Professional Documents

Culture Documents

Quality Tools: Failure Mode and Effects Analysis

Quality Tools: Failure Mode and Effects Analysis

Uploaded by

hlkhgljkhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Tools: Failure Mode and Effects Analysis

Quality Tools: Failure Mode and Effects Analysis

Uploaded by

hlkhgljkhCopyright:

Available Formats

Quality Tools

Failure Mode and Effects Analysis

Description Instructions Learn More

● Please follow the link for detailed To learn more about other quality tools, visit the ASQ Learn

This template illustrates a Failure Mode and

Effects Analysis (FMEA), also referred to as a instructions for data entry About Quality web site.

Potential Failure Mode and Effects Analysis

(PFMEA) or Failure Modes, Effects and ● Initiate action to reduce the RPN

Criticality Analysis (FMECA). A detailed

discussion can be found at www.ASQ.org

● Re-evaluate the RPN value after

completion of the recommended

actions

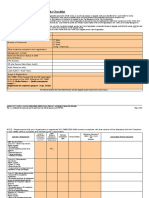

FAILURE MODE AND EFFECTS ANALYSIS

Item: Drill Hole Responsibility: J. Doe FMEA number: 123456

Model: Current Prepared by: J. Doe Page : 1 of 1

Core Team: J. Doe (Engineering), J. Smith (Production), B. Jones (Quality) FMEA Date (Orig): 1/1/2008 Rev: 1

C Potential O D Action Results

Potential Potential S l Cause(s)/ c Current e R Responsibility and

Process Recommended

Failure Effect(s) of e a Mechanis c Process t P Target S O D R

Function Action(s)

Mode Failure v s m(s) of u Controls e N Completion Date Actions Taken e c e P

s Failure r c v c t N

Break

Improper

through Operator training

Drill Blind Hole Hole to deep 7 machine 3 3 63 0

bottom of and instructions

set up

plate

Hole not Improper

Incomplete Operator training

deep 5 machine 3 3 45 0

thread form and instructions

enough set up

Broken Install Tool

5 5 None 9 225 J. Doe 3/1/2008 5 5 1 25

Drill Detectors

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

0 0

FMEA Procedure

(This is a general procedure. Specific details may vary with standards of your organization or industry.)

1. Assemble a cross-functional team of people with diverse knowledge about the process, product

or service and customer needs. Functions often included are: design, manufacturing, quality, testing,

reliability, maintenance, purchasing (and suppliers), sales, marketing (and customers) and customer

service.

2. Identify the scope of the FMEA. Is it for concept, system, design, process or service? What are

the boundaries? How detailed should we be? Use flowcharts to identify the scope and to make sure

every team member understands it in detail. (From here on, we’ll use the word “scope” to mean the

system, design, process or service that is the subject of your FMEA.)

3. Fill in the identifying information at the top of your FMEA form. Figure shows a typical format.

The remaining steps ask for information that will go into the columns of the form.

4. Identify the functions of your scope. Ask, “What is the purpose of this system, design, process or

service? What do our customers expect it to do?” Name it with a verb followed by a noun. Usually you

will break the scope into separate subsystems, items, parts, assemblies or process steps and identify the

function of each.

5. For each function, identify all the ways failure could happen. These are potential failure modes.

If necessary, go back and rewrite the function with more detail to be sure the failure modes show a loss

of that function.

6. For each failure mode, identify all the consequences on the system, related systems, process,

related processes, product, service, customer or regulations. These are potential effects of failure. Ask,

“What does the customer experience because of this failure? What happens when this failure occurs?”

7. Determine how serious each effect is. This is the severity rating, or S. Severity is usually rated on

a scale from 1 to 10, where 1 is insignificant and 10 is catastrophic. If a failure mode has more than one

effect, write on the FMEA table only the highest severity rating for that failure mode.

8. For each failure mode, determine all the potential root causes. Use tools classified as cause

analysis tool, as well as the best knowledge and experience of the team. List all possible causes for each

failure mode on the FMEA form.

9. For each cause, determine the occurrence rating, or O. This rating estimates the probability of

failure occurring for that reason during the lifetime of your scope. Occurrence is usually rated on a scale

from 1 to 10, where 1 is extremely unlikely and 10 is inevitable. On the FMEA table, list the occurrence

rating for each cause.

10. For each cause, identify current process controls. These are tests, procedures or mechanisms

that you now have in place to keep failures from reaching the customer. These controls might prevent

the cause from happening, reduce the likelihood that it will happen or detect failure after the cause has

already happened but before the customer is affected.

11. For each control, determine the detection rating, or D. This rating estimates how well the

controls can detect either the cause or its failure mode after they have happened but before the

customer is affected. Detection is usually rated on a scale from 1 to 10, where 1 means the control is

absolutely certain to detect the problem and 10 means the control is certain not to detect the problem

(or no control exists). On the FMEA table, list the detection rating for each cause.

12. (Optional for most industries) Is this failure mode associated with a critical characteristic?

(Critical characteristics are measurements or indicators that reflect safety or compliance with

government regulations and need special controls.) If so, a column labeled “Classification” receives a Y

or N to show whether special controls are needed. Usually, critical characteristics have a severity of 9 or

10 and occurrence and detection ratings above 3.

13. Calculate the risk priority number, or RPN, which equals S × O × D. Also calculate Criticality by

multiplying severity by occurrence, S × O. These numbers provide guidance for ranking potential failures

in the order they should be addressed.

14. Identify recommended actions. These actions may be design or process changes to lower

severity or occurrence. They may be additional controls to improve detection. Also note who is

responsible for the actions and target completion dates.

15. As actions are completed, note results and the date on the FMEA form. Also, note new S, O or D

ratings and new RPNs.

You might also like

- Aws Final ReportDocument27 pagesAws Final Reportkiswah computers100% (2)

- Process Hazard Analysis: (Failure Mode Effect Analysis)Document41 pagesProcess Hazard Analysis: (Failure Mode Effect Analysis)Nate JamesNo ratings yet

- ANPQP - Supplier Feasibility Commitment: Renault Project: Document Reference No / VersionDocument1 pageANPQP - Supplier Feasibility Commitment: Renault Project: Document Reference No / Versionjefry sitorusNo ratings yet

- Process Implementation V 1.1Document12 pagesProcess Implementation V 1.1Droisys IncNo ratings yet

- Customer Property Register PDFDocument1 pageCustomer Property Register PDFAl Rammohan0% (1)

- Extract PDF Fonts LinuxDocument2 pagesExtract PDF Fonts LinuxCarrieNo ratings yet

- 1 How To Setup The Bancnet Egov OnlineDocument15 pages1 How To Setup The Bancnet Egov OnlineEdward Quinto0% (1)

- APQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareDocument2 pagesAPQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareselvamNo ratings yet

- Supplier Manual-7th Revision - April 23 FinalDocument35 pagesSupplier Manual-7th Revision - April 23 FinalvishnuNo ratings yet

- 7.2.18 DFMEA-PFMEA-FMECA Comparison Guidance 13JUL2020Document4 pages7.2.18 DFMEA-PFMEA-FMECA Comparison Guidance 13JUL2020Moti Ben-ZurNo ratings yet

- Meenakshi Molding Private Limited Process FMEA: O C C U RDocument4 pagesMeenakshi Molding Private Limited Process FMEA: O C C U Rilaya raja100% (1)

- PPAP PriruckaDocument10 pagesPPAP PriruckaKin MattNo ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- ANSI Z1.4 Sampling and Inspection Tables, 'How To Guide'Document2 pagesANSI Z1.4 Sampling and Inspection Tables, 'How To Guide'NatalieNo ratings yet

- EEN Audit Format Sample GuideDocument2 pagesEEN Audit Format Sample GuideDuane SchumacherNo ratings yet

- 4.4.1 Product SafetyDocument5 pages4.4.1 Product SafetyVijayendran VijayNo ratings yet

- Bs 6143 1 Guide To The Economics of Quality Part 1 Process Cost ModelDocument23 pagesBs 6143 1 Guide To The Economics of Quality Part 1 Process Cost ModelFaber Camilo LlantenNo ratings yet

- Jakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeDocument24 pagesJakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeLeonardoViannaNo ratings yet

- Test Paper: Name: DateDocument2 pagesTest Paper: Name: DateDhinakaranNo ratings yet

- System-Based, Customer-Centered Quality Plan For ManufacturersDocument9 pagesSystem-Based, Customer-Centered Quality Plan For ManufacturersmsbarretosNo ratings yet

- QA Processes, Tools and Metrics: Group 1Document18 pagesQA Processes, Tools and Metrics: Group 1Rhea AgulayNo ratings yet

- AS9100 Rev D TransitionDocument104 pagesAS9100 Rev D TransitionSudhagarNo ratings yet

- COPQ Training - EPC (Repaired)Document15 pagesCOPQ Training - EPC (Repaired)syedfahadraza627No ratings yet

- Apqp MiniDocument14 pagesApqp MiniSudhagarNo ratings yet

- QMS ISO 9001 2015 Risk AssessmentDocument6 pagesQMS ISO 9001 2015 Risk AssessmentmominNo ratings yet

- System Audit Check SheetDocument8 pagesSystem Audit Check SheetFINAL QUALITYNo ratings yet

- Sop 7.4.4 Counterfeit Parts PreventionDocument6 pagesSop 7.4.4 Counterfeit Parts PreventionEDGAR GONZALEZNo ratings yet

- IATF16949+Chapter+21 +Automotive+Core+ToolsDocument18 pagesIATF16949+Chapter+21 +Automotive+Core+ToolsNhựt Nguyễn HữuNo ratings yet

- Blank Turtle DiagramDocument1 pageBlank Turtle DiagramnormalNo ratings yet

- ISO 13485: 2016 Planner and Delta Checklist: InstructionsDocument10 pagesISO 13485: 2016 Planner and Delta Checklist: InstructionsYogesh H NarkhedeNo ratings yet

- ISO 13485 - 2016-WPS OfficeDocument4 pagesISO 13485 - 2016-WPS Officerajesh.bNo ratings yet

- AAMI Quality Systems White Paper: Comparison of 21 CFR Part 820 To ISO 13485:2016Document28 pagesAAMI Quality Systems White Paper: Comparison of 21 CFR Part 820 To ISO 13485:2016Hong XuyenNo ratings yet

- Audit SkillsDocument36 pagesAudit SkillsSudhagar100% (1)

- Form - COTO LogDocument45 pagesForm - COTO LogAmit KuarNo ratings yet

- CounterfeitDocument5 pagesCounterfeitVivek GoudNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument52 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Sampling PlanDocument6 pagesSampling PlanGaurang DaveNo ratings yet

- GM CSR TrainingDocument9 pagesGM CSR TrainingVanessa GurrolaNo ratings yet

- Global Quality SystemsDocument17 pagesGlobal Quality Systemspavan1235No ratings yet

- Organization Context (4Document3 pagesOrganization Context (4Nguyen Trung Kien100% (1)

- Storage and Transshipment of Feed Checklist GMP+ B3: GeneralDocument23 pagesStorage and Transshipment of Feed Checklist GMP+ B3: GeneralGreissy EncinasNo ratings yet

- Shree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramDocument2 pagesShree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramS. R. OvhalNo ratings yet

- Ford Supplement K TemplateDocument3 pagesFord Supplement K TemplateelevendotNo ratings yet

- SQMP ManualDocument81 pagesSQMP ManualAnkita DwivediNo ratings yet

- Aqpaxi Phase 2.rev13Document7 pagesAqpaxi Phase 2.rev13Isabel SierraNo ratings yet

- Quality System Procedure For Change Point ControlDocument3 pagesQuality System Procedure For Change Point Controlrajesh sharmaNo ratings yet

- Iatf 16949 Quality Management System RequirementsDocument42 pagesIatf 16949 Quality Management System RequirementsKiki AditamaNo ratings yet

- Fmea Alignment Aiag and VdaDocument14 pagesFmea Alignment Aiag and Vdahaitem100% (1)

- Malati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDocument1 pageMalati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDhananjay PatilNo ratings yet

- Guidelines For Making PFMEA - A PDFDocument10 pagesGuidelines For Making PFMEA - A PDFKalimuthu PsNo ratings yet

- 08.03.04-Quality Assurance of Materials - Approval of Source-R2Document4 pages08.03.04-Quality Assurance of Materials - Approval of Source-R2tanmayascribdNo ratings yet

- 06 Breakout D-Quality Risk Management-Key MessagesDocument26 pages06 Breakout D-Quality Risk Management-Key MessagesAhmad KhreisatNo ratings yet

- Jipl CL Pur 10 Testing Lab AuditDocument8 pagesJipl CL Pur 10 Testing Lab AuditMeghna SharmaNo ratings yet

- Control of Monitoring and Measuring EquipmentDocument3 pagesControl of Monitoring and Measuring EquipmentLinda Setya WatiNo ratings yet

- Our Approach To QualityDocument3 pagesOur Approach To QualityabhirejanilNo ratings yet

- Supplier Quality System Audit Checklist - Elbit Systems of AmericaDocument8 pagesSupplier Quality System Audit Checklist - Elbit Systems of Americaamirkhakzad498No ratings yet

- Failure Mode Effects Analysis in Half The TimeDocument25 pagesFailure Mode Effects Analysis in Half The TimeRowdyRaheelNo ratings yet

- Lay Out OptimizationDocument43 pagesLay Out OptimizationRagul VinothNo ratings yet

- 16.0 Re-Validation / RequalificationDocument3 pages16.0 Re-Validation / RequalificationBhavik YadavNo ratings yet

- Quality Management Systems A Complete Guide - 2021 EditionFrom EverandQuality Management Systems A Complete Guide - 2021 EditionNo ratings yet

- ICH Q7 How To Do Version13 Final Jan 2020Document105 pagesICH Q7 How To Do Version13 Final Jan 2020Al RammohanNo ratings yet

- Selection and RequitmentDocument5 pagesSelection and RequitmentAl RammohanNo ratings yet

- INHYDPRINT02@celgene - Com 20170701 200709Document11 pagesINHYDPRINT02@celgene - Com 20170701 200709Al RammohanNo ratings yet

- 8 Scalable Flow Chemistry - A Flexible Tool.... - DR Charlotte WilesDocument33 pages8 Scalable Flow Chemistry - A Flexible Tool.... - DR Charlotte WilesAl RammohanNo ratings yet

- DMF PDFDocument17 pagesDMF PDFAl RammohanNo ratings yet

- DOPO-Me Bisphenol - UN Form SDS PDFDocument9 pagesDOPO-Me Bisphenol - UN Form SDS PDFAl RammohanNo ratings yet

- Long Term Lay-Up and Restart of Process and Industrial Plant - RTDocument15 pagesLong Term Lay-Up and Restart of Process and Industrial Plant - RTAl Rammohan100% (1)

- Quality Metrics DraftDocument19 pagesQuality Metrics DraftAl RammohanNo ratings yet

- APIC RSM Auditing - 201802 PDFDocument23 pagesAPIC RSM Auditing - 201802 PDFAl RammohanNo ratings yet

- Session 14 Train Personnel On CSV and Data Integrity ComplianceDocument36 pagesSession 14 Train Personnel On CSV and Data Integrity ComplianceAl RammohanNo ratings yet

- CFR 2017 Title21 Vol4 Part210Document4 pagesCFR 2017 Title21 Vol4 Part210Al RammohanNo ratings yet

- Bispynol Telugu MsdsDocument1 pageBispynol Telugu MsdsAl RammohanNo ratings yet

- PSW - Programming Manual - V1.5Document119 pagesPSW - Programming Manual - V1.5guillen j-cNo ratings yet

- Simplifying Rational Expressions: Algebra 2 9.1 NameDocument6 pagesSimplifying Rational Expressions: Algebra 2 9.1 Namedjvaughan01No ratings yet

- DIGICO SD7 BrochureDocument40 pagesDIGICO SD7 BrochureDave Ruiz HernandezNo ratings yet

- PM175 ManualDocument135 pagesPM175 ManualLuis Christian Davila CangalayaNo ratings yet

- Mainstream ETCO2 Module CM2200 Technical SpecificationDocument13 pagesMainstream ETCO2 Module CM2200 Technical SpecificationEmilio CánepaNo ratings yet

- MG Tint Wai Min Khant (Electrical and Electronic Principle A2)Document25 pagesMG Tint Wai Min Khant (Electrical and Electronic Principle A2)Sniper- KNo ratings yet

- Gockenbach-Partial Differential EquationsDocument639 pagesGockenbach-Partial Differential EquationsNaty CrissonNo ratings yet

- Componet of A Computer SystemDocument13 pagesComponet of A Computer System✬ SHANZA MALIK ✬No ratings yet

- Digital Image Processing of Remote Sensing Data - Unit 2 - Week 1Document3 pagesDigital Image Processing of Remote Sensing Data - Unit 2 - Week 1hitesh parmar0% (1)

- Tracking Workflow and Illustrating Value: Dr. Toby Pearlstein New York Chapter SLA March 11, 2008Document33 pagesTracking Workflow and Illustrating Value: Dr. Toby Pearlstein New York Chapter SLA March 11, 2008SLA-NYNo ratings yet

- Mechatronics Test Questions Set 2 PDFDocument13 pagesMechatronics Test Questions Set 2 PDFgauravkumar bhandariNo ratings yet

- Institute - Uie Department-Academic Unit-1Document27 pagesInstitute - Uie Department-Academic Unit-1Lovey PreetNo ratings yet

- Gta Product CatalogueDocument20 pagesGta Product Cataloguechristos1157No ratings yet

- Veritas Netbackup Cheat Sheet PDFDocument4 pagesVeritas Netbackup Cheat Sheet PDFAnvesh ReddyNo ratings yet

- Calculator-An Audit of Your Digital Thread AdoptionDocument2 pagesCalculator-An Audit of Your Digital Thread AdoptionsuritataNo ratings yet

- Mitsubishi Electric - InverterDocument38 pagesMitsubishi Electric - InverterAli AkbarNo ratings yet

- BBU Interconnection (SRAN9.0 - Draft A)Document51 pagesBBU Interconnection (SRAN9.0 - Draft A)Sam FicherNo ratings yet

- SatalightDocument35 pagesSatalightJael DavieNo ratings yet

- Synopsis of Password ProtectorDocument3 pagesSynopsis of Password ProtectorAnonymous QrLiISmpFNo ratings yet

- User Manual D4VDocument26 pagesUser Manual D4VCINTHYA MORENO RAMIREZNo ratings yet

- SOP in Case of Accidental DeathDocument4 pagesSOP in Case of Accidental DeathRajesh PatibandlaNo ratings yet

- Government Polytechnic College Muttom, Thodupuzha: Course File 6018: Material Testing LabDocument30 pagesGovernment Polytechnic College Muttom, Thodupuzha: Course File 6018: Material Testing Labsanjithr619No ratings yet

- Reading The Design Into PT: Learning ObjectivesDocument16 pagesReading The Design Into PT: Learning ObjectivessunnygogineniNo ratings yet

- Mems Switches Seminar ReportDocument29 pagesMems Switches Seminar ReportNidhi SaraswatNo ratings yet

- ITL PVBX Systems - Sample QuotesDocument2 pagesITL PVBX Systems - Sample QuotesKevin LathamNo ratings yet

- Addressing ModeDocument9 pagesAddressing ModeManelle TulodNo ratings yet

- PGO AKLAN-Revenue Collection Clerk IIIDocument2 pagesPGO AKLAN-Revenue Collection Clerk IIIChong GoNo ratings yet