Professional Documents

Culture Documents

Pathfinder 1995 Quick Reference Engine: Tune Up

Pathfinder 1995 Quick Reference Engine: Tune Up

Uploaded by

Luis Alfonso Ortiz ESpinosaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pathfinder 1995 Quick Reference Engine: Tune Up

Pathfinder 1995 Quick Reference Engine: Tune Up

Uploaded by

Luis Alfonso Ortiz ESpinosaCopyright:

Available Formats

Pathfinder 1995 Quick Reference Engine

VG30E

Engine Oil SAE 5W-30 (API SG, Energy Conserving Oil)

With Oil Filter 3 5/8 qt

Without Oil Filter 3 1/8 qt

Tune up

Spark Plugs Non California California

Standard Type BKR5EY BKR6EY

Hot Type BKR5EY

Cold Type BKR6EY BKR7EY

Plug Gap 0.031-0.035 in (.8 - .9 mm)

15 ± 2 BTDC

o o

Ignition Timing

Base Idle speed 700 rpm

Curb Idle (target) 750 ± 50 rpm

Idle Mixture Ratio Less Than 8 % CO

Throttle Position Sensor

T/P Closed Approx. 1 kΩ

T/P Open Approx. 9 kΩ

T/P/S On RPM Idle + 250 ± 150 rpm

T/P/S Idle Volt 0.5 V

Radiator Fill

Coolant Type Ethylene Glycol

2WD 4WD

Coolant Capacity 11 3/8 qt 12 3/8 qt

Compression Test

Standard 173 psi

Minimum 128 psi

Diff Between Cyl. 14 psi

Fuel System

Fuel Pump Pressure @ Idle

Vac. applied at fuel pressure regulator

34 psi

Vac. released at fuel pres. regulator

43 psi

Recommended Fuel 87 Octane

Fuel Pump Ω 0.2 - 5.0 Ω

Fuel Injector Ω 10 - 14 Ω

Pathfinder 1995 – Quick Reference – Engine 1

Sensors

O2 Sen Heater 3 - 1000 Ω

Mass Air Flow Sensor

Supply Volt. 11 - 14V

OutputVolt 1.5 - 2 V

Crank Pos Sen 166.5 - 203.5 Ω

Coolant Temp Sensor Ω

68°F (20°C) 2.1 - 2.9 kΩ

122°F (50°C) .68 - 1.00 kΩ

176°F (80°C) .30 - .33 kΩ

IACV-AAC Valve Ω Approx. 10Ω

IACV-Air Reg Ω Approx. 70 - 80 Ω

EGR Temp Sensor Ω

212°F (100°C) 85.3 ± 8.53 kΩ

Electrical

Ignition System

Firing Order 1-2-3-4-5-6

Ignition Coil

Primary Voltage 12V

Primary Ω Approx. 1 Ω

Secondary Ω Approx. 10 KΩ

Ign Coil Resistor Ω Approx. 2.2 kΩ

Ignition Wires Ω Less than 9.1 kΩ/ft (Less than 30 kΩ/m)

Battery Specs. USA Canada or USA option

Type 55D23R 75D31R

Capacity (V/AH) 12 / 60 12 /70

Cold Crank Amp 356 amps 447 amps

Discharge Amp 180 amps 210 amps

Charging System

Alternator Type LR170-745

Nom. Rated Out 12V / 70A

Reg. Volt 14.1- 14.7

Hot Output amp More than 22/1300

(Amps/rpm) More than 50/2500

More than 67/5000

EPA Mileage Estimate XE SE LE

(city/highway) 2WD (4WD) 4WD 2WD (4WD)

M/T 15/18 15/18

A/T 15/19 (15/19) 15/19 15/19 (15/18)

Pathfinder 1995 – Quick Reference – Engine 2

Pathfinder 1995 Quick Reference Engine

PREPARATION

Make sure that the following parts are in order.

1. Battery

2. Ignition system

3. Engine oil and coolant levels

4. Fuse

5. ECM harness connector

6. Vacuum hoses

7. Air intake system (Oil filler cap, oil level, etc.)

8. Fuel pressure

9. Engine compression

10. EGR valve operation (if equipped)

11. Throttle valve

12. Evaporative emission canister purge control valve.

Note:

• On A/C equipped vehicles, turn A/C "Off" for testing.

• Transmission should be in "Park" or "Neutral".

• "CO" probe should be inserted into exhaust approximately 16 inches.

• Turn off headlamps, heater blower, rear defogger, etc.

• Front wheels pointed straight.

• Perform inspection with cooling fans "Off".

Pathfinder 1995 – Quick Reference – Engine 3

Pathfinder 1995 Quick Reference A/T

RE4R01A

A/T Fluid Type Nissan Matic ‘D’

Oil Capacity 2WD 4WD

8 3/4 qt 9 qt

A/T Cooler Type Fin Type Structure

Up Shift Schedule Range

MPH(km/h)

2WD HalfThrottle Full Throttle

D 1 → D2 20 - 22 (32 - 36) 32 - 35 (52 - 56)

D 2 → D3 41 - 45 (66 - 72) 62 - 66 (99 - 107)

D 3 → D4 65 - 70 (105 - 113) 99 - 105 (159 - 169)

4WD (w/Final Gear Ratio 4.375)

D 1 → D2 20 - 22 (32 - 36) 31 - 34 (50 - 54)

D 2 → D3 40 - 43 (64 - 70) 60 - 65 (97 - 105)

D 3 → D4 69 - 74 (111 - 119) 101 - 107 (162 - 172)

4WD (w/Final Gear Ratio 4.625)

D 1 → D2 19 - 22 (30 - 34) 29 - 31 (46 - 50)

D 2 → D3 37 - 41 (60 - 66) 56 - 61 (90 - 98)

D 3 → D4 64 - 69 (103 - 111) 93 - 99 (150 - 160)

Torque Converter Lock-up

MPH(km/h)

2WD Lock-up ON Lock-up OFF

(Approx 1/2 Throttle)

O/D Sw ON (D4) 63 - 68 (101 - 109) 51 - 56 (82 - 90)

O/D Sw OFF (D3) 47 - 52 (76 - 84) 44 - 49 (71 - 79)

(Full Throttle)

O/D Sw ON (D4) 99 - 104 (160 - 168) 96 - 101(155 - 163)

O/D Sw OFF (D3) 62 - 66 (99 - 107) 57 - 62 (91 - 99)

4WD (w/Final Gear Ratio 4.375)

(Approx 1/2 Throttle)

O/D Sw ON (D4) 68 - 73 (110 - 118) 51 - 56 (82 - 90)

O/D Sw OFF (D3) 47 - 52 (76 - 84) 44 - 49 (71 - 79)

(Full Throttle)

O/D Sw ON (D4) 101 - 106 (163 - 171) 98 - 104(158 - 168)

O/D Sw OFF (D3) 60 - 65 (97 - 105) 57 - 67 (92 - 108)

4WD (w/Final Gear Ratio 4.625)

(Approx 1/2 Throttle)

O/D Sw ON (D4) 64 - 69 (103 - 111) 52 - 57 (83 - 91)

O/D Sw OFF (D3) 47 - 52 (76 - 84) 44 - 49 (71 - 79)

(Full Throttle)

O/D Sw ON (D4) 94 - 99 (151 - 159) 91 - 96 (146 - 154)

O/D Sw OFF (D3) 56 - 61 (90 - 98) 53 - 58 (86 - 94)

Stall RPM R, D, 2, 1 position 2,260 - 2,510 rpm

2

Line Pressure PSI (kg/cm )

At Curb Idle At Stall rpm

R - Position 122 - 128 (8.6 - 9) 202 - 213 (14.2 - 15)

D,2,1 - Position 77 - 82 (5.4 - 5.8) 128 - 139 (9 - 9.8)

Pathfinder 1995 – Quick Reference – A/T 4

Shift Solenoids

Gear Solenoid A Solenoid B

1st ON ON

2nd OFF ON

3rd OFF OFF

4th ON OFF

Solenoid Valves Resistance Pin Number

Shift Solenoid A 20 - 30 Ω 35

Shift Solenoid B 20 - 30 Ω 36

Ovr. Clutch Solenoid 20 - 30 Ω 21

Line Pres. Solenoid 2.5 - 5 Ω 34

T/Conv. Clutch Sol 10 - 16 Ω 22

ATF Temp Sensor

68° F (20° C) 2.5k Ω

176° F (80° C) 0.3k Ω

Rev Sensor 500 – 650 Ω

Drop Resistor 11.2 - 12.8 Ω

Brake Band

Anchor end pin torq. 35 - 52 in lbs.

Num of return turns 2.5

Pathfinder 1995 – Quick Reference – Engine 5

Pathfinder 1995 Quick Reference A/T

PRECAUTIONS

• Before performing any diagnostic test, vehicle should be driven for approximately 10 minutes

to raise transmission to the proper operating temperature of 122° to 176°.

• During stall testing, never hold throttle wide open for more than 5 seconds at a time. Extended

stall testing can overheat transmission and cause serious damage.

• Nissan Matic 'D' ATF is the only fluid accepted for warranty, service contracts and goodwill

repairs.

• Before performing any internal repairs, thoroughly clean the outside of the transmission case

to prevent contamination.

• Use lint free cloth or towels for wiping parts. Common shop towels can leave contaminating

fibers on the transmission parts and cause improper transmission operation.

• When servicing the valve body, valves, sleeves, plugs, etc. should slide along the bores in the

valve body under their own weight.

• Before assembly, apply a coat of ATF to all internal transmission parts. Use petroleum jelly to

protect o-rings and seals, or to hold bearings and washers in place during assembly.

Important Note: Nissan Matic 'D' must be used in performing repairs paid by Nissan/Infiniti, such

as warranty, service contract, or good-will repairs. There will not be reimbursement for repairs

when non-genuine Nissan Matic 'D' is used.

Pathfinder 1995 – Quick Reference – A/T 6

Pathfinder 1995 Quick Reference M/T

FS5R30A

Clutch

Pedal height "H" 8.94 - 9.33 in (227 - 237 mm)

Pedal free play “A” 0.039 - 0.059 in (1.0 - 1.5 mm)

Flywheel Run-out Less than 0.0059 in (0.15 mm)

Clutch Disc Run-out 0.039 in (1.00 mm)

Clutch Cover Torque 7 - 14 ft/lbs (1 - 2 kg/m)

(Two Stages) 16 - 22 ft/lbs (2.2 - 3.0 kg/m)

Diaphragm Spring Toe Height

Uneven Limit 0.020 in (0.5 mm)

Refill Capacity 2WD 4WD

(75W-90 API GL-4) 5 1/8 pt 7 5/8 pt

Gear End Play

1st - 2nd - 3rd-OD 0.0091 - 0.0130 in (0.23 - 0.33 mm)

Reverse main gear 0.0130 - 0.0169 in (0.33 - 0.43 mm)

Counter gear 0.0039 - 0.0098 in (0.10 - 0.25 mm)

Reverse idler gear 0.0118 - 0.0209 in (0.30 - 0.53 mm)

Clearance Between Baulk Ring And Gear

Standard Wear Limit

1st, 4th and OD Gear 0.0413 - 0.0512 in 0.028 in

(1.05 - 1.30 mm) (0.7 mm)

2nd & 3rd Outer (A) 0.024 - 0.043 in 0.008 in

(0.6 - 1.1 mm) (0.2 mm)

2nd & 3rd Inner (B) 0.028 - 0.035 in 0.008 in

(0.7 - 0.9 mm) (0.2 mm)

Reverse to Reverse Cone Rear Surface (A)

-0.0039 - 0.0138 in 0.028 in

(-0.10 - 0.35 mm) (0.7 mm)

Main Drive Gear Snap Ring

Specified Clearance 0 - 0.004 in (0 - 0.1mm)

Mainshaft Front Snap Ring

Specified Clearance 0 - 0.004 in (0 - 0.1mm)

Counter Gear Front Bearing Thrust Washer

Specified End-Play 0.0039 - 0.0098 in (0.10 - 0.25 mm)

Reverse Idler Gear Rear Thrust Washer

Specified End-Play 0.0118 - 0.0209 in (0.30 - 0.53 mm)

Mainshaft C Ring

Specified Clearance 0 - 0.004 in (0 - 0.1 mm)

Counter Gear Rear Snap Ring

Specified Clearance 0 - 0.004 in (0 - 0.1 mm)

Pathfinder 1995 – Quick Reference – M/T 7

Pathfinder 1995 Quick Reference M/T

PRECAUTIONS

• Nissan does not recommend flywheel resurfacing. If flywheel is not within specification,

replacement is recommended.

• Refill transmission with the proper viscosity and amount of gear lube for the anticipated

temperatures.

• To help prevent clutch judder, avoid excessive grease to clutch disc splines, input shaft and

throwout bearing. Be sure to clean off any excessive grease.

• On rear wheel drive vehicles, inspect the shift control lever bushing for wear and proper

alignment prior to reinstallation of a removed transmission.

• To avoid transmission contamination, inspect the shift lever dust boot for cracks or damage,

and replace if needed. Install plastic wire ties to insure a tight fit of the boot to the shifter and

housing.

• Before reinstallation of a removed transmission, inspect the engine to transmission alignment

dowels for damage. Damaged dowels can cause misalignment of the engine to transmission,

and this can cause the transmission to jump out of gear.

Pathfinder 1995 – Quick Reference – M/T 8

Pathfinder 1995 Quick Reference Heater & A/C

AIR CONDITIONER

Compressor

Make DKV-14C

Type Vane Rotary

Compressor Clutch

Disc-to-Pulley Clearance

0.12 - 0.024 in (0.3 - 0.6 mm)

Refrigerant

Type HFC-134a (R134a)

Capacity 1.65 - 1.87 lb.

Refrigerant Oil

Type Nissan Type "R" Lub.

Capacity 6.8 fl oz

Oil to Add Per Evaporator 2.5 oz (75 ml)

Condenser 2.5 oz (75 ml)

*Liquid Tank 0.2 oz (5 ml)

Large Refrig. Leak 1.0 oz (30 ml)

Compressor

(*Add only if comp. is not replaced.)

Engine Idle w/A/C On Approx. 800 ± 50 rpm in Neutral

Performance Test

Recirculating-to-Discharge Air Temp

Recirc .Air Temp. at Discharge Air Temp. at

Blower Assy. Inlet Center Ventilator

Relative Humidity F°° (C°°) F°° (C°°)

50 - 60 % 68°(20°) 44 - 47° (7 - 8°)

77°(25°) 51 - 54° (10 - 12°)

86°(30°) 58 - 62° (14 - 17°)

95°(35°) 65 - 70° (18 - 21°)

104° (40°) 72 - 77° (22 - 25°)

60 - 70 % 68°(20°) 47 - 50° (8 - 10°)

77°(25°) 54 - 58° (12 - 14°)

86°(30°) 62 - 66° (17 - 19°)

95°(35°) 70 - 74° (21 - 24°)

104° (40°) 77 - 83° (25 - 28°)

Pathfinder 1995 – Quick Reference – Heater & A/C 9

Ambient Air Temp-to-Operating Pressure

Air temperature Relative Humidity 50-70%

F°(C°) High-pres. PSI Low-pres. PSI

68°(20°) 139 - 172 16 - 23

77°(25°) 188 - 232 24 - 31

86°(30°) 186 - 228 24 - 31

95°(35°) 220 - 270 34 - 41

104°(40°) 256 - 313 42 - 51

Dual-Pres Switch High Side Line Pres Operation/Continuity

PSI

Inc. 23 - 34 On/Exists

Dec. 23 - 31 Off/No Continuity

Dec. 270 - 327 On/Exists

Inc. 356 - 412 Off/No Continuity

Thermo Control Amp F° (C°) Voltage

Dec. 32 - 34 (0.1 - 0.9) Off (12v)

Inc. 37 - 38 (2.5 - 3.5) On (0v)

Thermal Protector F°° (C°°) Compressor

Inc 293-311 (145-155) Off

Dec 266-284 (130-140) On

A/C Drive Belt Deflection

Engine Cold Used Belt New Belt

Deflection Limit 0.63 in (16 mm) 0.63 in (16 mm)

Deflection After Adjust

KA24E 0.35 - 0.43in (9 - 11mm) 0.28 - 0.35in (7 - 9mm)

VG30E 0.39 - 0.47in (10 - 12mm) 0.31 - 0.39in (8 - 10mm)

Pathfinder 1995 – Quick Reference – Heater & A/C 10

Pathfinder 1995 Quick Reference Heater & A/C

PERFORMANCE TEST CONDITIONS

• Vehicle indoors or in the shade

• Doors closed

• Windows open

• Hood open

• Temperature on "Max" setting

• Discharge air on "Face Vent"

• Recirculation switch on "Recirc"

• Fan speed on "High"

• A/C switch "On" and verify A/C Clutch engagement

• Engine speed at 1500 RPM

• Verify heater cock is closed

• Operate the A/C system for 10 minutes before taking measurements

Precautions:

1. When removing the compressor, store it in the same position as it is mounted in the vehicle.

Failure to do so may cause lubricant to enter the low pressure chamber and cause compressor

damage.

2. Allow components stored in cool areas to warm to area temperatures before removing seals.

This prevents condensation from forming inside A/C components.

Pathfinder 1995 – Quick Reference – Heater & A/C 11

Pathfinder 1995 Quick Reference Suspension

WHEEL ALIGNMENT (UNLADEN)

Toe-in Range Nominal

Total toe-in (A - B)

2WD 0.04 - 0.20 in 0.08 - 0.16 in

(1 - 5 mm) (2 - 4 mm)

4WD 0.12 - 0.20 in 0.08 - 0.16 in

(3 - 5 mm) (2 - 4 mm)

Total toe-in angle

2WD 10' - 20' 5' - 25'

4WD 14' - 24' 9' - 29'

Front Wheel Turning Angle (full turn)

2WD Range Nominal

In/Wheel 36° - 38° 34° - 38°

Out/Wheel 33° - 35° 31° - 35°

4WD

In/Wheel 33° - 35° 31° - 35°

Out/Wheel 31° - 33° 29° - 33°

4WD (31x10.5R15 Tire)

In/Wheel 27° - 29° 25° - 29°

Out/Wheel 25° - 27° 23° - 27°

Camber Range Nominal

2WD -0° 20' - 1° 10' -0° 05' - 0° 55'

4WD -0° 05' - 1° 25' 0° 10' - 1° 10'

Left/Right Difference 45' 45'

Caster Range Nominal

2WD -0° 20' - 1° 10' -0° 20' - 1° 10'

4WD -0° 20' - 1° 10' -0° 48' - 1° 48'

Left/Right Difference 45' 45'

Kingpin Inclination

Range 13.58° - 15.08° (13° 35' - 15° 05’)

Nominal 14° 33' (14° 20’)

Set Back 0.0in +/- (0.0 mm +/-)

Ride Height (H=A-B) Range Nominal

2WD 4.25 - 4.65 in 4.37 4.53 in

(108 - 118 mm) (111 - 115 mm)

4WD 1.73 - 1.89 in 1.61 - 2.01 in

(41 - 51 mm) (44 - 48 mm)

Rear Wheel Alignment

Toe-in Range Nominal

Total toe-in (A - B) 0.00 in - 0.00 in 0.00 in - 0.00 in

(0 - 0.0 mm) (0 - 0.0 mm)

Total toe-in angle 0.00° - 0.00° 0.00°

(left plus right) (0' - 00') (00')

Pathfinder 1995 – Quick Reference – Suspension 12

Camber

Range 0.00° - 0.00° (0° 00' - 0° 00’)

Nominal 0.00° (0° 00')

Thrust Angle 0.0° +/- (0°00’ +/-)

Ball Joint End Play Vertical End Play

Upper Lower 0.063 in (1.6 mm)

2WD Lower 0.063 in (1.6 mm)

4WD Lower 0.020 in (0.5 mm)

Front Wheel Bearing

2WD

Axial End Play 0.00 in (0.00 mm)

Bearing Preload New Seal 2.2 - 6.4 lb (1.0 - 2.9 kg)

Bearing Preload Old Seal 2.2 - 5.3 lb (1.0 - 2.4 kg)

4WD

Axial End Play of Drive Shaft 0.0177 in (0.45 mm) or less

Axial End Play of Front Wheel Hub 0.0 in (0.0 mm)

1st Tightening Torque 58 -72 ft/lb (8 - 10 kg/m)

2nd Tightening Torque 0.4 - 1.1 ft/lb (0.05 0 0.15 kg/m)

Turning Torque of wheel hub 1.59 - 4.72 lb (0.72 - 2.14 kg)

Rear Wheel Bearing Drum Brake Disc Brake

Total End Play 0.0008 - 0.0059 in 0.00 in

(0.02 - 0.15 mm) (0.00 mm)

Wheel Runout Aluminum Wheel Steel Wheel

Max. Lateral Runout: 0.012 in (0.3 mm) 0.031 in (0.8 mm)

Max. Radial Runout: 0.012 in (0.3 mm) 0.031 in (0.8 mm)

W/Lug Nut Torque 87 - 108 ft/lb (12-15 kg/m)

Pathfinder 1995 – Quick Reference – Suspension 13

Pathfinder 1995 Quick Reference Suspension

PRELIMINARY INSPECTION

• Check tires for wear and proper inflation

• Check wheel runout

• Check front wheel bearings excessive play

• Check front suspension for excessive play

• Check steering linkage for excessive play

• Check struts for leakage and condition

• Check vehicle for proper ride height

Precautions

1. When installing rubber parts, final tightening must be carried out under unladen conditions with

the tires on the ground.

2. Recheck alignment after installing removed suspension components.

Pathfinder 1995 – Quick Reference – Suspension 14

Pathfinder 1995 Quick Reference Brakes

BRAKE SYSTEM

Front Brake Model Code CL28VD

Brake Fluid DOT 3 (Recommended)

Master Cyl. Bore Dia. 1 in (25.40 mm)

Front Caliper Bore Dia. 1.685 in (42.8 mm)

Front Brake Pad Dimensions

Length 5.77 in (146.6 mm)

Width 1.909 in (48.5 mm)

Thickness 0.39 in (10.0 mm)

Front Brake Pad Wear Limit

Min. Thickness 0.079 in (2.0 mm)

Front Brake Rotor Dimensions

Outer Diameter 10.91 in (277.0 mm)

Standard Thickness 1.02 in (26.0 mm)

Front Brake Rotor Repair/Wear Limits

Max. Runout 0.007 in (0.28 mm)

Min. Thickness 0.945 in (24.0 mm)

Rear Drum Rear Disc

Brake Model Code LT26B AD14VB

Cylinder/Caliper 13/16 in (20.64 mm) 1.686 in (42.83)

Brake/Pad Shoe Dimensions

Length 9.83 in (249.6 mm) 3.929 in (99.8)

Width 1.97 in (50 mm) 1.319 in (33.5 mm)

Thickness 0.217 in (5.5 mm) 0.39 in (10.0 mm)

Brake/Pad Shoe Wear Limit

0.059 in (1.5 mm) 0.079 in (2.0 mm)

Brake Drum/Rotor Dimensions

Drum Inside Dia. 10.24 in (260.0 mm)

Rotor Thickness 0.71 in (18.0 mm)

Rotor Outside Dia. 11.26 in (286.0 mm)

Brake Drum/Rotor Repair/Wear Limits

Max Inner Diameter 10.30 in (261.5 mm)

Max Out Of Round 0.0012 in (0.03 mm)

Minimum Thickness 0.630 in (16.0 mm)

Maximum Runout 0.003 in (0.07 mm)

Parking Drum Brake DS19HB

Drum Inside Dia. 7.48 in (190.0 mm)

Brake/Pad Shoe Dimensions

Length 7.18 in (182.3 mm)

Width 1.18 in (30 mm)

Thickness 0.12 in (3.0 mm)

Pathfinder 1995 – Quick Reference – Brakes 15

Parking Drum Repair/Wear Limits

Max Inner Diameter 7.52 in (191.0 mm)

Minimum Pad Thk. 0.059 in (1.5 mm)

Brake Pedal Dimen. Manual Trans Auto Trans

Free Height 'H' 8.23 - 8.62 in 8.35 - 8.74 in

(209 - 219 mm) (212 - 222 mm)

Depressed Height 'D' 4.72 in (120 mm)

Pedal Free Play 'A'

At Clevis 0.04 - 0.12 in (1.0 - 3.0 mm)

At Pedal Pad 0.16 - 0.47 in (4.0 - 12.0 mm)

Switch Clearance 'C' 0.012 - 0.039 in (0.3 - 1.0 mm)

Brake Booster Model M215T

Output Rod Length 0.404 - 0.414 in (10.275 - 10.525 mm)

Dual Proportioning Valve

Applied Pressure Output Pressure

(Front Brakes) (Rear Brakes)

2

Std Pathfinder 995 psi (70 kg/cm ) 583 - 697 psi

2

(41 - 49 kg/cm )

2

SE Pathfinder 995 psi (70 kg/cm ) 711 - 825 psi

2

(50 - 58 kg/cm )

Parking Brake Control Number of Notches 7 - 9

ABS Wheel Sensor

Resistance 1.22 - 1.48 kΩ

Wheel Lug Nut 87 - 108 ft lb (12-15 kg-m)

Pathfinder 1995 – Quick Reference – Brakes 16

Pathfinder 1995 Quick Reference Brakes

PRECAUTIONS

1. Never reuse drained brake fluid.

2. Be careful not to splash brake fluid on painted surfaces.

3. Use clean brake fluid to clean or wash master cylinder wheel cylinders, and disc brake calipers

parts.

4. Mineral oils such as gasoline and kerosene should not be used. They can cause damage to

rubber parts of the hydraulic system.

5. Use flare nut wrench when removing or installing brake line fittings.

6. Always torque brake lines.

7. Always replace brake pad shims when replacing brake pads.

Warning:

Clean brake pads and shoes with a dust collector to minimize the hazard of airborne particles

or other materials.

Pathfinder 1995 – Quick Reference – Brakes 17

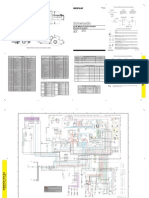

Pathfinder 1995 Quick Reference Electrical

ELECTRICAL NOTES

Wire Color Code

B = Black BR = Brown

W = White OR = Orange

R = Red P = Pink

G = Green PU = Purple

L = Blue GY = Gray

Y = Yellow SB = Sky Blue

LG = Light Green CH = Dark Brown

DG = Dark Green

When a wire color is striped, the base color is given first, followed

by the stripe color. Example L/W = Blue with white stripe

Battery specification:

Type 55D23R

Capacity 12 V / 60 AH

Cold cranking current 356 A

Load test at 3 × AH for 15 seconds.

Battery charging rates:

Amps Time

50 1 hour

25 2 hours

10 5 hours

5 10 hours

Do not charge battery over 50 ampere rate.

Do not "quick charge" a fully discharged battery.

If battery electrolyte temperature rises above 140°F, stop charging.

Starter:

S114-528A M1T60285

Type HITACHI MITSUBISHI

Reduction Reduction

Applied Model VG30E KA24E

No-load Current Less than 90 A 50 - 75 A

No-load RPM More than 2,650 3,000 - 4,000

Alternator:

VG30E KA24E

Type LR170-745 LR160-727

Nominal Rating 12 V / 70 AH 12 V / 60 A

Regulated Output Voltage 14.1 - 14.7 14.1 - 14.7

Output Current A/RPM More Than 22 / 1,300 More Than 17 / 1,300

(with 13.5 V applied) More Than 50 / 2,500 More Than 48 / 2,500

More Than 67 / 5,000 More Than 57 / 5,000

Thermal Transmitter (Water Temp. Sensor For Gauge)

Water Temperature Resistance

140°F (60°C) Approx. 70 - 90 Ω

212°F (100°C) Approx. 21 - 24 53 Ω

Oil Pressure Switch:

Oil pressure PSI Continuity

More Than 10 -20 NO

Less Than 10 - 20 YES

Pathfinder 1995 – Quick Reference – Electrical 18

Bulb Specifications:

Item Wattage (12V) Bulb No.

Headlamp

Conventional 65/55 6052

Halogen 65/35 H6054

Front Turn Signal 27 1156

Rear Turn Signal 27 1156

Front Parking Lamp 3.8 194

Stop/Tail Lamp 27/8 1157

Rear Side Marker 3.4 158

Center Stop Lamp 2.3 2723

Back-up Lamp 27 1156

License Plate Lamp 3.8 194

Interior Lamp 10

How to perform voltage drop test: See Illustrations

Pathfinder 1995 – Quick Reference – Electrical 19

Pathfinder 1995 Quick Reference Electrical

BATTERY CONDITION

Battery Sulphation:

A battery will be completely discharged if it is left unattended for a long time and the specific gravity

becomes less than 1.100. This may result in sulphation on the cell plates. To determine if a battery

has been sulfated, note its voltage and current when charging. If low current and higher voltage are

observed in the initial stages of charging a sulfated battery is likely. A sulfated battery may

sometimes be brought back into service by means of a long slow charge, 12 hours or more.

Checking Battery Specific Gravity With Hydrometer

Hydrometer temperature correction

Battery electrolyte temp. °C (°°F) Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

60 (140) 0.024

54 (129) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70) −0.004

16 (60) −0.008

10 (50) −0.012

4 (39) −0.016

−1 (30) −0.020

−7 (20) −0.024

−12 (10) −0.028

−18 (0) −0.032

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

• Do not quick charge a fully discharged battery.

• After charging, if the specific gravity of any two cells varies more then .050, the battery should be

replaced.

Pathfinder 1995 – Quick Reference – Electrical 20

You might also like

- Squadra Corse Huracan Super TrofeoDocument147 pagesSquadra Corse Huracan Super TrofeoDean BradshawNo ratings yet

- Diagrama Mazda-Ford Laser 1.8LDocument10 pagesDiagrama Mazda-Ford Laser 1.8LNixon Maldonado100% (5)

- Kawasaki ZR400 ZRZ500 ZRZ550 ZR 400 500 550 Maintenance Service Specifications Manual PDFDocument20 pagesKawasaki ZR400 ZRZ500 ZRZ550 ZR 400 500 550 Maintenance Service Specifications Manual PDFMotortrade Tayug Sales100% (2)

- Polaris Xplorer 400 ManualDocument7 pagesPolaris Xplorer 400 Manualdrashed76100% (2)

- Burgman I - Manual PDFDocument186 pagesBurgman I - Manual PDFAdriano CosmeNo ratings yet

- Strada 2001-2009 PDFDocument309 pagesStrada 2001-2009 PDFFernando MorenoNo ratings yet

- 2004 Infiniti G35 Coupe Quick Reference SpecsDocument17 pages2004 Infiniti G35 Coupe Quick Reference Specsnikkon1100% (2)

- Pathfinder 1997 Quick Reference Engine: Tune UpDocument18 pagesPathfinder 1997 Quick Reference Engine: Tune UpJoel DelgadoNo ratings yet

- Pathfinder 2003 - Quick Reference SpecificationsDocument18 pagesPathfinder 2003 - Quick Reference SpecificationsPaper-FaceNo ratings yet

- Quick Reference SpecsDocument19 pagesQuick Reference SpecsmatttmpomarNo ratings yet

- KA24DE: Frontier 2001 Quick Reference KA EngineDocument28 pagesKA24DE: Frontier 2001 Quick Reference KA EnginearbutacNo ratings yet

- 1500 Ccespesificaciones CarburadaDocument1 page1500 Ccespesificaciones Carburadajose marcialNo ratings yet

- General Specifications Model Identification: EngineDocument1 pageGeneral Specifications Model Identification: EngineFabianNo ratings yet

- KAWASAKI ZX11 - General SpecificationsDocument1 pageKAWASAKI ZX11 - General SpecificationsRaúl Di LolloNo ratings yet

- Sistema de CombustibleDocument97 pagesSistema de Combustiblesebastian velasquezNo ratings yet

- Kawasaki Ex500 PDFDocument120 pagesKawasaki Ex500 PDFpapergammaNo ratings yet

- Kawasaki Ex500 PDFDocument120 pagesKawasaki Ex500 PDFArmand Dudu100% (1)

- 6T70 IntroductionDocument45 pages6T70 IntroductionManuales Transmisiones Automaticas100% (4)

- Owners Manuel SupplementDocument6 pagesOwners Manuel SupplementJohn HansenNo ratings yet

- VN800A11Document1 pageVN800A1144887No ratings yet

- DR PB TD60M T3 6 11122023 ENG (M)Document6 pagesDR PB TD60M T3 6 11122023 ENG (M)ogi04No ratings yet

- Mustan 05-09 AutomaticDocument6 pagesMustan 05-09 AutomaticJohn MooreNo ratings yet

- Kaw 454 SpecsDocument2 pagesKaw 454 SpecsAnonymous pPacR7ydBNo ratings yet

- Specification Sheetapril 2016v3300 T E2bg2Document4 pagesSpecification Sheetapril 2016v3300 T E2bg2Richard Enciso JimenezNo ratings yet

- Service Specifications PDFDocument53 pagesService Specifications PDFAndrey GladyshevNo ratings yet

- Kawasaki ZX 9R E2 2001 Parts List WWW - Manualedereparatie.infoDocument65 pagesKawasaki ZX 9R E2 2001 Parts List WWW - Manualedereparatie.infocarvinte995No ratings yet

- YanmarDocument2 pagesYanmarRicardo Barbosa100% (2)

- Hyundai Exel 89 1.5l.full SistemDocument74 pagesHyundai Exel 89 1.5l.full SistemAlexander cesar neyra sotoNo ratings yet

- Automatic Transaxle SystemDocument111 pagesAutomatic Transaxle SystemJosue SanangoNo ratings yet

- 16h Electrical 6zjDocument2 pages16h Electrical 6zjqwureyquweryNo ratings yet

- SP VN1500P1Document1 pageSP VN1500P1Дмитрий КозловNo ratings yet

- S12R-Y1PTA-2 Mitsubishi Diesel Generator EngineDocument3 pagesS12R-Y1PTA-2 Mitsubishi Diesel Generator EnginealstomNo ratings yet

- Yanmar 9 HPDocument2 pagesYanmar 9 HPAhmet ErdemilNo ratings yet

- Sistema Electrico d5c Serie 7ps832Document2 pagesSistema Electrico d5c Serie 7ps832Jose MunizNo ratings yet

- Kawasaki Zx6r 00 02 PMDocument125 pagesKawasaki Zx6r 00 02 PMNurul Huda AliNo ratings yet

- 12Document35 pages12ED JO MenmarNo ratings yet

- 12 PDFDocument35 pages12 PDFED JO Menmar100% (1)

- 12 PDFDocument35 pages12 PDFED JO MenmarNo ratings yet

- Spec EngineDocument1 pageSpec EnginemannaihegbaaNo ratings yet

- 10106302-Arctic Cat 400 500 650 700 Utility Atv Service Manual Repair 2007 PDFDocument478 pages10106302-Arctic Cat 400 500 650 700 Utility Atv Service Manual Repair 2007 PDFROLANDO MELENDEZNo ratings yet

- TD AT A4CFX EngDocument18 pagesTD AT A4CFX EngjoseNo ratings yet

- MMR4 6105 Series Operation and Service ManualDocument46 pagesMMR4 6105 Series Operation and Service ManualJavier H Durán ValeroNo ratings yet

- Discover Dts I SRRDocument24 pagesDiscover Dts I SRRStev Betancur91% (11)

- Hydrostatic Transmissions: TB135 TB138-2 TB172 TB172-2 TB172-2Document2 pagesHydrostatic Transmissions: TB135 TB138-2 TB172 TB172-2 TB172-2Yundi GaoNo ratings yet

- 4L60E OperationDocument10 pages4L60E OperationcherokewagNo ratings yet

- Genera 1Document14 pagesGenera 1Denis RoscaNo ratings yet

- Yanmar 21 HPDocument2 pagesYanmar 21 HPAhmet ErdemilNo ratings yet

- 631e Plano ElectricoDocument2 pages631e Plano ElectricoMario Olivares Arambula100% (1)

- 2015 DG Charger SP 4 23Document9 pages2015 DG Charger SP 4 23Ayman RiyadhNo ratings yet

- 5 2 1Document1 page5 2 1soelist teoNo ratings yet

- TGB Service Manual 303R150 (BR9) and Delivery 150 (BK9)Document98 pagesTGB Service Manual 303R150 (BR9) and Delivery 150 (BK9)propaganda65No ratings yet

- S4S-Z3DT65SP (SPC-S4S-407 Rev 0) MEE StandardDocument17 pagesS4S-Z3DT65SP (SPC-S4S-407 Rev 0) MEE StandardPutra kurnia WijayaNo ratings yet

- 08.automatic Transaxle SystemDocument208 pages08.automatic Transaxle SystemTony D'AngeloNo ratings yet

- Subaru Engines Ex13 Ex17 Ex21 Ex27 sp170 sp210 Ex21efi Service PDFDocument113 pagesSubaru Engines Ex13 Ex17 Ex21 Ex27 sp170 sp210 Ex21efi Service PDFCristiano FerreiraNo ratings yet

- Robin EX 13 Service Manual 4.5 4.3 HP EngineDocument113 pagesRobin EX 13 Service Manual 4.5 4.3 HP Enginekatilicous100% (3)

- 4 Cylinder Deutz 50 KW - 90 KWDocument2 pages4 Cylinder Deutz 50 KW - 90 KWLeoven Jef Suzara LorinNo ratings yet

- Ffarm HC CabDocument2 pagesFfarm HC CabsindasilvaNo ratings yet

- Plano Eléctrico Tablero 7X6147Document2 pagesPlano Eléctrico Tablero 7X6147Anderson L RoncerosNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Reading The 17-Digit Vin: 1N6 A A0 6 B 9 7 N 1 2 3 4 5 6Document1 pageReading The 17-Digit Vin: 1N6 A A0 6 B 9 7 N 1 2 3 4 5 6Luis Alfonso Ortiz ESpinosaNo ratings yet

- Diagrama Seguros Switch 3 Patas - PNGDocument1 pageDiagrama Seguros Switch 3 Patas - PNGLuis Alfonso Ortiz ESpinosaNo ratings yet

- STR PDFDocument51 pagesSTR PDFLuis Alfonso Ortiz ESpinosaNo ratings yet

- Charging System: SectionDocument28 pagesCharging System: SectionLuis Alfonso Ortiz ESpinosaNo ratings yet

- 1996 - 1999 Nissan Pathfinder (R50) Automatic To Manual Transmission Conversion ManualDocument24 pages1996 - 1999 Nissan Pathfinder (R50) Automatic To Manual Transmission Conversion ManualLuis Alfonso Ortiz ESpinosaNo ratings yet

- STC PDFDocument23 pagesSTC PDFLuis Alfonso Ortiz ESpinosaNo ratings yet

- ST PDFDocument32 pagesST PDFLuis Alfonso Ortiz ESpinosaNo ratings yet

- Engine Cooling System: SectionDocument48 pagesEngine Cooling System: SectionLuis Alfonso Ortiz ESpinosaNo ratings yet

- Cruise Control System: SectionDocument4 pagesCruise Control System: SectionLuis Alfonso Ortiz ESpinosaNo ratings yet

- SRC PDFDocument87 pagesSRC PDFLuis Alfonso Ortiz ESpinosaNo ratings yet

- Brake System: SectionDocument42 pagesBrake System: SectionLuis Alfonso Ortiz ESpinosaNo ratings yet

- BRM PDFDocument102 pagesBRM PDFLuis Alfonso Ortiz ESpinosaNo ratings yet

- Body Control System: SectionDocument88 pagesBody Control System: SectionLuis Alfonso Ortiz ESpinosaNo ratings yet

- TEST 1pathfinderDocument20 pagesTEST 1pathfinderLuis Alfonso Ortiz ESpinosaNo ratings yet

- BMW Codes Obd IIDocument45 pagesBMW Codes Obd IIcepaezh67% (3)

- BRC PDFDocument241 pagesBRC PDFLuis Alfonso Ortiz ESpinosaNo ratings yet

- 1997 Nissan Pathfinder PDFDocument233 pages1997 Nissan Pathfinder PDFrodysoftNo ratings yet

- VESPA LX 2012 Service Station ManualDocument251 pagesVESPA LX 2012 Service Station ManualSamtakoiNo ratings yet

- Faresin Ita-Eng Mixer WagonDocument27 pagesFaresin Ita-Eng Mixer WagonGABRIELNo ratings yet

- 1 Scania Basic General Rev 1Document124 pages1 Scania Basic General Rev 1rozak maskubNo ratings yet

- MP190E35W: Technical DescriptionsDocument16 pagesMP190E35W: Technical DescriptionsBroCactusNo ratings yet

- Unit 2 - Automobile Suspension System: 1-Leaf Springs Absorb Shocks byDocument5 pagesUnit 2 - Automobile Suspension System: 1-Leaf Springs Absorb Shocks byDipak ZopeNo ratings yet

- Project ReportDocument87 pagesProject Reportavnish100% (1)

- Segway Villain Brochure WebDocument12 pagesSegway Villain Brochure Webanthonypippig5No ratings yet

- Active Body ControlDocument109 pagesActive Body ControlKishor ShiyaniNo ratings yet

- Analyzing Car Suspension System Using Finite Element AnalysisDocument32 pagesAnalyzing Car Suspension System Using Finite Element AnalysisEdd SamiNo ratings yet

- Front Wheel Alignment Rear Wheel AlignmentDocument8 pagesFront Wheel Alignment Rear Wheel AlignmentTecnoCar Services SDRNo ratings yet

- Lada Niva LiftDocument26 pagesLada Niva LiftFelipe EffeNo ratings yet

- 3 Elba Company Brochure PDFDocument2 pages3 Elba Company Brochure PDFSharafat AliNo ratings yet

- Ud Quester First GenDocument17 pagesUd Quester First GenSitichoke SemamonNo ratings yet

- Superliner Specsheet NZ 2022Document4 pagesSuperliner Specsheet NZ 2022SanBre ChannelNo ratings yet

- Fuzzy Sliding Mode Control ThesisDocument6 pagesFuzzy Sliding Mode Control Thesisgbwav8m4100% (2)

- ARO Industrial Chain HoistsDocument20 pagesARO Industrial Chain HoistsAhmedNo ratings yet

- Liebherr A918 T4F GBDocument44 pagesLiebherr A918 T4F GBCornelis JongenelenNo ratings yet

- British Icon 50 Years of The Range Rover - Issue 1 2020.Document100 pagesBritish Icon 50 Years of The Range Rover - Issue 1 2020.Digital EdukaNo ratings yet

- Spec Sheet Scania R520la6x2mnaDocument4 pagesSpec Sheet Scania R520la6x2mnaYanniNo ratings yet

- Proton JumbuckDocument5 pagesProton JumbuckirkeezNo ratings yet

- D85EX-15 Walkaround GuideDocument18 pagesD85EX-15 Walkaround Guidealcowo100% (1)

- 2832 TN Tipper BrochureDocument12 pages2832 TN Tipper BrochureJhamil CruzNo ratings yet

- Mark Raddenbury - Xpress EXECUTE FM1S - Sun Feb 13 2022Document1 pageMark Raddenbury - Xpress EXECUTE FM1S - Sun Feb 13 2022Tododesguace S.L.No ratings yet

- Catalogo Tecnico Reach Toyota BT 8FBRDocument8 pagesCatalogo Tecnico Reach Toyota BT 8FBRmostapha jawadNo ratings yet

- UM Racing Partner's HandbookDocument21 pagesUM Racing Partner's HandbookShaun AbelaNo ratings yet

- Cat StreetrodDocument132 pagesCat StreetrodMaxisys AutelNo ratings yet

- 3 Point Vs 4 Point Susdpension ControlDocument7 pages3 Point Vs 4 Point Susdpension ControlkalyanNo ratings yet