Professional Documents

Culture Documents

Design and Analysis of Disc Brake

Uploaded by

khuong_unoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Analysis of Disc Brake

Uploaded by

khuong_unoCopyright:

Available Formats

International Journal of Engineering Trends and Technology (IJETT) – Volume 8 Number 4- Feb 2014

Design and Analysis of Disc Brake

Swapnil R. Abhang#1, D.P.Bhaskar*2,

#1

P.G. Student & #2 Associate Professor Department of Mechanical Engineering, SRES College of Engineering,

Pune University, Kopargaon, India.

Abstract— Each single system has been studied and developed in the cylinder and piston. A schematic diagram is shown in the

order to meet safety requirement. Instead of having air bag, good figure 1

suspension systems, good handling and safe cornering, there is

one most critical system in the vehicle which is brake systems.

Without brake system in the vehicle will put a passenger in

unsafe position. Therefore, it is must for all vehicles to have

proper brake system. In this paper carbon ceramic matrix disc

brake material use for calculating normal force, shear force and

piston force. And also calculating the brake distance of disc

brake. The standard disc brake two wheelers model using in

Ansys and done the Thermal analysis and Modal analysis also

calculate the deflection and Heat flux, Temperature of disc brake

model. This is important to understand action force and friction

force on the disc brake new material, how disc brake works more

efficiently, which can help to reduce the accident that may

happen in each day.

Keywords— Disc Brake, Thermal Analysis, Modal Analysis,

Ansys

I. INTRODUCTION

The disc brake is a wheel brake which slows rotation of the

wheel by the friction caused by pushing brake pads against a

brake disc with a set of callipers. The brake disc (or rotor in

American English) is usually made of cast iron, but may in Fig 1 Disc Brake

some cases be made of composites such as reinforced carbon–

carbon or ceramic matrix composites. This is connected to the

wheel and/or the axle. To stop the wheel, friction material in II. PROBLEM OCCURRED IN DISC BRAKE

the form of brake pads, mounted on a device called a brake Discs are made up mainly gray cast iron, so discs are

calliper, is forced mechanically, hydraulically, pneumatically damaged in one of three ways: scarring, cracking, warping or

or electromagnetically against both sides of the disc. Friction excessive rusting. Service shops will sometimes respond to

causes the disc and attached wheel to slow or stop. Brakes any disc problem by changing out the discs entirely. This is

convert motion to heat, and if the brakes get too hot, they done mainly where the cost of a new disc may actually be

become less effective, a phenomenon known as brake fade. lower than the cost of workers to resurface the original disc.

Disc-style brakes development and use began in England Mechanically this is unnecessary unless the discs have

in the 1890s. The first calliper-type automobile disc brake was reached manufacturer's minimum recommended thickness,

patented by Frederick William Lanchester in his Birmingham, which would make it unsafe to use them, or vane rusting.

UK factory in 1902 and used successfully on Lanchester cars. severe (ventilated discs only). Most leading vehicle

Compared to drum brakes, disc brakes offer better stopping manufacturers recommend brake disc skimming (US: turning)

performance, because the disc is more readily cooled. A disc as a solution for lateral run-out, vibration issues and brake

brake consists of a cast iron disc bolted to the wheel hub and a noises.

stationary housing called calliper. The calliper is connected to The machining process is performed in a brake lathe,

some stationary part of the vehicle like the axle casing or the which removes a very thin layer off the disc surface to clean

stub axle as is cast in two parts each part containing a piston. off minor damage and restore uniform thickness. Machining

In between each piston and the disc there is a friction pad held the disc as necessary will maximize the mileage out of the

in position by retaining pins, spring plates etc. passages are current discs on the vehicle. Braking systems rely on friction

drilled in the calliper for the fluid to enter or leave each to bring the vehicle to a halt – hydraulic pressure pushes brake

housing. The passages are also connected to another one for pads against a cast iron disc or brake shoes against the inside

bleeding. Each cylinder contains rubber-sealing ring between of a cast iron drum. When a vehicle is decelerated, load is

transferred to the front wheels – this means that the front

ISSN: 2231-5381 http://www.ijettjournal.org Page 165

International Journal of Engineering Trends and Technology (IJETT) – Volume 8 Number 4- Feb 2014

brakes do most of the work in stopping the vehicle. Scarring Tangential force between pad and rotor (outer face) , FTRO.

can occur if brake pads are not changed promptly when they In this FTRO equal FTRI because same normal force and

reach the end of their service life and are considered worn out. same material

Cracking is limited mostly to drilled discs, which may

develop small cracks around edges of holes drilled near the 3.2 Brake Torque (TB) –

edge of the disc due to the disc's uneven rate of expansion in With the assumption of equal coefficients of friction and

severe duty environments. The discs are commonly made normal forces FR on the inner and outer faces:

from cast iron and a certain amount of what is known as TB = FT.R

"surface rust" is normal. Sometimes a loud noise or high Where TB = Brake torque

pitched squeal occurs when the brakes are applied. Most brake µ = Coefficient of friction

squeal is produced by vibration (resonance instability) of the FT = Total normal forces on disc brake,

brake components, especially the pads and discs (known as = FTRI + FTRO

force-coupled excitation). This type of squeal should not FT = 1000 N.

negatively affect brake stopping performance. R = Radius of rotor disc.

So, TB = (1000) (120×10-3)

III. CALCULATION OF DISC BRAKE TB = 120 N.m

The forces acting on the inner and outer rotor faces due to

contact with brake pads are shown in Figure 2 3.3 Brake Distance (x) –

We know that tangential braking force acting at the point

of contact of the brake, and

Work done = FT. x ..................(Equation A)

Where FT = FTRI + FTRO

X = Distance travelled (in meter) by the vehicle

before it come to rest.

We know kinetic energy of the vehicle.

Kinetic energy = (mv2) / 2 ................(Equation B)

Where m = Mass of vehicle

v = Velocity of vehicle

In order to bring the vehicle to rest, the work done against

friction must be equal to kinetic energy of the vehicle.

Therefore equating (Equation A) and (Equation B)

FT. x = (mv2) / 2

Assumption v = 100 kg/h = 27.77 m/s

M = 132 kg. (Dry weight of

Vehicle )

So we get x = (mv2) / 2 FT

Fig 2 Forces Acting On Rotor Due To Contact with Brake Pads

x = (132×27.772) / (2×1000) m.

Disc Brake Standard x = 50.89 m

Rotor disc dimension = 240 mm. (240×10-3 m)

Rotor disc material = Carbon Ceramic Matrix Heat Generated (Q) = M .Cр. ΔT J/S

Pad brake area = 2000 mm2 (2000×10-6 m) Flux (q) = Q/A W/m²

Pad brake material = Asbestos Thermal Gradient (K) = q / k K/m

Coefficient of friction (Wet) = 0.07-0.13

Coefficient of friction (Dry) = 0.3-0.5 Carbon Ceramic Matrix –

Maximum temperature = 350 ºC Heat generated Q= m*cp*∆T

Maximum pressure = 1MPa (106 Pa) Mass of disc = 0.5 kg

Specific Heat Capacity = 800 J/kg 0 c

3.1 Tangential force between pad and rotor (Inner face), Time taken Stopping the Vehicle = 5sec

FTRI Developed Temperature difference = 15 0 c

FTRI = µ1.FRI Q = 0.5 * 800 * 15= 6000 J

Where, FTRI = Normal force between pad brake Area of Disc = Π * ( R2 – r2 ) = Π * (0.120 2 – 0.055 2 )

And Rotor (Inner) = 0.03573 m 2

µ1 = Coefficient of friction = 0.5 Heat Flux = Heat Generated /Second /area = 6000 /5 /

FRI = P max / 2 × A pad brake area 0.0357 = 33.585 kw/m 2

So, FTRI = µ1.FRI Thermal Gradient = Heat Flux / Thermal Conductivity

FTRI = (0.5)(0.5)(1×106 N/m2) (2000×106 m2) = 33.582*10 3 / 40

FTRI = 500 N. = 839.63 k/m

ISSN: 2231-5381 http://www.ijettjournal.org Page 166

International Journal of Engineering Trends and Technology (IJETT) – Volume 8 Number 4- Feb 2014

IV. FEM USING ANSYS

Ansys is one of the useful software for design analysis in 4.2 Modal Analysis of Disc Brake

mechanical engineering. This software is based on the Finite

Element Method (FEM) to simulate the working conditions of

your designs and predict their behaviour. FEM requires the

solution of larges systems of equations. Powered by fast

solvers, Ansys makes it possible for designers to quickly

check the integrity of their designs and search for the optimum

solution.

A product development cycle typically includes the

following steps:

• Build your model in the Pro-Engineer system.

• Prototype the design.

• Test the prototype in the field.

• Evaluate the results of the field tests.

• Modify the design based on the field test results.

Fig 6 Frequency and Total Deformation of Disc Brake

4.1 Model of Disc Brake

V. CONCLUSIONS

Using carbon ceramic matrix disc brake material calculating

normal force, shear force and piston force and also calculating

the brake distance of disc brake. The standard disc brake two

wheelers model using in Ansys, done the Thermal and Modal

Analysis calculate the deflection, total heat flux, Frequency

and temperature of disc brake model. This is important to

understand action force and friction force on the disc brake

new material, which use disc brake works more efficiently,

which can help to reduce the accident that may happen in each

Fig 3 Model of Disc Brake day.

4.2 Thermal Analysis of Disc Brake ACKNOWLEDGMENT

The authors are thankful to all friends and Professors to

help the this paper and would like to thank the anonymous

reviewers for their comments which were very helpful in

improving the quality and presentation of this paper.

REFERENCES

[1] Dr. Ramesha, Santhosh Kumar and Bharath Shekar, “Temperature

Distribution Analysis of Aluminum Composite and Cast Iron Brake

Drum Using Ansys”, ‘International Journal of Emerging trends in

Engineering and Development’, 2012, Vol. 3, Issn 2249-6149, pp 281-

292.

[2] Ameer Shaik and Lakshmi Srinivas,“Structural and Thermal Analysis

Fig 4 Temperature Distribution of Disc Brake Without Cross-drilled Rotor Of Race Car”,

‘International Journal of Advanced Engineering Research and Studies’,

2012 , Vol. I, Issn 2249-8974, pp 39-43

[3] Chogdu Cho and Sooick Ahn, “Thermo-Elastic Analysis for Chattering

Phenomenon of Automotive Disk Brake”, ‘KSME International

Journal’, 2001,Vol-15, pp 569-579.

[4] Guru Murthy Nathi, K. Gowtham and Satish Reddy, “Coupled

Structual / Thermal Analysis of Disc Brake”, IJRET 2012, Vol.1,

pp.539-553.

[5] V. M. Thilak , R. Krishnara Deepan & R.Palani ,“Transient Thermal

and Structural Analysis of the Rotor Disc of Disc Brake ”, International

Journal of Scientific & Engineering Research Volume 2, Issue 8,

August-2011 Issn 2229-551..

Fig 5 Total Heat Flux

ISSN: 2231-5381 http://www.ijettjournal.org Page 167

You might also like

- How To Use A Vernier CaliperDocument11 pagesHow To Use A Vernier CaliperRoseCamilleGuzmanNo ratings yet

- Disc BrakeDocument77 pagesDisc BrakePathan ShamsheerkhanNo ratings yet

- ModelEngineersWorkshopMagazineJune2020 Sanet STDocument68 pagesModelEngineersWorkshopMagazineJune2020 Sanet STalemao7x1 DiehlNo ratings yet

- Mechanisms Notes 2012Document12 pagesMechanisms Notes 2012kookwfNo ratings yet

- Standards MaterialDocument19 pagesStandards MaterialnaveenkumarNo ratings yet

- WErbsen CourseworkDocument562 pagesWErbsen CourseworkRoberto Alexis Rodríguez TorresNo ratings yet

- KM-HM Rotate BoreDocument81 pagesKM-HM Rotate BoreEmersonGomesdaSilva100% (1)

- Stellar Structure and EvolutionDocument188 pagesStellar Structure and EvolutionMizanur RahmanNo ratings yet

- Disc Brake Analysis ProjectDocument7 pagesDisc Brake Analysis ProjectPathan ShamsheerkhanNo ratings yet

- GB 17395-2008ENgDocument35 pagesGB 17395-2008ENgGanesh Srinivasan100% (1)

- The Art Of Saw-Filing, Scientifically Treated And Explained On Philosophical Principles.From EverandThe Art Of Saw-Filing, Scientifically Treated And Explained On Philosophical Principles.No ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- US CAT Niagara Cutter Catalog GT17-136Document342 pagesUS CAT Niagara Cutter Catalog GT17-136MANUEL VICTORNo ratings yet

- Mini Mill Users GuideDocument28 pagesMini Mill Users Guidechriswood_gmailNo ratings yet

- Gauge BlockDocument6 pagesGauge BlockrexkingdomNo ratings yet

- Tube Rolling MachineDocument4 pagesTube Rolling MachinePushpa Mohan RajNo ratings yet

- Titanium DRILLINGDocument50 pagesTitanium DRILLINGDome StoiNo ratings yet

- Dapra Biax Article Art of ScrapingDocument2 pagesDapra Biax Article Art of ScrapingPedro Ernesto SilvaNo ratings yet

- Advance Theory of Radioactive Transformations635613680405172321Document40 pagesAdvance Theory of Radioactive Transformations635613680405172321Hrithik Goyal100% (1)

- 1099935205four SpeedDocument6 pages1099935205four SpeedchzhptopNo ratings yet

- 3 Jaw Chuck RepairDocument2 pages3 Jaw Chuck RepairbrianatburleighNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Climaxportable Lathe Pl3000-EDocument6 pagesClimaxportable Lathe Pl3000-EjpolancosNo ratings yet

- Syllabus For The Trade Of: Machinist (Grinder)Document27 pagesSyllabus For The Trade Of: Machinist (Grinder)swami061009No ratings yet

- Aviation Pocket Bo 00 MattDocument512 pagesAviation Pocket Bo 00 MattviorelcroitoruNo ratings yet

- Practical Treatise On Milling and Milling Machines PDFDocument345 pagesPractical Treatise On Milling and Milling Machines PDFmetalservis2009No ratings yet

- Ebook Tapping Away Guide To Tapping and Threading Xometry SuppliesDocument19 pagesEbook Tapping Away Guide To Tapping and Threading Xometry SuppliesAli KhubbakhtNo ratings yet

- Tread Hammer RahulDocument36 pagesTread Hammer RahulHemant MaheshwariNo ratings yet

- Acoustic Tractor Beam: 35 Steps (With Pictures) PDFDocument38 pagesAcoustic Tractor Beam: 35 Steps (With Pictures) PDFAmirNo ratings yet

- How To Weld - TIG WeldingDocument14 pagesHow To Weld - TIG Weldingjumpupdnbdj100% (1)

- (Metalworking) Welding and MachiningDocument1,767 pages(Metalworking) Welding and MachiningEugeneNo ratings yet

- Difference Between Drilling and Boring - Drilling Vs Boring ComparedDocument3 pagesDifference Between Drilling and Boring - Drilling Vs Boring ComparedPawan GuptaNo ratings yet

- Safety For LNG PlantsDocument13 pagesSafety For LNG Plantsravikb27100% (1)

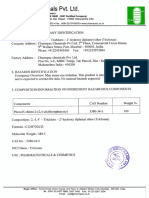

- F F O P L: Epofine - 1556 / FINEHARD - 3486Document2 pagesF F O P L: Epofine - 1556 / FINEHARD - 3486Karishma Prabhu0% (1)

- Aferican Oxcart Design and ManufactureDocument62 pagesAferican Oxcart Design and ManufacturereissmachinistNo ratings yet

- StovesDocument5 pagesStovesElsa LaminNo ratings yet

- Lathe Diagram With ExplanationDocument3 pagesLathe Diagram With ExplanationEnrico959No ratings yet

- 1953 Lucas Dynamos E3L E3LM E3N PDFDocument7 pages1953 Lucas Dynamos E3L E3LM E3N PDFepicenterrulezNo ratings yet

- DynamometerDocument21 pagesDynamometerHussam El'SheikhNo ratings yet

- Shaper Used As Surface GrinderDocument1 pageShaper Used As Surface Grinderradio-chaserNo ratings yet

- (250x450mm) Chinese Bench LatheDocument5 pages(250x450mm) Chinese Bench LathedudulemarcNo ratings yet

- Anyang Power HammerDocument7 pagesAnyang Power HammeraguswNo ratings yet

- Deep Hole SolutionsDocument28 pagesDeep Hole SolutionsyatinbhatNo ratings yet

- KurtDocument30 pagesKurtmachineCanNo ratings yet

- Morse Taper Dimensions and Drill Chuck ArborsDocument4 pagesMorse Taper Dimensions and Drill Chuck ArborskokiskoNo ratings yet

- ACESORIOScatalog PDFDocument80 pagesACESORIOScatalog PDFlmelmelmeNo ratings yet

- Metric Tap and Drill Chart PDFDocument1 pageMetric Tap and Drill Chart PDFelmfp7774676No ratings yet

- Lathe Accessories Price List: P/N Description WT Price P/N Description WT PriceDocument2 pagesLathe Accessories Price List: P/N Description WT Price P/N Description WT PriceAnonymous hos8odNo ratings yet

- LaserDocument29 pagesLaserGaurav YadavNo ratings yet

- Fordson Major ManualDocument47 pagesFordson Major ManualHassan GDOURANo ratings yet

- Benchworking StudyDocument100 pagesBenchworking StudyBrianRuaroNo ratings yet

- Barco: Tools CatalogDocument30 pagesBarco: Tools Catalogeternal_harpyNo ratings yet

- Slotting MachineDocument32 pagesSlotting Machinesanaashraf91% (11)

- Pioneer Avh-P3100dvd p3150dvd SMDocument190 pagesPioneer Avh-P3100dvd p3150dvd SMRogerio E. SantoNo ratings yet

- Engineering Vol 56 1893-12-15Document33 pagesEngineering Vol 56 1893-12-15ian_newNo ratings yet

- DrillingDocument36 pagesDrillingMax LuxNo ratings yet

- Operating: Maintenance ManualDocument18 pagesOperating: Maintenance ManualAnonymous reYe6iCCNo ratings yet

- BroachingDocument31 pagesBroachingOrville SutariNo ratings yet

- Gear Teeth: Clocks and ShipsDocument16 pagesGear Teeth: Clocks and ShipsČika BrkoNo ratings yet

- Negrini Hard Gun Cases CatalogDocument10 pagesNegrini Hard Gun Cases CatalognegrinicasesNo ratings yet

- Mini Lathe Angular Contact Bearing Change GuideDocument5 pagesMini Lathe Angular Contact Bearing Change GuidemallardfirstNo ratings yet

- (PN) Plasma Nitriding of Titanium AlloysDocument41 pages(PN) Plasma Nitriding of Titanium AlloysNgọc Minh LêNo ratings yet

- Circular Saw Grinding Machines Complete RangeDocument24 pagesCircular Saw Grinding Machines Complete RangeAttila PolacsekNo ratings yet

- Manual TornoDocument60 pagesManual Tornojulie2420140% (1)

- Lathe ToolslideDocument2 pagesLathe ToolslideFrenchwolf420No ratings yet

- 1904-Instruments For Forest Work-NeDocument33 pages1904-Instruments For Forest Work-NespaytNo ratings yet

- 14 StipperDocument33 pages14 Stippermahdi sakhaeeNo ratings yet

- Fatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965From EverandFatigue Design Procedures: Proceedings of the 4th Symposium of the International Committee on Aeronautical Fatigue held in Munich, 16–18 June 1965E. GassnerNo ratings yet

- ME21 Thermal Analysis of Disc Brake PDFDocument6 pagesME21 Thermal Analysis of Disc Brake PDFPathan ShamsheerkhanNo ratings yet

- Coupled Structual Thermal Analysis of Disc BrakeDocument15 pagesCoupled Structual Thermal Analysis of Disc BrakeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Jntuh M.tech r13Document10 pagesJntuh M.tech r13Pathan ShamsheerkhanNo ratings yet

- Application Form - VijayawadaDocument4 pagesApplication Form - VijayawadaPathan ShamsheerkhanNo ratings yet

- BBC - GCSE Bitesize - MaterialsDocument9 pagesBBC - GCSE Bitesize - MaterialsPathan ShamsheerkhanNo ratings yet

- Dual Phase SteelsDocument22 pagesDual Phase SteelsPathan ShamsheerkhanNo ratings yet

- Microalloyed Steel - Wikipedia, The Free EncyclopediaDocument1 pageMicroalloyed Steel - Wikipedia, The Free EncyclopediaPathan ShamsheerkhanNo ratings yet

- Engine Coolant Additives and RadiatorsDocument7 pagesEngine Coolant Additives and RadiatorsFERTG100% (1)

- Astm D8128 - 17Document9 pagesAstm D8128 - 17mancjaNo ratings yet

- MSDS TriclosanDocument4 pagesMSDS TriclosanIvanie SilviaNo ratings yet

- Ceran Greases TdsDocument4 pagesCeran Greases TdsАлексейNo ratings yet

- Cobalt Light Insight 100Document2 pagesCobalt Light Insight 100Marius CovrigNo ratings yet

- User Manual Redpoint - PirometroDocument13 pagesUser Manual Redpoint - PirometroPedro SilvaNo ratings yet

- High Performance Viscosity Modifying AgentDocument2 pagesHigh Performance Viscosity Modifying AgentGrv SrmNo ratings yet

- Humic Substances in WaterDocument11 pagesHumic Substances in WaterMaleehaNo ratings yet

- Aquatrac5 enDocument4 pagesAquatrac5 enTRIMECHNo ratings yet

- SemDocument1 pageSemjakelowNo ratings yet

- Acid Base Titration NotesDocument3 pagesAcid Base Titration NotesaminahNo ratings yet

- N Butanol As An Extractant For Lactic Acid Recovery PDFDocument4 pagesN Butanol As An Extractant For Lactic Acid Recovery PDFKanungnit ChawongNo ratings yet

- CPL PCL ReportDocument3 pagesCPL PCL Reportlisl.pietersenNo ratings yet

- Ertc 2017 PTQDocument20 pagesErtc 2017 PTQnghiemta18No ratings yet

- Ghulam Ishaq Khan Institute of Engineering Sciences and Technology, (GIKI) Faculty of Engineering Sciences (FES)Document3 pagesGhulam Ishaq Khan Institute of Engineering Sciences and Technology, (GIKI) Faculty of Engineering Sciences (FES)bilal khanNo ratings yet

- Classification of Wine Samples by Means of ANNDocument7 pagesClassification of Wine Samples by Means of ANNIvan CordovaNo ratings yet

- Siddha Medicine - RasaganthimezhuguDocument4 pagesSiddha Medicine - RasaganthimezhugujawsantoNo ratings yet

- H1000e K FJDocument8 pagesH1000e K FJSyarif HidayatullahNo ratings yet

- TrussDocument18 pagesTrussSYifa ShuhaIliNo ratings yet

- Fundamentals of Cyclic VoltammetryDocument8 pagesFundamentals of Cyclic VoltammetryIsraelNo ratings yet

- Styro LutionDocument3 pagesStyro LutionGanesan TNo ratings yet

- G B Veeresh Kumar, P S Shivakumar Gouda, R Pramod, CspraoDocument6 pagesG B Veeresh Kumar, P S Shivakumar Gouda, R Pramod, CspraoShivu RajNo ratings yet

- The Quantum-Mechanical Model of The Atom: Chemistry: A Molecular Approach, 1Document75 pagesThe Quantum-Mechanical Model of The Atom: Chemistry: A Molecular Approach, 1Claudine MarmolNo ratings yet