Professional Documents

Culture Documents

Us4023840 PDF

Uploaded by

Jagannathan Arumugam0 ratings0% found this document useful (0 votes)

20 views5 pagesOriginal Title

US4023840.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views5 pagesUs4023840 PDF

Uploaded by

Jagannathan ArumugamCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

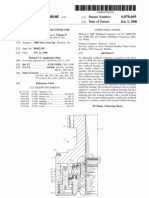

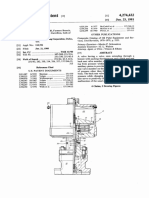

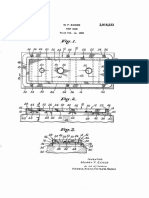

United States Patent (19) 11) 4,023,840

Souza et al. 45 May 17, 1977

54 LATCH ASSEMBLY 56 References Cited

UNITED STATES PATENTS

75 Inventors: Anthony J. Souza, Lancaster; John 3,134,617 5/1964 Slonneger .............................. 292/3

M. Michel, Downingtown, both of 3,181,905 5/1965 Bisbing .............................. 292/109

Pa. 3,490,805 1/1970 DiPerro ............................. 292/258

Primary Examiner-Robert L. Wolfe

73) Assignee: Woodstream Corporation, Pa.

57 ABSTRACT

22 Filed: May 13, 1976 A latch assembly for use with a tackle box or other

container is disclosed. The latch assembly includes a

21 Appl. No.: 685,748 latch top segment, a latch bottom segment and a re

ceiver, all of which may be manufactured by injection

molding. The latch assembly includes the feature that

52 U.S. C. ................................. 292/113; 292/66; no separate pins or rivets are required either to assem

292/DIG. 38 ble the components or to attach the latch assembly to

51 Int. Cl'......................................... E05C 19/12 the container with which it is employed.

58) Field of Search .............. 292/1 13, 114,66, 67,

292/DIG. 38, 256 2 Claims, 6 Drawing Figures

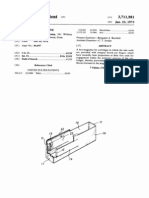

U.S. Patent May 17, 1977 Sheet 1 of 2 4,023,840

U.S. Patent May 17, 1977 Sheet 2 of 2 4,023,840

4,023,840 2

1

articles, or other polymer having similar properties

LATCH ASSEMBLY such as high density polyethylene.

The latch top segment 11 includes a planar base

The present invention to a latch assembly for use member 15, having attached thereto a pair of side

with tackle boxes and other containers. More particu flanges 16 and a top flange 17 which extend at right

larly, the present invention relates to a latch assembly angles to the base 15. A longitudinal rib member 20 is

having components which may be manufactured com attached to the top flange 17 and extends downwardly

pletely by injection molding. The latch assembly of the at an angle away from the base 15, the rib 20 being

present invention requires no separate rivets or pins to employed to releasably engage the container 14 when

assemble the operating components and the present 10 the latch assembly 10 is in the closed or latched posi

latch does not require a separate pin or pins to attach it tion, as described in more detail hereinafter. The base.

to the tackle box or other container with which it is 15 is provided with a sightly indented portion 18 which

employed. faciliates handling of the top segment 11 and imparts a

Previous latch assemblies for use with tackle boxes finished appearance to the latch assembly 10.

and other containers have typically required the use of 15 The top segment 11 also includes a longitudinally

one or more pins or rivets to assemble the latch for extending pin member 19 which is attached to and has

operation in connection with a container. Such prior its ends molded integrally with lower extensions 16a of

art latch assemblies have been accompanied by various the side flang4es 16. The side flange extensions 16a

disadvantages, including difficulty of assembly and the 20 extend beyond the base 15, sufficiently to allow clear

misalignment or loss of the pin or rivet during use of the ance for the latch bottom segment 12 to pivot about its

latch as installed upon the container. attachment to the pin member 19, as described herein

By the present invention, there is provided an im after.

proved latch assembly, the components of which may The latch bottom segment 12 includes a planar base

be completely injection molded. The latch is of rela 25 member 21 having attached thereto a pair of side

tively simple construction, requireing no separate pins flanges 22 which extend at right angles to the base 21.

or rivets to assemble the operating members. Further The side flanges 22 include extensions 22a which ex

more, the present latch assembly does not require a tend upwardly beyond the base member 21 to a point

separate pin or rivet to attach it to the tackle box or of attachment with a longitudinally extending pin mem

30 ber 23 which has its end portions molded integrally

other container.

BRIEF DESCRIPTION OF THE DRAWINGS with the side flange extensions 22a. At the midportion

of the inner edge of each side flange 22 an arcuate slot

The advantages and features of the latch assembly of 24 is provided, with these slots 24 being provided for

the present invention will be more fully understood the purpose of receiving the pin member 19 of the latch

from the following description of the preferred embodi 35 top segment 11. The slots 24 are shaped so as to encir

ments, taken in conjunction with the accompanying cle the pin 19 to an extent sufficient to hold it in place

drawings, wherein: while being discontinuous to an extent sufficient to

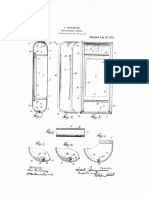

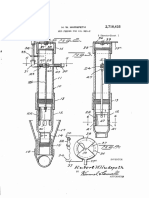

FIG. 1 is a front elevational view of the latch assem allow the pin 19 to be snapped in place within the slots

bly of the present invention, as applied to a tackle box, 24. A short reinforcing rib 37 is provided adjacent each

for example, the parts being shown in their closed or 40 slot 24 to serve as a seat against which the pin member

locked positions; 19 abuts as it turns or rotates in operative engagement

FIG. 2 is a side elevational view of the latch assembly within the slots 24.

shown in FIG. 1; In FIGS. 5 and 6, the latch top 11 and bottom 12

FIG. 3 is a vertical sectional view of the latch top segments have been removed from the container 14 for

segment, taken along line A-A of FIG. 1; 45 purposes of illustrating the latch receiver 13. As shown

FIG. 4 is a vertical sectional view of the latch bottom in FIGS. 5 and 6, the latch receiver 13 includes a lower

segment taken along line A-A of FIG. 1; component 25 which is attached by means such as

FIG. 5 is a front elevational view of a portion of the integral molding to the wall 30 of the container 14. The

receiver employed with the present latch assembly; and lower component 25 is provided with a longitudinally

FIG. 6 is a vertical sectional view of the receiver 50 extending arcuate slot 27 which opens downwardly for

taken along line B-B of FIG. 5., the purpose of receiving the pin member 23 of the latch

DESCRIPTION OF THE PREFERRED

bottom segment 12. The slot 27 is shaped so as to encir

EMBODEMENTS

cle the pin 23 along its length to an extent sufficient to

hold it in place while being discontinuous to an extent

In the embodiment of the present invention as illus 55 sufficient to allow the pin 23 to be snapped in place

trated in FIGS. 1 through 6, there is shown a latch within the slot 27. A latch stop 34 is also molded into

assembly 10 which includes a latch top segment 11 and the wall 30 to serve as a member aginst which the latch

a latch bottom segment 12. A latch receiver 13 is pro bottom segment 12 may abut for additional support

vided as an integral component of a tackle box or other when in the closed position. In molding the lower com

container 14 having side walls 30 and a hinged lid or 60 ponent 25 to the wall 30, cavities 36 may be provided

cover 31, as shown in FIG. 2. A latch guard in the form in that portion adjacent wall 30.

of a vertical rib 32 may be attached to the lid 31 on The upper component 26 of the latch receiver 13 is

either side of the latch top segment 11, while the wall best shown in FIG. 2. The upper component 26 of the

30 is provided with a projecting rib 33, as also shown in receiver 13 is an essentially planar member which an

FIG. 2. The latch top segment 11 and the latch bottom 65 gles upwardly away from the lid 31 to which it is at

segment 12, as well as the receiver 13, may be made by tached, with a longitudinally extending notch 35 which

injection molding of a material such as polypropylene, receives the rib 20 of the latch top segment 11 when

having excellent durability when employed in molded the assembly 10 is in the closed position.

3

4,023,840 4

In FIG. 2 there is shown the position of the latch a latch receiver having a lower component which is

assembly 10 when the assembly is in place on the con integrally molded to a side wall of said container

tainer 14 and securing the lid 31 of such container 14. and an upper component which is integrally

In dashed lines of FIG. 2 there is shown the open posi molded to the cover adjacent said side wall, said

tion with the latch top segment 11a having been re- 5 lower component having a longitudinally extending

leased from the receiver 13 and pulled downwardly to : arcuate slot which opens downardly, and said

the fully open position in order to release the latch upper component including a planar member

assembly 10 and thus allow the container 14 to be which angles upwardly away from the cover and

opened. having a notch at the outer edge of the top portion

As can be seen from the drawings taken in conjunc-10 of said planar member;

tion with the foregoing description, the latch assembly b. a latch top segment having a planar base portion

may be assembled by first snapping the pin 19 of the with a pair of side flanges and a top flange attached

latch top segment 11 in place within the slots 24 of the thereto and extending at right angles to said base; a

latch bottom segment 12. The pin 23 of the latch bot 15 longitudinal rib member attached to the top flange

tom segment 12 is then snapped in place within the and extending downwardly at an angle away from

arcuate slot 27 of the latch receiver 13 which has been the base, said rib releasably engaging the notch of

previously molded to the side wall 30 and lid 31 of the said latch receiver when the latch assembly is in the

container 14. closed position, the side flanges having extensions

To close the latch 10, the lower end of the bottom 20 which project beyond said base portion at the end

segment 12 may be manually pivoted outwardly and opposite to said top flange, a pin member located

upwardly to a point which allows the top segment 11 to between said flange extensions and having one end

be affixed with its rib 20 engaged over the notch 35 of thereof molded integrally with each of said flange

the upper component 26 of the receiver 13. The bot extensions; and

tom segment 12 is then pivoted downwardly to a verti 25 c. a latch bottom segment having a planar base por

cal position with the result that the latch assembly 10 tion with a pair of side flanges attached thereto and

assumes the locked or closed position. The assembly 10 extending at right angles to said base of the bottom

may be released by pivoting the bottom segment 12 segment, the side flanges having extensions which

upwardly, releasing the tight engagement of the rib 20 project beyond said base of the bottom segment at

one end thereof, a pin member located between

with the notch 35 and allowing the top segment 11 to said flange extensions of the bottom segment and

be pivoted downwardly to the position shown as 11a in having one end thereof molded integrally with each

FIG. 2, with the result that the lid 31 may then be of said flange extensions of the bottom segment,

opened. said pin member of the latch bottom segment being

As will be understood from the previous description, received within the arcuate slot of said latch re

the present latch assembly 10 may be completely injec- 35 ceiver, an arcuate slot provided at the midportion

tion molded and no separate pins or rivets are required of the inner edge of each side flange of the bottom

to assemble the operating members. In addition, no segment, said arcuate slots of the side flanges re

pins or rivets are required to attach the assembly 10 to ceiving the pin member of said latch top segment;

the tackle box or other container. each of said arcuate slots of said latch receiver and said

It is thought that the invention and many of its atten- 40 latch bottom segment being shaped so as to encircle the

dant advantages will be understood from the foregoing respective pin to an extent sufficient to hold it in place

description, and it will be apparent that various while being discontinuous to an extent sufficient to

changes may be made in the form, construction and allow the pin to be snapped in place within the slot,

arrangement of the parts without departing from the and the side flange extensions of the latch top segment

spirit and scope of the invention or sacrificing its mate- 45 projecting beyond the base of said top segment suffi

rial advantages, the forms hereinbefore described being ciently to allow clearance for the latch bottom segment

merely the preferred embodiments thereof. to pivot about its attachment to the pin member of said

The embodiments of the invention in which an exclu latch top segment.

sive property or privilege is claimed are defined as 2. The latch of claim 1 wherein the latch top segment

follows: 50 and the latch bottom segment each comprise a one

1. A latch assembly for releasably fastening a cover piece molding of polypropylene.

on a container having side walls, comprising: sk k

55

60

65

You might also like

- Mammal Anatomy An Illustrated GuideDocument289 pagesMammal Anatomy An Illustrated GuideVintila LiviuNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Skeletal SystemDocument54 pagesSkeletal Systemanurag.dNo ratings yet

- The Skeletal System: Powerpoint Lecture SlidesDocument152 pagesThe Skeletal System: Powerpoint Lecture SlidesTricia Mae CorpuzNo ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Swine Diagnostic Manual 4thedDocument44 pagesSwine Diagnostic Manual 4thedthanh ba matNo ratings yet

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pages1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongNo ratings yet

- Crash Analysis Criteria 1.6.2Document90 pagesCrash Analysis Criteria 1.6.2keepingbusyNo ratings yet

- Field Care of GameDocument19 pagesField Care of GameKen HouseNo ratings yet

- PatentDocument4 pagesPatentapi-352371094No ratings yet

- The Respiratory System: Supplement To Text, Chapter 9Document77 pagesThe Respiratory System: Supplement To Text, Chapter 9Christina GonezNo ratings yet

- March 13, 1934.: C. H. Howell Et AlDocument6 pagesMarch 13, 1934.: C. H. Howell Et AlJohn TLNo ratings yet

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- Camera PatentDocument4 pagesCamera PatentAndrei PoseaNo ratings yet

- Part 1 Biological Science ReviewerDocument5 pagesPart 1 Biological Science ReviewerChester Kim DiscarNo ratings yet

- Wellhead Connector H4 TypeDocument9 pagesWellhead Connector H4 Typeste7ieNo ratings yet

- US2900999-metal SealDocument3 pagesUS2900999-metal Sealasen tsaiNo ratings yet

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Document3 pagesErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshNo ratings yet

- United States Patent (113,565,212: 3. AFE No. 1969 3,454,131 7/1969 Johnson....................... 182/115Document5 pagesUnited States Patent (113,565,212: 3. AFE No. 1969 3,454,131 7/1969 Johnson....................... 182/115Jesus Antonio Esquivel HernandezNo ratings yet

- Folding AparatusDocument4 pagesFolding AparatusUbunterNo ratings yet

- Filed July 30, 1923: Pedal of Erator For Flush ValvesDocument3 pagesFiled July 30, 1923: Pedal of Erator For Flush ValvesmarlondijiNo ratings yet

- Tube Saport PDFDocument4 pagesTube Saport PDFjr110livecomNo ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- United States Patent (19) 11 4,274,432: 75 Inventors: Karl N. Tunstall, Farmers Branch E636 / ... 137/315Document5 pagesUnited States Patent (19) 11 4,274,432: 75 Inventors: Karl N. Tunstall, Farmers Branch E636 / ... 137/315Taufik Budi WibowoNo ratings yet

- %.E4 4Zz57/7 Afzzazzzzz: A. H. BeckmanDocument4 pages%.E4 4Zz57/7 Afzzazzzzz: A. H. BeckmanDiogo CorreaNo ratings yet

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- Umted States Patent (191 (11) 4,173,936: Secord Et Al. (45) Nov. 13, 1979Document8 pagesUmted States Patent (191 (11) 4,173,936: Secord Et Al. (45) Nov. 13, 1979venkatrangan2003No ratings yet

- Siled Sept. 8, 1966: T, N. NccomeDocument5 pagesSiled Sept. 8, 1966: T, N. NccomeliNo ratings yet

- H!!!!! - EEHHE) : Nonononononon Niinin 'Document4 pagesH!!!!! - EEHHE) : Nonononononon Niinin 'Hadi KoraniNo ratings yet

- 06.damper Apparatus and Mounting Clip ToDocument4 pages06.damper Apparatus and Mounting Clip ToRohit BirajdarNo ratings yet

- Cement BasketDocument4 pagesCement Basketराजकुमार यादवNo ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNo ratings yet

- Dec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LDocument5 pagesDec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LcheesewizzNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- Limited States Patent: LngramDocument7 pagesLimited States Patent: LngramJin SongNo ratings yet

- Filed Sept. 8, l942Document4 pagesFiled Sept. 8, l942HaithemNo ratings yet

- Us 3378330Document5 pagesUs 3378330James LindonNo ratings yet

- March 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1Document5 pagesMarch 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1david19775891No ratings yet

- US3982767Document6 pagesUS3982767takanobu ouraNo ratings yet

- O/65ézá / /zzáez: Ozzezz67Document4 pagesO/65ézá / /zzáez: Ozzezz67TECUMCE GOMEZ PEREZNo ratings yet

- Anemometer - US1905444Document4 pagesAnemometer - US1905444Aaron Choco De GuzmanNo ratings yet

- United States Patent: SchwartzmanDocument4 pagesUnited States Patent: SchwartzmanJames LindonNo ratings yet

- Us 5117735Document14 pagesUs 5117735sdfsdf333No ratings yet

- Diseño ElectricoDocument5 pagesDiseño ElectricoemernelsonmanNo ratings yet

- Oct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Document5 pagesOct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Юрий РуденкоNo ratings yet

- Tow Target Release Mechanism (1927)Document5 pagesTow Target Release Mechanism (1927)CAP History LibraryNo ratings yet

- 2.7%uy Aal: Sept. 3, 1957 J. D., KRSCH Mann 2,804,998Document4 pages2.7%uy Aal: Sept. 3, 1957 J. D., KRSCH Mann 2,804,998Vijayakumar G VNo ratings yet

- Clem Engine Paper PresentationDocument6 pagesClem Engine Paper PresentationDankamialNo ratings yet

- United States Patent (191: SeecampDocument4 pagesUnited States Patent (191: Seecamp9aszerfNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- Arts5.: in RunDocument4 pagesArts5.: in RunMuzammil AmirNo ratings yet

- Dau TomDocument6 pagesDau TomPham LoiNo ratings yet

- Filed March 9, 1928: Le Roy H. KieslingDocument3 pagesFiled March 9, 1928: Le Roy H. KieslingGino CastroNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Us 1633228Document8 pagesUs 1633228Vincent Grangé-PradérasNo ratings yet

- United States Patent 1191: MasuyamaDocument7 pagesUnited States Patent 1191: MasuyamaAbdullah AljabriNo ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- Us1434007 PDFDocument5 pagesUs1434007 PDFsebastian escobarNo ratings yet

- Mlliambn/Ef?Ey: M As A?Document4 pagesMlliambn/Ef?Ey: M As A?scibduser001No ratings yet

- Filed Sept. 30, 1963: C. C. BrownDocument8 pagesFiled Sept. 30, 1963: C. C. BrownyasamanNo ratings yet

- Rat Hole DiggerDocument4 pagesRat Hole DiggerDarshan MakwanaNo ratings yet

- Dec. 8, 1959 M. F. Ecker 2,916,233: 16-NEEEL2-aODocument3 pagesDec. 8, 1959 M. F. Ecker 2,916,233: 16-NEEEL2-aOErin GokNo ratings yet

- April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965Document4 pagesApril 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965fgrt490No ratings yet

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Document7 pagesUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91No ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- United States Patent (19) : Assistant Examiner-Charles L. WillisDocument5 pagesUnited States Patent (19) : Assistant Examiner-Charles L. WillisJagannathan ArumugamNo ratings yet

- June 17, 1952 P. A. Derham 2,601,101: y Philip A. DerhanDocument7 pagesJune 17, 1952 P. A. Derham 2,601,101: y Philip A. DerhanJagannathan ArumugamNo ratings yet

- United States Patent (19) : 11) Patent Number: (45) Date of PatentDocument9 pagesUnited States Patent (19) : 11) Patent Number: (45) Date of PatentJagannathan ArumugamNo ratings yet

- ?80HMIDT: PATENTED JAN?29,1907. Garment PastenerDocument4 pages?80HMIDT: PATENTED JAN?29,1907. Garment PastenerJagannathan ArumugamNo ratings yet

- No. 595,070, Patented Dec. 7, 1897.: E Olden BuschDocument2 pagesNo. 595,070, Patented Dec. 7, 1897.: E Olden BuschJagannathan ArumugamNo ratings yet

- 3.4 E6.4-Tavre 22 Foz: W. Z. W. ChapmanDocument2 pages3.4 E6.4-Tavre 22 Foz: W. Z. W. ChapmanJagannathan ArumugamNo ratings yet

- Drawing Pages of EP0957263 A1Document1 pageDrawing Pages of EP0957263 A1Jagannathan ArumugamNo ratings yet

- PDF 28Document17 pagesPDF 28Jagannathan ArumugamNo ratings yet

- 60 Autocad 2D & 3D Practice: Drawings and Projects ProjectsDocument65 pages60 Autocad 2D & 3D Practice: Drawings and Projects ProjectsJagannathan ArumugamNo ratings yet

- Jag AnDocument2 pagesJag AnJagannathan ArumugamNo ratings yet

- Mother and Child The Erotic BondDocument10 pagesMother and Child The Erotic BondJagannathan ArumugamNo ratings yet

- Class 6 Biology Body MovementsDocument12 pagesClass 6 Biology Body MovementsRishabh SahuNo ratings yet

- Single Squamous EpitheliumDocument28 pagesSingle Squamous EpitheliumLyndonn Santos100% (1)

- D BirdsDocument45 pagesD Birdsmurse101No ratings yet

- Cat Vs Dog Anatomy Anatomical DifferencesDocument2 pagesCat Vs Dog Anatomy Anatomical DifferencesAlliNo ratings yet

- Penetrating Trauma CheatsheetDocument3 pagesPenetrating Trauma Cheatsheetdruhh100% (1)

- Biology 3Document126 pagesBiology 3khaledNo ratings yet

- Thorax: Thoracic Spine Anatomy and Biomechanics Level IIIDocument23 pagesThorax: Thoracic Spine Anatomy and Biomechanics Level IIIAnonymous ecI8GUbaNo ratings yet

- Important Points Class 9 Subject - Biology Ls 12 Skeleton-Movements and LocomotionDocument6 pagesImportant Points Class 9 Subject - Biology Ls 12 Skeleton-Movements and LocomotionP. Varshith ReddyNo ratings yet

- Muscular System NotesDocument11 pagesMuscular System NotesnokiaNo ratings yet

- Locomotion & Movement ResonanceDocument34 pagesLocomotion & Movement ResonanceEkta ManglaniNo ratings yet

- ANPATH1 ReviewerDocument17 pagesANPATH1 ReviewerRashid DayaoNo ratings yet

- The Skeletal SystemDocument25 pagesThe Skeletal SystemEyda CartagenaNo ratings yet

- Anatomical, Physiological and Mechanical Bases of Movements: Body Really Made Of? "Document10 pagesAnatomical, Physiological and Mechanical Bases of Movements: Body Really Made Of? "Jay Carlo BagayasNo ratings yet

- Human Anatomy and Fiology: by Firdaus. M.PDDocument15 pagesHuman Anatomy and Fiology: by Firdaus. M.PDPrinces 1234No ratings yet

- Lab 7 Skeletal System PowerPointDocument19 pagesLab 7 Skeletal System PowerPointNguyen (Harry) Xuan HoangNo ratings yet

- Sessions Case Notes PDFDocument31 pagesSessions Case Notes PDFSini AdvNo ratings yet

- LocomotionDocument13 pagesLocomotionPrakhar SrivastavaNo ratings yet

- Thorax BonesDocument59 pagesThorax BonesMido TooNo ratings yet

- Contribución Al Estudio de La Embriología de Reptiles ChilenosDocument23 pagesContribución Al Estudio de La Embriología de Reptiles ChilenosAlejandro Bruno Miranda CalleNo ratings yet

- Work Sheet 6 Skeletal System A28 Group1Document8 pagesWork Sheet 6 Skeletal System A28 Group1Japet Floyd AlipioNo ratings yet

- Pso-Rite Multi Product How-To Booklet Vfinal CompressedDocument86 pagesPso-Rite Multi Product How-To Booklet Vfinal CompressedViktor Velasquez GustavssonNo ratings yet

- Biology For EngineersDocument43 pagesBiology For EngineersshivanshNo ratings yet