Professional Documents

Culture Documents

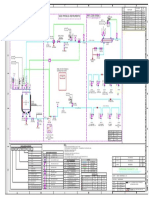

Separated water pump data sheet

Uploaded by

Sara Khan0 ratings0% found this document useful (0 votes)

48 views1 pageOriginal Title

4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps).xls

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

48 views1 pageSeparated water pump data sheet

Uploaded by

Sara KhanCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

Spec. No.

4823-DS-2287

DATA SHEET FOR Prep. SR Chk. DF Apr. PR

SEPARATED WATER PUMPS Date 01-06-10

Sheet 1 of 1 Rev. 0

Applicable To: Proposals Purchase As Built

Note: Indicates information to be completed by purchaser.

Indicates information to be completed by manufacturer.

For EPRF-II Site Karachi

Unit Offsite Service SEPARATED WATER PUMPS

No. Pumps Req'd. 2 No. Motors Req'd 2 Provided By Mtd By

Item No. P-5007A/B Item Description

No. Engines Req'd. --- No. Turbines Req'd ---- Provided By Mtd By

Pump Mfr. Size and Type Serial No.

OPERATING CONDITIONS, EACH PUMP PERFORMANCE (STA)

Liquid Water Flow at PT. gpm Nor. 225 Rated 250 Proposal Curve No.

Disch. Press. (psig) 35.0 RPM NPSHR (Water)

PT.(ºC) Nor. 30 Max. 45 Suct. Press.(psig) -1.5 Rated 0 Eff. BHP Rated

Sp.Gr. at PT. 1 Diff. Press. (psi) 36.5 Max. BHP rated IMP

Vap. Press. at PT. (psia) 1 Diff. Head (FT) 84 Max. Head Rated IMP

Vis. at PT. cP 0.6 NPSHA (ft) 20.0 gpm

Corr/Eros. Caused by Hyd. HP 5.32 Rotation (Viewed from CPLG End)

Location: Indoor Outdoor Area: Safe Hazardous Head rise to shut off

Working: Continuous Intermittent Random

CONSTRUCTION SHOP TESTS

Nozzles Size Rating Facing Location Non-Wit. Perf. Wit. Perf.

Suction 4" (Note-3) 150# RF outdoor Non-Wit. Hydro v Wit. Hydro

Discharge 4" (Note-3) 150# RF outdoor NPSH Req'd. v Wit. NPSH

Case-mount: Centerline Foot Bracket Vert. (Type) Shop Inspection

- Split: Axial Rad; Volute Type: SGL DBL Diffuser Dismant. & Insp. After Test

- Press: Max. Allow, psig @ ºC; Hydro Test psig Other

- Connect: Vent Drain Gage

Impeller Dia. : Rated Max. Type:

Mount: Between Bearings Overhung

Bearings-type: Radial Thrust MATERIALS

Lube: Ring Oil Flood Oil Mist Flinger Pressure CASE

Coupling: Mfr. Model IMPELLER (S)

Driver Mtd. By: Pump Mfr. Driver Mfr. Purchaser SHAFT

Packing: Mfr. & Type Size/No. of Rings WEAR RING

Mech. Seal: Mfr. & Model

Mfr. Code --

AUXILIARY PIPING VERTICAL PUMPS

C.W. Pipe Plan CU SS Tubing; Pipe Pit or Sump Depth 4 Ft

Total Cooling Water Req'd (m3/hr)

req gpm Sight F.I. Req'd Min. Submergence Req'd.

Packing Cooling Injection Req'd: Total . gpm psig Column Pipe: Flanged Threaded

Seal Flush Piping Plan CS SS Tubing Pipe Line Shaft: Open Enclosed

External Seal Flush Fluid gpm psig Brgs: Bowl Line Shaft

Auxiliary Seal Plan CS SS Tubing Pipe Brg.Lube Water Oil Grease

Aux. Seal Quench Fluid Float & Rod CS SS BRZ None

Float Switch

MOTOR DRIVER Pump thrust,lb. UP Down

HP RPM Frame Volts/Phase/Cycles 400/3 Phase/50 Hz

Mfr. Bearings Lube

Cooling Type TEFC Insulation Class F Full Load Amps

Cable Entries Temp. Rise Class B Locked Rotor Amps

Enclosure IP 55, Class I, Zone-2, Gas Group IIA, Ex 'd' type, temperature classification T3 Approx. WT. Pump & Base

Motor Turbine

NOTES: 4) Refer to site & Environmental data 4823-A-1009.

1) NPSH(A) at Pump suction Nozzle.

2) STA: Supplier to Advise.

3) Suction and Discharge Line Sizes.

You might also like

- Nitrogen Determination by Kjeldahl MethodDocument7 pagesNitrogen Determination by Kjeldahl MethodLinh VũNo ratings yet

- C Elementar Vario MACRO Cube PDFDocument16 pagesC Elementar Vario MACRO Cube PDFWaleed El-azab100% (1)

- MAN0011430 Pierce BCA Protein Asy UGDocument8 pagesMAN0011430 Pierce BCA Protein Asy UGIvie João GabrielNo ratings yet

- LX 1108Document2 pagesLX 1108yuribon1986No ratings yet

- Factory: Gut No.402,403 Part, 434 Part, Dinkar Pada, Post-Kondala, Taluka-Wada, Dist - Thane-421312 (M.S.)Document1 pageFactory: Gut No.402,403 Part, 434 Part, Dinkar Pada, Post-Kondala, Taluka-Wada, Dist - Thane-421312 (M.S.)Ravi YadavNo ratings yet

- Palintest Water Testing CatalogueDocument80 pagesPalintest Water Testing CatalogueAbdul GhafoorNo ratings yet

- Polmon CatalogueDocument56 pagesPolmon CatalogueAtri GulatiNo ratings yet

- Chemistry InstrumentsDocument19 pagesChemistry Instrumentshani1986yeNo ratings yet

- Is-11255.2.1985 - Methods For Measurement of Emissions From Stationary-SO2Document14 pagesIs-11255.2.1985 - Methods For Measurement of Emissions From Stationary-SO2Stacy WilsonNo ratings yet

- Two-Wire Radar Level Transmitter: Rosemount 5400 SeriesDocument36 pagesTwo-Wire Radar Level Transmitter: Rosemount 5400 SeriesthotalnNo ratings yet

- Assay Determination: General IndexDocument10 pagesAssay Determination: General IndexDavid SanabriaNo ratings yet

- Handing OverDocument2 pagesHanding OverjackjbandaraNo ratings yet

- TOC-L OQR Rev1.04 ZEMH-8100DDocument24 pagesTOC-L OQR Rev1.04 ZEMH-8100DLolaNo ratings yet

- CALIBRATION OF Piston Pipette and Buritte PDFDocument98 pagesCALIBRATION OF Piston Pipette and Buritte PDFBan ZanganaNo ratings yet

- BS en 12823-1-2014Document20 pagesBS en 12823-1-2014Abdullah FouadNo ratings yet

- Atomic Absorption Spectrometer User ManualDocument39 pagesAtomic Absorption Spectrometer User ManualKidus YohannesNo ratings yet

- Polarized Zeeman Atomic Absorption Spectrophotometer ZA3000 Series Sales InformationDocument2 pagesPolarized Zeeman Atomic Absorption Spectrophotometer ZA3000 Series Sales InformationAnh Vương0% (1)

- Manual For Perkin Elmer Series 200 PumpDocument245 pagesManual For Perkin Elmer Series 200 PumpEugene Kulikov100% (1)

- Manual 870 KF Titrino Plus 8 (1) .870.8001ENDocument76 pagesManual 870 KF Titrino Plus 8 (1) .870.8001ENahmedNo ratings yet

- List of AbbreviationsDocument61 pagesList of AbbreviationsrkponrajNo ratings yet

- JT BAKER CatalogDocument73 pagesJT BAKER CatalogwardoyogussanNo ratings yet

- Digital Process Indicator Selectron PIC152Document1 pageDigital Process Indicator Selectron PIC152industrialindiaNo ratings yet

- K P Pathrose Vaidyan'S Kandamkulathy Vaidyasala Po Mala, KuzhurDocument2 pagesK P Pathrose Vaidyan'S Kandamkulathy Vaidyasala Po Mala, KuzhurANU M ANo ratings yet

- Certificate of Analysis: OFN EI Checkout Standard 1 PG/ LDocument1 pageCertificate of Analysis: OFN EI Checkout Standard 1 PG/ LYony Jhontan Guerreros IñigoNo ratings yet

- Continuous Emissions Monitoring System IIDocument27 pagesContinuous Emissions Monitoring System IIAndy LuthorNo ratings yet

- Install and calibrate pH meterDocument15 pagesInstall and calibrate pH meterrichard limNo ratings yet

- 001 AbbrevationsDocument86 pages001 AbbrevationssreeniNo ratings yet

- Belz Calibration Lab ISO AccreditationDocument24 pagesBelz Calibration Lab ISO AccreditationrohanmanimaniNo ratings yet

- EAU S1 - Fan SelectionDocument1 pageEAU S1 - Fan SelectionMohsin ShaikhNo ratings yet

- Requirements For NABLDocument1 pageRequirements For NABLSiva ShankarNo ratings yet

- WFI system design and specificationsDocument1 pageWFI system design and specificationsvinay singhNo ratings yet

- MA180-005 subPUR-duoPUR User ManualDocument34 pagesMA180-005 subPUR-duoPUR User ManualDiana Putri SofyanNo ratings yet

- Consumables Catalog: ShimadzuDocument208 pagesConsumables Catalog: ShimadzuHarveenkaur Malhan100% (1)

- FAT Protocol PDFDocument2 pagesFAT Protocol PDFvinodNo ratings yet

- HPLC Analysis of AnthocyanidinDocument14 pagesHPLC Analysis of AnthocyanidinNaeem MalikNo ratings yet

- 29-Stop Watch Calibration CartificateDocument1 page29-Stop Watch Calibration CartificateCustomer SupportNo ratings yet

- Vacuum Pumps Catalog PDFDocument8 pagesVacuum Pumps Catalog PDFsriguruprasathsNo ratings yet

- HPLC Verification - Pic Added &shortendDocument40 pagesHPLC Verification - Pic Added &shortendMD Fahad MiajiNo ratings yet

- Vacuum Oven SOPDocument4 pagesVacuum Oven SOPOtávio Augusto Titton DiasNo ratings yet

- Internal Calibration Check HPLC SystemDocument6 pagesInternal Calibration Check HPLC SystemAayushi SanghalNo ratings yet

- NABL accredited temperature controller calibration certificateDocument1 pageNABL accredited temperature controller calibration certificateCustomer SupportNo ratings yet

- Dissolution CatalogueDocument48 pagesDissolution Catalogueabhijit_gothoskar6039No ratings yet

- Citrix MODocument6 pagesCitrix MObilalmasNo ratings yet

- 11 FlasksDocument5 pages11 FlasksImad AghilaNo ratings yet

- Skalar Methods: Analysis: Ortho Phosphate Range: 5 200 G P/liter Sample: Sea Water SANDocument6 pagesSkalar Methods: Analysis: Ortho Phosphate Range: 5 200 G P/liter Sample: Sea Water SANBruno PereiraNo ratings yet

- A Study On Verification of SphygmomanometersDocument3 pagesA Study On Verification of SphygmomanometerssujudNo ratings yet

- Cary SpecificationsDocument8 pagesCary SpecificationsmafiwarsNo ratings yet

- TF6 ReportDocument19 pagesTF6 ReportTing Kee Chuong100% (1)

- Room Pressure and Airflow Specifications for Pharmaceutical FacilityDocument11 pagesRoom Pressure and Airflow Specifications for Pharmaceutical FacilityAlison LewisNo ratings yet

- ThermoregulationDocument64 pagesThermoregulationapi-3703371No ratings yet

- B-324 Operationmanual en D LowresDocument32 pagesB-324 Operationmanual en D LowresOchie Yusuf100% (1)

- V Type Solid BlenderDocument7 pagesV Type Solid Blendermmk111No ratings yet

- Zero Headspace Extractor (ZHE) Manual 08.2016Document6 pagesZero Headspace Extractor (ZHE) Manual 08.2016Mari Sherlin Salisi-ChuaNo ratings yet

- Testcoo Sample Report-Air FryerDocument41 pagesTestcoo Sample Report-Air FryerraulNo ratings yet

- Chemical Analysis Group Document Provides Helpful Cabling DiagramsDocument21 pagesChemical Analysis Group Document Provides Helpful Cabling DiagramsBaroto Setyo SuryoNo ratings yet

- Stop Watch-ID-23 - 24 To 25Document2 pagesStop Watch-ID-23 - 24 To 25monwar hosenNo ratings yet

- Verifical Turbine Pump PDFDocument1 pageVerifical Turbine Pump PDFnecio77No ratings yet

- Data Sheet P-0560 - Hot Oil Drain Tank Sump PumpDocument2 pagesData Sheet P-0560 - Hot Oil Drain Tank Sump Pumpcygnus marine panamaNo ratings yet

- Data Sheet Item 2Document3 pagesData Sheet Item 2Bagus SigitNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Molecular SievesDocument5 pagesMolecular SievesgeogeogeoNo ratings yet

- PumpDocument48 pagesPumpArman Malik100% (2)

- Return of Ppftz-03 (Carbon Copy)Document4 pagesReturn of Ppftz-03 (Carbon Copy)7ndik4No ratings yet

- Install and Maintain Air ValvesDocument11 pagesInstall and Maintain Air ValvesSannyBombeoJomocNo ratings yet

- Cat Bs 1103 Drainage Sewage Int ScreenDocument412 pagesCat Bs 1103 Drainage Sewage Int Screenscribd99190No ratings yet

- Hollow Section Connection Using BoltDocument4 pagesHollow Section Connection Using Boltikanyu79No ratings yet

- Control Valve Question and Answer - 2Document13 pagesControl Valve Question and Answer - 2TATA STEELNo ratings yet

- Centrifugal pump lab experimentDocument17 pagesCentrifugal pump lab experimentKarla PerezNo ratings yet

- Certificate: Neltex Development Company IncorporatedDocument3 pagesCertificate: Neltex Development Company IncorporatedEva MarquezNo ratings yet

- Shell and Tube Type Heat Exchanger Explained - saVReeDocument7 pagesShell and Tube Type Heat Exchanger Explained - saVReenuvvnak nachaNo ratings yet

- Water pollution lecture: MCLG, MCL, TT, effects, reuseDocument2 pagesWater pollution lecture: MCLG, MCL, TT, effects, reuseUsama EjazNo ratings yet

- Simulation of Chemical Processes Subject in The Chemical Engineering DegreeDocument19 pagesSimulation of Chemical Processes Subject in The Chemical Engineering DegreeAmoul DhahriNo ratings yet

- M-54 K4670433 Sewage Treatment SystemDocument8 pagesM-54 K4670433 Sewage Treatment SystemeconmechNo ratings yet

- New Microsoft Office Word DocumentDocument9 pagesNew Microsoft Office Word DocumentjaimonjoyNo ratings yet

- Oxidation Ponds & LagoonsDocument31 pagesOxidation Ponds & LagoonsDevendra Sharma100% (1)

- Lecture 5 GRANULATION PT 506Document45 pagesLecture 5 GRANULATION PT 506ahmed sharafNo ratings yet

- Plumbing Code Summarized-1Document22 pagesPlumbing Code Summarized-1dino100% (2)

- Greenlane Biogas Cover Page See Content On Following Page (S)Document3 pagesGreenlane Biogas Cover Page See Content On Following Page (S)Cibele AlvesNo ratings yet

- Guilbaud Et Al 2010 Laundry Water Recycling in Ship by Direct Nanofiltration With Tubular MembranesDocument7 pagesGuilbaud Et Al 2010 Laundry Water Recycling in Ship by Direct Nanofiltration With Tubular MembranesULISES ROJAS ZAMORANo ratings yet

- Aviation CatalogDocument110 pagesAviation CatalogSharrife JNo ratings yet

- VAG Non-Return Valves: The Optimum Valve For Each MediumDocument4 pagesVAG Non-Return Valves: The Optimum Valve For Each MediumAhmedRamadanNo ratings yet

- 2 3 10 01-GB PDFDocument2 pages2 3 10 01-GB PDFbeu catalinNo ratings yet

- Exercises Problem 4 Heat TransferDocument3 pagesExercises Problem 4 Heat TransferMeeko TanNo ratings yet

- Hazard Identification Hazard IdentificationDocument32 pagesHazard Identification Hazard IdentificationTowfiq AhmedNo ratings yet

- 23.05.2021 2020 Well-Wise Daily Geological Report For Drilling Wells (Status at 5:00 AM)Document1 page23.05.2021 2020 Well-Wise Daily Geological Report For Drilling Wells (Status at 5:00 AM)Manash HazarikaNo ratings yet

- Hot Water Generation and StorageDocument10 pagesHot Water Generation and StorageAhamed Manazir HazzaanNo ratings yet

- Microsoft Word - Man 2 Chap 11 Well Control EquipmentDocument77 pagesMicrosoft Word - Man 2 Chap 11 Well Control EquipmentЕмиль АббасовNo ratings yet

- STP Review Benitez - June 10 2013 Brahms PDFDocument2 pagesSTP Review Benitez - June 10 2013 Brahms PDFcoolth2No ratings yet

- GRINNELL Model B302 and Model BN302 Grooved End Butterfly Valves With Gear Operators or Lever-Lock Operators General DescriptionDocument6 pagesGRINNELL Model B302 and Model BN302 Grooved End Butterfly Valves With Gear Operators or Lever-Lock Operators General DescriptionСергей КолесниковNo ratings yet

- Jar&Jar Placement PDFDocument32 pagesJar&Jar Placement PDFAlejandro PonceNo ratings yet