Professional Documents

Culture Documents

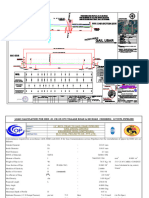

TABLE01: CS PIPE Acorrding ASME B31.3-2018: 2 T P 1 T P 2

Uploaded by

Sihem GhamlouliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TABLE01: CS PIPE Acorrding ASME B31.3-2018: 2 T P 1 T P 2

Uploaded by

Sihem GhamlouliCopyright:

Available Formats

TABLE01: CS PIPE Acorrding ASME B31.

3-2018

× t×Ip×

L1= (𝑓 ≤ 𝐿2/360) ×[ ]t×Wp

CS PIPE Acorrding q L2= Inertia Section

q I =π(D4-d4)/64 Wp=πD3×(1-α4)/32 (herein α=d/D) L=Min(L1, L2)

ASME B31.3-2018 Moment p Modulus

Wall Thickness/mm Elasticity allowable Basic Span

Piping Load per meter Basic Span under

negative deviation: 12.5% Modulus, bending stress, Coefficient underStrength

Piping including water, q Rigidness Criterion, L1 Basic Span, L /m

Outside corrosion allowance: Insulation Insulation Et [σ]t of bending Criterion, L2

Load per /(kg/m) Second Moment of Area, Ip /m

DN NPS Diameter SCH. 3.0mm Thickness density

3

/10 MPa (MPa) resistance, /m

meter /mm4 Wp

/mm

nominal calculated

/mm /(kg/m3)

/(kg/m)

Non- Non- /mm 3 Non- Non-

wall wall Insulation 300℃ Insulation 300℃ Insulation Insulation

insulation insulation insulation insulation

thickness thickness

15 1/2 21,30 Sch80 3,73 0,26 0,14 40 150 0,48 1,63 182 964 3,1 1,9 25 91 2,4 1,3 2,4 1,3

20 3/4 26,70 Sch80 3,91 0,42 0,27 40 150 0,80 2,06 182 3003 3,8 2,6 25 225 2,9 1,8 2,9 1,8

25 1 33,40 Sch80 4,55 0,98 0,78 50 150 1,56 3,53 182 13141 5,0 3,7 25 787 3,9 2,6 3,9 2,6

40 1-1/2 48,30 Sch80 5,08 1,45 1,67 70 150 3,29 7,19 182 58426 6,3 4,7 25 2419 4,7 3,2 4,7 3,2

50 2 60,30 Sch80 5,54 1,85 2,66 70 150 5,18 9,48 182 145040 7,3 5,8 25 4811 5,3 3,9 5,3 3,9

80 3 88,90 Sch40 5,49 1,80 3,87 70 150 9,59 14,83 182 468190 8,6 7,3 25 10533 5,7 4,6 5,7 4,6

100 4 114,30 Sch40 6,02 2,27 6,26 70 150 15,73 21,81 182 1252617 10,0 8,8 25 21918 6,5 5,5 6,5 5,5

150 6 168,30 Sch40 7,11 3,22 13,11 70 150 33,69 41,55 182 5692777 12,7 11,7 25 67650 7,8 7,0 7,8 7,0

200 8 219,10 Sch30 8,18 4,16 22,04 70 150 56,93 66,47 182 16218941 14,9 14,1 25 148051 8,9 8,2 8,9 8,2

250 10 273,10 Sch30 9,27 5,11 33,78 70 150 88,06 99,37 182 38645210 17,1 16,3 25 283011 9,9 9,3 9,9 9,3

300 12 323,80 STD 9,53 5,34 41,93 70 150 118,93 131,92 182 67731752 18,4 17,7 25 418355 10,3 9,8 10,3 9,8

GENERAL NOTES:

1. Basic span between pipe supports for hori-zontal straight runs of standard and heavier steel pipe at maximum operating temperature of 300°C.

2. When concentrated loads between supports (such as flanges, valves, specialties, etc.) exsiting, they are considered as equivalent length of straight pipes with same weight.

3. The basic span is based on a fixed beam support with a bending stress not exceeding 25 MPa and insulated pipe filled with water or the equivalent weight of steel pipe for steam, gas,

or air service, and the pitch of the line is such that a sag of 1/360 plus basic span between supports is permissible.

You might also like

- COLUMNDocument3 pagesCOLUMNGaneshalingam Ramprasanna2No ratings yet

- Blocking Calc - 3x2x2Document3 pagesBlocking Calc - 3x2x2RUBEN BARTOLOME GARCIANo ratings yet

- End Panel S3 Development of Maa Samleswari at Sambalpur: One-WayDocument1 pageEnd Panel S3 Development of Maa Samleswari at Sambalpur: One-Wayselvakumar sNo ratings yet

- GM Dharampur Churu Balh OKDocument1 pageGM Dharampur Churu Balh OKRishav ChaudharyNo ratings yet

- Design of One Way SlabDocument4 pagesDesign of One Way SlabSherwin PonsNo ratings yet

- Design Excel SheetDocument17 pagesDesign Excel SheetbuntyNo ratings yet

- HDD-LC-0001 Rev 0Document24 pagesHDD-LC-0001 Rev 0SAUGAT DUTTANo ratings yet

- HDD Calculation For Gas PipelineDocument3 pagesHDD Calculation For Gas Pipelinesamotavijaypal26No ratings yet

- Table1. The Deposition Parameters of The As Prepared FilmsDocument3 pagesTable1. The Deposition Parameters of The As Prepared FilmsNader HemayaNo ratings yet

- 13-CAL AT CH 6.293 (27jan)Document4 pages13-CAL AT CH 6.293 (27jan)subudhiprasannaNo ratings yet

- Useful Data From IS456 & Is-13920Document29 pagesUseful Data From IS456 & Is-13920MayurNo ratings yet

- Calculate Scaffolding Inedependent Common TowerTube 4mmDocument4 pagesCalculate Scaffolding Inedependent Common TowerTube 4mmDunya Fildzah100% (1)

- g+4 Building DesignDocument22 pagesg+4 Building Designellocster21No ratings yet

- Polyacetal (POM) : Polyplastics Co., LTDDocument19 pagesPolyacetal (POM) : Polyplastics Co., LTDPhuoc Thinh TruongNo ratings yet

- Lexan FR Resin 505rDocument3 pagesLexan FR Resin 505rShabi HadashNo ratings yet

- Extrusion Molding: Description ApplicationsDocument2 pagesExtrusion Molding: Description ApplicationsbobNo ratings yet

- Radial Check EtcDocument38 pagesRadial Check EtcDEBASIS BARMANNo ratings yet

- Radial Check EtcDocument38 pagesRadial Check EtcDEBASIS BARMANNo ratings yet

- S2 Slab Calculation PDFDocument1 pageS2 Slab Calculation PDFashishNo ratings yet

- HANDRAILDocument3 pagesHANDRAILGaneshalingam Ramprasanna2No ratings yet

- Grade of Concrete Grade of Steel,: LoadsDocument22 pagesGrade of Concrete Grade of Steel,: LoadsEr. Hisham Ajmal PCNo ratings yet

- Cycolac MG 47Document3 pagesCycolac MG 47Juan DanielNo ratings yet

- Faleswork Design Checking - RC Beam - (Updated)Document5 pagesFaleswork Design Checking - RC Beam - (Updated)Chan Kin CheungNo ratings yet

- Duracon M90 44Document2 pagesDuracon M90 44PradeepNo ratings yet

- Design of Steel Tubular Pile Subject To Axial Load and BendingDocument5 pagesDesign of Steel Tubular Pile Subject To Axial Load and BendingEdward Albert BañagaNo ratings yet

- LANDINGDocument2 pagesLANDINGGaneshalingam Ramprasanna2No ratings yet

- ALDECK3Document5 pagesALDECK3Mustafa ÇakırNo ratings yet

- Valid Design: Design of Two Way Slab (S-1)Document1 pageValid Design: Design of Two Way Slab (S-1)Pipoy ReglosNo ratings yet

- ESR ST - DesignDocument33 pagesESR ST - DesignTarkeshwar Lal SrivastavaNo ratings yet

- One Way SlabDocument1 pageOne Way SlabMark Brien Vincent YbañezNo ratings yet

- Continuous Two Way Slab DesignDocument2 pagesContinuous Two Way Slab DesignFarah Wahida100% (1)

- Segmental Tunnel DesignDocument36 pagesSegmental Tunnel DesignStructural Spreadsheets0% (1)

- Shear Wall Sample Design CalculationsDocument2 pagesShear Wall Sample Design CalculationsRohan DharmadhikariNo ratings yet

- Sensitivity: This Document Is Classified As "LNT Internal Use"Document6 pagesSensitivity: This Document Is Classified As "LNT Internal Use"ravi yemmadiNo ratings yet

- Annex-1: Foundation Design: Footing D E S I G N Rea C Ti o N SDocument21 pagesAnnex-1: Foundation Design: Footing D E S I G N Rea C Ti o N SSudip ShresthaNo ratings yet

- Load Calculation - Bar Mill - 20 02 2020Document15 pagesLoad Calculation - Bar Mill - 20 02 2020DARA SINGH100% (1)

- SOM Lab ManualDocument39 pagesSOM Lab ManualdineshvaricomNo ratings yet

- Crack Width CheckDocument2 pagesCrack Width CheckJitendra SinghNo ratings yet

- HDPE Physical PropertiesDocument7 pagesHDPE Physical PropertiesshaffetiNo ratings yet

- 341+265 Design Report - 19Document1 page341+265 Design Report - 19VivekNo ratings yet

- CALC SHEET ZOLA - CompressedDocument33 pagesCALC SHEET ZOLA - CompressedSami Abdelgadir MohammedNo ratings yet

- D R S HD: Enso OCK HieldDocument4 pagesD R S HD: Enso OCK HieldPabloCesarCamargoNo ratings yet

- 96aluminaprops PDFDocument1 page96aluminaprops PDFHerdi ArdianaNo ratings yet

- Restrained Two-Way SlabsDocument5 pagesRestrained Two-Way SlabsBABAN GUHANo ratings yet

- Referance Calculations Design Data Dimensions: Edge 1Document32 pagesReferance Calculations Design Data Dimensions: Edge 1sachinthaNo ratings yet

- Design of Two-Way SlabDocument48 pagesDesign of Two-Way SlabAboobackar SidheeqNo ratings yet

- Laminated CompressDocument42 pagesLaminated CompressMACHINE-30 ISTENNo ratings yet

- Blutex - Part 2 - Slab Design - One Way - 2021 - 05 - 01Document24 pagesBlutex - Part 2 - Slab Design - One Way - 2021 - 05 - 01Niraj100% (1)

- 23882Document1 page23882skiu paket 31No ratings yet

- Lumiplas Ld7890: Description ApplicationDocument2 pagesLumiplas Ld7890: Description ApplicationLong HomaNo ratings yet

- US-1003 Catalog 194Document1 pageUS-1003 Catalog 194Dhinakaran BhuvaneshwaryNo ratings yet

- Chumba Slab 01Document5 pagesChumba Slab 01OCHILLOH STEVENo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)thusiNo ratings yet

- Armadillo TDSDocument1 pageArmadillo TDSPIETRO DAVID DE LUCANo ratings yet

- Fi RE2Document303 pagesFi RE2vedranNo ratings yet

- Formulae For Calculating Draw Load of Round Parts in Sheet Metal F Pi Dts (D/D-C) Sr. No. Shortform Full Form 0 0 0 60 0.6 ### 3.14 #Div/0! #Div/0!Document2 pagesFormulae For Calculating Draw Load of Round Parts in Sheet Metal F Pi Dts (D/D-C) Sr. No. Shortform Full Form 0 0 0 60 0.6 ### 3.14 #Div/0! #Div/0!kunku7No ratings yet

- Two Way SlabDocument3 pagesTwo Way Slabsamir bendreNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Pressure Seal Bonnet Design: Dedication To DeliveryDocument44 pagesPressure Seal Bonnet Design: Dedication To DeliverylutNo ratings yet

- 3D Numerical Modelling of Open Channel Flow With Submerged VegetationDocument9 pages3D Numerical Modelling of Open Channel Flow With Submerged VegetationIhtesham KhanNo ratings yet

- Cambridge International Examinations Cambridge International General Certificate of Secondary EducationDocument20 pagesCambridge International Examinations Cambridge International General Certificate of Secondary EducationequakeroatsNo ratings yet

- DPP-2 (Coulomb's Law and Principle of Superposition)Document6 pagesDPP-2 (Coulomb's Law and Principle of Superposition)Youtuber RSNo ratings yet

- Vegetation Patterns Along A Rainfall Gradient: Ehud Meron, Erez Gilad, Jost Von Hardenberg, Moshe Shachak, Yair ZarmiDocument10 pagesVegetation Patterns Along A Rainfall Gradient: Ehud Meron, Erez Gilad, Jost Von Hardenberg, Moshe Shachak, Yair ZarmiEmmanuel kpegloNo ratings yet

- Solved 2024 Specimen Paper ICSE Class 10 ChemistryDocument11 pagesSolved 2024 Specimen Paper ICSE Class 10 ChemistrymmroyalethegreatNo ratings yet

- 16kw ManualDocument48 pages16kw ManualJamesBrionesNo ratings yet

- Neet 2021 Physics Paper With SolutionDocument13 pagesNeet 2021 Physics Paper With SolutionAnilNo ratings yet

- Airflow Sensors AWM5000 Series High Flow Mass Airflow/AmplifiedDocument4 pagesAirflow Sensors AWM5000 Series High Flow Mass Airflow/AmplifiedwidsonmeloNo ratings yet

- Microtrip Line PDFDocument11 pagesMicrotrip Line PDFthap_dinhNo ratings yet

- Gen2MR 31173Document12 pagesGen2MR 31173gtravaNo ratings yet

- Xii Physics Experiment 1Document5 pagesXii Physics Experiment 1Solomon Peter SunilNo ratings yet

- Refrigeration Troubleshooting GuideDocument8 pagesRefrigeration Troubleshooting GuideJuan Jose Ramirez CorralesNo ratings yet

- New Radar Technology 8 500-10 500 MHZ BandDocument18 pagesNew Radar Technology 8 500-10 500 MHZ BandChinmaya_Mishr_4215No ratings yet

- Lighting Plan Guidelines 2020Document7 pagesLighting Plan Guidelines 2020Eddie TweNo ratings yet

- AssignmentDocument3 pagesAssignmentdola indupriyaNo ratings yet

- KS4 Methods BookletDocument135 pagesKS4 Methods Bookletbluesn0002No ratings yet

- Philosophy ReviewerDocument9 pagesPhilosophy ReviewerLeinard ManahanNo ratings yet

- Voltage Fed Full Bridge DC-DC and DC-AC Converter For High-Frequency Inverter Using C2000Document17 pagesVoltage Fed Full Bridge DC-DC and DC-AC Converter For High-Frequency Inverter Using C2000Afonso HoversNo ratings yet

- Projet RockyDocument19 pagesProjet RockyCassella AdrianoNo ratings yet

- Book 1Document44 pagesBook 1Soubhik ChoudhuryNo ratings yet

- A Review On Current Status and Challenges of Inorganic Phase Change Materials For Thermal Energy Storage SystemsDocument18 pagesA Review On Current Status and Challenges of Inorganic Phase Change Materials For Thermal Energy Storage SystemsAnagha GhoshNo ratings yet

- Power Supply Board (Tantalum Less) : Solidworks Drawing: All Changes Must Be Done in Solidworks DatabaseDocument2 pagesPower Supply Board (Tantalum Less) : Solidworks Drawing: All Changes Must Be Done in Solidworks DatabasezizouhicheNo ratings yet

- Fracture MechanicsDocument13 pagesFracture MechanicsNishant Patil100% (1)

- Rooftex BrochureDocument2 pagesRooftex BrochureTRAG ProjectsNo ratings yet

- Presentation - Company Products - Eng (June 2012)Document11 pagesPresentation - Company Products - Eng (June 2012)Ricky Ocktavi RizkyNo ratings yet

- Computational Fluid Dynamics Analysis of Greenhouse Solar DryerDocument19 pagesComputational Fluid Dynamics Analysis of Greenhouse Solar DryerPurusothamanManiNo ratings yet

- Fundamentals of Ultrasonic Phased Arrays - 171-180Document10 pagesFundamentals of Ultrasonic Phased Arrays - 171-180Kevin HuangNo ratings yet

- Lab 3Document19 pagesLab 3Nosheen AliNo ratings yet

- 2020-2021 S5 - M2 - Half-Yearly Exam (With Marking Scheme)Document35 pages2020-2021 S5 - M2 - Half-Yearly Exam (With Marking Scheme)15 15No ratings yet