Professional Documents

Culture Documents

Lecithin Gum Rheology and Processing Implications: David Lambourne, Geoff H. Covey, Eugene Chai and David Dunstan

Uploaded by

Lukman HakimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecithin Gum Rheology and Processing Implications: David Lambourne, Geoff H. Covey, Eugene Chai and David Dunstan

Uploaded by

Lukman HakimCopyright:

Available Formats

Lecithin Gum Rheology and Processing Implications

David Lambournea, Geoff H. Coveya,*, Eugene Chaib, and David Dunstanb

a

Department of Chemical Engineering, and bCooperative Research Centre for Industrial Plant Biopolymers,

University of Melbourne, Parkville, Australia, 3052

ABSTRACT: The rheology of canola, sunflower, and soybean ditions and proceeds to derive practical engineering solutions

lecithin gum was examined by studying samples of different to processing problems.

moisture contents produced in a batch evaporator (70°C, 0.1 De-oiled lecithin, even in low concentrations in aqueous

atm). Soybean lecithin was found to have the lowest viscosity, solutions, exhibits considerable viscoelastic and non-New-

approximately 10 poise (100 s−1, 70°C), compared to canola tonian behavior (6), to a degree not normally associated with

and sunflower lecithin with viscosities of approximately 90 and

low molecular weight polymer chains. This results from the

90,000 poise, respectively. The high sunflower viscosity was

attributed to the presence of long-chain waxes. Lecithin gum

formation of an electrostatic gel arising from the electrostatic

was shown to change from a Bingham (water continuous phase) nature of the polar portion of the lecithin molecule, the

to a pseudoplastic (oil continuous phase) type fluid as the mois- charged nature of the micelles, and the large dipole moment

ture content of the lecithin gum decreased. The viscosity max- and hydrogen bonding capacity of water (7). The importance

ima occurred between 6.9 and 19.3% moisture content of water in the creation of an electrostatic gel was underlined

(100 s−1), with the variation found to be related to the oil/water through the confirmation that de-oiled lecithin in a hydrocar-

ratio of the system. Rheological results indicated that vertical bon solvent exhibited Newtonian characteristics and the so-

scraped surface evaporator design could be optimized through lutions followed a modified Einstein equation for suspensions

the addition fluidizing of agents prior to the evaporator and/or of noninteracting spheres (7).

increased heating at the evaporator outlet. Lecithin gum approximates a lecithin/water/oil mixture in a

Paper no. J8826 in JAOCS 76, 67–72 (January 1999).

ratio of about 35:50:15, depending upon degumming process-

KEY WORDS: Canola, lecithin gum, processing, rheology,

ing conditions. The phospholipid species of lecithin form an

soybean, sunflower. interface between the polar (water) and nonpolar (oil) compo-

nents of the system, through bilayer and micellar structures.

Commercial lecithin has traditionally been derived from soy-

MATERIALS AND METHODS

beans owing to its high quality and low cost. Alternative

commercial sources of lecithin have emerged with the in- Materials. Canola (Brassica napus), sunflower (Helianthus

creased production of sunflower and canola/rapeseed. The annus), and soybean (Glycine max) lecithin gums were ob-

qualities of lecithin derived from these “soft” varieties of tained from Cargill Oilseed processors, West Footscray, Vic-

oilseeds have often been seen as inferior to that of soybean in toria, Australia. The corresponding refined and deodorized

respect to color, taste, and consistency (1,2). However, with vegetable oils were obtained from Meadow Lea Foods of the

effective quality control measures “soft” seed lecithin of same location. Fatty acids of animal origins were supplied by

comparable quality to existing commercial soy lecithin can Unichema, Port Melbourne, Victoria, Australia.

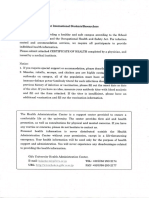

be produced (Schneider, M., personal communication, 1997). Lecithin gum drying. Samples (600 g) of lecithin gum

The unique rheology of the lecithin-water system has lead were dried at a temperature of 70°C, under a vacuum of 0.1

to processing difficulties in the drying of lecithin. The rapid atm, at an agitator speed of 60 rpm. A torque arm attached to

increase in viscosity that occurs when soybean lecithin gum the drive motor was used to detect relative changes in viscos-

contains 5–15% moisture (3) has further complicated thin ity of the mixture (Fig.1). Sampling frequency was concen-

film continuous drying. The rheological characteristics of trated toward the period in which maximum torque was

soybean lecithin gum during drying are ill-defined in the lit- recorded, with a minimum of eight samples taken per run.

erature. Even less is known about the rheological characteris- Lecithin gum samples (n = 27) were put into sealed glass con-

tics of sunflower and canola/rapeseed lecithin gum, apart tainers, and moisture and rheological measurements were

from some processing difficulties noted in early attempts at performed within 2 h of the samples being taken. Fluidized

production of rapeseed lecithin (4,5). This study focuses upon lecithin samples (n = 14) were produced through the addition

comparisons of lecithin gum rheology under steady state con- of oil and/or fatty acid to the lecithin gum. Fluidization

achieved through the use of diavalent salts and acetylation

*To whom correspondence should be addressed. was performed in accordance with the methodology de-

E-mail: g.covey@chemeng.unimelb.edu.au scribed by Lantz (8) and Davis (9). Moisture was determined

Copyright © 1999 by AOCS Press 67 JAOCS, Vol. 76, no. 1 (1999)

68 D. LAMBOURNE ET AL.

FIG. 1. Schematic diagram of batch drying of lecithin gum: 1, reaction vessel; 2, top flange; 3, agitator shaft; 4,

drive motor; 5, torque arm; 6, weight scales; 7, temperature controller; 8, thermostat; 9, water bath; 10, pressure

gauge; 11, condenser; 12, vacuum pump.

by placing duplicate samples in an oven at 105°C until constant ian mixtures. The flow curves (Fig. 2) reveal that lecithin gum

weight was achieved. [This method produces apparent mois- initially exhibits Bingham flow characteristics, i.e.,

ture levels which are 0.5–1% higher than the actual level (8)].

Rheological measurements. Analysis was performed at the σ12 = A + Bγ·—Bingham equation [1]

Cooperative Research Centre (CRC) for Industrial Plant

Biopolymers, functional testing laboratory. A Carri-Med As the moisture levels decrease, so does the linearity of the

Controlled Stress Rheometer CSL^2 (TA Instruments Ltd., curve, with the mixture becoming more accurately described

Dorking, Surrey, England), was used with the cone and plate by the Power Law equation. The Herschel-Bulkley equation,

measurement system set at 2 cm, 2 degrees and 0.054 mm a hybrid of the Bingham and Power Law equations, best de-

gap. Rheology measurements were performed at 70°C for hy- scribes the fluid behavior of the hydrated lecithin (The Her-

drated and 25°C for fluidized samples. schel-Bulkley equation is equal to the Power Law equation

To be able to measure the yield stress and viscosity of the when A = 0).

samples, which varied from oil-like to paste-like in texture, a

stress range from 10–4500 Pa was used. This was employed in σ12 = Kγ· η —Herschel-Bulkley equation [2]

20 incremental steps on a log scale. The dynamic yield stress as

defined by the Herschel-Bulkley equation was used in calcula- This change in flow behavior can be explained by the domi-

tions by the rheometer’s software. The instrument’s measured nating intermolecular forces changing from electrostatic

yield stress was not used owing to sample slippage that oc- forces at high moisture levels to van der Waals forces as the

curred below a shear rate of 1.00 × 10−4 s−1, rendering these re- moisture levels decrease (7). The Bingham constant (A) may

sults invalid. Sample slippage was attributed to hexane-insolu- be seen as the yield stress required to overcome the electro-

ble matter in the samples. The viscosity of the hydrated and flu- static forces and enable fluid flow. The yield stress reached a

idized lecithin samples was determined from the shear stress vs. maximum at between 9 and 19% moisture for the lecithin

shear rate data, through the rheometer’s software. gum varieties analyzed (Fig. 3). The maximum yield stress

The viscosity curves produced by the regression model all will correspond to the minimum moisture level at which mi-

had a correlation coefficient of above 0.97, with the majority celles and/or liquid crystalline domains maximize hydrogen

exceeding 0.99. The shear rate range obtained for the lecithin bonding interaction. This moisture level represents the

samples varied from 1.00 × 10−4 to 3.30 × 102 s−1. The upper boundary between oil and water continuous-phase systems.

limit of the shear rate range was constrained by the 4500 Pa Further removal of moisture beyond this point involves the

maximum operating shear stress of the rheometer. This neces- removal of hydrogen bonding and a decreased surface area

sitated the extrapolation of data to simulate the viscosity curve interface between the oil and water phases. Alternatively, the

(Fig. 5) at commercial operating shear rates (10,000 s−1), a addition of water beyond this point adds to the layer of the

practice used by commercial equipment designers. water continuous phase and lowers resistance to flow. Both

actions result in a lower yield stress.

Comparisons of lecithin gums. Although the sunflower

RESULTS AND DISCUSSION

and canola hydrated lecithin had yield stress maxima at simi-

Rheology of hydrated lecithin. Flow curves of hydrated lecithin lar moisture levels of 8.8 and 12.2%, respectively, the soy-

reveal the rheological complexity of these highly non-Newton- bean hydrated lecithin peaked at a level of 19.3% moisture

JAOCS, Vol. 76, no. 1 (1999)

LECITHIN GUM RHEOLOGY AND PROCESSING IMPLICATIONS 69

FIG. 2. Selective flow curves showing the rheological transition from a Bingham to a pseudoplastic type fluid as the

moisture content of hydrated sunflower lecithin decreases.

(Fig. 3). This may be partly explained by the higher ratio of method minimizes charring, it suffers from long drying peri-

oil to lecithin [or lower ex-dryer Acetone Insolubles (AI) ods of up to 8 h, and difficulties in consistently reducing the

content] in this sample (Table 1). The increased oil level cre- moisture levels to below 1% (Iwanyszcuk, R., private com-

ates a more elliptical micelle (7), thus increasing the surface munication, 1997). These operating limitations can be di-

area available for hydrogen bonding. This theory was sup- rectly attributed to the rheology characteristics within the

ported by the shift in the maximum yield stress to a higher evaporator. A combination of temperature and shear rate gra-

moisture level on the addition of oil (and/or fatty acids) to the dients across the reactor causes the viscosity of the mixture

starting canola and sunflower lecithin gum (Fig. 4). to vary significantly. It is conceivable that, at the same mois-

Commercial process. Drying of lecithin gum is performed ture level, the mixture may be in either a liquid or a near-solid

commercially via either batch or continuous processing, with state, depending on its position (and hence shear rate) in the

the latter technique dominating large-scale operations. Batch reactor (Fig. 5). The resultant poor mixing (and hence poor

processing equipment consists of a reactor which is heated heat exchange) contributes to both long reactor residence

via a rotating coil heat exchanger. Although this drying times and difficulties in achieving low moisture contents.

The scraped surface evaporators used in the continuous

processing have a film thickness of approximately 1–2 mm

and an operating speed of approximately 600 rpm (5). As a

commercial evaporator’s circumference is at least 1 m, the

operational shear rate will be in excess of 10,000 s−1. The

widespread usage of continuous thin film evaporators reflects

the domination of lecithin production by the large-scale

processors. However, while continuous processing is suited

to steady-state production conditions, the maintenance of the

steady state is not always possible. This is especially so with

oilseed crushers which process multiple oilseed varieties. Un-

steady-state startup conditions cause difficulties with vertical

continuous evaporators, as lecithin gum viscosity changes

with increasing shear rate (Fig. 5). As film thickness is di-

FIG. 3. Yield stress curves of soybean, canola, and sunflower hydrated rectly proportional to shear rate within the evaporator, equip-

lecithin. ment maintenance is also critical. Worn blades have caused

JAOCS, Vol. 76, no. 1 (1999)

70 D. LAMBOURNE ET AL.

TABLE 1 levels of sunflower waxes present in their lecithin, an ele-

Characteristics of Fluidized Lecithin (γ· = 1 s−1) vated operating temperature of 95°C at 100 mbar operating

Viscosity Acetone pressure (Kovari, K., personal communication, 1997) and the

(poise at 25°C) insolubles (%) use of a horizontal scraped surface evaporator. This is more

Commercial standard 200 max 62% min robust than a vertical evaporator, as mechanical rather than

Canola #1:ex-dryer 20000a 76 gravitational forces drive the flow of lecithin in the horizon-

+ 3.5% Fatty acids 15000 73 tal scraped surface evaporator (11).

+ 5% Fatty acids 6600 72

On an operational level, processability and production out-

+ 5% Oil 4600 72

+ 5% Oil + 3.5% fatty acids 920 70 put goals can have precedence over quality concerns (Veer-

+ 10% Oil + 3.5% fatty acids 240 67 abhadrappa, S., personal communication, 1997). However,

Canola #2: ex-dryer 1500 69 through better control over lecithin rheology, production and

+ MgSO4 690 69 quality objectives can both be achieved.

Acetylated 920 69

Effect of process temperature. The operating conditions at the

Sunflower: ex-dryer 30000a 78

+ 10% Oil 6300 71 Martfu plant are typical for continuous oilseed lecithin process-

+ 20% Oil 230 65 ing. Temperatures approaching or exceeding 100°C aid in in-

Soybean: ex-dryer 5970 72 creasing evaporator output and lowering fatty acid hydroperox-

+ 3.5% Fatty acids 70 70 ides [measured by the peroxide value (10)]. In contrast, reduced

+ MgSO4 64 72

processing temperatures are desirable to avoid deterioration of

Acetylated 120 72

organoleptic properties. In addition to phospholipids being eas-

a

Viscosity measured at a shear rate of 0.1 s−1.

ily hydrolyzed and oxidized, they are prone to react with decom-

position products of fatty acid hydroperoxides and reducing sug-

severe processing difficulties and led to early design modifi- ars. The production of what are known as melanophospholipids,

cations which included a change from hinged to fixed blades pigments not occurring in seeds, has been reported in the drying

(4) and the use of holes in the blades (5). In more recent of rapeseed gum at elevated temperatures (5). Rapeseed/canola

times, the use of Ni/Cr plated cylinders with fixed stainless lecithin is especially prone to thermal degradation owing to the

steel blades have been recommended to reduce maintenance presence of reactive low molecular weight components: glucosi-

costs (Veerabhadrappa, S., personal communication, 1997). nolates, phytates, and phenolics.

Processing implications. Hydrated canola and soybean One method to improve fluid flow without compromising

lecithin viscosities at these shear rate levels tend to approach an product quality would be to confine process temperature in-

asymptote at around 0.1 centipoise (cP), with marginally higher creases to around the evaporator outlet. This region has been

levels where electrostatic forces peak (Fig. 5). Conversely, responsible for process blockages because of elevated fluid

below 5% moisture content sunflower lecithin solutions experi- viscosity resulting from heat losses from the outlet pump

ence a rapid rise in viscosity due to the presence of sunflower (12). Furthermore, whereas the viscosity profile of the

waxes. This would suggest that under these processing condi- lecithin gum is relatively constant at the operational shear

tions, an agitated thin film evaporator would not be suitable. rate, it may change dramatically in the low shear rate zone of

The commercial sunflower lecithin plant in Martfu, Hun- the evaporator outlet (Fig. 6), especially if excessive residual

gary, has had minimal drying problems because of the lower moisture is present. This study suggests that the reported in-

FIG. 4. Yield stress curves of canola and sunflower with viscosity-reducing additives.

JAOCS, Vol. 76, no. 1 (1999)

LECITHIN GUM RHEOLOGY AND PROCESSING IMPLICATIONS 71

FIG. 5. Viscosity curves of lecithin sludge at 70°C.

ternal lecithin film breakage is not directly due to a rapid vis- ages at the evaporator outlet, which cause misalignment of

cosity change of lecithin as previously postulated (3), as the rotor shaft and hence propagate the process shock up-

under the operating shear rate there is no rapid viscosity stream. The resultant vibration of the shaft would cause rapid

change. It is more probable that it results from fluid block- variations in the lecithin film thickness (and hence apparent

viscosity) and thus induce the film breakage. It follows that

the elevation of process temperatures to improve product

flow should be centered around the outlet region. Although

not a standard feature, some evaporator models have the op-

tion to extend the jacketed heating to cover the outlet zone.

Alternatively, the use of lagging and a heat trace could serve

a similar purpose. A temperature gradient stemming from the

evaporator outlet may also be considered, because the low

moisture content of the lecithin in this region is less prone to

thermal degradation. An added benefit would be increasing

the evaporation rate of residual amounts of moisture, which

are reported to be approximately 2–3 times lower than for the

evaporation of the bulk moisture (13). These figures were

supported by the evaporation rate of the laboratory-scale

batch evaporator, in which evaporation rates declined signifi-

FIG. 6. Schematic diagram of vertical scraped surface evaporator: 1, cantly once the moisture level had dropped below 4%.

lecithin thin film; 2, flange; 3, water/steam inlet; 4, water/steam outlet;

5, rotor shaft; 6, agitated zone entry—high shear, high moisture zone;

Effect of adding oil. The difficulties associated with sun-

7, agitated zone exit—high shear, low moisture zone; 8, evaporator out- flower lecithin drying may be avoided by lowering the equiv-

let —low shear, low moisture zone. alent dry-basis AI value through increasing the oil content of

JAOCS, Vol. 76, no. 1 (1999)

72 D. LAMBOURNE ET AL.

the wet gum. This may be achieved through the adjustment of etable oil has been the preferred method of controlling vis-

degumming conditions (10) or the addition of oil prior to en- cosity, with individual supply agreements allowing lower AI

tering the evaporator. The lowering of the initial wet gum AI levels for bulk handling requirements (Iwanyszczuk, personal

(dry basis) from 78 to 65% resulted in the dried lecithin vis- communication, 1997).

cosity at 70°C dropping from above 100 cP to reach an asymp- The rheology of oilseed lecithin gum is dependent upon

tote to 0.1 cP at the operational shear rate (i.e. 10,000 s−1). The both the oilseed variety and the composition of the lecithin

adjustment of AI levels in the lecithin gum before the drying gum. As opposed to batch evaporation, the high shear rates

operation has the advantages of eliminating postdrying unit op- of the vertical scraped surface evaporator ensure that the

erations and improving the lecithin gum rheology in the drying lecithin gum experiences minimal viscosity variation under

stage. An increased oil content ensures that the electrostatic- steady-state conditions. This study indicates that the low

induced viscosity peak occurs at a higher moisture level and at shear rate zone at the vertical scraped surface evaporator’s

a greater distance from the dryer outlet in a vertical scraped outlet is most susceptible to flow blockages, especially if

surface evaporator and thus ensures a greater robustness to residual moisture in the lecithin is not minimized. Processing

process shocks. The mild steam-deodorizing action of the ver- difficulties are more likely to be experienced in the process-

tical evaporator also aids in the removal of crude oil volatile ing of canola and sunflower lecithin, which have a relatively

components which adversely affect product taste and odor. higher viscosity compared with soy lecithin. These process-

Future processing directions. The processing problems ex- ing difficulties may be avoided by a number of means, in-

perienced in removing residue moisture have led to the need cluding: (i) implementation of external heating to the evapo-

for either extended drying periods (Iwanyszczuk, R., personal rator outlet zone, (ii) addition of fluidity-controlling additives

communication, 1997) (batch) or elevated drying tempera- to lecithin gum; (iii) increased evaporation temperature; and

tures (continuous) (5). The emergence of microwave technol- (iv) use of a horizontal scraped surface evaporator.

ogy in the chemical and food industries may offer some ad- The latter two options are least preferred because an in-

vantages compared to traditional evaporation techniques. Mi- creased evaporator temperature is detrimental to lecithin

crowave drying has a number of advantages, including quality and the use of a horizontal scraped surface evaporator

shorter drying times, smaller temperature gradients, and the increases capital costs.

ability to achieve low moisture levels (13). The production of

chemically modified lecithin products is also likely to be en- REFERENCES

hanced by microwave-assisted organic reactions. In addition,

1. Persmark, U., in Rapeseed: Cultivation, Composition, Process-

bacterial growth would be minimized owing to the lower ing and Utilisation, edited by L.A. Applqvist, and R. Ohlson,

cycle times and aseptic environment induced by microwave Elsevier Publishing Company, Amsterdam, 1972, p. 288.

radiation. This technology is likely to appeal to small produc- 2. Hollo, J., J. Peredi, A. Ruzics, M. Jeranek, and A. Erdelyi, Sun-

ers who manufacture specialty lecithin products, whether by flower Lecithin and Possibilities for Utilization, J. Am. Oil

oilseed variety, chemical modification, or both. Chem. Soc. 70:997–1001 (1993).

3. Nieuwenhuizen, W.V., Lecithin Production and Properties, Ibid.

Standardization of lecithin rheology. The viscosity of 53:425–427 (1976).

crude lecithin is commonly adjusted to below 200 poise at 4. Cerny, J., Lecitin, Prum. Potravin 24:250–253 (1973).

25°C to improve its material handling properties. Fluidized 5. Bratkowska, I., and H. Niewiadomski, The Quality of Techni-

lecithin is made by further dilution of the mixture with veg- cal Rapeseed Lecithin. Part II. The Effects of Drying Post-Hy-

etable oil and/or fatty acids, with the constraints of compet- dration Gums, Acta Aliment. Pol. 26:251–61 (1975).

6. Bourgoin, D., and W. Shankland, Rheology of the Lecithin-

ing acidity and purity requirements. The addition of divalent Water System in Its Lamellar Phase, Rheol. Acta 19:226–238

salts (7) and chemical modification through acetylation (8) (1980).

have also been used to control lecithin viscosity. 7. Duke, R.W., and L.L. Chapoy, The Rheology and Structure of

The viscosity of dried lecithin fluctuates between different Lecithin in Concentrated Solution and the Liquid Crystalline

batches according to seasonal and varietal compositional State, Ibid. 15:548–557 (1976).

8. Davis, P.F., U.S. Patent 3,301,881 (1967).

characteristics. However, the results (Table 1) indicated that 9. Lantz, R.A., Industrial Methods of Analysis, in Lecithins, Man-

soybean lecithin tended to have a lower viscosity than sun- ufacture and Uses, edited by B.F. Szuhaj, American Oil

flower or canola lecithin, although all were likely to satisfy Chemists’ Society, Champaign, 1989, p. 165.

the commercial viscosity specifications when diluted down 10. List, G.R., Commercial Manufacture of Lecithin, Ibid. pp.

to an AI content of 62%. The European Community specifi- 145–161.

11. Parker, N., Part 2. Equipment and Economics, Chemical Engi-

cations (Guideline 78/664/EWG) for lecithin (E322) specify neering. Sept 13:179–185 (1965).

that lecithin shall have greater than or equal to 60% AI, al- 12. Fischer, R., Part 3. Process Applications, Ibid. 11, Sept.

though commercial specifications are more commonly 13:186–190 (1965).

greater than or equal to 62%. The inferior consistency of sun- 13. Technical Data Sheet, Thin Film Evaporator, GEA Canzler,

flower and canola lecithin may be partly attributed to their Düren, Germany, undated.

14. Raner, K.D., C.R. Strauss, and R.W. Trainor, A New Mi-

“soft” seed characteristics, which lead to generally higher crowave Reactor for Batchwise Organic Synthesis, J. Org.

hexane insoluble levels in the form of fine seed particulates Chem. 60:2456–2460 (1995).

(Schneider, M., personal communication, 1997). In small

lecithin production facilities, dilution of lecithin with veg- [Received March 23, 1998; accepted September 10, 1998]

JAOCS, Vol. 76, no. 1 (1999)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Material Safety Data Sheet: Pgeo Edible Oils SDN BHDDocument3 pagesMaterial Safety Data Sheet: Pgeo Edible Oils SDN BHDLukman HakimNo ratings yet

- ASME - PTC4.1 .Boiler Efficiency TestDocument29 pagesASME - PTC4.1 .Boiler Efficiency TestBC Harish92% (13)

- Brookfield Viscosimetro PDFDocument59 pagesBrookfield Viscosimetro PDFKike BayonaNo ratings yet

- Confectionery Gum and Jelly ProductsDocument31 pagesConfectionery Gum and Jelly ProductsercanefeogluNo ratings yet

- Daftar Gambar: Minyak Atau Lemak Secara Langsung 18Document1 pageDaftar Gambar: Minyak Atau Lemak Secara Langsung 18Lukman HakimNo ratings yet

- FBC by ARDocument35 pagesFBC by ARAmitav MishraNo ratings yet

- Appendix CDocument21 pagesAppendix CririiyiNo ratings yet

- Pembuatan EtanolDocument2 pagesPembuatan EtanolLukman HakimNo ratings yet

- ProductionandAnalysisofSoapusingLocallyAvailableRaw MaterialsDocument6 pagesProductionandAnalysisofSoapusingLocallyAvailableRaw MaterialsLukman HakimNo ratings yet

- Neraca Basis BismillahDocument523 pagesNeraca Basis BismillahLukman HakimNo ratings yet

- Patent of Viscous Liqud Soap US4312771Document8 pagesPatent of Viscous Liqud Soap US4312771Lukman HakimNo ratings yet

- Health CertificateDocument3 pagesHealth CertificateLukman HakimNo ratings yet

- JCHPS20191201001 PDFDocument5 pagesJCHPS20191201001 PDFLukman HakimNo ratings yet

- Characteristics and Properties of Fatty Acid Distillates From Palm OilDocument7 pagesCharacteristics and Properties of Fatty Acid Distillates From Palm OilRony DwihartaNo ratings yet

- Studi Kinetika Proses Kimia Dan Fisika Penghilangan Getah Crude Plam Oil (Cpo) Dengan Asam FosfatDocument6 pagesStudi Kinetika Proses Kimia Dan Fisika Penghilangan Getah Crude Plam Oil (Cpo) Dengan Asam FosfatUlfahNo ratings yet

- F10awi1 PDFDocument78 pagesF10awi1 PDFLukman HakimNo ratings yet

- Ekaw EksimglucoseDocument1 pageEkaw EksimglucoseDevi ANo ratings yet

- Wa0002Document8 pagesWa0002Lukman HakimNo ratings yet

- SirangDocument2 pagesSirangLukman HakimNo ratings yet

- Saxena2006 PDFDocument8 pagesSaxena2006 PDFLukman HakimNo ratings yet

- SirangDocument2 pagesSirangLukman HakimNo ratings yet

- AbcDocument9 pagesAbcLukman HakimNo ratings yet

- @6106210Document4 pages@6106210Lukman HakimNo ratings yet

- Qian 2013Document10 pagesQian 2013Lukman HakimNo ratings yet

- Combustion Kinetics of Coal Chars in Oxygen-Enriched EnvironmentsDocument20 pagesCombustion Kinetics of Coal Chars in Oxygen-Enriched EnvironmentsLukman HakimNo ratings yet

- OTRDocument51 pagesOTRNithi AnandNo ratings yet

- Combustion Kinetics of Coal Chars in Oxygen-Enriched EnvironmentsDocument20 pagesCombustion Kinetics of Coal Chars in Oxygen-Enriched EnvironmentsLukman HakimNo ratings yet

- Du Long Petit PDFDocument3 pagesDu Long Petit PDFTahir ArshadNo ratings yet

- HasilDocument3 pagesHasilLukman HakimNo ratings yet

- Hydrogen Production From Water by Using Hydrogen Sulfide As Reducing Agent in Hydrothermal ReactionsDocument4 pagesHydrogen Production From Water by Using Hydrogen Sulfide As Reducing Agent in Hydrothermal ReactionsLukman HakimNo ratings yet

- WWTP Chap 8 Oxygen Req & AerationDocument7 pagesWWTP Chap 8 Oxygen Req & AerationCassie HendersonNo ratings yet

- Simulation of The Single Bubble Ascent With OpenfoamDocument8 pagesSimulation of The Single Bubble Ascent With OpenfoamWunkey WunkruNo ratings yet

- Rheological Characterization of Paints and CoatingsDocument10 pagesRheological Characterization of Paints and CoatingsRinox RachidNo ratings yet

- 2510.practical Aspects of Finite Element Modelling of Polymer Processing by Vahid NassehiDocument282 pages2510.practical Aspects of Finite Element Modelling of Polymer Processing by Vahid Nassehihalukg26No ratings yet

- Film Extrusion PDFDocument63 pagesFilm Extrusion PDFTrần Hữu Như100% (1)

- Styrene-Maleic Anhydride Copolymer Esters As Flow Improvers of Waxy Crude OilDocument9 pagesStyrene-Maleic Anhydride Copolymer Esters As Flow Improvers of Waxy Crude OilMichael MedinaNo ratings yet

- Drilling and Cementing Lab ManualDocument22 pagesDrilling and Cementing Lab ManualTheo AnkamahNo ratings yet

- Rheology: By: Physical Pharmacy TeamDocument48 pagesRheology: By: Physical Pharmacy TeamSuratiNo ratings yet

- Overcome Cellulosics Drawbacks With Rheotech™ x800Document18 pagesOvercome Cellulosics Drawbacks With Rheotech™ x800ForeverNo ratings yet

- Rfa 7Document9 pagesRfa 7tyagi rishabhNo ratings yet

- Elementis-Bentone De-TdsDocument2 pagesElementis-Bentone De-Tdsmgamal1080No ratings yet

- Current Opinion in Colloid & Interface Science: David Julian McclementsDocument8 pagesCurrent Opinion in Colloid & Interface Science: David Julian McclementsGabriel GabiNo ratings yet

- Investigation of DSR Test Methods To Determine Binder Low Temperature PropertiesDocument78 pagesInvestigation of DSR Test Methods To Determine Binder Low Temperature Propertieshghghg3No ratings yet

- Some Basics On OBMDocument27 pagesSome Basics On OBMRamanamurthy PalliNo ratings yet

- Assignment - Rehabilitation Engineering - Sem V-Biomedical Engineering Page - 1Document4 pagesAssignment - Rehabilitation Engineering - Sem V-Biomedical Engineering Page - 1MANAV DIVEKARNo ratings yet

- Lubrication Fluids For Micro-Tunnelling & Pipe-JackingDocument6 pagesLubrication Fluids For Micro-Tunnelling & Pipe-JackingEnri05No ratings yet

- How Rheological Properties Affect Fine-Line Screen Printing - of Pastes - A Combined Rheological and High-Speed Video Imaging - StudyDocument12 pagesHow Rheological Properties Affect Fine-Line Screen Printing - of Pastes - A Combined Rheological and High-Speed Video Imaging - StudyAmar KasbeNo ratings yet

- Amran Et Al. 2022 - 3D-Printable Alkali-Activated Concretes For Building Applications-A Critical ReviewDocument24 pagesAmran Et Al. 2022 - 3D-Printable Alkali-Activated Concretes For Building Applications-A Critical Review孟嫣然No ratings yet

- Analyzing Effects of Multi-Wall Carbon Nanotubes (MWCNT) & Polyethylene Glycol (PEG) On Performance of Water Base Mud (WBM) in Shale FormationDocument19 pagesAnalyzing Effects of Multi-Wall Carbon Nanotubes (MWCNT) & Polyethylene Glycol (PEG) On Performance of Water Base Mud (WBM) in Shale FormationMuhammad Rafly AndraNo ratings yet

- Fluid Flow TheoryDocument24 pagesFluid Flow TheoryjaydeepnaruleNo ratings yet

- Chap - 05 - RHEALOGY PDFDocument36 pagesChap - 05 - RHEALOGY PDFKarim WasiNo ratings yet

- BASF Oilfield-Solutions CementingDocument6 pagesBASF Oilfield-Solutions CementingRonald Figo Torres EcheNo ratings yet

- Fabricación Aditiva de Geopolímeros para Un Entorno Construido SostenibleDocument8 pagesFabricación Aditiva de Geopolímeros para Un Entorno Construido SostenibleGEYLI YURELI BLANCO PRADANo ratings yet

- Cap - Novos Métodos ReológicosDocument14 pagesCap - Novos Métodos ReológicosAlexandra SoaresNo ratings yet

- Carbohydrate PolymersDocument9 pagesCarbohydrate PolymersAnonymous Wcj4C3jNo ratings yet

- Fundamentals of RheologyDocument76 pagesFundamentals of Rheologytonysanchez67No ratings yet

- Beneficiation of Rungta SlimeDocument32 pagesBeneficiation of Rungta SlimesssadangiNo ratings yet

- PGDBST 03Document61 pagesPGDBST 03UJJWAL RAJ SINGHNo ratings yet

- Solvent-Free Radiation-Curing Wood and Furniture Coatings: Technical Information L-TI 7Document20 pagesSolvent-Free Radiation-Curing Wood and Furniture Coatings: Technical Information L-TI 7zagNo ratings yet