams & Wilkins Co, 1971:89-107.

maxillofacial material as a function of accelerated aging. J Dent Res

2. Clarke CD. Facial and body prosthesis. St. Louis: C.V. Mosby, 194513.

1980;59:1141-8.

31.

25. Wiens JP. A comparative study of selected elastomers subjected to ac-

3. Barnhart GW. A new material and technic in the art of somato prosthe-

celerated and outdoor weathering. Thesis. University of Minnesota,

sis. J Dent Res 1960;39:836-44.

1980:1-183.

4. Bulbulian AH. Facial prostheses. Philadelphia: W. B. Saunders Co.,

26. Udagama A, Drane JB. Use of a medical grade methyltriacetoxy silane

194527.

cross-linedsiliconeforfacialprostheses. JPROSTHETDENT 1982;48:86-8.

5. Bulhulian AH. Problems of facial prosthesis. Surg Clin North Am

27. Abdelnnahi MM, Moore DJ, Sakamura JS. In vitro comparison study

1946;26:846-58.

of MDX 4-4210 and polydimethyl siloxane silicone materials. J PROS-

6. Sweeney AB, Fischer TE, Castleberry DJ, Cowperthwaite GF. Evalu-

THET DENT 1984;51:523-6.

ation of improved maxillofacial prosthetic materials. J PROSTHET DENT

28. Turner GE, Fischer TE, Castleberry DJ, Lemons JE. Intrinsic color of

1972;27:297-305.

isophorone polyurethane for maxillofacial prosthetics. Part I. Physical

7. Schaaf NG. Materials in maxillofacial prosthetics. Dent Clin North Am

properties. J PROSTHET DENT 1984;51:519-22.

19’75;19:347-56.

29. Turner GE, et al. Intrinsic color of isophorone polyurethane for max-

8. Lewis DH, Cowper DR, Castleberry DJ, Fischer TE. New and improved

illofacial prosthetics. Part II. Color stability. J PROSTHET DENT

elastomers for extraoral maxillofacial prostheses [Abstract]. J Dent Res

1984;51:673-5.

1977;56(Special Issue A):l74.

30. Wolfaardt JF, Chandler HD, Smith BA. Mechanical properties of a new

9. Moore DJ, Glaser ZR, Tabacco MJ, Linebaugh MGJ. Evaluation of

facial prosthetic material. J PRO~THET DENT 1985;53:228-34.

polymeric materials for maxillofacial prosthetics. J PROSTHET DENT

31. Kouyoumdjian J, Chalian VA, Moore BK. A comparison of the physical

1977;38:319-26.

properties of a room temperature vulcanizing silicone modified and un-

10. Lewis DH, Castleberry DJ. An assessment of recent advances in max-

modified. J PROSTHET DENT 1985;53:388-91.

illofacial prosthetic materials. J PROSTHET DENT 1980;43:426-32.

32. Bell WT, Chalian VA, Moore BK. Polydimethyl siloxane materials in

11. Craig RG, Koran A, Yu R. Elastomers for maxillofacial application. Bi-

maxillofacial prosthetics: evaluation and comparison of physical prop-

omaterials 1980;1:112-7.

erties. J PROSTHET DENT 1985;54:404-10.

12. Cantor R, Webber RL, Stroud L, Ryge G. Methods for evaluating pros-

33. Farah JW, Robinson JC, Koran A, Craig RG, Hood JAA. Properties of

thetic facial materials. J PROSTHET DENT 1969;23:324-32.

a modified cross-linked silicone for maxillofacial prostheses. J Oral Re-

13. Lontz JF, Schweiger JW, Burger AW. Modifying stress strain profiles

habil 1987;14:599-605.

of polysiloxane elastomers for improved maxillofacial conformity [Ab-

34. Udagama A. Urethane lined silicone facial prostheses. J PROSTHET

stract]. J Dent Res 1974;(Special issue):53.

DENT 1987;58:351-4.

14. Koran A, Craig RG. Dynamic mechanical properties of maxillofacial

materials. J Dent Res 1975;54:216-21.

15. Firtell DN, Donneau ML, Anderson CR. Lightweight RTV silicone for Reprint requests to:

maxillofacial prostheses. J PROSTHET DENT 1976;36:544-9. DR. CARL J. AN~RES

16. Gonzales JB. Polyurethane elastomers for facial prosthesis. J PROSTHET DEPARTMENT OF PROSTHODONTICS

DENT 1978;39:179-87. INDIANA UNIVERSITY SCHOOL OF DENTISTRY

17. Gonzales JB, Chao EYS, An Kai-Nan. On physical and mechanical be- 1121 WEST MICHIGAN ST.

havior of polyurethane formulations used for facial prostheses. J PROS- INDIANAPOLIS, IN 46202

THET DENT 1978;39:307-18.

330 AUGUST 1992 VOLUME 68 NUMBER 2

You might also like

- Yu 1980Document7 pagesYu 1980kiran suzNo ratings yet

- How Environmental Factors Impact Maxillofacial Elastomer PropertiesDocument8 pagesHow Environmental Factors Impact Maxillofacial Elastomer PropertiespalliNo ratings yet

- Custom Impression Trays: Part I-Mechanical Properties: IjniDocument4 pagesCustom Impression Trays: Part I-Mechanical Properties: IjniaabdoNo ratings yet

- Ojsadmin, 51ftgDocument6 pagesOjsadmin, 51ftgRIONo ratings yet

- Dynamic Mechanical Properties: of Maxillofacial MaterialsDocument6 pagesDynamic Mechanical Properties: of Maxillofacial MaterialsNirav RathodNo ratings yet

- Comparison of Physical and Mechanical PropertiesDocument8 pagesComparison of Physical and Mechanical PropertiesSorour 2No ratings yet

- ASTM D415 Journal Proof Gunay2008Document5 pagesASTM D415 Journal Proof Gunay2008Abinash PurushothamanNo ratings yet

- Wear Resistance of Four Types of Vacuum-Formed Retainer Materials - A Laboratory StudyDocument9 pagesWear Resistance of Four Types of Vacuum-Formed Retainer Materials - A Laboratory StudysintaNo ratings yet

- Evaluation of Plasticity and Radiopacity of Elastic Separators by Means of Traction Tests and RadiographyDocument10 pagesEvaluation of Plasticity and Radiopacity of Elastic Separators by Means of Traction Tests and RadiographyYun AkbarNo ratings yet

- جديدDocument7 pagesجديدمأب فارس ذنون فارسNo ratings yet

- Comparative Evaluation of Flexural Strength of ProDocument6 pagesComparative Evaluation of Flexural Strength of Proامير اللياليNo ratings yet

- Nanocomposite Compresssive and FlexuralDocument5 pagesNanocomposite Compresssive and FlexuralRITIK sharmaNo ratings yet

- Evaluation of Peel Bond Strength Between Self Cure Acrylic Resin Material and Two Different Commercially Avaliable Maxillofacial Silicone Material Using A Primer - An in Vitro StudyDocument11 pagesEvaluation of Peel Bond Strength Between Self Cure Acrylic Resin Material and Two Different Commercially Avaliable Maxillofacial Silicone Material Using A Primer - An in Vitro StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Bioceramic Materials in Endodontics PDFDocument28 pagesBioceramic Materials in Endodontics PDFPoy ParinphornNo ratings yet

- Ben Ammar 2014Document12 pagesBen Ammar 2014Anand NagarajanNo ratings yet

- Clinical Performance of Various Resilient LinersDocument4 pagesClinical Performance of Various Resilient LinersHoshang AbdelrahmanNo ratings yet

- Review On Metal Matrix Composites For Marine Applications: SciencedirectDocument8 pagesReview On Metal Matrix Composites For Marine Applications: SciencedirectDavid MejiaNo ratings yet

- Force Extension Relaxation of Medium Force Orthodontic Latex ElasticsDocument8 pagesForce Extension Relaxation of Medium Force Orthodontic Latex ElasticsRocio RiosNo ratings yet

- Efeito Da Temp AramidaDocument13 pagesEfeito Da Temp Aramidapinto.carolina2015No ratings yet

- Flexural Strength of Heat Polymerized PoDocument4 pagesFlexural Strength of Heat Polymerized PoMorteza AtaeiNo ratings yet

- Fabbri 2014Document14 pagesFabbri 2014José Carlos Herrera IbarraNo ratings yet

- Materiales - Bioceramicos - Endo With Cover Page v2Document29 pagesMateriales - Bioceramicos - Endo With Cover Page v2ftorrefNo ratings yet

- International Journal of Fatigue: M. Abo-Elkhier, A.A. Hamada, A. Bahei El-DeenDocument8 pagesInternational Journal of Fatigue: M. Abo-Elkhier, A.A. Hamada, A. Bahei El-DeenHernando ZambranoNo ratings yet

- Content ServerDocument6 pagesContent ServerAndrea Castro BarahonaNo ratings yet

- QWQDocument6 pagesQWQLeila MoghadasNo ratings yet

- Mechanical Properties of Flax Fiber Reinforced Composites Manufactured Using Hand Layup and Compression Molding-A ComparisonDocument9 pagesMechanical Properties of Flax Fiber Reinforced Composites Manufactured Using Hand Layup and Compression Molding-A ComparisonsriyajambukarNo ratings yet

- Literature ReviewDocument10 pagesLiterature ReviewsithananthansithuNo ratings yet

- Effects of Thermoforming On The Physical and Mechanical Properties of Thermoplastic Materials For Transparent Orthodontic AlignersDocument11 pagesEffects of Thermoforming On The Physical and Mechanical Properties of Thermoplastic Materials For Transparent Orthodontic AlignersLady SolarteNo ratings yet

- Nanohybrid Versus Nano LL Composite in Class I CavitiesDocument5 pagesNanohybrid Versus Nano LL Composite in Class I CavitiessonygabrielNo ratings yet

- Sudarisman FullDocument329 pagesSudarisman FullOlawale John AdeotiNo ratings yet

- Jod 10 548Document7 pagesJod 10 548bharath m c gowdaNo ratings yet

- Duffy 1989Document12 pagesDuffy 1989Mariana CatiniNo ratings yet

- Douglas Terry Flowable CompositeDocument17 pagesDouglas Terry Flowable CompositeToDownload81100% (2)

- Bond Strength of A New Generation of Universal Bonding Systems To Zirconia CeramicDocument7 pagesBond Strength of A New Generation of Universal Bonding Systems To Zirconia Ceramicgerson fabian arangoNo ratings yet

- Self-Healing Epoxy Composites: Preparation, Characterization and Healing PerformanceDocument11 pagesSelf-Healing Epoxy Composites: Preparation, Characterization and Healing PerformanceSatya AsatyaNo ratings yet

- Chemical Elements Characterization of Root Canal Sealers Using Sem and Energy Dispersive Xray Analysis 2247 2452.1000538Document9 pagesChemical Elements Characterization of Root Canal Sealers Using Sem and Energy Dispersive Xray Analysis 2247 2452.1000538TalalKhanNo ratings yet

- Simulation-1251112-Attached File-82356777Document10 pagesSimulation-1251112-Attached File-82356777alfredolfosterNo ratings yet

- Natural Fiber Composite Design and Characterization For Limit Stress Prediction in Multiaxial Stress StateDocument14 pagesNatural Fiber Composite Design and Characterization For Limit Stress Prediction in Multiaxial Stress StatevikirhythmNo ratings yet

- Reference For SEM For SP FiberDocument20 pagesReference For SEM For SP FiberShervin Jose SebastianNo ratings yet

- Filtek P60: Posterior Restorative SystemDocument36 pagesFiltek P60: Posterior Restorative SystemPutri MortezaNo ratings yet

- Dimensional Stability of Irreversible Hydrocolloid Impression Materials As A Function of Pouring Time: A Systematic ReviewDocument8 pagesDimensional Stability of Irreversible Hydrocolloid Impression Materials As A Function of Pouring Time: A Systematic ReviewAndi Sindy Windiya OkNo ratings yet

- EntureDocument4 pagesEntureRIONo ratings yet

- Failure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreDocument8 pagesFailure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreGerardo XZNo ratings yet

- Skin Surface Model Material As A Substrate For Adhesion To Skin TestingDocument17 pagesSkin Surface Model Material As A Substrate For Adhesion To Skin TestingAnakyn JaegerNo ratings yet

- Estimation of The Tensile Bond Strength of AcrylicDocument4 pagesEstimation of The Tensile Bond Strength of AcrylicHoshang AbdelrahmanNo ratings yet

- EFFECT OF EXTRAORAL AGING CONDITIONS ON MECHANICAL PROPERTIES OF FACIAL SILICONE ELASTOMER REINFORCED WITH TITANIUM-OXIDE NANOPARTICLES (IN VITRO STUDY)Document8 pagesEFFECT OF EXTRAORAL AGING CONDITIONS ON MECHANICAL PROPERTIES OF FACIAL SILICONE ELASTOMER REINFORCED WITH TITANIUM-OXIDE NANOPARTICLES (IN VITRO STUDY)dwlat.mostafaNo ratings yet

- Comparison of 4 Brands of Elastomeric Chains Based On Time Dependent Force DecayDocument12 pagesComparison of 4 Brands of Elastomeric Chains Based On Time Dependent Force DecayIOSRjournalNo ratings yet

- A Randomized Controlled Evaluation of Posterior Resin Restorations of An Altered Resin Modified Glass-Ionomer Cement With Claimed BioactivityDocument9 pagesA Randomized Controlled Evaluation of Posterior Resin Restorations of An Altered Resin Modified Glass-Ionomer Cement With Claimed BioactivityPRADNJA SURYA PARAMITHANo ratings yet

- J2017 ICNF3 Aitor ProcediaDocument10 pagesJ2017 ICNF3 Aitor ProcediaPhan DuyNo ratings yet

- Article Publication ART20181751Document5 pagesArticle Publication ART20181751Satya AsatyaNo ratings yet

- Oushabi 2017 (Alakli Treatment)Document8 pagesOushabi 2017 (Alakli Treatment)Miguel Angel Ramos RuizNo ratings yet

- Composite Materials For Railway SleeperDocument20 pagesComposite Materials For Railway SleeperPratik Pattanaik100% (1)

- Semnas, Journal Manager, BK1 A DR Shukur KeynoteDocument7 pagesSemnas, Journal Manager, BK1 A DR Shukur KeynoteIndra JayaNo ratings yet

- Natural Fibre Composites-A Review: IOP Conference Series: Materials Science and EngineeringDocument7 pagesNatural Fibre Composites-A Review: IOP Conference Series: Materials Science and EngineeringmichealNo ratings yet

- Determination of Elastic Modulus of Gelatin Gels BDocument11 pagesDetermination of Elastic Modulus of Gelatin Gels Bahmad aboudNo ratings yet

- Keywords:, Sisal Fiber, Dyneema Fiber, Epoxy, Mechanical Properties, Structural AnalysisDocument3 pagesKeywords:, Sisal Fiber, Dyneema Fiber, Epoxy, Mechanical Properties, Structural AnalysisKiran Kumar BollamNo ratings yet

- Sasaki2016 Effect of Long-term Water Immersion or Thermal Shock on Mechanical PropertiesDocument6 pagesSasaki2016 Effect of Long-term Water Immersion or Thermal Shock on Mechanical Propertiesnafsiyah xyzNo ratings yet

- 1 C PDFDocument9 pages1 C PDFSaad LiaqatNo ratings yet

- Filler Dental ResinDocument10 pagesFiller Dental Resinmflorian69No ratings yet

- Skin Complexion and Pigmentary Disorders in Facial Skin of 1204 Women in 4 Indian CitiesDocument8 pagesSkin Complexion and Pigmentary Disorders in Facial Skin of 1204 Women in 4 Indian CitiespalliNo ratings yet

- Lemon1995 PDFDocument6 pagesLemon1995 PDFpalliNo ratings yet

- Effect of Different Disinfecting Procedures On The Hardness and Color Stability of Two Maxillofacial Elastomers Over TimeDocument6 pagesEffect of Different Disinfecting Procedures On The Hardness and Color Stability of Two Maxillofacial Elastomers Over TimepalliNo ratings yet

- Haug1992 PDFDocument4 pagesHaug1992 PDFpalliNo ratings yet

- Effect of Aging on Color Stability of Silicone Elastomer ProsthesesDocument8 pagesEffect of Aging on Color Stability of Silicone Elastomer ProsthesespalliNo ratings yet

- Pigments and Their Application in Maxillofacial Elastomers: A Literature ReviewDocument5 pagesPigments and Their Application in Maxillofacial Elastomers: A Literature ReviewpalliNo ratings yet

- S of Environmental Factors On Maxillofacial Elastomers: Part II-Report of SurveyDocument4 pagesS of Environmental Factors On Maxillofacial Elastomers: Part II-Report of SurveypalliNo ratings yet

- Effect of Disinfection and Aging on Maxillofacial Silicone ColorDocument4 pagesEffect of Disinfection and Aging on Maxillofacial Silicone ColorpalliNo ratings yet

- A study on reproducing silicone shade guide for maxillofacial prostheses matching Indian skin colorDocument5 pagesA study on reproducing silicone shade guide for maxillofacial prostheses matching Indian skin colorpalliNo ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To InformationpalliNo ratings yet

- The Colour of Human Skin: Abstract. (1) From Spectral Reflectance Curves of 631 Individuals of Three Ethnic GroupsDocument8 pagesThe Colour of Human Skin: Abstract. (1) From Spectral Reflectance Curves of 631 Individuals of Three Ethnic GroupspalliNo ratings yet

- Effect of Denture Cleansers and Accelerated Aging On The Color Stability of Maxillofacial Silicone: An in Vitro StudyDocument5 pagesEffect of Denture Cleansers and Accelerated Aging On The Color Stability of Maxillofacial Silicone: An in Vitro StudypalliNo ratings yet

- Defining and Communicating Color PDFDocument8 pagesDefining and Communicating Color PDFpalliNo ratings yet

- Skin Color Measurements in Terms of CIELAB Color Space ValuesDocument6 pagesSkin Color Measurements in Terms of CIELAB Color Space ValuespalliNo ratings yet

- Indian Journal of Dermatology, Venereology ADocument7 pagesIndian Journal of Dermatology, Venereology ApalliNo ratings yet

- Lyetal Del Bino JID2020 RTMSCutaneouscolorimetry AreliabletehcniqueforobjectiveskincolormeasurementDocument12 pagesLyetal Del Bino JID2020 RTMSCutaneouscolorimetry AreliabletehcniqueforobjectiveskincolormeasurementpalliNo ratings yet

- L. D.D.S., M.Sc. : Anatomy of Facial Expression AND Its Prosthodontic SignificanceDocument23 pagesL. D.D.S., M.Sc. : Anatomy of Facial Expression AND Its Prosthodontic SignificanceankitaNo ratings yet

- Lemon1995 PDFDocument6 pagesLemon1995 PDFpalliNo ratings yet

- Virtual Facebow Technique: DentalDocument5 pagesVirtual Facebow Technique: DentalpalliNo ratings yet

- Effect of Disinfection On Some Properties of Heat-Vulcanized Maxillofacial Silicone Elastomer Reinforced by Nano Silicone DioxideDocument6 pagesEffect of Disinfection On Some Properties of Heat-Vulcanized Maxillofacial Silicone Elastomer Reinforced by Nano Silicone DioxidepalliNo ratings yet

- A study on reproducing silicone shade guide for maxillofacial prostheses matching Indian skin colorDocument5 pagesA study on reproducing silicone shade guide for maxillofacial prostheses matching Indian skin colorpalliNo ratings yet

- Role of facial muscles in complete denturesDocument7 pagesRole of facial muscles in complete denturesPhoebe DavidNo ratings yet

- Attachment Systems For Implant Retained Overdentures: A Literature ReviewDocument11 pagesAttachment Systems For Implant Retained Overdentures: A Literature ReviewpalliNo ratings yet

- Fixed Partial Dentures: Diagnosis and Treatment Planning For Fixed ProsthodonticsDocument6 pagesFixed Partial Dentures: Diagnosis and Treatment Planning For Fixed ProsthodonticspalliNo ratings yet

- BCBR MCQs With AnswersDocument74 pagesBCBR MCQs With Answerspalli88% (52)

- A Shade Guide For Acrylic Resin Facial Prostheses: Prosthet DentDocument3 pagesA Shade Guide For Acrylic Resin Facial Prostheses: Prosthet DentpalliNo ratings yet

- An Investigation Into The Effect of Denture Adhesives On Incisal Bite Force of Complete Denture Wearers Using Pressure Transducers - A Clinical StudyDocument6 pagesAn Investigation Into The Effect of Denture Adhesives On Incisal Bite Force of Complete Denture Wearers Using Pressure Transducers - A Clinical StudypalliNo ratings yet

- Clinical Evaluation of Denture AdhesivesDocument9 pagesClinical Evaluation of Denture AdhesivespalliNo ratings yet

- Practical 5.17 Protein MaterialsDocument2 pagesPractical 5.17 Protein MaterialsdeeyamullaNo ratings yet

- Vegetarianism A Salvation Issue?Document7 pagesVegetarianism A Salvation Issue?ChetiweKapilaNo ratings yet

- ID 2019 CourseDescription MIKE21FlowModelFM HydrodynamicModellingUsingFlexibleMesh UKDocument2 pagesID 2019 CourseDescription MIKE21FlowModelFM HydrodynamicModellingUsingFlexibleMesh UKsaenuddinNo ratings yet

- Noise DetectorDocument19 pagesNoise DetectorPlaban Pratim BhuyanNo ratings yet

- Onan RV GenSet Service ManualDocument136 pagesOnan RV GenSet Service ManualAlbert A Ghazaleh100% (2)

- Pipe Material & Dimension Standard MatrixDocument2 pagesPipe Material & Dimension Standard MatrixHemantNo ratings yet

- S35MC Engine Layout and Load DiagramsDocument17 pagesS35MC Engine Layout and Load DiagramsMuhammad AlfaniNo ratings yet

- Tarbucks: Starbucks Corporation Is An International Coffee and Coffeehouse Chain BasedDocument12 pagesTarbucks: Starbucks Corporation Is An International Coffee and Coffeehouse Chain BasedVenu GopalNo ratings yet

- Etymology: StructureDocument2 pagesEtymology: StructureNaga VNo ratings yet

- A Review of Empathy Education in NursingDocument11 pagesA Review of Empathy Education in Nursinglora ardyaNo ratings yet

- There Came A Gypsy RidingDocument45 pagesThere Came A Gypsy RidingMartin McNelisNo ratings yet

- Why encouraging entrepreneurship to boost economies is flawedDocument9 pagesWhy encouraging entrepreneurship to boost economies is flawedLaureanoNo ratings yet

- Pharm.D 2nd Year SyllabusDocument21 pagesPharm.D 2nd Year Syllabus12 E 36 Yatri PatelNo ratings yet

- Research 1Document7 pagesResearch 1Rhea Mae ObligarNo ratings yet

- Viom Networks Becomes The First Indian Telecom Infrastructure Company To Receive ISO 14001 & OHSAS 18001 CertificationDocument2 pagesViom Networks Becomes The First Indian Telecom Infrastructure Company To Receive ISO 14001 & OHSAS 18001 CertificationViom NetworksNo ratings yet

- Sibling RivalryDocument2 pagesSibling Rivalrycarlokim14No ratings yet

- Practical-2 Simulation of ReactorsDocument2 pagesPractical-2 Simulation of ReactorsniralNo ratings yet

- SGLGB Form 1 Barangay ProfileDocument3 pagesSGLGB Form 1 Barangay ProfileHELEN CASIANONo ratings yet

- AA3 My Favorite City - Comparing Places Ejercicio FinalDocument6 pagesAA3 My Favorite City - Comparing Places Ejercicio FinalCesar Augusto Triana AyalaNo ratings yet

- X80 Io PDFDocument446 pagesX80 Io PDFHATEM68No ratings yet

- A Review of Drug-Induced Acute Angle Closure Glaucoma For Non-Ophthalmologists PDFDocument8 pagesA Review of Drug-Induced Acute Angle Closure Glaucoma For Non-Ophthalmologists PDFMeida Putri UtamiNo ratings yet

- Space suit essentialsDocument6 pagesSpace suit essentialsAdam PaiggeNo ratings yet

- Exercise 5 - Journalizing TransactionsDocument10 pagesExercise 5 - Journalizing TransactionsMichael DiputadoNo ratings yet

- Brachytherapy GYN Applicator CatalogDocument64 pagesBrachytherapy GYN Applicator CatalogJuan Lombardero100% (1)

- Managing Hypertension and Insomnia Through Family Nursing Care PlansDocument4 pagesManaging Hypertension and Insomnia Through Family Nursing Care PlansChristian UmosoNo ratings yet

- Create Windows XP boot CD with McAfee Command Line ScannerDocument3 pagesCreate Windows XP boot CD with McAfee Command Line ScannerSudheesh PuthusseryNo ratings yet

- Rolling Stock Design CriteriaDocument17 pagesRolling Stock Design CriteriahamzaNo ratings yet

- Sub-Zero Icing Your Testicles For Increased Male Performance - MyBioHack Unlock Your Maximus PotentialDocument7 pagesSub-Zero Icing Your Testicles For Increased Male Performance - MyBioHack Unlock Your Maximus PotentialfortnitediscordbgweeNo ratings yet

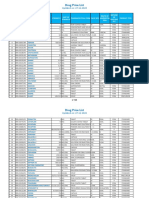

- PPR - LISTS - Registered Medicine Price List - 20221127 BahrainDocument318 pagesPPR - LISTS - Registered Medicine Price List - 20221127 BahrainvdvedNo ratings yet

- Convey 1996Document8 pagesConvey 1996Moises Tinte100% (1)

- The Age of Magical Overthinking: Notes on Modern IrrationalityFrom EverandThe Age of Magical Overthinking: Notes on Modern IrrationalityRating: 4 out of 5 stars4/5 (13)

- LIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionFrom EverandLIT: Life Ignition Tools: Use Nature's Playbook to Energize Your Brain, Spark Ideas, and Ignite ActionRating: 4 out of 5 stars4/5 (402)

- Techniques Exercises And Tricks For Memory ImprovementFrom EverandTechniques Exercises And Tricks For Memory ImprovementRating: 4.5 out of 5 stars4.5/5 (40)

- The Ritual Effect: From Habit to Ritual, Harness the Surprising Power of Everyday ActionsFrom EverandThe Ritual Effect: From Habit to Ritual, Harness the Surprising Power of Everyday ActionsRating: 3.5 out of 5 stars3.5/5 (3)

- Think This, Not That: 12 Mindshifts to Breakthrough Limiting Beliefs and Become Who You Were Born to BeFrom EverandThink This, Not That: 12 Mindshifts to Breakthrough Limiting Beliefs and Become Who You Were Born to BeNo ratings yet

- Why We Die: The New Science of Aging and the Quest for ImmortalityFrom EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityRating: 3.5 out of 5 stars3.5/5 (2)

- The Ultimate Guide To Memory Improvement TechniquesFrom EverandThe Ultimate Guide To Memory Improvement TechniquesRating: 5 out of 5 stars5/5 (34)

- Summary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedFrom EverandSummary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedRating: 5 out of 5 stars5/5 (78)

- Raising Mentally Strong Kids: How to Combine the Power of Neuroscience with Love and Logic to Grow Confident, Kind, Responsible, and Resilient Children and Young AdultsFrom EverandRaising Mentally Strong Kids: How to Combine the Power of Neuroscience with Love and Logic to Grow Confident, Kind, Responsible, and Resilient Children and Young AdultsRating: 5 out of 5 stars5/5 (1)

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 5 out of 5 stars5/5 (4)

- By the Time You Read This: The Space between Cheslie's Smile and Mental Illness—Her Story in Her Own WordsFrom EverandBy the Time You Read This: The Space between Cheslie's Smile and Mental Illness—Her Story in Her Own WordsNo ratings yet

- The Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaFrom EverandThe Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaRating: 4.5 out of 5 stars4.5/5 (266)

- Raising Good Humans: A Mindful Guide to Breaking the Cycle of Reactive Parenting and Raising Kind, Confident KidsFrom EverandRaising Good Humans: A Mindful Guide to Breaking the Cycle of Reactive Parenting and Raising Kind, Confident KidsRating: 4.5 out of 5 stars4.5/5 (169)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (33)

- Summary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisFrom EverandSummary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisRating: 4.5 out of 5 stars4.5/5 (41)

- The Happiness Trap: How to Stop Struggling and Start LivingFrom EverandThe Happiness Trap: How to Stop Struggling and Start LivingRating: 4 out of 5 stars4/5 (1)

- Outlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisFrom EverandOutlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisRating: 4 out of 5 stars4/5 (1)

- The Courage Habit: How to Accept Your Fears, Release the Past, and Live Your Courageous LifeFrom EverandThe Courage Habit: How to Accept Your Fears, Release the Past, and Live Your Courageous LifeRating: 4.5 out of 5 stars4.5/5 (253)

- Mindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessFrom EverandMindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessRating: 4.5 out of 5 stars4.5/5 (327)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 5 out of 5 stars5/5 (5)

- Summary: It Didn't Start with You: How Inherited Family Trauma Shapes Who We Are and How to End the Cycle By Mark Wolynn: Key Takeaways, Summary & AnalysisFrom EverandSummary: It Didn't Start with You: How Inherited Family Trauma Shapes Who We Are and How to End the Cycle By Mark Wolynn: Key Takeaways, Summary & AnalysisRating: 5 out of 5 stars5/5 (3)

- The Tennis Partner: A Doctor's Story of Friendship and LossFrom EverandThe Tennis Partner: A Doctor's Story of Friendship and LossRating: 4.5 out of 5 stars4.5/5 (4)