Professional Documents

Culture Documents

MasterPozzolith 409

Uploaded by

fajar yudhaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MasterPozzolith 409

Uploaded by

fajar yudhaCopyright:

Available Formats

MasterPozzolith® 409

Set retarding and water reducing concrete admixture

DESCRIPTION Offset effects of too early hardeningduring

extended delays between mixing and placing.

MasterPozzolith® 409 is a ready-to-use, liquid

Helps eliminate cold joints

admixture for producing high quality concrete with

Lower peak temperature and/or rateof

consistent performance.

temperature rise in mass concrete–reduces

It reduces the quantity of mixing water required to thermal cracking

produce concrete of a given workability with greater

economy for a given strength. The retarding nature DOSAGE

of the admixture also aids placing and finishing of MasterPozzolith® 409 admixture is recommended

concrete. for use at the rate of 200 - 750 mL per 100 kg of

MasterPozzolith® 409 meets ASTM C494/C494M cementitious content for most concrete mixes using

–Type B (Retarding) and Type D (water- typical concrete ingredients. Because of variations

reducingand retarding) admixtures. It does not in job conditions and concrete materials, dosage

containchloride-based ingredients and will not rates other than recommended amounts may be

initiate orpromote corrosion of reinforcing steel in required. In such cases, contact your local Master

concrete. Builders Solutions representatives.

FIELDS OF APPLICATION PACKAGING

MasterPozzolith® 409 is recommended for use in MasterPozzolith® 409 is available in 205L drum or

all types of concrete where moderate to extended in bulk delivery.

retardation of set and improved performance are SHELF LIFE

desired. The admixture improves workability of MasterPozzolith® 409 admixture has a minimum

pumped concrete, shotcrete (wet mix) and

shelf life of 12 months. Depending on storage

conventionally placed concrete.

conditions, the shelf life may be greater than stated.

MasterPozzolith® 409 can be used with high Please contact your Master Builders Solutions

content of manufactured sand and with air representative regarding suitability for use and

entraining admixtures approved under ASTM. When dosage recommendations if the shelf life of

used in conjunction with another admixture, each MasterPozzolith® 409 admixture has been

admixture must be dispensed separately into the exceeded.

mix. By itself, MasterPozzolith® 409 admixture

PACKAGING

does not entrain air.

Concrete produced with MasterPozzolith® 409 MasterPozzolith® 409 is available in 205L drum or in

admixture will have appreciable strength bulk delivery.

development after initial set occurs. If retardation is SHELF LIFE

within the normal ASTM C 494/C494M – types B

MasterPozzolith® 409 admixture has a minimum

and D specifications, MasterPozzolith® 409

shelf life of 12 months. Depending on storage

admixture will develop higher early (24 hours) and conditions, the shelf life may be greater than stated.

higher ultimate strengths than plain concrete when Please contact your Master Builders Solutions

used within the recommended dosage range and representative regarding suitability for use and dosage

under normal, comparable curing conditions. recommendations if the shelf life of MasterPozzolith®

FEATURES AND BENEFITS 409 admixture has been exceeded.

MasterPozzolith® 409 used at optimum dosage PRECAUTIONS

enhances the performance of concrete providing the Health: MasterPozzolith® 409 does not contain any

following special qualities: hazardous substances requiring labeling. It is safe

Improved workability for use with standard precautions followed in the

Reduced segregation construction industry, such as use of hand gloves,

Superior finishing characteristic safety goggles, etc. For detailed Health, Safety and

Controlled retardation depending onthe rate of Environmental recommendations, please consult

addition and follow a instructions in the product Material

Provides flexibility in scheduling of placing and Safety Data Sheet.

finishing

MasterPozzolith® 409

MasterPozzolith® 409

The technical information and application advice given in this BASF Construction Chemicals publication are based

STATEMENT OF on the present state of our best scientific and practical knowledge. As the information herein is of a general

RESPONSIBILITY nature, no assumption can be made as to a product's suitability for a particular use or application and no warranty

as to its accuracy, reliability or completeness either expressed or implied is given other than those required by law.

The user is responsible for checking the suitability of products for their intended use.

Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF either

NOTE

orally or in writing may be followed, modified or rejected by the owner, engineer or contractor since they, and not

BASF Construction Chemicals, are responsible for carrying out procedures appropriate to a specific application.

PT BASF Indonesia

DBS Bank Tower 27th Floor

Ciputra World 1 Jakarta

Jl. Prof. Dr. Satrio Kav. 3-5

Jakarta 12940

Phone: +6221 29886000

Website: www.master-builders-solutions.basf.co.id

You might also like

- Sk200-8 Sk210lc-8 Super AsiaDocument16 pagesSk200-8 Sk210lc-8 Super AsiaAnwar Rashid86% (7)

- IRS Form 13909Document2 pagesIRS Form 13909whoiscolleenlynnNo ratings yet

- OMT ReviewDocument12 pagesOMT ReviewKyle Derouen100% (6)

- Allison - Dp-8000 - Manual de Servicio - Pag-390Document390 pagesAllison - Dp-8000 - Manual de Servicio - Pag-390Manuales De Maquinaria Jersoncat100% (1)

- Nitric Acid - Nitrous Acid - Nitrogen Oxides - Ullman's EncyclopediaDocument49 pagesNitric Acid - Nitrous Acid - Nitrogen Oxides - Ullman's Encyclopediapoly6icsNo ratings yet

- CS 702 Lec10Document9 pagesCS 702 Lec10Muhammad TausifNo ratings yet

- Bachelor of Computer Applications: Pondicherry UniversityDocument49 pagesBachelor of Computer Applications: Pondicherry Universitybalaanand_mcaNo ratings yet

- Polyurethanes: Science, Technology, Markets, and TrendsFrom EverandPolyurethanes: Science, Technology, Markets, and TrendsRating: 1 out of 5 stars1/5 (1)

- Master Pozzolith 333Document2 pagesMaster Pozzolith 333sufian100% (1)

- QWQDocument2 pagesQWQdana setiawanNo ratings yet

- Basf Masterpozzolith 55 TdsDocument2 pagesBasf Masterpozzolith 55 TdsshunanlatheefNo ratings yet

- Masterrheobuild: High Range, Water Reducing Superplasticiser For Rheoplastic ConcreteDocument2 pagesMasterrheobuild: High Range, Water Reducing Superplasticiser For Rheoplastic ConcreteweamNo ratings yet

- Basf Masterpozzolith 55 TdsDocument2 pagesBasf Masterpozzolith 55 TdsOsmondNo ratings yet

- Pozzolith Standard PDFDocument2 pagesPozzolith Standard PDFFrancois-No ratings yet

- MasterPozzolith 384 Technical Data SheetDocument3 pagesMasterPozzolith 384 Technical Data Sheetabukayes.abdinNo ratings yet

- Tds - Pozzolith 55rDocument2 pagesTds - Pozzolith 55rFrancisco M. RamosNo ratings yet

- Basf Masterrheobuild 858 TdsDocument2 pagesBasf Masterrheobuild 858 TdsHassan SyedNo ratings yet

- Pozzolith 80 PDFDocument2 pagesPozzolith 80 PDFDoby YuniardiNo ratings yet

- Basf Masterpolyheed 8118 TdsDocument2 pagesBasf Masterpolyheed 8118 Tdsaji arafat100% (2)

- Tds - Pozzolith Ld10Document2 pagesTds - Pozzolith Ld10hammadali49No ratings yet

- Pozzolith CRP4+: High Performance Retarding Plasticiser For ConcreteDocument2 pagesPozzolith CRP4+: High Performance Retarding Plasticiser For ConcreteFrancois-No ratings yet

- Conplast SP430 0914Document4 pagesConplast SP430 0914Vipul AroraNo ratings yet

- Pozzolith 390N PDFDocument2 pagesPozzolith 390N PDFFrancois-No ratings yet

- Basf Masterpolyheed 8840 TdsDocument2 pagesBasf Masterpolyheed 8840 Tdssattar12345No ratings yet

- MasterPel 777 v2Document3 pagesMasterPel 777 v2ReaidNo ratings yet

- Tds - Rheofit 763Document2 pagesTds - Rheofit 763aahtagoNo ratings yet

- Masterpozzolith® MR 25s (Formerly Known As Pozzolith® MR 25 S)Document3 pagesMasterpozzolith® MR 25s (Formerly Known As Pozzolith® MR 25 S)RajNo ratings yet

- Basf Masterlife SF 100 TdsDocument2 pagesBasf Masterlife SF 100 Tdsaji arafatNo ratings yet

- Masterpozzolith R 300: Description DosageDocument2 pagesMasterpozzolith R 300: Description DosageMPS KALIBARUNo ratings yet

- Eng Masterrheobuild 850 TdsDocument4 pagesEng Masterrheobuild 850 TdsaghamshahidNo ratings yet

- Masterrheobuild 1126 v2Document2 pagesMasterrheobuild 1126 v2Shub KotiNo ratings yet

- Fosroc Structuro W415: Constructive SolutionsDocument2 pagesFosroc Structuro W415: Constructive SolutionsVincent JavateNo ratings yet

- Mastermatrix Uw 404: Description PackagingDocument2 pagesMastermatrix Uw 404: Description PackagingKhlif NadaNo ratings yet

- MasterPel 777 v3Document3 pagesMasterPel 777 v3Mohamed KhanNo ratings yet

- Pozzolith 101ri: Set Retarding and Water Reducing AdmixtureDocument2 pagesPozzolith 101ri: Set Retarding and Water Reducing AdmixtureDoby Yuniardi100% (1)

- Fosroc Conplast SP430: Constructive SolutionsDocument2 pagesFosroc Conplast SP430: Constructive SolutionsVincent JavateNo ratings yet

- Conplast P211 Concrete AdmixtureDocument4 pagesConplast P211 Concrete AdmixtureMel AdNo ratings yet

- Conplast SP430RDocument2 pagesConplast SP430RTori Small100% (1)

- Fosroc Conplast WP400 waterproofing admixtureDocument2 pagesFosroc Conplast WP400 waterproofing admixtureVincent JavateNo ratings yet

- TDS Conplast SP430 IndiaDocument2 pagesTDS Conplast SP430 IndiaAnonymous Gb9LeJcINo ratings yet

- MasterPolyheed 927Document2 pagesMasterPolyheed 927AMAURY DE JESUS GOMEZNo ratings yet

- Fosroc Conplast WP400: Constructive SolutionsDocument2 pagesFosroc Conplast WP400: Constructive SolutionsVincent JavateNo ratings yet

- Pozzolith LD10: Water-Reducing, Plasticiser / Retarder For ConcreteDocument2 pagesPozzolith LD10: Water-Reducing, Plasticiser / Retarder For ConcreteFrancois-No ratings yet

- Plasocrete Super: Product Data SheetDocument2 pagesPlasocrete Super: Product Data SheetmohammedNo ratings yet

- Conplast P211Document4 pagesConplast P211Vipul AroraNo ratings yet

- Auramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeDocument2 pagesAuramix 350: High Performance PCE Based Super Plasti-Cizing Admixture - Retarding TypeVipin Kumar Parashar100% (1)

- Sika Plast 257Document3 pagesSika Plast 257HasithaNo ratings yet

- Sikacontrol PlusDocument2 pagesSikacontrol PlusSurajWickramasinghaNo ratings yet

- Plastiment AR-340: Water Reducing and Retarding Concrete AdmixtureDocument3 pagesPlastiment AR-340: Water Reducing and Retarding Concrete AdmixtureHumamNo ratings yet

- Conplast SP430Document2 pagesConplast SP430Tori Small100% (1)

- TDS-MasterLife WP730 (Rheomac730)Document2 pagesTDS-MasterLife WP730 (Rheomac730)Ayo OshoNo ratings yet

- MasterRheobuild 1100 v1Document2 pagesMasterRheobuild 1100 v1Vivek GaurNo ratings yet

- Basf Masterroc Aga 155 TdsDocument2 pagesBasf Masterroc Aga 155 TdsPablo Quinteros PizarroNo ratings yet

- Construction Chemical Advanced SuperplasticiserDocument2 pagesConstruction Chemical Advanced SuperplasticiserShaik QutubuddinNo ratings yet

- TDS MasterRheobuilld-623Document2 pagesTDS MasterRheobuilld-623Taposh PaulNo ratings yet

- Conplast sp337Document3 pagesConplast sp337pravi3434No ratings yet

- MasterKure 106 (Masterkure 106) - ZADocument2 pagesMasterKure 106 (Masterkure 106) - ZAKiran ReddyNo ratings yet

- TDS Auramix 402 India4Document2 pagesTDS Auramix 402 India4anoopkishankNo ratings yet

- Conplast SP480Document2 pagesConplast SP480Tori SmallNo ratings yet

- MasterRheobuild 859 Technical Data SheetDocument3 pagesMasterRheobuild 859 Technical Data Sheetabukayes.abdinNo ratings yet

- High performance water reducing admixture for microsilica concreteDocument2 pagesHigh performance water reducing admixture for microsilica concreteVenkata Raju KalidindiNo ratings yet

- Pozzolith 555: Non-Chloride Accelerating AdmixtureDocument3 pagesPozzolith 555: Non-Chloride Accelerating AdmixtureFrancois-No ratings yet

- TDS 5041Document1 pageTDS 5041Alex VilchezNo ratings yet

- Masterglenium Sky 504: Description Features and BenefitsDocument2 pagesMasterglenium Sky 504: Description Features and BenefitsvikasNo ratings yet

- Current Advances in Drug Delivery Through Fast Dissolving/Disintegrating Dosage FormsFrom EverandCurrent Advances in Drug Delivery Through Fast Dissolving/Disintegrating Dosage FormsNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- High Strength Epoxy Grout for Heavy LoadsDocument2 pagesHigh Strength Epoxy Grout for Heavy LoadsAcho SupraholicNo ratings yet

- Tambahan Baru Mortar UtamaDocument3 pagesTambahan Baru Mortar UtamaRiko Ardana PutraNo ratings yet

- SF 100Document2 pagesSF 100mandorNo ratings yet

- PRODUCT DATA SHEET Sika®Chapdur®Document3 pagesPRODUCT DATA SHEET Sika®Chapdur®Thamizhanban RNo ratings yet

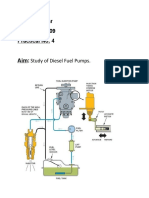

- Study of Diesel Fuel Pumps ComponentsDocument6 pagesStudy of Diesel Fuel Pumps ComponentsPro GamerssNo ratings yet

- Strategic Human Resources Planning 5th Edition Belcourt Solutions ManualDocument25 pagesStrategic Human Resources Planning 5th Edition Belcourt Solutions ManualMarioAbbottojqd100% (52)

- Nano-technology for Post-Harvest Management of Fruits and VegetablesDocument3 pagesNano-technology for Post-Harvest Management of Fruits and VegetablesArin RujinNo ratings yet

- Unit 7 Chapter 7 International Marketing NotesDocument7 pagesUnit 7 Chapter 7 International Marketing NotesGv HarishNo ratings yet

- Kick Control: BY: Naga Ramesh D. Assistant Professor Petroleum Engineering Dept. KlefDocument13 pagesKick Control: BY: Naga Ramesh D. Assistant Professor Petroleum Engineering Dept. Klefavula43No ratings yet

- Quiz ConsolidatedDocument131 pagesQuiz ConsolidatedSudhanshu GuptaNo ratings yet

- Working Capital Management OF: Submitted by Priya BanerjeeDocument102 pagesWorking Capital Management OF: Submitted by Priya BanerjeeSushmita BarlaNo ratings yet

- United States Government and PoliticsDocument21 pagesUnited States Government and PoliticsTony BuiNo ratings yet

- Credit Risk ManagementDocument85 pagesCredit Risk ManagementDarpan GawadeNo ratings yet

- Optical Burst Switching (OBS)Document27 pagesOptical Burst Switching (OBS)adityaNo ratings yet

- IPUMS CPS Exercise 2 For RDocument7 pagesIPUMS CPS Exercise 2 For RKateO838No ratings yet

- Forms6i 10GDocument42 pagesForms6i 10GRolando OcañaNo ratings yet

- GPS Consent and TrackingDocument3 pagesGPS Consent and TrackingJoel KionisalaNo ratings yet

- DL 57 PDFDocument2 pagesDL 57 PDFmaheshm_erpNo ratings yet

- Monthly-Company (Indian-and-Foreign) - and LLPs-20230301Document724 pagesMonthly-Company (Indian-and-Foreign) - and LLPs-20230301Yogesh Paigude0% (1)

- Mos Project Report-"Customer Satisfaction Survey: Telecom Sector"Document16 pagesMos Project Report-"Customer Satisfaction Survey: Telecom Sector"Kabejor Rahman Aka-NickyNo ratings yet

- Aoc ts185 LCD MonitorDocument56 pagesAoc ts185 LCD MonitoraldinaenNo ratings yet

- Manual DishwashingDocument2 pagesManual Dishwashingkean redNo ratings yet

- RTC Order Granting Motion for Execution in Ejectment Case Despite Pending AppealDocument5 pagesRTC Order Granting Motion for Execution in Ejectment Case Despite Pending AppealAmmie AsturiasNo ratings yet

- Green Economy in The Transport SectorDocument138 pagesGreen Economy in The Transport Sectorclayton MaramwidzeNo ratings yet

- Activity#tachometer - MEC 0326.1-2Document4 pagesActivity#tachometer - MEC 0326.1-2MarkJude MorlaNo ratings yet

- Optimize School Distribution With MappingDocument5 pagesOptimize School Distribution With MappingRolyn ManansalaNo ratings yet

- Modified Variable Neighborhood Search Algorithm For Maximum Power Point Tracking in PV Systems Under Partial Shading ConditionsDocument8 pagesModified Variable Neighborhood Search Algorithm For Maximum Power Point Tracking in PV Systems Under Partial Shading ConditionsTELKOMNIKANo ratings yet