Professional Documents

Culture Documents

BSI Standards Publication - BS 5834-2 - 2011

BSI Standards Publication - BS 5834-2 - 2011

Uploaded by

khai rule67%(3)67% found this document useful (3 votes)

673 views34 pagesOriginal Title

BSI Standards Publication - BS 5834-2_2011

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

67%(3)67% found this document useful (3 votes)

673 views34 pagesBSI Standards Publication - BS 5834-2 - 2011

BSI Standards Publication - BS 5834-2 - 2011

Uploaded by

khai ruleCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 34

BS 5834-2:2011

@

bsi. making excellence a habit”

BS 5834-2:2011 BRITISH STANDARD

Publishing and copyright information

‘The B51 copyright notice displayed in this document indicates when the document

was last issued.

© 851.2011

ISBN 978 0 580 56121 4

ICS 91,140.40; 91,140.60 .

‘The following 8s! references relate to the work on this standard:

Committee reference a/S04 FN

Draft for comment 08/30142158 DC 4

Publication history oye

Part 2 fist published January 1983 ryt

Part 3 fist published October 1985 jon

Second (present) ealtian as Part 2 (combined revision oF art 2 and Part 3), July 2011

Amendments issued since publication

Date Text affected

* STRIH TRU

sniTsh staNDARD iu

Contents

Foreword ii

(i I BS 5834-2:2011

18

Scone 1

Normative references 1

Terms and definitions 2 '

Classification and grading 3 \

Materials 4 .

Frames for combination units 5

Fasteners 6

Dimensions and design of surface boxes 7

Manufacture and workmanship 13

410 Coatings and corrosion protection 14

11 Bedding-in, permanent set and durability regatemépts 4

12 Marking 16

Annexes

Annex A (normative) Loading tests 17

‘Annex B (informative) Optional items to beac jee between the manufacturer

and the purchaser 24

Bibliography 27 aff

List of figures

Figure 1 - Typical section and minirium dimensions for a combination unit and

frame for a small surface box Sin...

Figure 2 - Typical section and minicpuiii dimensions for combination unit and

frame for a large surface box"”6

Figure 3 ~ Height or depth Bt raised or recessed patterns 9

Figure 4 Dimensions obgingslots 10

Figure 5 ~ Open keyway,,

Figure 6 ~ Closed Keyra ue

Figure 7 ~ Keys 12°

Figure A. - Example "a.measuring device support used for measuring cover

and frame movement pefamrectig dee sre

Figure A.2 ~ Test Idad positions for large surface boxes 27

Figure A3 -Coverand frame: arrangement of measurements 22

Figure A.4 - Gover.to frame alignment relative to cover planar surface for raised

patterns 22.

Figure, AS. Cover to frame alignment relative to cover planar surface for

recessed patterns 23

Figure’A,6 - Views of cover and frame assemblies illustrating measurement

positions 24

Libtof tables

aac = Surface box grades 3

“fable 2 - Performance of thermoplastics materials 4

able 3 = Designations and specified dimensions of small surface boxes 7

: ‘of large surface box frames“) 8

‘Table 5 Prising slots 10

Table 6 ~ Keyway dimensions 11

Table 7 Key dimensions 13

Table A.1 Test loads for small surface boxes 19

Table A.2 ~ Test loads for large surface boxes 19

Table 8.1 - Example of a test report 26

Summary of pages

This document comprises a front cover, an inside front cover, pages i to ii,

pages 1 to 28, an inside back cover and a back cover.

© BSI2011 + |

+ @Bsi2011

BRITISH STANDARD

Foreword

Publishing information

This part of 85 5834 is published by BSI and came into effect on 31 July 2011. It

was prepared by Technical Committee B/504, Water supply. A list of

organizations represented on this committee can he obtained on fequest to its

secretary. sth

Supersession o

This part of BS 5834 supersedes BS 5834-21983 and BS s534°s965, which are

withdrawn, ye

Relationship with other publications

BS 5824 Is published in three parts:

+ Part 1: Specification for guards and plinths;’

+ Part 2: Specification for surface boxes;

+ Part 4: Specification for utility chambers

Information about this document

This standard is @ revision and an amalgamation of BS $834-2:1983 and

BS 5834-3:1985. It has been extended 0 iiclude surface boxes made from cast

iron, cast aluminium, plasties and fabricated steel and to include surface boxes

designed for use with all types*of uty

Product certification, Users of this Byitish Standard are advised to consider the

desirability of third-party cextifi¢ation of conformity to this British Standard,

Users seeking assistance ifhidentifying appropriate conformity assessment bodies

or Schernes may ask BS};to-forard their enquiries tothe relevant association

n

Presentational convtishs

The provisions of thisstandard are presented in roman (ie. upright) type. ts

requirements are expressed in sentences in which the principal ausiliary verb i

“shall” we

Commentéry,éxplanation and general informative material is presented in

smaller afl ype, and does not constitute a normative element

Contiactital and legal considerations

Tilis publication does not purport to include all the necessary provisions of a

SeENTE, Users are responsible for its correct application.

See with a British Standard cannot confer immunity from legal

‘obligations,

BRITISH STANDARD BS 5834-2:2011

1 Scope

This part of BS 5834 specifies requirements for surface boxes to be used with

guards and underground chambers designed for the purposes of utilities

including those intended for factory infill having a maximum designated overall

clear opening of 450 mm x 450 mm, This British Standard specifies surface boxes

made from cast iron, cast aluminium, plastics and fabricated steel. The selection,

use and surface finish of infill materials for factory infilled covers is outside the

scope of this standard, *

A test method for loading tests is specified in Annex A an agummary of the

optional items to be agreed between the manufacturer andthe purchaser is

given in Annex B

NOTE 1 See Table 4 for peimited intrusions to the dear Senin.

NOTE 2 Requirements for covers having a larger clear opening than

1450 mm x 450 mm are specified in BS EN 124. In BS EN 124, such covers are referred

0 as gully or manhole tops

2 Normative references

The following referenced documents are inidispensable for the application of

this document. For dated references, only the edition cited applies, For undated

references, the latest edition of thé referenced document (including any

amendments) applies

85 3412:1992, Methods of specifying general purpose polyethylene materials for

moulding and extrusion;

BS 4190, 60 metric back bbxggall hots, screws and nuts - Specfcetion

85 4439;1991, Specification Yar screwed studs for general purposes ~ Metric

series ‘agers

85 5139, Method at spétitying general purpose polypropylene and propylene

copolymer materjaly formmoulding and extrusion

85 5834-1:20097'5uPfare boxes, guards and underground chambers for the

purposes of utilis ~ Part 1: Specification for guards and plinths

BS 7668, Weldabié : ‘structural steels - Hot finished structural hollow sections in

weathed estan steals Speciation

85 EN 1561 Rounding - Grey cast rons

85 EN 1363, Founding ~ Spheroidal graphite cast iron

8§.g1v 1676, Aluminium and aluminium alloys ~ Alloyed ingots for remelting ~

ification

\4,°BS,EN 1706, Aluminium and aluminium alloys ~ Castings - Chemical composition

or Sand. mechanical properties _

"BS EN 10025-1, Hot rolled products of structural steels ~ Part 1; General technical

delivery conditions

8S EN 10025-2, Hot rolled products of structural steels ~ Part 2: Technical delivery

conditions for non-alloy structural steels

BS EN 10025-3, Hot rolled products of structural steels - Part 3: Technical delivery

conditions for normalizedinormalized rolled weldable fine grain structural steels

BS EN 10025-4, Hot rolled products of structural steels ~ Part 4: Technical delivery

conditions for thermomechanical rolled weldable fine grain structural steels

BS EN 10025-5, Hot rolled products of structural steels ~ Part 5: Technical delivery

conditions for structural steels with improved atmospheric corrosion resistance

essizo1 + 1

Bt

32

33

3.6

2+ @BsI2011

85 EN 10025-6, Hot rolled products of structural steels ~ Part 6: Technical delivery

conditions for flat products of high yield strength structural steels in the

quenched and tempered condition

28 EN 10028, Specification for tolerances on dimensions, shape and mass for hot

rolled steel plates ? mm thick or above

85 EN 10210-1, Hot finished structural hollow sections of non-alloy.and fine

grain steels Part 1: Technical delivery measurements |

85 EN 12380-3, Testing hardened concrete ~ Part 3: Compressivastrendth of test

specimens f dew

85 EN 14598-3, Reinforced thermosetting moulding com Specification

for sheet moulding compound (SMC) and bulk moulding eortvound (BMC) ~ Part

3 Specific requirements

BS EN ISO 527-2:1996, Plastics ~ Determination of ténsileyBroperties - Part 2: Test

conditions for moulding and extrusion plastics ys.

85 EN ISO 580:2005, Plastics piping and ducting’systems - Injection-moulded

thermoplastic fittings - Methods for vsuallyasgessing the effects of heating

BS EN ISO 1461, Hot dlp galvanized coatings an Bpbricoted iron and steel articles

= Specifications and test methods ne

8 EN ISO 2063, Thermal spraying - Metallic and other inorganic coatings ~ Zine

aluminium and their alloys

D0 CENTS 14541:2007, Pastis pis and fttngs for non-pressure applications —

Unilisation of non-virgin PVC-U, PP * PE materials

Terms and definitions’

For the purposes of this pa 5 5834 the following terms and definitions

apply. A

bedding load. 7

load applied to,a.stifface box to achieve bedding.in of the load-bearing parts

clear opening, ,

access ongfng i Surface box through which » horizontal dsc ofa horizontal

rectangylagplatepases unimpeded, without deviation from a vertical ax,

when Fe urfaag‘box is placed in its normal position and with the cover fully

open.

QTE See Note A to Table 4 for permitted intrusions,

Ba,

agent fation unit

ind frame set in a concrete surround and suitable for bedding on @

n

. seal ‘type guard or chamber

| SNOTE A surface box embedded in concrete past production does not constitute a

1 combination unit

cover

‘moveable part of a surface box that covers the access opening

NOTE The cover may comprise one or more sections.

designation

categorization of a small surface box by grade and type

frame

part of a surface box that receives and supports the cover

BRITISH STAN! BS 5834-2:2011

3.7 horizontal disc

theoretical disc used to assess the clear opening of a small surface box when

passed through at a horizontal angle

3.8 horizontal rectangular plate

theoretical rectangular plate used to assess the clear opening of a large surface

box when passed through at a horizontal angle ‘

3.9. planar surface

horizontal plane of a surface box cover, the vertical locatigh of. wbich Is

determined by the percentage covered by raised or recessédipattern

3.10 raised pattern ;

areas of a surface box cover raised above the cover plandi surface

3.11 recessed pattern .

areas ofa surface box cover recessed below th doug planar surface

3.12 surface box wy, y

assembly of a frame and cover to allow, access {8 any utility apparatus

3.13 test load uf

load applied to a surface box cover, for the determination of load-bearing

capacity te of

4 Classification and-grading

4.1 Classification ta oon!

Surface boxes shall be Saiieu as one of the following.

a) Small surface boxA surface box having a clear opening of 225 mm or less

in diameter. "s.

b) Large surfaces i A surface box having at least one specified clear opening

dimensigh exceeding 225 mm, up to a maximum overall clear opening

of 450 mig x 450 mm,

42 Grading,’

Surfgées bos shall be graded in accordance with Table 1

Table 1 Surface box grades

Grade Description

Grade A Surfae boxes suitable for use in carviageways carrying fast-moving commercial vehicles

(heavy) having Wheel loads * up to 5 tonnes, and in accordance with 8.10.

gt Sy _

Grade B [Sulake boxes capable of bearing wheel loads up to 5 tonnes, for use in areas to which

(medium) ® 9, Vehicles would have only occasional acces,

Grade c

ay

{e?*Surface boxes for use in situations not intended for use by vehicles

igh) >

* The magnitude of the stated wheel load is as exerted by a stationary vehicle.

© Grade B1 and Grade C1 boxes (see 8.1 and Table 3) are suitable for use for pipe-type guards conforming to

85 5834-1

©Bsi2011 + 3

BS 5834-2:2011 BRITISH STANDARD.

5 Materials

5.1 General

The materials used for the manufacture of surface boxes or combination units

shall conform to 5.2, 5.3, 5.4, 5.8 and 5.6, as applicable.

5.2 Cast iron :

The metal sed for the manufacture of iron covers or framesshallb be éither:

2) gfey cast iron (fake graphite iron) conforming to 8S EN 156i"

©) ductile cast iron (spheroidal graphite iron or nodulaggraphite iron)

conforming to BS EN 1563,

5.3 Cast aluminium

The metal used for the manufacture of aluminiyttigagtings shall suit the design

and dimensions of the surface box and conforth td thé applicable grade in

accordance with either 5 EN 1676 or BS EN 1706.

5.4 Plastics Beg

5.4.1 Thermoplastic

Thermoplastic materials used shall comiptise’ one of the following plastics,

Incorporated or blended with otheingredients in accordance with Table 2

a) Unpiasticized poly(vinylchloride) (PVCU).

b)_ Polyethylene (PE), specified as Gode W in accordance with 85 3412:1982,

Table 2.

Polypropylene (PP),

Table 2.

@) Non virgin materia" ‘accordance with DD CEN/TS 14541:2007,

34.2 and 3.4.Bayf

Table 2__ Performance of thermoplaties materials

Performance PP _=PVC-U__Test method :

Tensile strength (Wimin’) 8 2 BS EN ISO 527-2:1996

Elongation at break (%) 200 100 BS EN ISO 527-2:1996

Temperature resistance (°C) © 150 120 150 BS EN ISO 580:2005,

fe

5.42 Theimoset

a igetosee materials used shall be either:

|y BMC conforming to BS EN 14598-3:2005; or

Ps SMC conforming to 85 EN 14598-3:2005

Fad oe Steel for fabrication

Cr

(steel for fabrication shall conform to BS 7668, 8S EN 10029, BS EN 10210-1,

ww" BS EN 10025-1, BS EN 10025-2, BS EN 1025-3, BS EN 1025-4, BS EN 10025-5 or

BS EN 10025-6, as applicable.

5.6 Concrete surround for combination units

The materials used for the concrete surround shall conform to

BS 5834-1:2009, 8.3.

4+ @ 8512011

BRITISH STANDARD BS 5834-2:2011

6 Frames for combination units

Frames for combination units shall be set in the concrete surround and conform

to the minimum dimensions given in Figure 1 and Figure 2,

Typical section and minimum dimensions for a combination unit and frame for a small

Figure 1

surface box (1 of 2) A

Dimensions in millimetres

Key :

1 Frame 4 Concrete yes

2 Cover 5 Base arrangement #) ©

3 Hinge tage!

"9 The concrete shall be a minimum thickness of 38 fin {OF 150 mm guards or of 50 mm for 175 mm guards

© The base arrangement shall match the ype.gf yard specified by the purchaser. The type of guard shell

conform to BS 5834-1

© asi2011 +

5

BS 5834-2:2011 BRITISH STANDARD.

Figure 2 Typical section and minimum dimensions for combination unit and frame for a large surface

box (1 of 2)

Dimensions in millimetres

key

Dimension D: Grade A 35 mm

Grade 8 50 mm {

Grade 25 mm _

NOTE This figure gives minimum dimensions.

7 Fasteners oe

7.4 General tee

Fasteners supplied for lodsely ‘cqupling separate sections of covers shall be of

steel or ductile iron and shallyhave cross sections of not less than

a) 28 mm? for smatlisurface boxes having minimum clear opening diameters of

100 mm and 135 srrn(see Table 3),

b) 50 mm? for:small'syrtace boxes having a minimum clear opening diameter

of 225 mm (sce Table 3);

100 mph? foP large surface boxes having clear openings of 380 mm x 230 mm

and 450 stim, 300 mm (see Table 4);

4). 146'mmP4dt surface boxes having larger clear openings than all of those

specified in 7.14) to 7.10).

Where bolts or studs are used, they shall conform to B85 4180 or BS 4438

mail Surface boxes having clear openings of 100 mm, 135 mm and 225 mm in

agnatl 9

», diameter, respectively, shall have a nominal size and thread diameter of not less

_Ssthaty M6, MB and M110,

7 _,pokarge surface boxes having clear openings greater than 225 mim ih diameter

“sg shall have a nominal size and thread diameter of not less than M12.

wy

Sy ae

7.2 Hinge pins for small surface boxes

Hinge pins used shall be solid (e.g. not hollow, roll or split pins) and made

from stainless steel, plastic or non-ferrous metals. Plastics hinge pins shall only

be used in conjunction with plastic surface boxes.

el

Hinge pins shall be not less than 6 mm in diameter. Hinged units shall be

capable of supporting the specified test loads without the hinge pins forming

part of the load-bearing surface.

6 + © 8512011

BRITISH STANDARD BS 5834-2:2011

NOTE A surtace box having a hinged cover may be referred to as a “Type H”

surface box.

7.3. Swivel pins for small surface boxes

Swivel pins shall be solid (e.g. not hollow, roll or split pins) and made from

stainless steel, plastics or non-ferrous metals, securely anchored or integral to

the cover, and captive to the frame, Plastic swivel pins shall only be used iny

conjunction with plastic surface boxes, The swivel pin shall have-a minimum,

diameter of 12 mm and shall be of such a length as to alloweithe cover to be

lifted and swivelled, ¢

NOTE A surface box with a swivel pin may be referred te as a *Type $” surface box:

8 Dimensions and design of surface boxes

81 General

With the exception of combination units, thé defigrlations and dimensions

of surface boxes shall conform to Table 3 or Table4, as applicable

The minimum depth of frame for combination units shall conform to the

combined surface box and concrete surround measurements given in Figure 1

and Figure 2.

Table 3_ Designations and specified dimensions of sal Scale boxes

Designations Minimum — Minimum Minimum

a depth of bedding bedding

_ “opening frame width area

Non-rock © Hinged — Swivel. “warnetos® of frame

cover,

— _ segeenadty mm mm _

Grade A 100 AN 100 AH * 100 100 35, ~

(heavy) 135 AN. 135 AH 135 100, 35 -

225 AN = 225 100 35 =

Grade a1 100 15 =

(medium) — 135 6 = See 8.2.2

Grade 82 — 100,824 100 75 2 15.000

(medium) = 435 BH 135 75 = 15000

Grade C19 = Teac 100 5 - See 8.2.2

(light) — 4 8H = 135 75 = See 8.2.2

Grade — roan — 100 % 7 10 000

Wight) nd 135, 2H 135 mB ___10 900

2 Thins dear Boeing ameter may

© Grade 81 ani} foxes conform to 8.2.2 and are suitable for ute with or without pipe type guards conforming to

BS 5834190 My

© Grade 2 art CP boxes shall be permanently supported over their entire bedding area

8.2 Small surface boxes

82.1 General

The minimum clear opening sizes shall be as specified in Table 3

@psi2011 + 7

cee poem se pein ee a a

BS 5834-2:2011 BRITISH STANDARD.

Table 4 Minimum dimensions of large surface box frames * (1 of 19)

- - Dimensions in mm

lear Overall depth, Bedding width

opening ©

| Grade a Grade 8 Grade B Grade C

mos [neo eee

380x230 [100 150 75125 50 iQ

430x280 | 100 150 75125 om a0

450x450 | 100 150 125 _

* All dimensions may be #1 mm,

* intrusions into the minimum clear opening sea are permitted at the corners provided thafeach intrusion does

not exceed 1 600 mm for 380 mm x 230 mim and 430 mm x 280 mm sizes and 3 g6D iim! for larger sizes

on

}on-cambination unit.

8.2.2 Contact and bedding surfaces for small Surface boxes

The contact surfaces of the bedding surface¥:of Grade B1 and Grade C1 surface

boxes shall be not less than 85% of the flange face for Grade 8 boxes and shall

be not less than 70% of the flange face for Grade C boxes (see Table 3), when

placed centrally over a circular flange ‘havirg an internal diameter of 150 mm

and a width of 25 mm, a

NOTE 1 The shape (e.g. square/Yectahgular or circular) and the actual size are due

to the individual manufacturet’s design.

NOTE 2 Ifthe purchaser débicg?wiSrticular shape, this ought to be stated on the

enquity andior order.

cents

83 Large surface boxes,

Large surface boxes shallbe nominally rectangular in plan, and the frames shall

conform to Table 4.

NOTE The acta! dhiensions are determined by the manufacturer,

8.4 Resistance to over displacement

The deglgn Yaapfncorporate features to resist cover displacement arising from

loadings iepplicable to the cover grade as specified in 4.2

NOTE Examples of such features are locking pins, additional mass or cover and

frdlpe design methodology.

1

85, “brzinage and skid/slip resistance

= 3.5i “Beneral_

Surface box covers shall be self-draining with the exception of small enclosed

_, » areas of lettering or logo.

With the exception of factory infilled surface box covers, surface box covers shall

have either a defined raised or a defined recessed pattern that is well

distributed across the upper surface of the cover, The raised or recessed pattern

shall conform to 8.5.2 or 8.5.3, as applicable.

@ + @asi2011

eens

BRITISH STANDARD BS 5834-2:2011

Figure 3

8.5.2 Raised pattern

For skidislip resistance, raised patterns on Grade A surface boxes shall be

measured in accordance with Figure 3 and have a height of between 3 mm and

5 mim, Raised patterns on Grade 8 and Grade C surface boxes shall be measured

in accordance with Figure 3 and have a height of between | mm and 4 mm.

Raised pattern measurements shall be recorded in a test report (ee Table B.1).

Parts of lettering or markings shall be considered to be part of the raised

pattern, ee

NOTE 1 Although there are some frictional test methods thé determine the

resistance of pavement surfaces to skidislip, recent research has questioned their

suitability for the macro textures and variable raised patterns of sal surface boxes

These test methods are therefore not referenced within this standard. It i

recognized, however, that reducing the size of raised Pattern,blocks increases the

interlock with fectwear and vehicle (res, thereby reusing the risk of ssc

The raised pattern on large surface boxes shalb'tover'an area of between 10%

‘and 70% of the total upper surface area of the cover

NOTE 2 The upper surface area of the cover icopiidered to be that which isin

contact with traffic when the surface box is install in its in-service condition,

NOTE 3. Small surface bores should confor afire rated pattem turface oreo

requirements where practable however Is seepted thor cue wo the sai eee of

some smal surface bores and marke ceaufemants Sk snot sivas posable

a) Raised patiein’!

key

Coyer planar surface |

b) Recessed pattern

th of raised or recessed pattern

85.3 Recessed patterns

FoPskidislip resistance, recessed patterns on Grade A surface boxes shall be

“eymeasured in accordance with Figure 3 and have a depth of between 3 mm and

os, em. Recessed patterns on Grade 8 and Grade C surface boxes shall be

svg, Muqpeasured in accordance with Figure 3 and have a depth of between T mm and

ooo mm, Recessed pattern measurements shall be recorded in a test report (see

€ Table B.1).

Sy," Parts of lettering or markings shail be considered to be part of the recessed

pattern,

‘The recessed pattern on large surface boxes shall cover an area of between 10%

and 70% of the total upper surface area of the cover,

NOTE 1 The upper surface area of the cover is considered to be that which Is in

contact with traffic when the surface box is installed in its serviceable condition,

NOTE 2 Small surface boxes should conform to the recessed pattern surface area

requirements where practicable; however, itis accepted that due to the small area of

some small surface boxes and marking requirements, this is not always possible,

©psi2011 «8

BS 5834-2:2011 BRITISH STANDARD

8.6 Prising slots

At least one prising stot per cover section shall be provided for the purpose of

‘opening hinged covers and for initially loosening removable covers,

The dimensions of the prising slots shall conform to Figure 4 and Table 5.

Where the prising slot is integral to the frame, dimension W shall apply to the

width of the recess in the upper edge of the frame and shall exterid at least

49 min below the upper edge, This may take the form of a tapered recess.

Figure 4 Dimensions of pr

Key

See Table 5 ce

NOTE The prising slot. may hevincorporated in either cover section or the adjacent

frame, Ny

Table 5

Width (W) Thickness (T) Depth (D)

6 4 6

1023" 5-8 210

NOTE tis advisable to Incorporate prising slots widths (W) that are towards the upper

“Ghelardne specified, which can permit operation with a wider range of prising ba tip

Smgrtons

te

10 + © 8512011

BRITISH STANDARD. BS 5834-2:2011

87 Keyways and keys

8.7.1 General

Covers that are not hinged shall incorporate at least one keyway per cover

section, either open or closed, and conform to the dimensions given in Table 6,

Figure 5 and Figure 6, for lifting

NOTE The purchaser should specify in the enquiry andlor order jf.open or closed

keyways are required,

Table 6 _Keyway dimensions

Dimensions in mm

Keyway A

size mint

= X

Small 1416

Large 22-25

Figure S Open keyway

a) Plan

by Cross-section

Key

[Sts tine of raised pattern

ITE Dimensions A, B and C are given in Table 6 A indicates a section line,

are

8:72 “Large surface boxes

4 “Large keyways (see Table 6) shall be used in Grade A and Grade 8 covers. In

ag

Grade C covers the keyway shall be small or large, as appropriate for the design

and mass of the cover.

Keys

For compatibility with small and large keyways, keys shall conform to the

dimensions given in Figure 7 and Table 7.

easi201 + 11

«cmap epee i co a

ws 5834-22011

2

Figure 6

Figure 7

© © Bs! 2011

BRITISH STANDARD

Closed keyway

a) Plan

b) Cross section

Key

1

NOTE 1 Dimépsions'A, & and C are given in Table 6 B indicates a section fine.

NOTE 2 Gs Keyilays may incorporate a drainage aperture

key

1 Alternative shape

NOTE Dimensions G, J, H and K are given in Table 7.

BRITISH STANDARD BS 5834-2:2011

Table 7 Key dimensions

Dimensions in mm

Keys # J K

Small 2 6 25

Large 20 15 6 40

8.8 Clearance

The maximum clearance between the cover and is frame shall.be.3 mm all

round, having a further clearance of a maximum of 3 mm between cover

sections Hoag

8.9 Coupling of cover sections

Where cover sections are to be loosely coupled, fasighers (see Clause 7) shall be

provided with a means to prevent overtighteniig which would result in the

Cover sections being drawn together too clostly.sindjbeing raised up,

Large surface box cover sections that are lodSely %upled shall be provided with

two fasteners to ensure stability during bfting..

8.10 Non-rock feature

Grade A units shall incorporate a permanent non-rock feature (Type N, see

Table 3), to prevent rocking between thé cover and frame.

NOTE Other grades may aso incoipbrate this feature.

8.11. Metal detection component for plastics surface boxes

Plastics surface box cover'shall’be provided with a corrosion-resistant or suitably

protected metal comporiént moulded into or permanently fixed to

their underside to ehble'détection via an electronic surface-box finder. The

metal of the componeritshall have a minimum plan area of § 000 mm? and @

minimum thickness of mm.

9 Manufacture and workmanship

9.1 Cast ‘ivon’and ¢ cast aluminium surface boxes

All pits of te surface box shal be cat without defects and irregularities and

shall be'visibly free from air holes, sand holes, cold shuts and chil. All castings

shall be free from voids, whether due to shrinkage, gas inclusions or other

tg wore” All parts of the surface box should be neatly dressed and carefully fettled,

0 Fabricated steel components

41, f°" The joints in fabricated steel components shall be formed, welded or riveted to

Sy cfeate a firm and rigid assembly that is free from distortion, All weld slag, burrs

and sharp edges shall be removed.

ae. When assembled, covers shall sit in their frames without twist or distortion

‘Where temporary retaining straps are provided with the frame, these shall be

fitted in such a way that the straps can be easily removed after the frame has

been fixed in position.

© psi2011 «13

You might also like

- Coal Dust MsdsDocument4 pagesCoal Dust Msdskhai ruleNo ratings yet

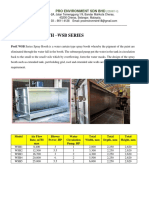

- BROCHUREWMOTOXTREME150iN1 Xtreme150i 20230914164943Document4 pagesBROCHUREWMOTOXTREME150iN1 Xtreme150i 20230914164943khai ruleNo ratings yet

- COMPANY Catalogue - PROEDocument18 pagesCOMPANY Catalogue - PROEkhai ruleNo ratings yet

- Standardsmark Licence As 4181.2013 Repair and Offtake ClampsDocument28 pagesStandardsmark Licence As 4181.2013 Repair and Offtake Clampskhai ruleNo ratings yet

- SDS - Ashapura Ultrabond - V3Document6 pagesSDS - Ashapura Ultrabond - V3khai ruleNo ratings yet

- Vital Technical Sdn. BHD.: VT-210 High Performance SealantDocument4 pagesVital Technical Sdn. BHD.: VT-210 High Performance Sealantkhai ruleNo ratings yet

- Bentonite MSDSDocument10 pagesBentonite MSDSkhai ruleNo ratings yet

- NYY006.18 VA 5001 WRAS CertificationDocument1 pageNYY006.18 VA 5001 WRAS Certificationkhai ruleNo ratings yet

- Iteh Standard Preview (Standards - Iteh.ai) : Graphite Structure European Standard Designation Short NameDocument1 pageIteh Standard Preview (Standards - Iteh.ai) : Graphite Structure European Standard Designation Short Namekhai ruleNo ratings yet

- Wet Spray Booth - WSB Series: Pro Environment SDN BHDDocument2 pagesWet Spray Booth - WSB Series: Pro Environment SDN BHDkhai ruleNo ratings yet

- Irca Iso 90012015Document1 pageIrca Iso 90012015khai ruleNo ratings yet

- BODY DN100-mergedDocument9 pagesBODY DN100-mergedkhai ruleNo ratings yet

- BODY DN150-mergedDocument10 pagesBODY DN150-mergedkhai ruleNo ratings yet

- C220-E001E Shimadzu General Testing MachineDocument10 pagesC220-E001E Shimadzu General Testing Machinekhai ruleNo ratings yet

- RUBBER FLAP TYPE CHECK VALVE-front-BDocument1 pageRUBBER FLAP TYPE CHECK VALVE-front-Bkhai ruleNo ratings yet

- Avk Fabricated Flange Adaptor, Pn16 260: Features: OptionsDocument2 pagesAvk Fabricated Flange Adaptor, Pn16 260: Features: Optionskhai ruleNo ratings yet

- Bs en 14901Document20 pagesBs en 14901khai rule100% (1)

- HWA GUAN Material Spec PDFDocument12 pagesHWA GUAN Material Spec PDFkhai ruleNo ratings yet

- Outsource DrawingDocument1 pageOutsource Drawingkhai ruleNo ratings yet

- Ofm Part Number B14-H0015 RECIEVED ON 08-10-2018: RevisionsDocument1 pageOfm Part Number B14-H0015 RECIEVED ON 08-10-2018: Revisionskhai ruleNo ratings yet

- E-Soft E-HR System Manual (Login As Employee) PDFDocument22 pagesE-Soft E-HR System Manual (Login As Employee) PDFkhai rule0% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)